32 Ford Truck Build 5.3 H/C 4L60E

#21

TECH Enthusiast

Thread Starter

iTrader: (15)

Join Date: Aug 2006

Location: DFW....TX

Posts: 624

Likes: 0

Received 0 Likes

on

0 Posts

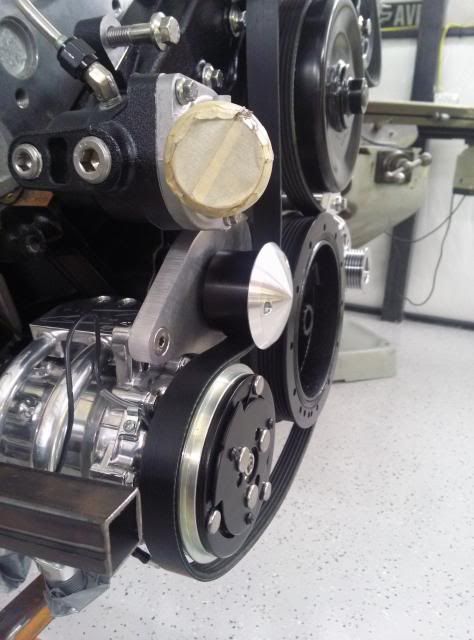

Got the engine out to the shop to work on the AC compressor bracket after hours. I dont have it finished yet as Im waiting for a specific shoulder bolt from billet specialties to finish the rear bracket. I also had to order more ARP fasteners from totally stainless.

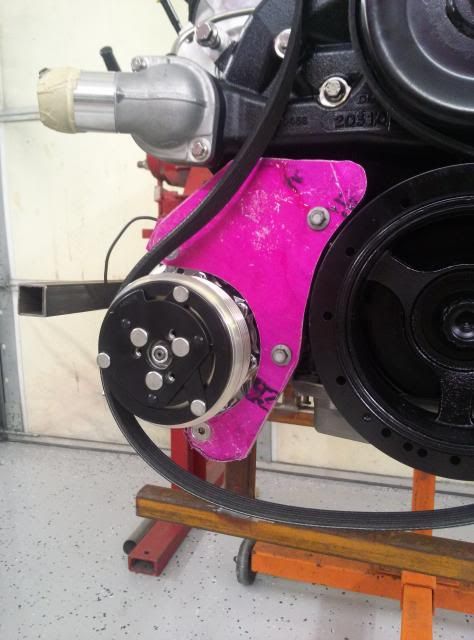

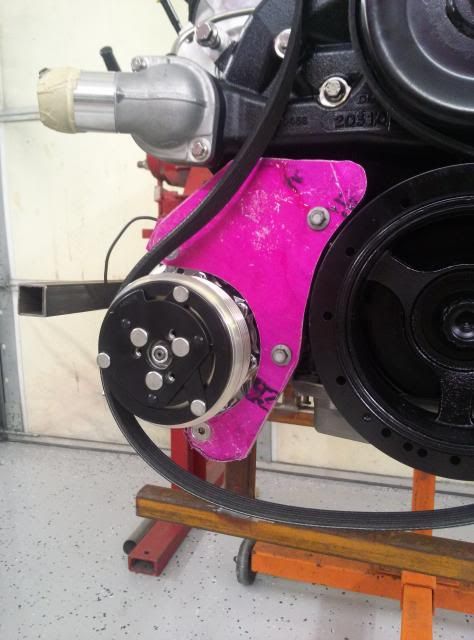

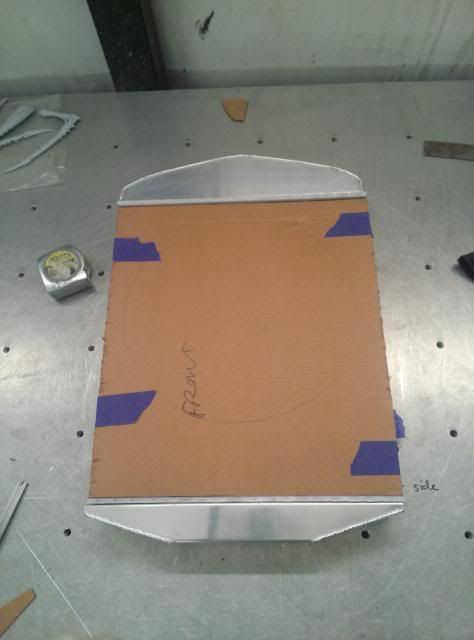

Bracket in the rough. Dont mind the random 1" square tube. It is the reference point of where the frame is when the engine is in the truck.

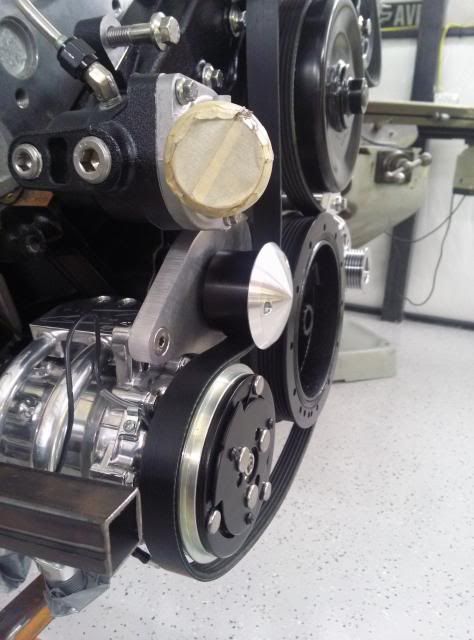

Bracket in its final shape with a 2.25" March idler pulley.

A bit of elbow grease

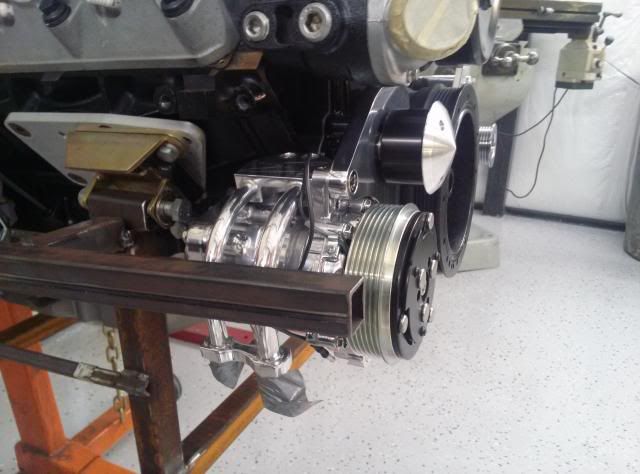

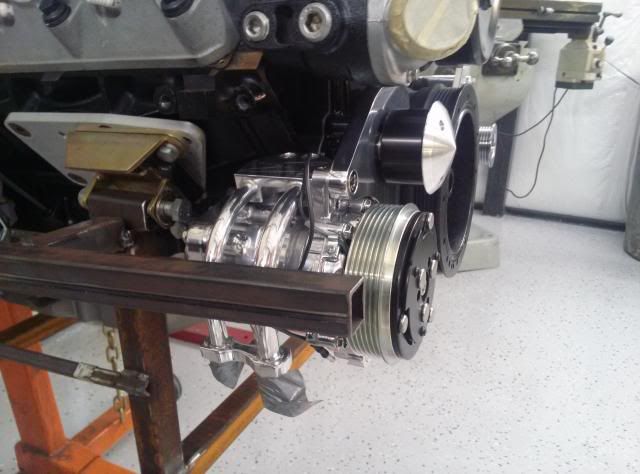

Mounted back on the engine (the valve covers are boxed up and the intake is being polished)

Bracket in the rough. Dont mind the random 1" square tube. It is the reference point of where the frame is when the engine is in the truck.

Bracket in its final shape with a 2.25" March idler pulley.

A bit of elbow grease

Mounted back on the engine (the valve covers are boxed up and the intake is being polished)

#22

TECH Enthusiast

Thread Starter

iTrader: (15)

Join Date: Aug 2006

Location: DFW....TX

Posts: 624

Likes: 0

Received 0 Likes

on

0 Posts

Rear bracket from start to finish

Got the Dash, front panhard bar, and drag link sealed, primed, and painted

Engine back in the Chassis

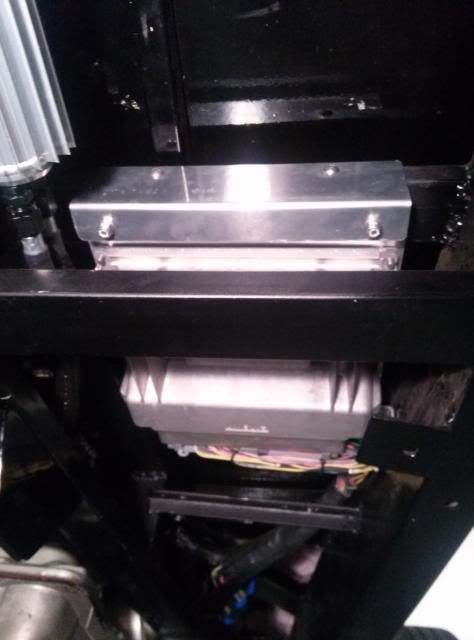

Also got the harness and pigtails back from BP-Automotive. He installed the PCM Pins and pinned the PCM connectors for me.

Got the Dash, front panhard bar, and drag link sealed, primed, and painted

Engine back in the Chassis

Also got the harness and pigtails back from BP-Automotive. He installed the PCM Pins and pinned the PCM connectors for me.

#23

TECH Enthusiast

Thread Starter

iTrader: (15)

Join Date: Aug 2006

Location: DFW....TX

Posts: 624

Likes: 0

Received 0 Likes

on

0 Posts

Tiny update:

I got ahold of one of the billet specialties compressor covers that only comes in their tru trac kits

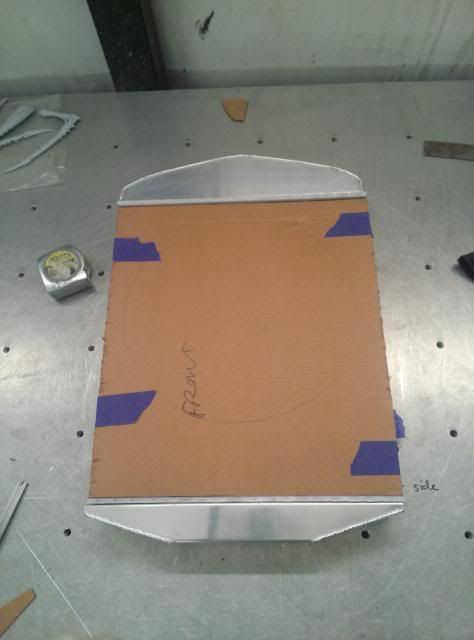

Got the Battery Tray Finished and painted

Fitting the Dash to get the idea... I still think I may take the column an Dash and shoot them a Satin Dark Charcole or Dove Gray color to better fit the interior

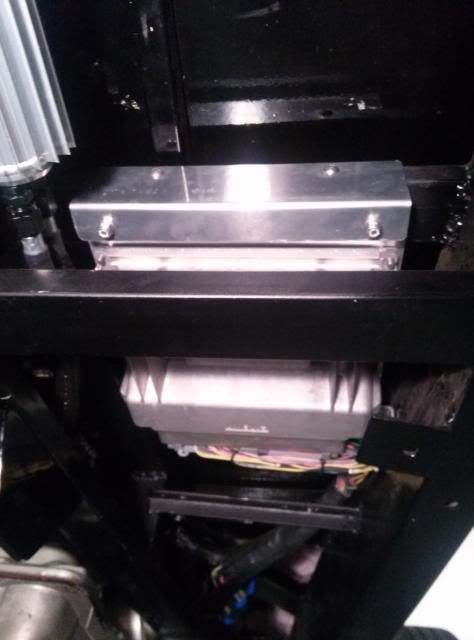

Transmission crossmember painted and cooler lines run (sorry for the dark pics)

Under dash switch panel

Got the bed off the truck to cut out the old battery tray and inspect it and the rear frame. I have attached a picture of the two things that has to be removed and changed. The circled area is a bracket that held the spreader bar. This was cut off and I will not be running the rear spreader bar as it serves no purpose. The arrow is a 1x2 that was welded in with the 2in width sideways and took up valuable space for the new fuel tank. This was changed to a 1x3.

Fixed

I also found that the front crossbar that is also the front mounts for the bed, was the original 80 year old metal cross bar that was cut up about 6 different times. So I cut it all out and remade the cross bar and tied it into the rest of the bed frame.

You can see the old cross bar on the bed in this picture... see all the holes.... yeah thats years of drilling holes for god knows what.

Fixed

Also got some parts **** from the guy that polished the Vic Jr. It should be back next week sometime.

I got ahold of one of the billet specialties compressor covers that only comes in their tru trac kits

Got the Battery Tray Finished and painted

Fitting the Dash to get the idea... I still think I may take the column an Dash and shoot them a Satin Dark Charcole or Dove Gray color to better fit the interior

Transmission crossmember painted and cooler lines run (sorry for the dark pics)

Under dash switch panel

Got the bed off the truck to cut out the old battery tray and inspect it and the rear frame. I have attached a picture of the two things that has to be removed and changed. The circled area is a bracket that held the spreader bar. This was cut off and I will not be running the rear spreader bar as it serves no purpose. The arrow is a 1x2 that was welded in with the 2in width sideways and took up valuable space for the new fuel tank. This was changed to a 1x3.

Fixed

I also found that the front crossbar that is also the front mounts for the bed, was the original 80 year old metal cross bar that was cut up about 6 different times. So I cut it all out and remade the cross bar and tied it into the rest of the bed frame.

You can see the old cross bar on the bed in this picture... see all the holes.... yeah thats years of drilling holes for god knows what.

Fixed

Also got some parts **** from the guy that polished the Vic Jr. It should be back next week sometime.

#28

TECH Enthusiast

Thread Starter

iTrader: (15)

Join Date: Aug 2006

Location: DFW....TX

Posts: 624

Likes: 0

Received 0 Likes

on

0 Posts

Well Finally got the PCM mounted. I used MSD isolators to avoid any possibility of shorting it out.

Shortly after cleaning the garage up I got a call from the boss and he let me know my "spot" in the shop had opened up...

So I immediately loaded it up and had it at the shop at 8am the next morning.

In it's spot

Started on the radiator first... FML

Next I pulled out the outlet from the waterpump and welded up a 90 to kick it straight up to the inlet of the radiator.

After much thought I cut up the thermostat housing and made some parts on the lathe to make my own housing. This will be a huge help in getting the outlet of the radiator hooked up.

My rod-ends made it and screwed them on to give you the idea of how we are using the radiator support bars. Beats the hell out of using nuts to pinch a bracket on top of the radiator. The rod ends in the first pic are aluminum. The lower pic is stainless. I think I'm going to run the stainless ones after a bit of work on the buffing wheel.

Also got my big nasty Spal 2082 Fan... 16" Paddle blade is wicked and should pull the truck along with the CFM it pulls... HYBRID? LMAO

Shortly after cleaning the garage up I got a call from the boss and he let me know my "spot" in the shop had opened up...

So I immediately loaded it up and had it at the shop at 8am the next morning.

In it's spot

Started on the radiator first... FML

Next I pulled out the outlet from the waterpump and welded up a 90 to kick it straight up to the inlet of the radiator.

After much thought I cut up the thermostat housing and made some parts on the lathe to make my own housing. This will be a huge help in getting the outlet of the radiator hooked up.

My rod-ends made it and screwed them on to give you the idea of how we are using the radiator support bars. Beats the hell out of using nuts to pinch a bracket on top of the radiator. The rod ends in the first pic are aluminum. The lower pic is stainless. I think I'm going to run the stainless ones after a bit of work on the buffing wheel.

Also got my big nasty Spal 2082 Fan... 16" Paddle blade is wicked and should pull the truck along with the CFM it pulls... HYBRID? LMAO

#29

TECH Enthusiast

Thread Starter

iTrader: (15)

Join Date: Aug 2006

Location: DFW....TX

Posts: 624

Likes: 0

Received 0 Likes

on

0 Posts

About got the radiator finished. Just need to make the lower frame tabs and the grille mounts.

http://i93.photobucket.com/albums/l59/sprayed99/CAM01009_zps94f26f39.jpg

http://i93.photobucket.com/albums/l59/sprayed99/CAM01009_zps94f26f39.jpg

Everything fits good so we proceeded

Drying off after being tested in the tank

Condensor tabs made and them welded to the radiator

Boss man welding on the radiator

Also managed to get the fan stuff done before shutting it down for the night. More to come.

http://i93.photobucket.com/albums/l59/sprayed99/CAM01009_zps94f26f39.jpg

http://i93.photobucket.com/albums/l59/sprayed99/CAM01009_zps94f26f39.jpgEverything fits good so we proceeded

Drying off after being tested in the tank

Condensor tabs made and them welded to the radiator

Boss man welding on the radiator

Also managed to get the fan stuff done before shutting it down for the night. More to come.

#31

TECH Enthusiast

Thread Starter

iTrader: (15)

Join Date: Aug 2006

Location: DFW....TX

Posts: 624

Likes: 0

Received 0 Likes

on

0 Posts

0411 PCM out of a 2001 tahoe. Modified harness from the same tahoe. Edelbrock Vic Jr EFI intake and a Accufab 4150 throttle body. The injectors are bosch red tops. This does not use a MAF.

#32

LS1Tech Sponsor

iTrader: (3)

Wow. Just wow.

absolutely freaking awesome. period.

absolutely freaking awesome. period.

__________________

Standalone LS Swap Harnesses IN STOCK!

LSX, LTX Stand alone swap harnesses. S10 LSX conversion PLUG AND PLAY harnesses, 24x conversion PLUG AND PLAY harnesses. LT1 to LSX PLUG AND PLAY Harnesses.

sales@bp-automotive.com

www.bp-automotive.com

1-888-467-4491

Standalone LS Swap Harnesses IN STOCK!

LSX, LTX Stand alone swap harnesses. S10 LSX conversion PLUG AND PLAY harnesses, 24x conversion PLUG AND PLAY harnesses. LT1 to LSX PLUG AND PLAY Harnesses.

sales@bp-automotive.com

www.bp-automotive.com

1-888-467-4491

#35

TECH Enthusiast

Thread Starter

iTrader: (15)

Join Date: Aug 2006

Location: DFW....TX

Posts: 624

Likes: 0

Received 0 Likes

on

0 Posts

got the frame mounts done and the thermostat welded up. The upper and lower hoses are fitted. Next will be mounting the grille and making an overflow tank then the cooling system will be done.

#36

TECH Enthusiast

Thread Starter

iTrader: (15)

Join Date: Aug 2006

Location: DFW....TX

Posts: 624

Likes: 0

Received 0 Likes

on

0 Posts

A few polished items and the master cylinder cap we made to match the air cleaner top.

Radiator is finished along with the overflow tube and the grille mounting.

Also this bad boy arrived.

Also started on the headers. The start of the primaries are 1.750" on the shortest run it is 8.75" and the longest it is 9.125" then they step to a 1.875" then go into the collector. All the steps are hidden by the frame rail to try to keep the number of visible welds down. I have about a 12% length difference from the longest to the shortest primary. I wanted it closer to 10% but the space I have dictates where the tubes can go.

PICS

Radiator is finished along with the overflow tube and the grille mounting.

Also this bad boy arrived.

Also started on the headers. The start of the primaries are 1.750" on the shortest run it is 8.75" and the longest it is 9.125" then they step to a 1.875" then go into the collector. All the steps are hidden by the frame rail to try to keep the number of visible welds down. I have about a 12% length difference from the longest to the shortest primary. I wanted it closer to 10% but the space I have dictates where the tubes can go.

PICS

#37

TECH Enthusiast

Thread Starter

iTrader: (15)

Join Date: Aug 2006

Location: DFW....TX

Posts: 624

Likes: 0

Received 0 Likes

on

0 Posts

In your case you have a hood and probably an area where you can run a carb hat or an elbow and utilize an intake tube. I would build the intake tubing out of aluminum and use the LS3/LS7 card style MAF and weld the bung into the intake tube.

#40

TECH Enthusiast

Thread Starter

iTrader: (15)

Join Date: Aug 2006

Location: DFW....TX

Posts: 624

Likes: 0

Received 0 Likes

on

0 Posts

You have the best of both worlds from both tubing sizes. Do some research on step headers and you will get the idea. It also helps having the ability to slide the 1.75 into the 1.875 tube for ease of building them.