Those who have done your own standalone

#1

TECH Apprentice

Thread Starter

Join Date: Jan 2002

Location: san diego

Posts: 343

Likes: 0

Received 0 Likes

on

0 Posts

Need some advice.

I have a standalone in my jeep and yesterday it melted. I'm wondering how hard it would be to take it off, stretch it out on the living room floor and replace/ fix all the damage?

Any tips or pointers?

Also where would I buy the necessary parts and wires?

I have a standalone in my jeep and yesterday it melted. I'm wondering how hard it would be to take it off, stretch it out on the living room floor and replace/ fix all the damage?

Any tips or pointers?

Also where would I buy the necessary parts and wires?

#2

TECH Addict

iTrader: (22)

Be careful with melted wires, they will give you ALOT more frustration than you expect. When the bundle gets hot enough to melt the jacket off, you can imagine how much gets transferred up/down the wire slightly melting the inside of the jacket as well. Not a big deal except it wont strip off so you have a hard time soldering the repairs on and when you do strip a section lots of little remnants remain contaminating the splice

Other than that hurdle, its nothing major. A large workspace is a must though. Find replacement connectors in a JY. A late 90's S10 harness should have 90% of the connectors necessary to build a LSx harness, but individual connectors can be scavenged from nearly any 90+ GM vehicle. The wire type you want is TXL jacket, 18/20ga. For a small repair job Id just use leftovers from the JY harness instead of buying new

Other than that hurdle, its nothing major. A large workspace is a must though. Find replacement connectors in a JY. A late 90's S10 harness should have 90% of the connectors necessary to build a LSx harness, but individual connectors can be scavenged from nearly any 90+ GM vehicle. The wire type you want is TXL jacket, 18/20ga. For a small repair job Id just use leftovers from the JY harness instead of buying new

#3

TECH Apprentice

Thread Starter

Join Date: Jan 2002

Location: san diego

Posts: 343

Likes: 0

Received 0 Likes

on

0 Posts

Be careful with melted wires, they will give you ALOT more frustration than you expect. When the bundle gets hot enough to melt the jacket off, you can imagine how much gets transferred up/down the wire slightly melting the inside of the jacket as well. Not a big deal except it wont strip off so you have a hard time soldering the repairs on and when you do strip a section lots of little remnants remain contaminating the splice

Other than that hurdle, its nothing major. A large workspace is a must though. Find replacement connectors in a JY. A late 90's S10 harness should have 90% of the connectors necessary to build a LSx harness, but individual connectors can be scavenged from nearly any 90+ GM vehicle. The wire type you want is TXL jacket, 18/20ga. For a small repair job Id just use leftovers from the JY harness instead of buying new

Other than that hurdle, its nothing major. A large workspace is a must though. Find replacement connectors in a JY. A late 90's S10 harness should have 90% of the connectors necessary to build a LSx harness, but individual connectors can be scavenged from nearly any 90+ GM vehicle. The wire type you want is TXL jacket, 18/20ga. For a small repair job Id just use leftovers from the JY harness instead of buying new

I caught your write up on the third gen website and it looks pretty straight forward. I didn't plan on splicing in replacement lengths of wire so much as I planned to replace whole lengths of with from the connector to the PCM.

#4

TECH Junkie

iTrader: (18)

If it got hot enough to melt more than 5 or 6 wires, you'll probably find that it's easier to just get a different harness and mod it for your needs. Where the harness got hot, all of the wires there will have the insulation melted together and it's almost impossible to seperate them without tearing the remaining insulation loose.

#5

TECH Apprentice

Thread Starter

Join Date: Jan 2002

Location: san diego

Posts: 343

Likes: 0

Received 0 Likes

on

0 Posts

If it got hot enough to melt more than 5 or 6 wires, you'll probably find that it's easier to just get a different harness and mod it for your needs. Where the harness got hot, all of the wires there will have the insulation melted together and it's almost impossible to seperate them without tearing the remaining insulation loose.

I figure if I separate them like in this guide

http://www.thirdgen.org/techboard/lt...rt-finish.html

and lay them out on the engine I can put in new wires to the correct length...

I am not to sure where the grounds fall into this. From looking at the schematics I don't see how they hook up...

#6

TECH Addict

iTrader: (22)

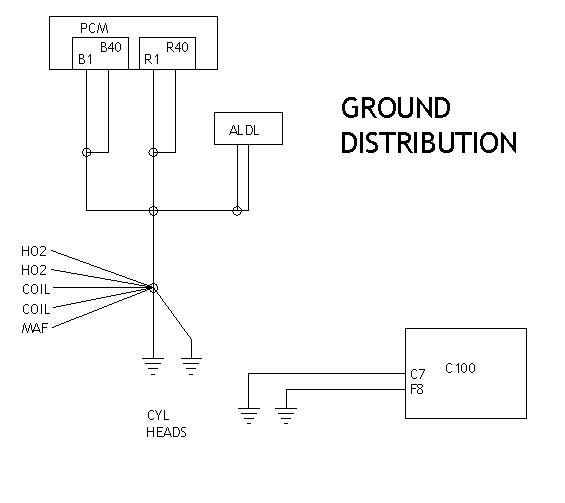

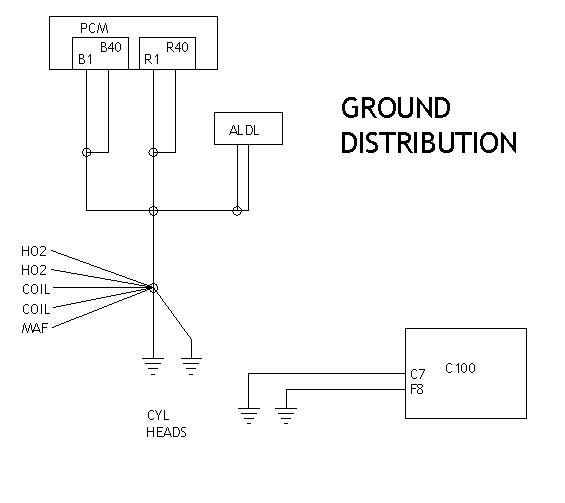

Grounds are connected last, atleast for me. Pull them out of the bundles and splice them into large commons for 2-3 heavy gauge ring terminals. I like to hide the ground points behind the cyl heads. Most companies seem to prefer to place them on the front/side of the cyl heads instead. Where they go is irrelevant, just be sure its a good clean spot

Grounds should be:

Coils x2

HO2s x2

PCM x4

MAF x1

ALDL x2

Fuel relay x1

AC x1

+ non-LSx electronics

Basic schematic

Grounds should be:

Coils x2

HO2s x2

PCM x4

MAF x1

ALDL x2

Fuel relay x1

AC x1

+ non-LSx electronics

Basic schematic