LS1 Custom Pulley setup

#1

On The Tree

Thread Starter

Join Date: Jun 2004

Location: Melbourne, Australia

Posts: 132

Likes: 0

Received 0 Likes

on

0 Posts

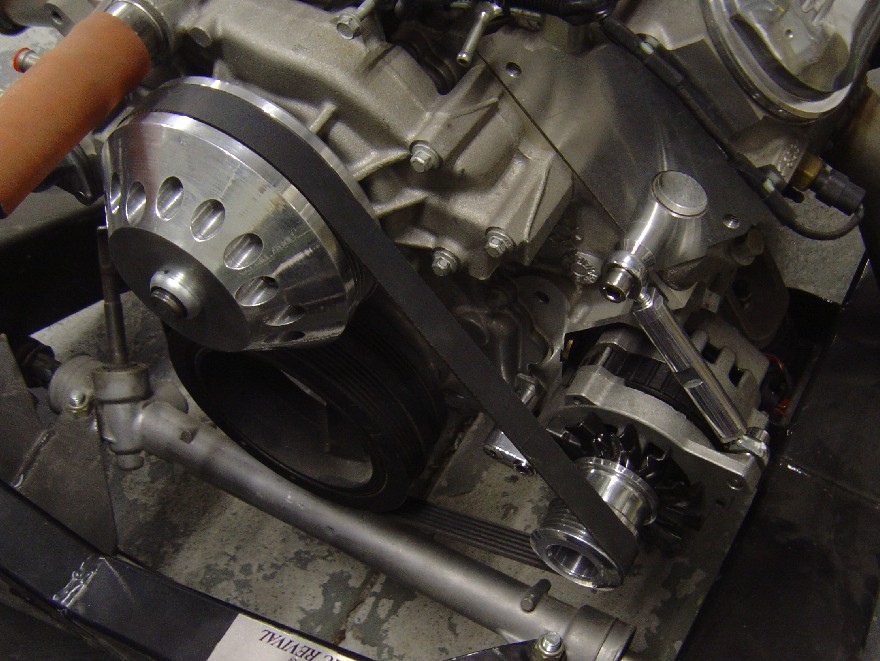

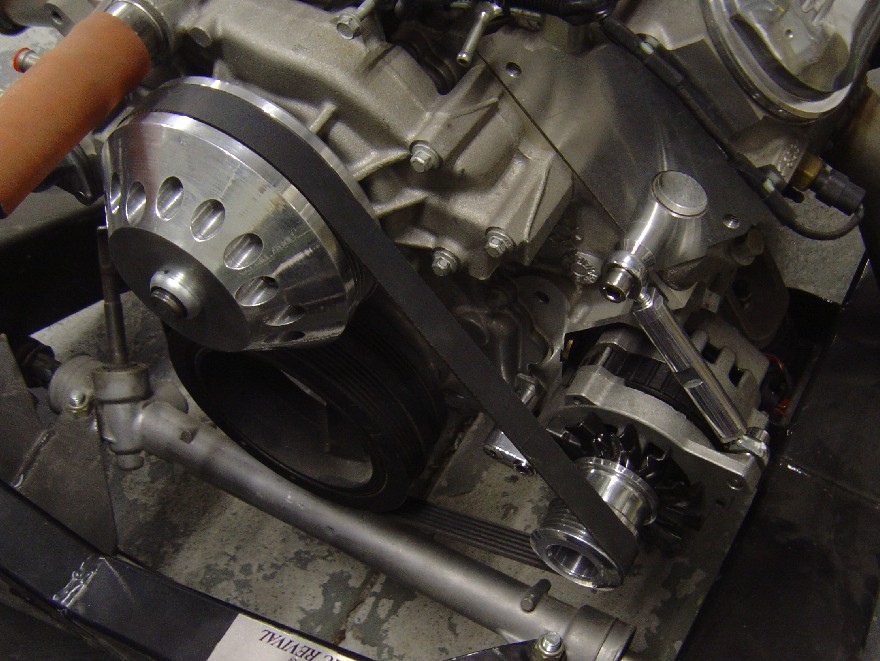

I finally sorted out my reverse rotation water pump setup and belt tensioner. I was orignally going to make up a spring loaded tensioner but decided to dump the whole factory alternator and adapt something else up.

I found a Delco 80 amp alternator at the wreckers that was significantly smaller than the LS1 alternator. I machined up a new pulley for it and a bracket. I did the tensioner using left and right hand threaded rod ends which makes it easy to set the belt tension. The smaller alternator gives me heaps more clearance to the chassis rail too.

I set the alternator back a bit and machined up an extended pulley. the reason for this is that later I plan on running the alternator off the rear crank pulley leaving the main pulley for an Eaton M112 blower setup I'm building. I figure I'll be able to get more belt wrap around the pulley without having the alternator in there.

Cheers

Michael

I found a Delco 80 amp alternator at the wreckers that was significantly smaller than the LS1 alternator. I machined up a new pulley for it and a bracket. I did the tensioner using left and right hand threaded rod ends which makes it easy to set the belt tension. The smaller alternator gives me heaps more clearance to the chassis rail too.

I set the alternator back a bit and machined up an extended pulley. the reason for this is that later I plan on running the alternator off the rear crank pulley leaving the main pulley for an Eaton M112 blower setup I'm building. I figure I'll be able to get more belt wrap around the pulley without having the alternator in there.

Cheers

Michael

#4

On The Tree

Thread Starter

Join Date: Jun 2004

Location: Melbourne, Australia

Posts: 132

Likes: 0

Received 0 Likes

on

0 Posts

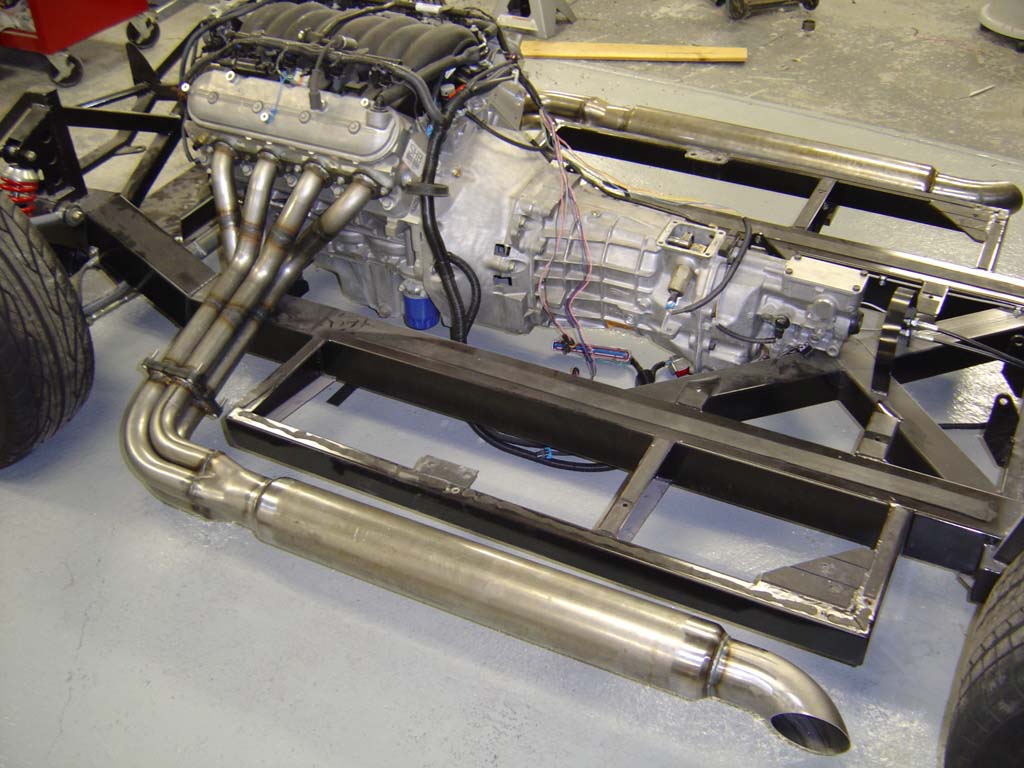

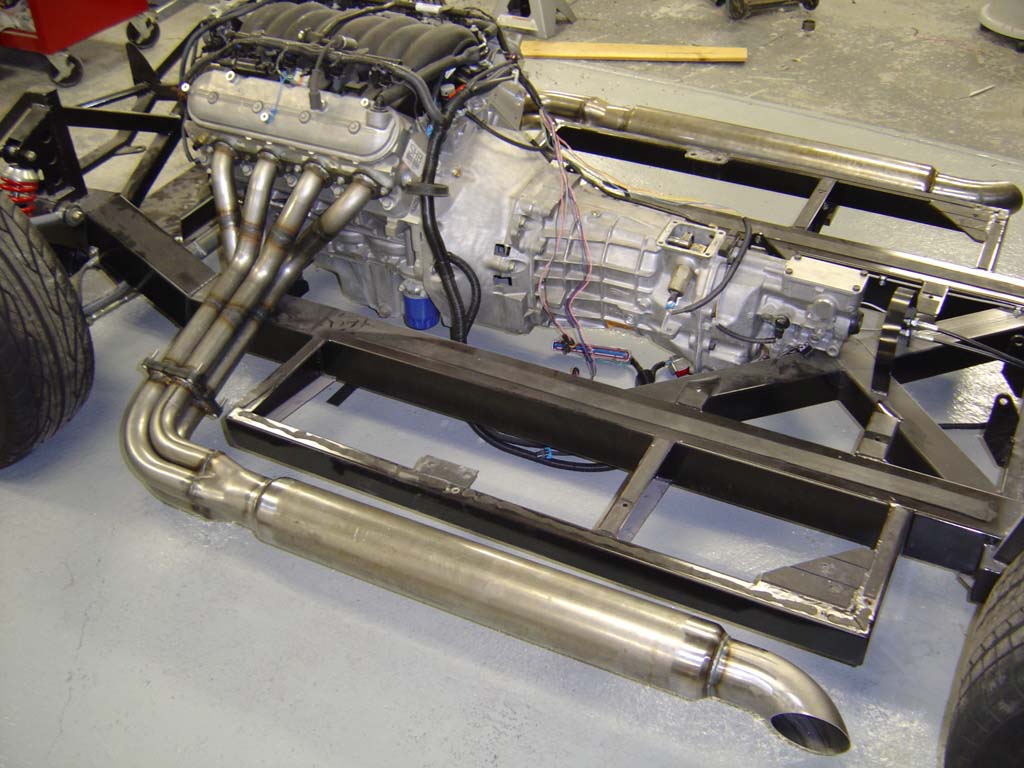

Yep, it's a streeter. Don't need power steer because the engine is set so far back and the car will only weigh 1000KG. Don't need A/C since it's an open top roadster.

Trying to keep the whole thing minimalist with no extra weight or complexity. It'll get a fair bit of use on the circuit and at the strip as well as cruising the streets.

Haven't had much time to work on it for a while but I've been getting back to it lately.

Cheers

Michael

Trying to keep the whole thing minimalist with no extra weight or complexity. It'll get a fair bit of use on the circuit and at the strip as well as cruising the streets.

Haven't had much time to work on it for a while but I've been getting back to it lately.

Cheers

Michael

#7

He said reverse rotation not reverse direction. Reverse rotation is on all LS-X motors they use a smooth wp pulley and the shaft rotates counter clockwise. to direct the coolant in the traditonal path.

A reverse direction would be like the LT1 and LT4 Gen 2 motors. In those applications the coolant hit the heads first then the block.

A reverse direction would be like the LT1 and LT4 Gen 2 motors. In those applications the coolant hit the heads first then the block.

Trending Topics

#8

On The Tree

Thread Starter

Join Date: Jun 2004

Location: Melbourne, Australia

Posts: 132

Likes: 0

Received 0 Likes

on

0 Posts

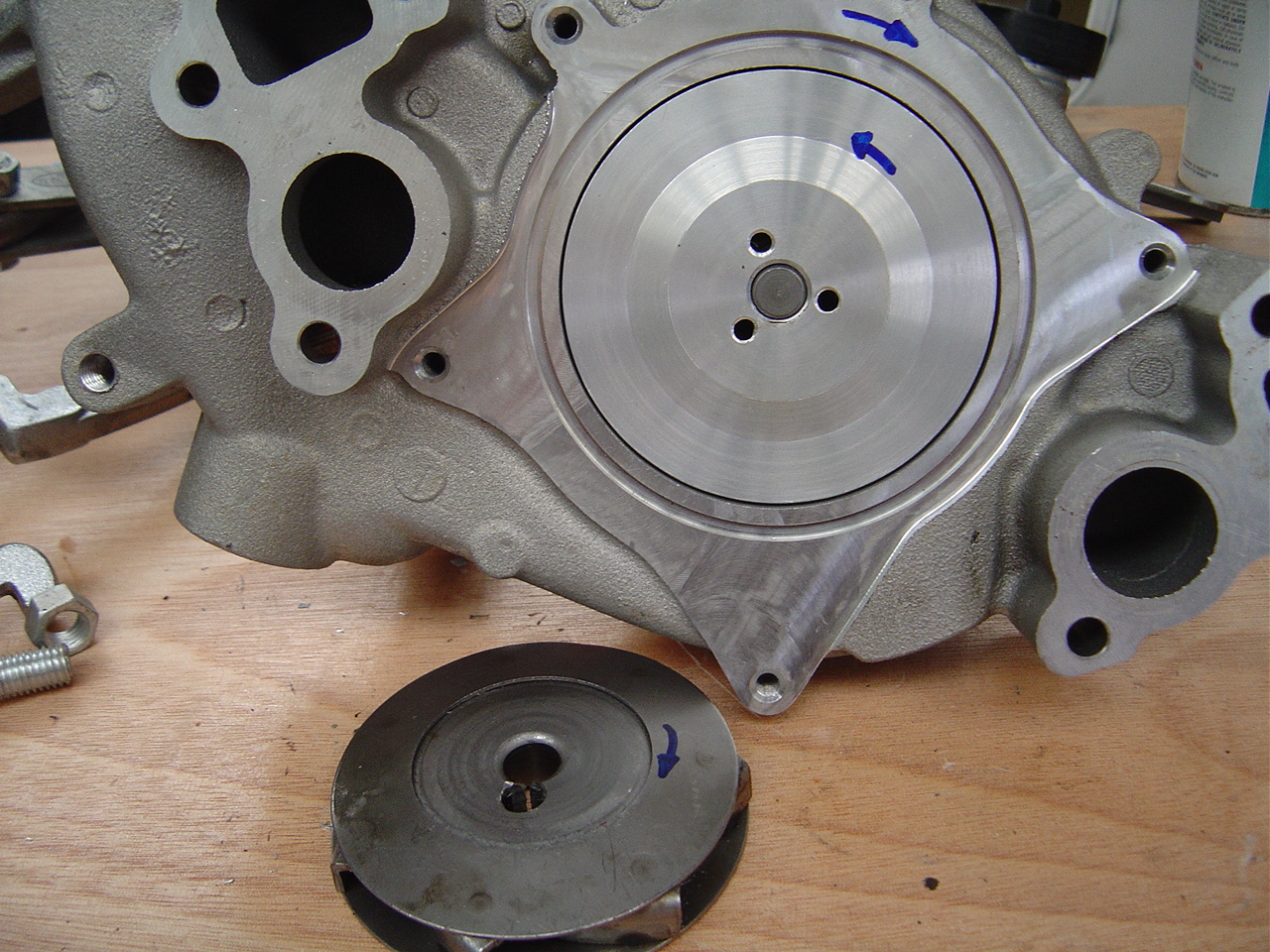

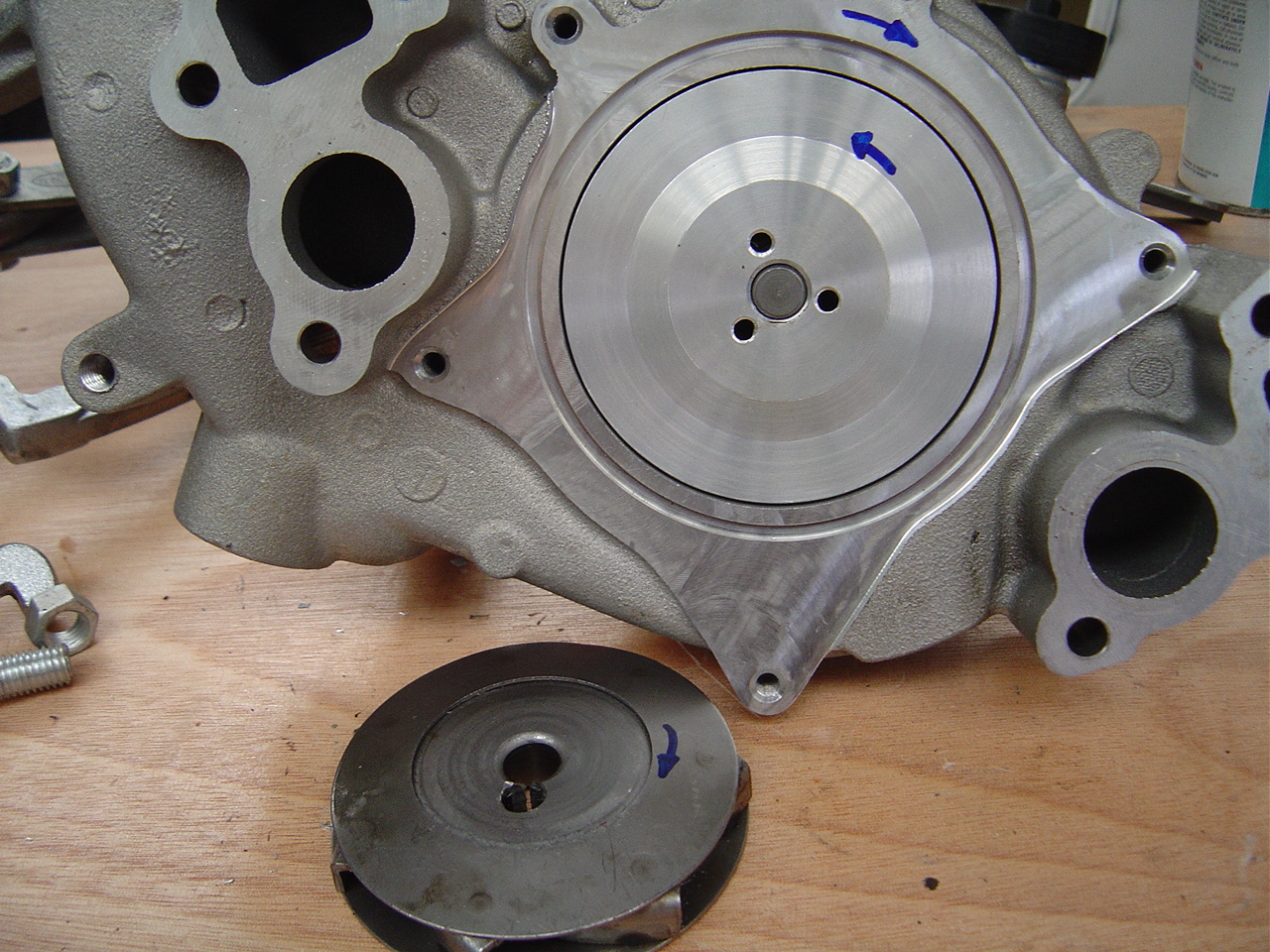

No it's actually reverse rotation from the conventional pump too. I machined up a new impeller with the blades running the other way. The coolant flow is the same as normal.

Here's the new impeller taking shape.

Here's a shot comparing the new reverse impeller to the original.

Impeller in place.

Cheers

Here's the new impeller taking shape.

Here's a shot comparing the new reverse impeller to the original.

Impeller in place.

Cheers

#10

Originally Posted by SMSFRC99

He said reverse rotation not reverse direction. Reverse rotation is on all LS-X motors they use a smooth wp pulley and the shaft rotates counter clockwise. to direct the coolant in the traditonal path.

A reverse direction would be like the LT1 and LT4 Gen 2 motors. In those applications the coolant hit the heads first then the block.

A reverse direction would be like the LT1 and LT4 Gen 2 motors. In those applications the coolant hit the heads first then the block.

So LS1 Cobra, is this the only available solution? With Fords, you can get reverse rotation water pumps. BTW, very nice work!!

Andy1

#13

Another LS1Cobra hehe..

Michael,

I had this same problem when I had to move my alternator. My solution was Electric water pump. Of course if I have the equipment you have I would have come up with the same solution as yours. But here is a picture of my set up:

My engine will get a nice clean up upon the final installation. I have a lot of stainless steels and aluminum in my engine bay also. Nice work BTW.

Mike,

I see you don't have a lot of room in the engine bay just like me. What did you do with the exhaust headers? I've searched around and couldn't find headers that fits my engine bay so I used the stock C5 SS headers and modified them. They fit pretty good and clear the steering shaft. I have an extra set of these SS headers. Let me know if you have not gotten your headers yet.

Vinh

Michael,

I had this same problem when I had to move my alternator. My solution was Electric water pump. Of course if I have the equipment you have I would have come up with the same solution as yours. But here is a picture of my set up:

My engine will get a nice clean up upon the final installation. I have a lot of stainless steels and aluminum in my engine bay also. Nice work BTW.

Mike,

I see you don't have a lot of room in the engine bay just like me. What did you do with the exhaust headers? I've searched around and couldn't find headers that fits my engine bay so I used the stock C5 SS headers and modified them. They fit pretty good and clear the steering shaft. I have an extra set of these SS headers. Let me know if you have not gotten your headers yet.

Vinh

Last edited by LS1Cobra; 02-10-2006 at 10:22 PM.

#15

On The Tree

Thread Starter

Join Date: Jun 2004

Location: Melbourne, Australia

Posts: 132

Likes: 0

Received 0 Likes

on

0 Posts

No problem Andy, I'm not quite sure what the right description is myself.

Most of the guys in The Cobra car club I belong to run Fords and have plenty of choises when it comes to water pumps and accessory drives. I haven't seen any other reversed LS1 for the LS1. I probably could have done it some other way but part of the reason for doing it was the challenge. I've always enjoyed making stuff rather than buying it.

Hi TJ,

I'll switch to the 4 rib pulley for the alternator when I fabricate the blower manifold. The mount will stay the same I'll just machine a new alternator pulley to suit the rear 4 rib crank pulley. That way I can use around 180 degrees for belt wrap on the 6 rib crank pulley belt pulley for the blower. Hopefully this should let me run a reasonable bost level before I get belt slip.

I'm contemplating switching to a Corvette crank pulley as I think the whole thing is closer to the engine block. Just trying to keep everything compact.

Hi Vinh,

What Sort of Cobra is that? Is ist a Mustang Cobra? Looks like a compact drive setup but have you got enough belt wrap to stop the belt slipping?

I built my own headers and side pipes. A few of the guys Running LS1s in Cobras have run under body systems using the factory Comodore shorty headers but most people seem to use hand made pipes.

I did mine from 1 7/8" mild steel mandrel bends into 3 1/2" collectors. There are Hi Flo cat converters inside the sidepipes too so I can meet the strict emissions rules down here.

Hi Brains,

The impeller is machined to much closer tollerances than the original pressed stainless steel unit. The blades of the impeller run only about 1mm clear of the face of the housing. There's just no where for the water to go but outwards, it can't get around the impeller so hopefully cavitation shouldn't be to much of a problem. If anything I'm worried about it being a bit to eficient and might have to trim the blades. I can experiment with different impeller designs If I have any problems since it's fairly easy to pull the impeller out to change it.

Hi Scot,

I'll see if I can find a better pic. It's a pretty simple mount though.

Cheers

Most of the guys in The Cobra car club I belong to run Fords and have plenty of choises when it comes to water pumps and accessory drives. I haven't seen any other reversed LS1 for the LS1. I probably could have done it some other way but part of the reason for doing it was the challenge. I've always enjoyed making stuff rather than buying it.

Hi TJ,

I'll switch to the 4 rib pulley for the alternator when I fabricate the blower manifold. The mount will stay the same I'll just machine a new alternator pulley to suit the rear 4 rib crank pulley. That way I can use around 180 degrees for belt wrap on the 6 rib crank pulley belt pulley for the blower. Hopefully this should let me run a reasonable bost level before I get belt slip.

I'm contemplating switching to a Corvette crank pulley as I think the whole thing is closer to the engine block. Just trying to keep everything compact.

Hi Vinh,

What Sort of Cobra is that? Is ist a Mustang Cobra? Looks like a compact drive setup but have you got enough belt wrap to stop the belt slipping?

I built my own headers and side pipes. A few of the guys Running LS1s in Cobras have run under body systems using the factory Comodore shorty headers but most people seem to use hand made pipes.

I did mine from 1 7/8" mild steel mandrel bends into 3 1/2" collectors. There are Hi Flo cat converters inside the sidepipes too so I can meet the strict emissions rules down here.

Hi Brains,

The impeller is machined to much closer tollerances than the original pressed stainless steel unit. The blades of the impeller run only about 1mm clear of the face of the housing. There's just no where for the water to go but outwards, it can't get around the impeller so hopefully cavitation shouldn't be to much of a problem. If anything I'm worried about it being a bit to eficient and might have to trim the blades. I can experiment with different impeller designs If I have any problems since it's fairly easy to pull the impeller out to change it.

Hi Scot,

I'll see if I can find a better pic. It's a pretty simple mount though.

Cheers

#17

Michael,

Here is a picture of the other Cobra that my kit model after and it's NOT a mustang Cobra. Since my car is a kit car and I don't have much room in engine compartment I can't run the headers like those. Otherwise I would have built my own headers as well. Nice exhaust system though.

I think I am going to get a lath and mill very soon. :o)

Here is a picture of the other Cobra that my kit model after and it's NOT a mustang Cobra. Since my car is a kit car and I don't have much room in engine compartment I can't run the headers like those. Otherwise I would have built my own headers as well. Nice exhaust system though.

I think I am going to get a lath and mill very soon. :o)

#18

LS1 Cobra: Noticed that you have moved the shifter forward. With your fabricating skills it seems likely that you have engineered the solution yourself?!? Any chance you could share the how-to?

Thanks

Thanks

#19

On The Tree

Thread Starter

Join Date: Jun 2004

Location: Melbourne, Australia

Posts: 132

Likes: 0

Received 0 Likes

on

0 Posts

Hi Vinh, Looks like a good project you've taken on. Sorry, I didn't notice your signature line. I'll have to keep looking in to see your progress. I like the Daytona Coupe, I was checking out the Superformance Coupe at our Cobra Nationals. Awesome machine.

I developed a mid shift conversion for the T56 several years ago and have been converting boxes for Cobras and Hot rods for some time. It's a bit of a side line buisiness so I don't really want to give away all my development work, Sorry.

I recently completed a box for a LS1 powered 57 Chev with the original bench seat. It turned out a treat and should be a beast of a car when it's done. Iron block 400 cube plus LS1 being built for it at the moment.

I also do rebuilds and beef up the internals. There's a Cobra down here with a procharged LS1 making 550RWHP that gets a fair bit of circuit work with one of my boxes. He broke it last year so I rebuilt it (sheard all the keys). It also got billet keys and a steel 3-4 Shift fork. We'll see how it holds up over the next few events.

Here's what one of my boxes looks like.

Cheers

I developed a mid shift conversion for the T56 several years ago and have been converting boxes for Cobras and Hot rods for some time. It's a bit of a side line buisiness so I don't really want to give away all my development work, Sorry.

I recently completed a box for a LS1 powered 57 Chev with the original bench seat. It turned out a treat and should be a beast of a car when it's done. Iron block 400 cube plus LS1 being built for it at the moment.

I also do rebuilds and beef up the internals. There's a Cobra down here with a procharged LS1 making 550RWHP that gets a fair bit of circuit work with one of my boxes. He broke it last year so I rebuilt it (sheard all the keys). It also got billet keys and a steel 3-4 Shift fork. We'll see how it holds up over the next few events.

Here's what one of my boxes looks like.

Cheers