Jeep Republicon, One Ton Jeep on 42's with LQ4/TH400 Build Thread

#1

I wanted to get a build thread on here started to keep track of my progress and hopefully share some info along the way with others who are putting LS motor in their Jeep.

Sorry this thread isn't about a track car or a sleeper daily driver...

We like to go fast in the woods and up the hills out here in Virginia so this is my build thread and I'm sticking to it. So grab a beer, have a seat and enjoy my progress!

Here's the Jeep. She started out as a Jeep on one tons (kingpin Dana 60 up front and a 14 bolt out back) with 5.13 gears, 106" wheel base, PSC hydro assist up steering front, Atlas 4.3:1 transfer case, DIY beadlock wheels and 42" Pitbull Rocker bias ply tires. The rear has a spool in it and the front is Lincoln locked (welded). She would go just about anywhere... but hardly get there fast... with the stock Jeep 4.0L under the hood.

Rewind to 2015, I had another project going at the time where I was planning to build the exact same Jeep and put my LS in it. It didn't go as planned so I parted it out and kept the LS motor that I built for this project.

Fast forward to August of 2017. Two months ago, I decided I was tired of the 4.0L in the current Jeep so I went full retard with the plasma cutter and decided it was now or never for the LS swap to begin.

So I started pulling the 4.0L and had it sold in a week.

Once the motor was out, I hacked off the motor mounts and bought a set of Daves Offroad Unlimited mounts. They indexed off of a hole in each side of the frame which made setting the LS between the frame rails a breeze. If you can follow directions, you can set these up and have them as a perfect fit the first shot around.

Sorry this thread isn't about a track car or a sleeper daily driver...

We like to go fast in the woods and up the hills out here in Virginia so this is my build thread and I'm sticking to it. So grab a beer, have a seat and enjoy my progress!

Here's the Jeep. She started out as a Jeep on one tons (kingpin Dana 60 up front and a 14 bolt out back) with 5.13 gears, 106" wheel base, PSC hydro assist up steering front, Atlas 4.3:1 transfer case, DIY beadlock wheels and 42" Pitbull Rocker bias ply tires. The rear has a spool in it and the front is Lincoln locked (welded). She would go just about anywhere... but hardly get there fast... with the stock Jeep 4.0L under the hood.

Rewind to 2015, I had another project going at the time where I was planning to build the exact same Jeep and put my LS in it. It didn't go as planned so I parted it out and kept the LS motor that I built for this project.

Fast forward to August of 2017. Two months ago, I decided I was tired of the 4.0L in the current Jeep so I went full retard with the plasma cutter and decided it was now or never for the LS swap to begin.

So I started pulling the 4.0L and had it sold in a week.

Once the motor was out, I hacked off the motor mounts and bought a set of Daves Offroad Unlimited mounts. They indexed off of a hole in each side of the frame which made setting the LS between the frame rails a breeze. If you can follow directions, you can set these up and have them as a perfect fit the first shot around.

#2

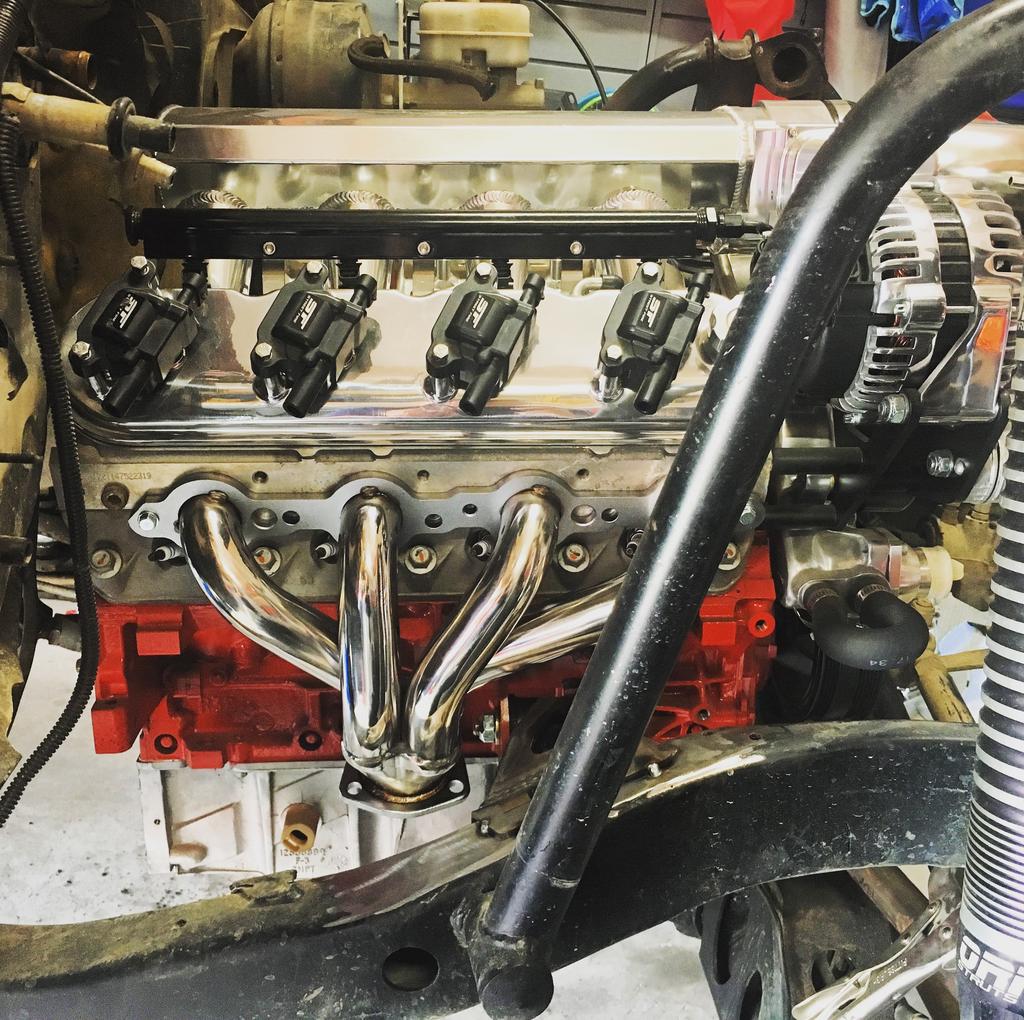

The motor is a 2007 LQ4 out of a Chevy 3500 Express Van. It has a drive by wire pedal/TAC and a Gen III PCM (blue/green connectors).

When I picked the motor up from the local salvage yard, it had 80k on the odometer and was pretty filthy.

I wanted a little bit of bling and wanted to dress it up a little bit, just because. I did very little research back in 2015 when I built this so if I had to do it all over again, I would have done things completely different. This was my first motor build ever and my first time even touching an LS. I have been a 4.0L Jeep guy all my life so this was all new and uncharted territory for me... Lots of lessons learned along the way.

So I worked with John McLaughlin of Broadview Automotive in Warrenton, VA to mildly build the motor, clean it up and put a cam in it. I worked with Martin Smallwood over at Tick Performance and we spec'ed out a cam to suit my needs and driving style as well.

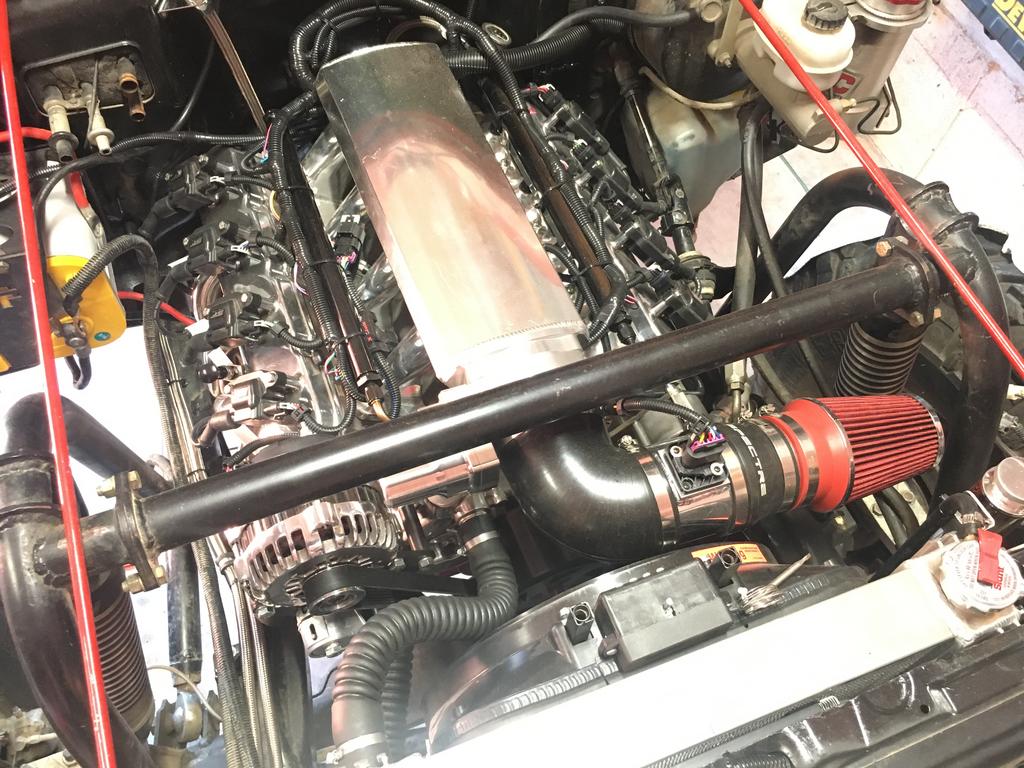

I ended up with a Custom 222/234 .610/.595 113 lsa cam, Dual .660" spring kit, hardened chromoly push rods, VVT Delete kit, ARP Head bolts, new head gaskets, Morel 5315 lifters, new LS2 timing chain, Ported oil pump, all new bolt/gasket kit needed to swap cam, Holley polished LS valve covers, SLP polished intake, all polished drive accessories, GoatBuilt relocation brackets for the accessories, MSD coils, a Nick Williams DBW 102mm polished throttle body, Improved Racing baffled shallow Fbody oil pan and TCI SFI rated rated flex plate and some other goodies.

I worked on this since August and got the motor dropped in between the frame rails and then started assembly.

When I picked the motor up from the local salvage yard, it had 80k on the odometer and was pretty filthy.

I wanted a little bit of bling and wanted to dress it up a little bit, just because. I did very little research back in 2015 when I built this so if I had to do it all over again, I would have done things completely different. This was my first motor build ever and my first time even touching an LS. I have been a 4.0L Jeep guy all my life so this was all new and uncharted territory for me... Lots of lessons learned along the way.

So I worked with John McLaughlin of Broadview Automotive in Warrenton, VA to mildly build the motor, clean it up and put a cam in it. I worked with Martin Smallwood over at Tick Performance and we spec'ed out a cam to suit my needs and driving style as well.

I ended up with a Custom 222/234 .610/.595 113 lsa cam, Dual .660" spring kit, hardened chromoly push rods, VVT Delete kit, ARP Head bolts, new head gaskets, Morel 5315 lifters, new LS2 timing chain, Ported oil pump, all new bolt/gasket kit needed to swap cam, Holley polished LS valve covers, SLP polished intake, all polished drive accessories, GoatBuilt relocation brackets for the accessories, MSD coils, a Nick Williams DBW 102mm polished throttle body, Improved Racing baffled shallow Fbody oil pan and TCI SFI rated rated flex plate and some other goodies.

I worked on this since August and got the motor dropped in between the frame rails and then started assembly.

#3

The first thing that I noticed was that I had some clearance issues with the front axle truss, steering linkage and other stuff.

I had to move my original steering linkage up and out of the way because the header was coming in contact with it.

I'm running ORI struts with internal bump stops too. Rather than doing a front stretch and going to full hydro steering or cutting up my front truss, I went the cheater way and made a set of bump stops to keep the harmonic balancer

Once I got the clearance issues worked out... I started putting the rest of it together.

I got the trans mocked up and then had fitment issues with my transfer case so I had to cut the floor out to make it fit. I didn't want anything hanging below the frame rails as I wanted a flat belly skid plate under the Jeep.

So I made a trans cross member using some universal transmission mounts from Barnes 4WD.

While I had everything out, I had to swap the input shaft over to a 32 spline input shaft on the Atlas transfer case since the TH400 is 32 spline and the old Jeep AX-15 was 23 spline.

While I was in there, I decided to make a floor cage to mount my seats to. The Jeep mounts wouldn't work anymore because I had to cut the floor out.

So I notched some tube around the BTF A pillar section of my cage and welded some pieces from the A to B pillar. Then connected the two sections with some 1.5" DOM to mount the seats to. I added new harness tabs and seat mounts to the floor cage then made some floor pans to cover everything up. It's just a trail rig so I didn't care about cosmetics on the floor pans. I just wanted to keep the dirt and grease off of the driveshaft from slinging up and hitting me in the legs/face. It's not pretty but it works.

Just tacked in to test fitment here...

I filled the floor in with a little box. This was the easiest and quickest method.

I had to move my original steering linkage up and out of the way because the header was coming in contact with it.

I'm running ORI struts with internal bump stops too. Rather than doing a front stretch and going to full hydro steering or cutting up my front truss, I went the cheater way and made a set of bump stops to keep the harmonic balancer

Once I got the clearance issues worked out... I started putting the rest of it together.

I got the trans mocked up and then had fitment issues with my transfer case so I had to cut the floor out to make it fit. I didn't want anything hanging below the frame rails as I wanted a flat belly skid plate under the Jeep.

So I made a trans cross member using some universal transmission mounts from Barnes 4WD.

While I had everything out, I had to swap the input shaft over to a 32 spline input shaft on the Atlas transfer case since the TH400 is 32 spline and the old Jeep AX-15 was 23 spline.

While I was in there, I decided to make a floor cage to mount my seats to. The Jeep mounts wouldn't work anymore because I had to cut the floor out.

So I notched some tube around the BTF A pillar section of my cage and welded some pieces from the A to B pillar. Then connected the two sections with some 1.5" DOM to mount the seats to. I added new harness tabs and seat mounts to the floor cage then made some floor pans to cover everything up. It's just a trail rig so I didn't care about cosmetics on the floor pans. I just wanted to keep the dirt and grease off of the driveshaft from slinging up and hitting me in the legs/face. It's not pretty but it works.

Just tacked in to test fitment here...

I filled the floor in with a little box. This was the easiest and quickest method.

#4

After five or six belts, I finally got the right size to fit... Thank god for Amazon returns!

I used a Novak Jeep TJ fuel pressure regulator bypass kit in my OEM Jeep fuel pump. It removes the 40 psi regulator and opens the fuel pump straight up so you then go into a Corvette style filter/regulator for 58 PSI with a return to the tank. I used the -6 AN line that I already had in the Jeep from the filter/regulator to the fuel rail with an inline gauge at the rail.

I used a Novak Jeep TJ fuel pressure regulator bypass kit in my OEM Jeep fuel pump. It removes the 40 psi regulator and opens the fuel pump straight up so you then go into a Corvette style filter/regulator for 58 PSI with a return to the tank. I used the -6 AN line that I already had in the Jeep from the filter/regulator to the fuel rail with an inline gauge at the rail.

#5

I had some fitment issues with my Flex-A-Lite TJ Direct Fit LS Swap radiator/fan combo. My plumbing for the intake/air filter were jammed up against the fan so I had to trim the grill about 2.5" inches to flush the radiator into the grill more than what it was. That worked and then I got everything to fit.

I wired up the motor with a PSI Conversions HAR-1015 harness. That was pretty straight forward. Plug and play for the most part.

I wired up the motor with a PSI Conversions HAR-1015 harness. That was pretty straight forward. Plug and play for the most part.

#6

I installed a set of Sport Comp II gauges in the dash. I wasn't sure how I was going to get my speedo signal just yet so I held off on buying a speedo.

A lot of guys with bouncers and Jeeps don't run a VSS setup so until I figure that out, I'm leaving the hole blank. My Atlas has a 3 wire hall sender in it but it's not sending a signal for some reason. I need to drain the case and reseat the VSS sender and see if that fixes is. I could also do a reluctor wheel around the output shaft of the transfer case and do a regular 2 wire GM VSS but again, I'd need to drop the t-case and figure this out. I haven't had the time to do this yet but will focus on this soon.

I went with a Perma Cool remote mount oil cooler for the TH400. Seems like a nice product. Hoping it keeps up with the heat from my TH400 while i'm idling through the rocks.

It's time for a beer break....

A lot of guys with bouncers and Jeeps don't run a VSS setup so until I figure that out, I'm leaving the hole blank. My Atlas has a 3 wire hall sender in it but it's not sending a signal for some reason. I need to drain the case and reseat the VSS sender and see if that fixes is. I could also do a reluctor wheel around the output shaft of the transfer case and do a regular 2 wire GM VSS but again, I'd need to drop the t-case and figure this out. I haven't had the time to do this yet but will focus on this soon.

I went with a Perma Cool remote mount oil cooler for the TH400. Seems like a nice product. Hoping it keeps up with the heat from my TH400 while i'm idling through the rocks.

It's time for a beer break....

Trending Topics

#8

#12

I got my Summit builder exhaust kit in today. I'm only doing a 2 1/2" exhaust with a Magnaflow Delta 10 muffler for now due to clearance issues with my skid plates. I should be able to start putting the exhaust on the Jeep Friday night hopefully. I need to get an exhaust on it before I get it tuned.

Since I've done my swap, I've been starting it periodically to try and keep it running long enough to back it out of my garage and load in my enclosed trailer to take to the tuner's shop... but the tune is way off and it's only idling around 300-500 RPM then dies right when I go to put it in reverse... regardless if I give it a little throttle or not. Three of my neighbors have walked over and kindly asked me to stop starting my Jeep all day on the weekends with open headers. I guess they don't like the sound of f*cking freedom!

Anyways, I've also bought the HP Tuners kit so my tuner can help me remotely once I have the exhaust on it. Hopefully I can log some data during it's rough idle and capture enough for him to see what needs to be set enough to keep the motor running at 700-800 RPM and for it to go into gear enough to drive it around (or into my trailer).

More updates to come!

Since I've done my swap, I've been starting it periodically to try and keep it running long enough to back it out of my garage and load in my enclosed trailer to take to the tuner's shop... but the tune is way off and it's only idling around 300-500 RPM then dies right when I go to put it in reverse... regardless if I give it a little throttle or not. Three of my neighbors have walked over and kindly asked me to stop starting my Jeep all day on the weekends with open headers. I guess they don't like the sound of f*cking freedom!

Anyways, I've also bought the HP Tuners kit so my tuner can help me remotely once I have the exhaust on it. Hopefully I can log some data during it's rough idle and capture enough for him to see what needs to be set enough to keep the motor running at 700-800 RPM and for it to go into gear enough to drive it around (or into my trailer).

More updates to come!

#13

Awesome build. Love the details on the motor, flashy but not overwhelming. Nicely done.

Good deal on getting HP Tuners to. Have you done any tuning before? I have thought about getting it but am pretty intimidated by it for some odd reason.

Good deal on getting HP Tuners to. Have you done any tuning before? I have thought about getting it but am pretty intimidated by it for some odd reason.

#14

I have never done any tuning before. I'm an IT guy by trade some anything computer driven is in my blood so I'm not intimidated. I understand the concept of back up your original file and make changes to your second Save-As file so I can always revert back if I screw something up. I'm self taught in IT (been in IT for 20 years and owned two IT consulting firms) and I'm self taught in fab and car stuff stuff. I figure why not try to learn how to do it? After this, I'm building a 48-52 Chevy 3100 truck with an a turbo LS setup as my next project... so if I can learn a little bit with the Jeep motor setup, then I can apply it to my street rod truck build next.

#15

You do nice work. Good project and good write up.

#16

I had had some time yesterday so I made my exhaust. I bought way too much material. I picked up a 2.5” builder exhaust kit from Summit and Magnaflow 2.5 In/out Delta Force 10 muffler. I had to wrap it around the front of the motor and run it along the passenger side due to clearance issues with my front driveshaft and upper link on the 3 link.

Its *slightly* quieter now but probably not enough to appease the nosy neighbors.

Its *slightly* quieter now but probably not enough to appease the nosy neighbors.

Last edited by michaelmaxim; 10-30-2017 at 02:39 PM.

#18

I went to thread in my O2 sensors in the bungs that I welded into the exhaust two days ago and realized that the plugs weren't the right ones to match up to the harness. I didn't even tighten them down but when I went to unscrew the O2 sensor on the passenger side, it was seized in the threaded bung. So I PB'ed it up and hit it with my IR impact gun to get it out. Of course the threads were all mangled up when it came out. So I had to order a thread chaser to try and correct these threads. Kinda pissed that I threaded it one time and it gets screwed up before even tightening it and now I have to fix the threads before I can install the correct o2 sensors...

Do an LS swap they said... it will be great, they also said.... hmmmph!

Do an LS swap they said... it will be great, they also said.... hmmmph!

#19

Appreciate the comments! Thanks!

I have never done any tuning before. I'm an IT guy by trade some anything computer driven is in my blood so I'm not intimidated. I understand the concept of back up your original file and make changes to your second Save-As file so I can always revert back if I screw something up. I'm self taught in IT (been in IT for 20 years and owned two IT consulting firms) and I'm self taught in fab and car stuff stuff. I figure why not try to learn how to do it? After this, I'm building a 48-52 Chevy 3100 truck with an a turbo LS setup as my next project... so if I can learn a little bit with the Jeep motor setup, then I can apply it to my street rod truck build next.

I have never done any tuning before. I'm an IT guy by trade some anything computer driven is in my blood so I'm not intimidated. I understand the concept of back up your original file and make changes to your second Save-As file so I can always revert back if I screw something up. I'm self taught in IT (been in IT for 20 years and owned two IT consulting firms) and I'm self taught in fab and car stuff stuff. I figure why not try to learn how to do it? After this, I'm building a 48-52 Chevy 3100 truck with an a turbo LS setup as my next project... so if I can learn a little bit with the Jeep motor setup, then I can apply it to my street rod truck build next.

Ahh, you have a the skills that pay the bills working in IT. I'm just a weldor, no computer skills at all.

It is the way to go and learn how to do it on your own. Its hard finding a decent tuner locally.

I went to thread in my O2 sensors in the bungs that I welded into the exhaust two days ago and realized that the plugs weren't the right ones to match up to the harness. I didn't even tighten them down but when I went to unscrew the O2 sensor on the passenger side, it was seized in the threaded bung. So I PB'ed it up and hit it with my IR impact gun to get it out. Of course the threads were all mangled up when it came out. So I had to order a thread chaser to try and correct these threads. Kinda pissed that I threaded it one time and it gets screwed up before even tightening it and now I have to fix the threads before I can install the correct o2 sensors...

Do an LS swap they said... it will be great, they also said.... hmmmph!

Do an LS swap they said... it will be great, they also said.... hmmmph!

That does suck. When you get it fixed, drop a little anti seize on the threads.

Do an ls swap

, that's what everyone does haha

, that's what everyone does haha

#20

The thread chaser should be here today so I'll clean up the threads tonight and see if I have any better luck threading in the correct O2 sensors that I picked up last night.

I'll definitely be applying some anti-seize to both.

I'm hoping that having the front O2's installed will let the Jeep start and idle on the base tune enough to get some data logged in HP Tuners so I can get Jeff Lowry to help me fine tune the rest of the tune. It will start now, then it shuts down in a few seconds and smells really rich.