5.3 harness rewire

#1

Staging Lane

Thread Starter

Join Date: Aug 2018

Location: San Jose

Posts: 52

Likes: 0

Received 0 Likes

on

0 Posts

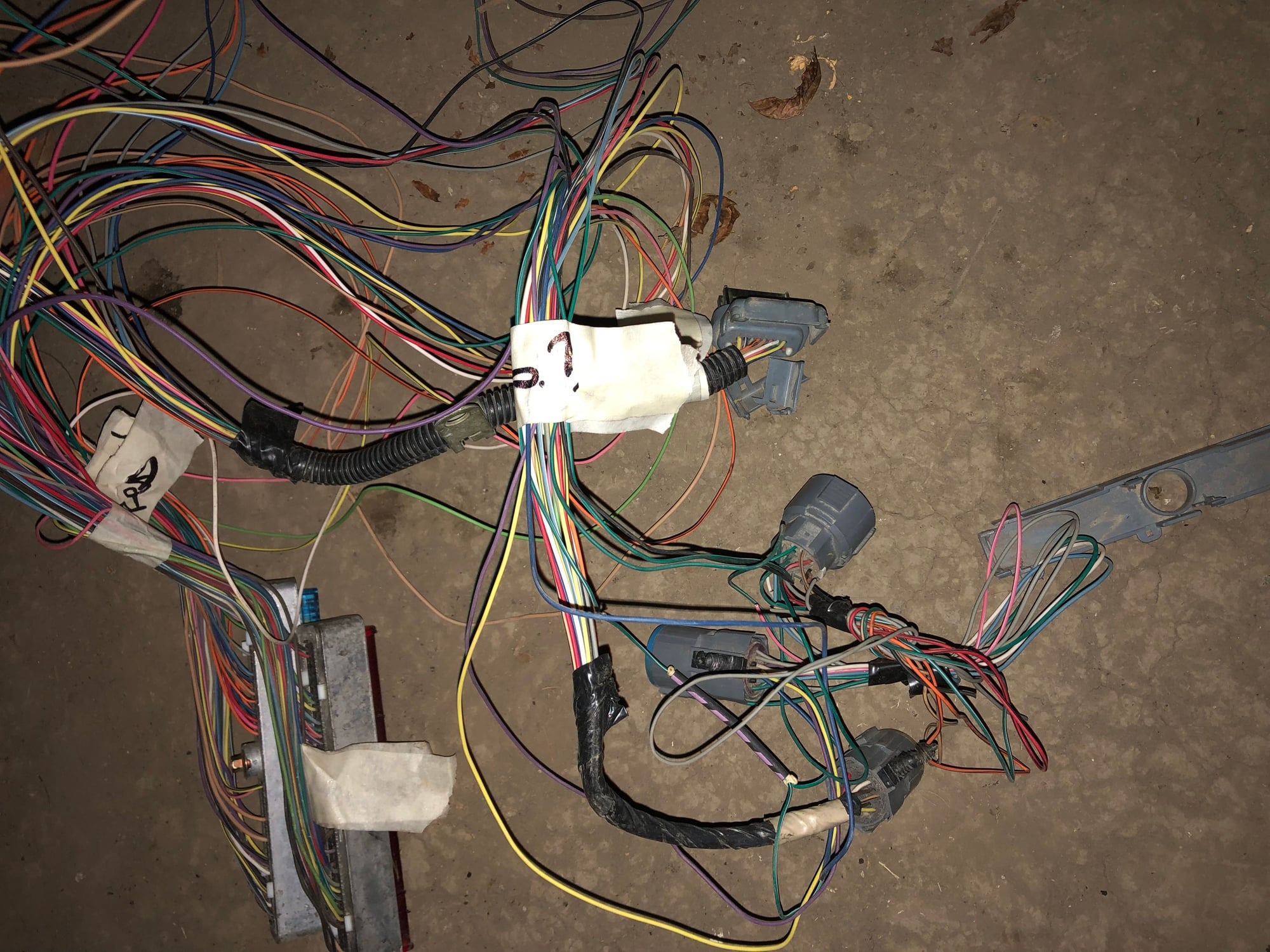

Swapping a 01 Silverado 5.3/TH350 (until I get a 4l60e) into a 79 Malibu. Put a LS1 intake on, running the 01 5.3 PCM & have a 01 Corvette LS1 harness I started to depin follo

wing the lt1swap.com instructions come to find out some of those pins led out to the trans plug & some of the depinned wires led to plugs that are now only missing a couple wires Iím completely lost & overwhelmed it seemed easy maybe Iím just not following the steps correctly I really need some help not sure if I will need another harness I would really appreciate the help !

#4

Staging Lane

Thread Starter

Join Date: Aug 2018

Location: San Jose

Posts: 52

Likes: 0

Received 0 Likes

on

0 Posts

ok ok I will do that tomorrow then maybe I can get some help figuring it out from you guys thanks!

#5

Staging Lane

Thread Starter

Join Date: Aug 2018

Location: San Jose

Posts: 52

Likes: 0

Received 0 Likes

on

0 Posts

#7

Staging Lane

Thread Starter

Join Date: Aug 2018

Location: San Jose

Posts: 52

Likes: 0

Received 0 Likes

on

0 Posts

Trending Topics

#8

I'm running a truck harness with car intake, that doesn't matter except for engine bay cleanliness. Delete everything you dont need, then mock it up and start looking at what needs to be lengthened, shortened, or changed based on changes you make. lt1swap can have errors too, it told me to depin stuff that I had to add back. Be patient and stock up on heat shrink butt connectors or solder!

#9

I just went through this myself. I started with an '02 Suburban harness and 5.3L engine, and dropped the engine (after rebuilding) into a '70 Chevrolet C-10 pick up. I removed ALL pins from both connectors when I started this process. As I removed each & every pin I would label them such as "B-28 TAN/WHITE" which would mean B for BLUE connector, 28 for PIN location. After you label, and remove each and every wire from both connectors, you then mount your computer where you want it to go. It's important that you get the computer mounted NOW so that the wires will end up the exact length you need them to be. Then, once the computer is mounted, cut/open up the entire harness and remove ALL of the things you are not going to use such as EVAP wiring, fuel level sensor, EGR, After-cat O2's, etc;. Now, once you have the harness pared down to ONLY what you are going to use, or need. Plug the connectors in 1 at a time, and then run the wires back to the PCM at it's new location. You can either lengthen, or shorten, the wires as you go so that they end up the exact length that you need them, OR you can just run the wire back to the PCM, and then double loop the wire back on itself and tape it together to save having to cut & solder so many wires.

Even if you just remove all wires without labeling them, it's really not hard figuring out where they go. LT1 swap will help you there. Just focus on doing 1 connector at a time and I promise you it will all come together quicker than you think. For simplicity-start at the farthest connection from the computer... If you are mounting the computer in the engine bay, then *typically* the speed sensor connector on the auto trans will be the farthest away. Unless you are not using an electronic trans????? Anyway, start with the connector farthest away from the PCM and once all of it's wires are terminated at PCM/12V+/Switched 12V+/Ground then just keep moving towards the PCM doing 1 connector at a time, and finish those connectors closest to the PCM last. Then, once all of your wires are connected to their final points, you can look at which wires to group together and tuck inside wiring loom, and then get it all wrapped up.

On my project I ran the harness down the back of the engine, right across the top of the transmission, with the front 2 O2 sensor wires acting as holders to keep the harness centered on the trans. All wires for both O2 sensors & trans, and neutral safety switch, and frame mounted fuel pump, all come together and run up to the back of the intake where the knock sensor wires, cam position sensor, map sensor, oil pressure sending unit, crank position sensor, starter trigger wire, all come together into 1 loom. Then going forward those wires are joined by the injectors & coil wiring on the PASSENGER side of the engine and then run forward to the computer which I have located behind the passenger side head-light. Then 1 other harness comes from the drivers side of the engine and it has alternator, IAC, TPS, engine coolant temp, injectors & coils from that side of the engine and those run under the throttle body and join up with the 1st harness and become 1 big harness that runs over to the PCM. So, that's it. 2 harnesses running over to PCM, and the majority of the wires coming together at the back of the engine.

If you get stuck on which connectors go where-simply try and plug them into the devices on the engine (if available?), and then start doing your wiring from there. Honestly, I think I pared my entire harness down to like 86 wires total. That's off the top of my head.. So, even though there are a TON of wires between both connectors, you will not be fiddling with all of them.

If you need ANY help at all, I would love to support you. Having just gone through this, it's all fresh in my mind! Use me before I lose it! Ha ha ha!

Even if you just remove all wires without labeling them, it's really not hard figuring out where they go. LT1 swap will help you there. Just focus on doing 1 connector at a time and I promise you it will all come together quicker than you think. For simplicity-start at the farthest connection from the computer... If you are mounting the computer in the engine bay, then *typically* the speed sensor connector on the auto trans will be the farthest away. Unless you are not using an electronic trans????? Anyway, start with the connector farthest away from the PCM and once all of it's wires are terminated at PCM/12V+/Switched 12V+/Ground then just keep moving towards the PCM doing 1 connector at a time, and finish those connectors closest to the PCM last. Then, once all of your wires are connected to their final points, you can look at which wires to group together and tuck inside wiring loom, and then get it all wrapped up.

On my project I ran the harness down the back of the engine, right across the top of the transmission, with the front 2 O2 sensor wires acting as holders to keep the harness centered on the trans. All wires for both O2 sensors & trans, and neutral safety switch, and frame mounted fuel pump, all come together and run up to the back of the intake where the knock sensor wires, cam position sensor, map sensor, oil pressure sending unit, crank position sensor, starter trigger wire, all come together into 1 loom. Then going forward those wires are joined by the injectors & coil wiring on the PASSENGER side of the engine and then run forward to the computer which I have located behind the passenger side head-light. Then 1 other harness comes from the drivers side of the engine and it has alternator, IAC, TPS, engine coolant temp, injectors & coils from that side of the engine and those run under the throttle body and join up with the 1st harness and become 1 big harness that runs over to the PCM. So, that's it. 2 harnesses running over to PCM, and the majority of the wires coming together at the back of the engine.

If you get stuck on which connectors go where-simply try and plug them into the devices on the engine (if available?), and then start doing your wiring from there. Honestly, I think I pared my entire harness down to like 86 wires total. That's off the top of my head.. So, even though there are a TON of wires between both connectors, you will not be fiddling with all of them.

If you need ANY help at all, I would love to support you. Having just gone through this, it's all fresh in my mind! Use me before I lose it! Ha ha ha!

#10

TECH Senior Member

Wow! Good stuff Kawabuggy! This looks VERY helpful for sorting out a harness!

#11

Staging Lane

Thread Starter

Join Date: Aug 2018

Location: San Jose

Posts: 52

Likes: 0

Received 0 Likes

on

0 Posts

I just went through this myself. I started with an '02 Suburban harness and 5.3L engine, and dropped the engine (after rebuilding) into a '70 Chevrolet C-10 pick up. I removed ALL pins from both connectors when I started this process. As I removed each & every pin I would label them such as "B-28 TAN/WHITE" which would mean B for BLUE connector, 28 for PIN location. After you label, and remove each and every wire from both connectors, you then mount your computer where you want it to go. It's important that you get the computer mounted NOW so that the wires will end up the exact length you need them to be. Then, once the computer is mounted, cut/open up the entire harness and remove ALL of the things you are not going to use such as EVAP wiring, fuel level sensor, EGR, After-cat O2's, etc;. Now, once you have the harness pared down to ONLY what you are going to use, or need. Plug the connectors in 1 at a time, and then run the wires back to the PCM at it's new location. You can either lengthen, or shorten, the wires as you go so that they end up the exact length that you need them, OR you can just run the wire back to the PCM, and then double loop the wire back on itself and tape it together to save having to cut & solder so many wires.

Even if you just remove all wires without labeling them, it's really not hard figuring out where they go. LT1 swap will help you there. Just focus on doing 1 connector at a time and I promise you it will all come together quicker than you think. For simplicity-start at the farthest connection from the computer... If you are mounting the computer in the engine bay, then *typically* the speed sensor connector on the auto trans will be the farthest away. Unless you are not using an electronic trans????? Anyway, start with the connector farthest away from the PCM and once all of it's wires are terminated at PCM/12V+/Switched 12V+/Ground then just keep moving towards the PCM doing 1 connector at a time, and finish those connectors closest to the PCM last. Then, once all of your wires are connected to their final points, you can look at which wires to group together and tuck inside wiring loom, and then get it all wrapped up.

On my project I ran the harness down the back of the engine, right across the top of the transmission, with the front 2 O2 sensor wires acting as holders to keep the harness centered on the trans. All wires for both O2 sensors & trans, and neutral safety switch, and frame mounted fuel pump, all come together and run up to the back of the intake where the knock sensor wires, cam position sensor, map sensor, oil pressure sending unit, crank position sensor, starter trigger wire, all come together into 1 loom. Then going forward those wires are joined by the injectors & coil wiring on the PASSENGER side of the engine and then run forward to the computer which I have located behind the passenger side head-light. Then 1 other harness comes from the drivers side of the engine and it has alternator, IAC, TPS, engine coolant temp, injectors & coils from that side of the engine and those run under the throttle body and join up with the 1st harness and become 1 big harness that runs over to the PCM. So, that's it. 2 harnesses running over to PCM, and the majority of the wires coming together at the back of the engine.

If you get stuck on which connectors go where-simply try and plug them into the devices on the engine (if available?), and then start doing your wiring from there. Honestly, I think I pared my entire harness down to like 86 wires total. That's off the top of my head.. So, even though there are a TON of wires between both connectors, you will not be fiddling with all of them.

If you need ANY help at all, I would love to support you. Having just gone through this, it's all fresh in my mind! Use me before I lose it! Ha ha ha!

Even if you just remove all wires without labeling them, it's really not hard figuring out where they go. LT1 swap will help you there. Just focus on doing 1 connector at a time and I promise you it will all come together quicker than you think. For simplicity-start at the farthest connection from the computer... If you are mounting the computer in the engine bay, then *typically* the speed sensor connector on the auto trans will be the farthest away. Unless you are not using an electronic trans????? Anyway, start with the connector farthest away from the PCM and once all of it's wires are terminated at PCM/12V+/Switched 12V+/Ground then just keep moving towards the PCM doing 1 connector at a time, and finish those connectors closest to the PCM last. Then, once all of your wires are connected to their final points, you can look at which wires to group together and tuck inside wiring loom, and then get it all wrapped up.

On my project I ran the harness down the back of the engine, right across the top of the transmission, with the front 2 O2 sensor wires acting as holders to keep the harness centered on the trans. All wires for both O2 sensors & trans, and neutral safety switch, and frame mounted fuel pump, all come together and run up to the back of the intake where the knock sensor wires, cam position sensor, map sensor, oil pressure sending unit, crank position sensor, starter trigger wire, all come together into 1 loom. Then going forward those wires are joined by the injectors & coil wiring on the PASSENGER side of the engine and then run forward to the computer which I have located behind the passenger side head-light. Then 1 other harness comes from the drivers side of the engine and it has alternator, IAC, TPS, engine coolant temp, injectors & coils from that side of the engine and those run under the throttle body and join up with the 1st harness and become 1 big harness that runs over to the PCM. So, that's it. 2 harnesses running over to PCM, and the majority of the wires coming together at the back of the engine.

If you get stuck on which connectors go where-simply try and plug them into the devices on the engine (if available?), and then start doing your wiring from there. Honestly, I think I pared my entire harness down to like 86 wires total. That's off the top of my head.. So, even though there are a TON of wires between both connectors, you will not be fiddling with all of them.

If you need ANY help at all, I would love to support you. Having just gone through this, it's all fresh in my mind! Use me before I lose it! Ha ha ha!

you just made me open my eyes to this whole theatrical better. Ok so do you think I need O2 sensors for tuning at all ? If not Iím not running any at all. I believe some of the connectors might be a bit different since I have truck accessories any idea on that ? I see you ran a truck harness on your 5.3, I have a corvette harness no idea if they are similar but Iím plugging in stuff right now. THANKS A MILLION !

#12

In regards to whether or not you need O2 sensors.. That is going to be decided by how you end up tuning it. You going to a SDOL tune, or???

I have heard, and read, that the car fuel injectors, ARE DIFFERENT than the truck injectors. So, you will need to match the injectors to the harness that you are using. If you have a CAR harness, and CAR injectors, you should be fine. You can use truck injectors with a car harness if you swap the injector connectors, or vice/versa...

Also, depending on what year engine you are using, other things change such as the crank position sensor-there are 24 & 58 tooth reluctors. You need to have the correct harness to match the year of your engine. On earlier engines the cam position sensor is behind the intake beside the oil pressure sending unit.. On newer motors, its on the timing chain cover on the front of the engine. Also, the map position sensor location changes, and the arrangement of the wires in the connector also swap locations.

Since you are running an 01 harness, and 01 engine, I think your connectors will all be the same, and *should* work. The only issue I think you might have is that the accessories are in different locations between the car & truck engines so you may have to re-reoute, or lengthen, or shorten, wires as you go. UNLESS you are running the CAR accessory brackets... If running the car access. brackets then the harness will be darn close as-is, unless you plan on drastically moving the PCM from the factory location. I have NO IDEA where GM put the PCM in an 01 Corvette... Never worked on one..

Are you going to DBC, or DBW? I think, but could be wrong, that all Corvettes are DBW.. So, you might need to figure out what you are going to do about that.. I know FOR SURE that you have to match the PCM to whatever throttle body you are going to run... Be very cautious with this part of the swap.

I have heard, and read, that the car fuel injectors, ARE DIFFERENT than the truck injectors. So, you will need to match the injectors to the harness that you are using. If you have a CAR harness, and CAR injectors, you should be fine. You can use truck injectors with a car harness if you swap the injector connectors, or vice/versa...

Also, depending on what year engine you are using, other things change such as the crank position sensor-there are 24 & 58 tooth reluctors. You need to have the correct harness to match the year of your engine. On earlier engines the cam position sensor is behind the intake beside the oil pressure sending unit.. On newer motors, its on the timing chain cover on the front of the engine. Also, the map position sensor location changes, and the arrangement of the wires in the connector also swap locations.

Since you are running an 01 harness, and 01 engine, I think your connectors will all be the same, and *should* work. The only issue I think you might have is that the accessories are in different locations between the car & truck engines so you may have to re-reoute, or lengthen, or shorten, wires as you go. UNLESS you are running the CAR accessory brackets... If running the car access. brackets then the harness will be darn close as-is, unless you plan on drastically moving the PCM from the factory location. I have NO IDEA where GM put the PCM in an 01 Corvette... Never worked on one..

Are you going to DBC, or DBW? I think, but could be wrong, that all Corvettes are DBW.. So, you might need to figure out what you are going to do about that.. I know FOR SURE that you have to match the PCM to whatever throttle body you are going to run... Be very cautious with this part of the swap.

#13

TECH Senior Member

All Vettes are DBW.....

#14

Staging Lane

Thread Starter

Join Date: Aug 2018

Location: San Jose

Posts: 52

Likes: 0

Received 0 Likes

on

0 Posts

In regards to whether or not you need O2 sensors.. That is going to be decided by how you end up tuning it. You going to a SDOL tune, or???

I have heard, and read, that the car fuel injectors, ARE DIFFERENT than the truck injectors. So, you will need to match the injectors to the harness that you are using. If you have a CAR harness, and CAR injectors, you should be fine. You can use truck injectors with a car harness if you swap the injector connectors, or vice/versa...

Also, depending on what year engine you are using, other things change such as the crank position sensor-there are 24 & 58 tooth reluctors. You need to have the correct harness to match the year of your engine. On earlier engines the cam position sensor is behind the intake beside the oil pressure sending unit.. On newer motors, its on the timing chain cover on the front of the engine. Also, the map position sensor location changes, and the arrangement of the wires in the connector also swap locations.

Since you are running an 01 harness, and 01 engine, I think your connectors will all be the same, and *should* work. The only issue I think you might have is that the accessories are in different locations between the car & truck engines so you may have to re-reoute, or lengthen, or shorten, wires as you go. UNLESS you are running the CAR accessory brackets... If running the car access. brackets then the harness will be darn close as-is, unless you plan on drastically moving the PCM from the factory location. I have NO IDEA where GM put the PCM in an 01 Corvette... Never worked on one..

Are you going to DBC, or DBW? I think, but could be wrong, that all Corvettes are DBW.. So, you might need to figure out what you are going to do about that.. I know FOR SURE that you have to match the PCM to whatever throttle body you are going to run... Be very cautious with this part of the swap.

I have heard, and read, that the car fuel injectors, ARE DIFFERENT than the truck injectors. So, you will need to match the injectors to the harness that you are using. If you have a CAR harness, and CAR injectors, you should be fine. You can use truck injectors with a car harness if you swap the injector connectors, or vice/versa...

Also, depending on what year engine you are using, other things change such as the crank position sensor-there are 24 & 58 tooth reluctors. You need to have the correct harness to match the year of your engine. On earlier engines the cam position sensor is behind the intake beside the oil pressure sending unit.. On newer motors, its on the timing chain cover on the front of the engine. Also, the map position sensor location changes, and the arrangement of the wires in the connector also swap locations.

Since you are running an 01 harness, and 01 engine, I think your connectors will all be the same, and *should* work. The only issue I think you might have is that the accessories are in different locations between the car & truck engines so you may have to re-reoute, or lengthen, or shorten, wires as you go. UNLESS you are running the CAR accessory brackets... If running the car access. brackets then the harness will be darn close as-is, unless you plan on drastically moving the PCM from the factory location. I have NO IDEA where GM put the PCM in an 01 Corvette... Never worked on one..

Are you going to DBC, or DBW? I think, but could be wrong, that all Corvettes are DBW.. So, you might need to figure out what you are going to do about that.. I know FOR SURE that you have to match the PCM to whatever throttle body you are going to run... Be very cautious with this part of the swap.

i am am looking behind the intake their is 2 sensors one tall sensor one flush. Also do I need the knock sensors ? I have DBW tb, itís a vette intake. Iím mounting the pcm inside the car I also want obd plug so I can run a Bluetooth gauge set up.

#17

Staging Lane

Thread Starter

Join Date: Aug 2018

Location: San Jose

Posts: 52

Likes: 0

Received 0 Likes

on

0 Posts

Have a sensor that stands upright on the engine here behind the intake didnít end up having a connection from the harness what sensor is this? Also a loose plug here..

#20

Staging Lane

Thread Starter

Join Date: Aug 2018

Location: San Jose

Posts: 52

Likes: 0

Received 0 Likes

on

0 Posts

Trans plugs? No idea on these. Everything is plugged in. Engine has 1 sensor with no plug as well as oil pan. Harness I have about 9 loose connections. That really helped a lot I appreciate your time very much thank you so much !