32 Ford Truck Build 5.3 H/C 4L60E

#41

TECH Enthusiast

Thread Starter

iTrader: (15)

Join Date: Aug 2006

Location: DFW....TX

Posts: 624

Likes: 0

Received 0 Likes

on

0 Posts

Passenger Header ready to be welded at the flange and collector. Starter fought me for space!

Called the guys at ridetech and they hooked me up with a custom built shock with the correct valving for the straight axle.

Got time to drill the holes for the Climate control bulkhead

Started on A/C lines also... This is going to be interesting.

Called the guys at ridetech and they hooked me up with a custom built shock with the correct valving for the straight axle.

Got time to drill the holes for the Climate control bulkhead

Started on A/C lines also... This is going to be interesting.

#42

TECH Enthusiast

Thread Starter

iTrader: (15)

Join Date: Aug 2006

Location: DFW....TX

Posts: 624

Likes: 0

Received 0 Likes

on

0 Posts

Some progress has finally been made. I hauled my Tig from home out to the shop so I could have a machine dedicated to my build to knock out the few things I needed to get done.

Exterior A/C SS hardlines and rubber are 100% complete. The SS Hardlines for the heater hoses are also complete.

Gates Powergrip SB Clamps are awesome BTW

Headers are 100% done and will be dropped off for coating on Friday.

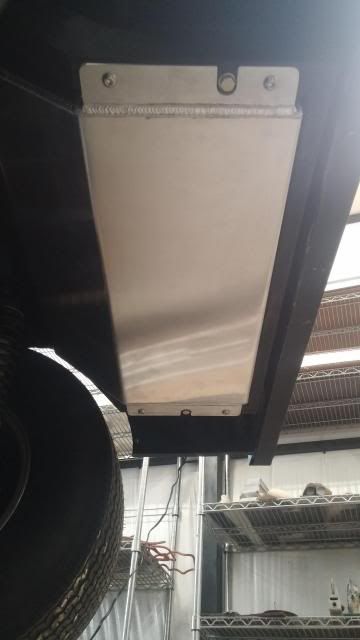

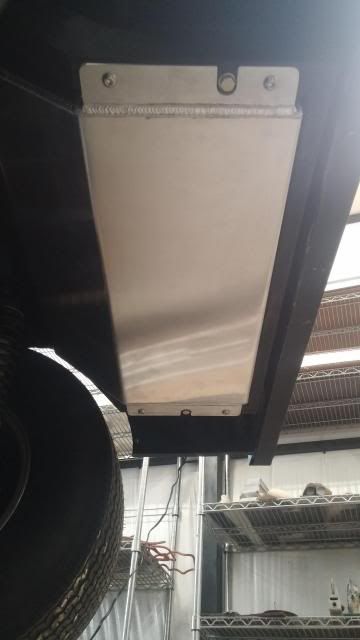

Exhaust is about 95% complete as of the end of today. I have to turn a spud on the lathe in the morning to recess weld into the frame so the hanger is bolted in with a single 3/8th bolt. FYI it does tuck up further than the pictures depict. I did not have the hangers set in the pictures.

.125" Stainless sheet worked well for my hanger.

And the big brown truck dropped this off today.... VHX 32 Ford gauge kit!!!!

Exterior A/C SS hardlines and rubber are 100% complete. The SS Hardlines for the heater hoses are also complete.

Gates Powergrip SB Clamps are awesome BTW

Headers are 100% done and will be dropped off for coating on Friday.

Exhaust is about 95% complete as of the end of today. I have to turn a spud on the lathe in the morning to recess weld into the frame so the hanger is bolted in with a single 3/8th bolt. FYI it does tuck up further than the pictures depict. I did not have the hangers set in the pictures.

.125" Stainless sheet worked well for my hanger.

And the big brown truck dropped this off today.... VHX 32 Ford gauge kit!!!!

#43

TECH Enthusiast

Thread Starter

iTrader: (15)

Join Date: Aug 2006

Location: DFW....TX

Posts: 624

Likes: 0

Received 0 Likes

on

0 Posts

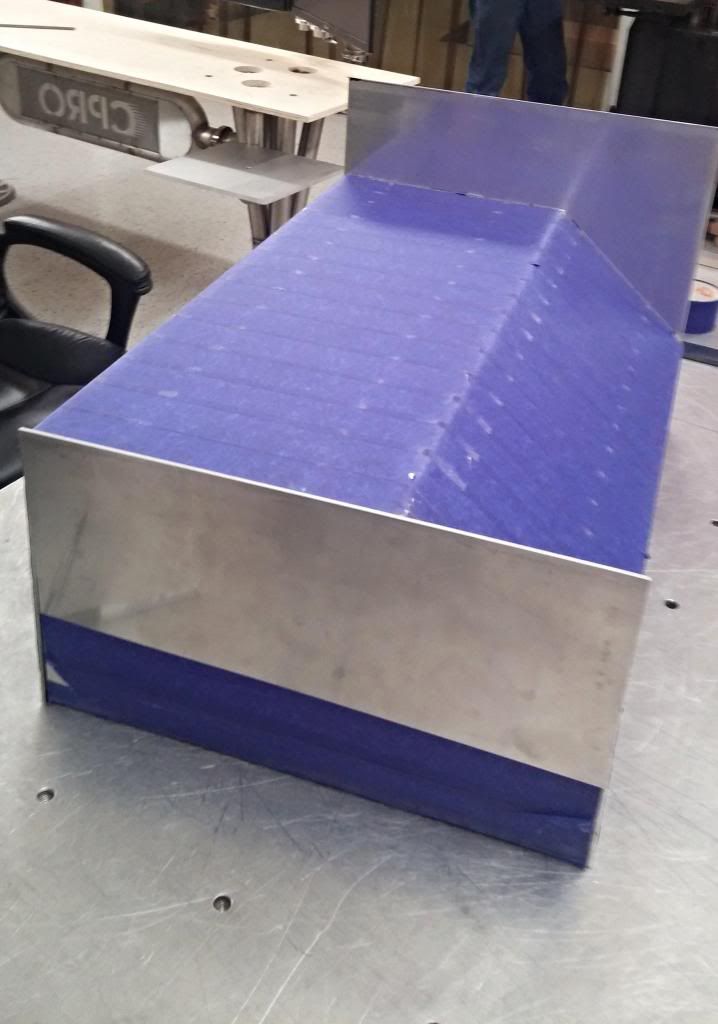

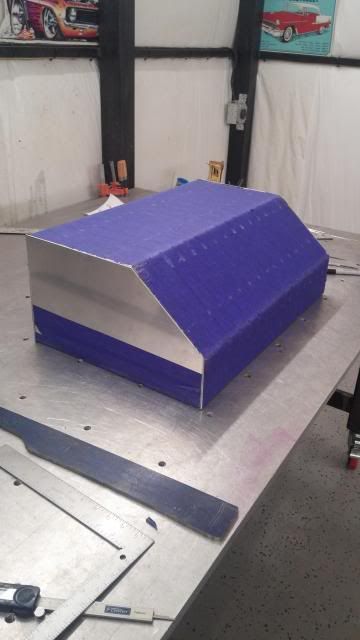

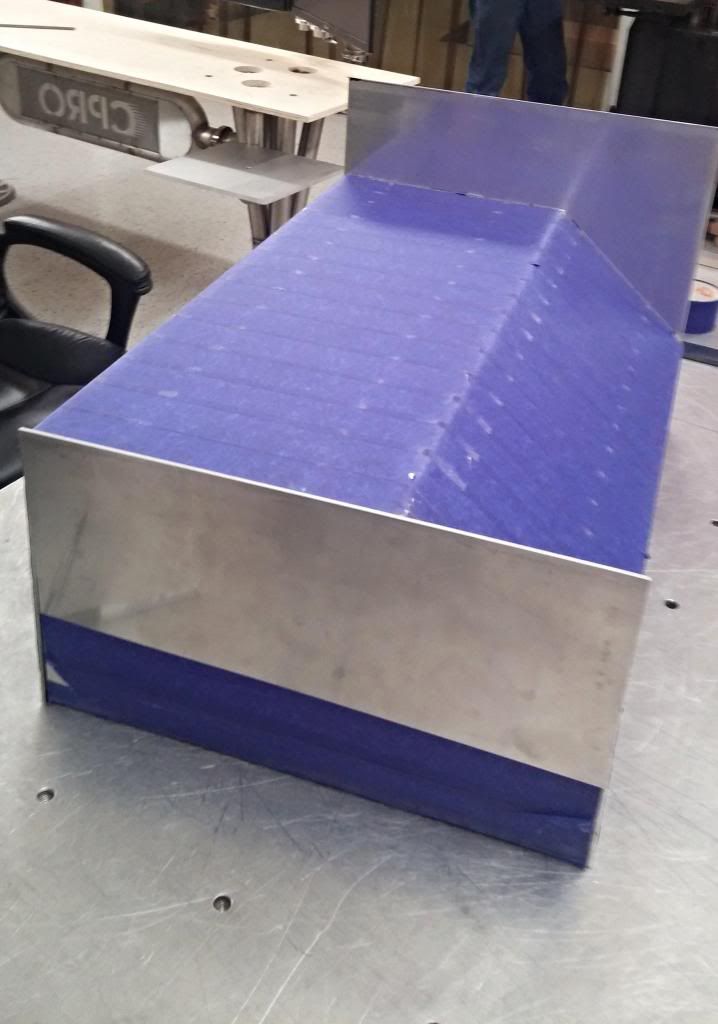

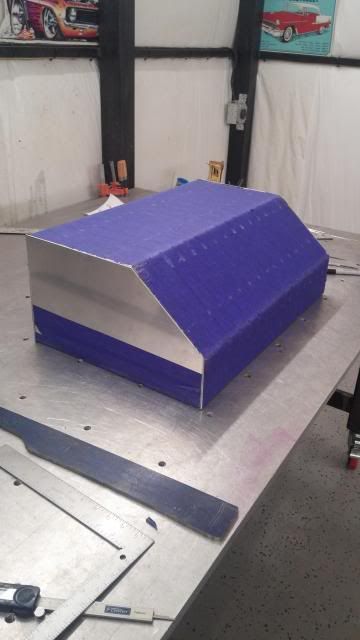

While waiting on the coaters I decided to tackle the fuel tank.

Started late Tuesday and finished this morning. I still have to weld in the filler and do you crafty work on the bed floor to tie it all together.

Roughing it in just using the brake and stomp sheer

Setting the Aeromotive fuel pump assembly and the sending unit

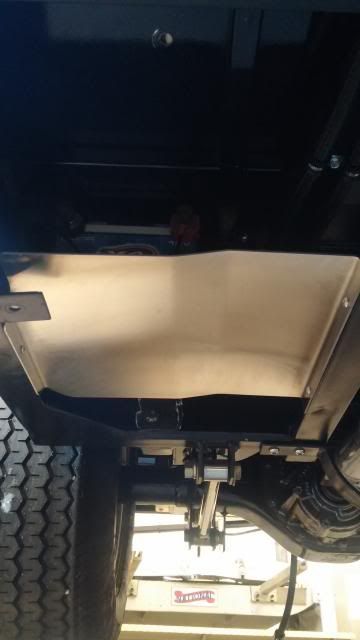

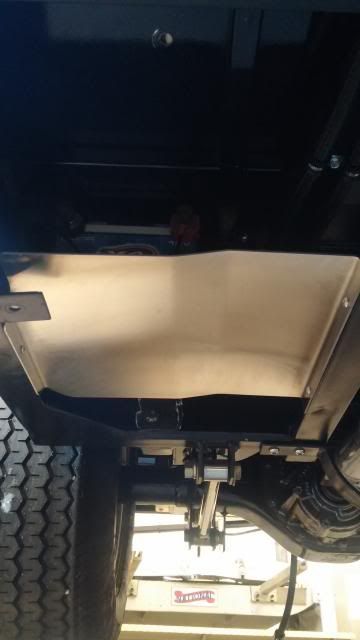

Final fit check

Welded it up

Bolted up!

Fill cap sits about .100" below the floor

Started late Tuesday and finished this morning. I still have to weld in the filler and do you crafty work on the bed floor to tie it all together.

Roughing it in just using the brake and stomp sheer

Setting the Aeromotive fuel pump assembly and the sending unit

Final fit check

Welded it up

Bolted up!

Fill cap sits about .100" below the floor

#44

On The Tree

Join Date: Nov 2008

Location: Evansville, IN

Posts: 149

Likes: 0

Received 0 Likes

on

0 Posts

Your work is awesome! This thread is what made me want to swap a 5.3 in my 29 ford sedan. Haven't started yet but every time i see this thread it makes me want to get started.

#45

TECH Enthusiast

Thread Starter

iTrader: (15)

Join Date: Aug 2006

Location: DFW....TX

Posts: 624

Likes: 0

Received 0 Likes

on

0 Posts

Headers are back from the coater.

Thought I would also show the merge spikes. The polishing substrate has since been removed from the tubing joint.

Here are a few pictures of them on the truck and the master cylinder mounted.

Next are few pictures of the finished fuel lines. The lines from the tank to the bulkheads and from the front bulkheads to the engine are 6 AN PTFE lined hoses made for me by Nitrous Outlet. The hardlines are stainless.

The list to get this thing ready to be torn apart for paint is shrinking fast.

I have to do the following before the tear down

1.Fabricate under dash brake pedal assembly

2.Mount front brake line bulkhead tabs

3.Make front brake lines

4.Finish inside A/C and Heater lines

5.Mount Throttle Pedal assembly and drill a hole in the firewall

6.Make throttle cable

7.Make evap unit drain line

8.Relocate power window and headlight switches

Doesn't look like much, but the brake pedal assembly is going to be a fight.

Thought I would also show the merge spikes. The polishing substrate has since been removed from the tubing joint.

Here are a few pictures of them on the truck and the master cylinder mounted.

Next are few pictures of the finished fuel lines. The lines from the tank to the bulkheads and from the front bulkheads to the engine are 6 AN PTFE lined hoses made for me by Nitrous Outlet. The hardlines are stainless.

The list to get this thing ready to be torn apart for paint is shrinking fast.

I have to do the following before the tear down

1.Fabricate under dash brake pedal assembly

2.Mount front brake line bulkhead tabs

3.Make front brake lines

4.Finish inside A/C and Heater lines

5.Mount Throttle Pedal assembly and drill a hole in the firewall

6.Make throttle cable

7.Make evap unit drain line

8.Relocate power window and headlight switches

Doesn't look like much, but the brake pedal assembly is going to be a fight.

#46

TECH Enthusiast

Thread Starter

iTrader: (15)

Join Date: Aug 2006

Location: DFW....TX

Posts: 624

Likes: 0

Received 0 Likes

on

0 Posts

Ok guys looks like I'm going to stick with 15's. That being said. Which wheel do you prefer? Also be aware that the wheels pictured have a smooth lip. My wheels will have a step lip similar to what an American Racing TT II has.

Fronts will be 15x6 rear 15x12

Rear tires will be Hoosier Pro street 31/16.5-15

Fronts Yokohama AVID ENvigor 175/65-15

Foose four 42

US Mags Bonneville

US Mags Spade

Fronts will be 15x6 rear 15x12

Rear tires will be Hoosier Pro street 31/16.5-15

Fronts Yokohama AVID ENvigor 175/65-15

Foose four 42

US Mags Bonneville

US Mags Spade

#51

TECH Enthusiast

Thread Starter

iTrader: (15)

Join Date: Aug 2006

Location: DFW....TX

Posts: 624

Likes: 0

Received 0 Likes

on

0 Posts

Update*

Truck will be hauled back to my home garage on Sunday. The list above and then some has been knocked out. Now it is time to finish about 4-5 hours of small crap and then pulled apart to start on the paint process.

I see a few sharpie markers and a case of zip-lock bags in my future

Now for those that were interested in the process of the under dash brake pedal assembly. Below are a few pictures. Yes, it is way over built but we are dealing with one of the most important parts of the truck...Brakes.

It all started with paper and a pen. It saved me a good bit of material in the end.

Next I cut the base plate and side plates out of .250 plate and the pivot bolt is .625"

Test Fit

Pivot tube is 1" OD chromoly that is bored .750" for the .625" bronze bushings. I cut the master arm and pedal attachment out of .375". All welded up!

Final test fit. I'm waiting on my water jet guy to cut out the pedal arm that I drew in CAD earlier today.

The suggested pedal ratio from Wilwood was 5.5:1 for their 7/8" bore tandem master and their disc brakes. Final finished pedal ratio is 5.48:1 so I think I did ok. I also managed to keep the pedal at a decent resting height from the floor and the pedal does completely compress the master without contacting the floor. I have about .300" to accommodate for sound deadening and carpet.

DXF. File of the pedal

I also managed to get the brake lines made and the braided line tabs welded on the frame.

Stainless heat shields made and installed.

Throttle cable and pedal done (Pedal will be changing to a black version)

Inside A/C Lines and heater hoses are also done.

Bed to filler neck tube was also welded in. This will be ground down and welded several time to create a nice rounded edge. ( Dont mind the arch on the cap some idiot hit the pedal while the torch was laying in the bed... Yeah that would be me )

)

Truck will be hauled back to my home garage on Sunday. The list above and then some has been knocked out. Now it is time to finish about 4-5 hours of small crap and then pulled apart to start on the paint process.

I see a few sharpie markers and a case of zip-lock bags in my future

Now for those that were interested in the process of the under dash brake pedal assembly. Below are a few pictures. Yes, it is way over built but we are dealing with one of the most important parts of the truck...Brakes.

It all started with paper and a pen. It saved me a good bit of material in the end.

Next I cut the base plate and side plates out of .250 plate and the pivot bolt is .625"

Test Fit

Pivot tube is 1" OD chromoly that is bored .750" for the .625" bronze bushings. I cut the master arm and pedal attachment out of .375". All welded up!

Final test fit. I'm waiting on my water jet guy to cut out the pedal arm that I drew in CAD earlier today.

The suggested pedal ratio from Wilwood was 5.5:1 for their 7/8" bore tandem master and their disc brakes. Final finished pedal ratio is 5.48:1 so I think I did ok. I also managed to keep the pedal at a decent resting height from the floor and the pedal does completely compress the master without contacting the floor. I have about .300" to accommodate for sound deadening and carpet.

DXF. File of the pedal

I also managed to get the brake lines made and the braided line tabs welded on the frame.

Stainless heat shields made and installed.

Throttle cable and pedal done (Pedal will be changing to a black version)

Inside A/C Lines and heater hoses are also done.

Bed to filler neck tube was also welded in. This will be ground down and welded several time to create a nice rounded edge. ( Dont mind the arch on the cap some idiot hit the pedal while the torch was laying in the bed... Yeah that would be me

)

)

#52

TECH Enthusiast

Thread Starter

iTrader: (15)

Join Date: Aug 2006

Location: DFW....TX

Posts: 624

Likes: 0

Received 0 Likes

on

0 Posts

#54

TECH Enthusiast

Thread Starter

iTrader: (15)

Join Date: Aug 2006

Location: DFW....TX

Posts: 624

Likes: 0

Received 0 Likes

on

0 Posts

Read this...Third paragraph down

http://aeromotiveinc.com/products-pa...h-fuel-system/

#55

TECH Enthusiast

Thread Starter

iTrader: (15)

Join Date: Aug 2006

Location: DFW....TX

Posts: 624

Likes: 0

Received 0 Likes

on

0 Posts

It has been a little bit since my last update. I got the truck home and about 4 hours after I unloaded it off the trailer it was completely torn down. I will have the frame back home in about 16 hours. I will cut and buff it at the end of the weekend and start final assembly of the suspension and other components.

Tear down picture

Here it is after I made a quick frame roller. I had to do some final welding and off to a friends shop the frame and I went.

After hitting it with 80 on a DA and making damn sure any and all rust has been removed.

Then I applied 2 coats of SPI Black Epoxy... Let me tell you SPI has my business from here on out. Fantastic products and prices! Here is a picture after the filler work over the epoxy. Oh, the Wife-to-be says "HI"

After filler work was complete it went back into the booth for some slick sand. Here she is all blocked out and ready to for another 2 coats of epoxy to seal it back up.

Sealed up!

Over 24 hours later we wet sanded it and I applied 3 coats of Spies Hecker FP 2002 Blue/Black!

After I let the base sit 16 hours I cleared it this morning. 3 coats of SPI Universal Clear. This alone took over 4 hours with 30 minute flash times. I really like this clear. I have been a PPG DCU2002 Guy for years. I'm done paying for PPG's stuff!

Let me tell you this is by far the most difficult object I have ever had to paint. What a nightmare to get to every surface. Lucky me not a single area of dry spray and not a single run!

Tear down picture

Here it is after I made a quick frame roller. I had to do some final welding and off to a friends shop the frame and I went.

After hitting it with 80 on a DA and making damn sure any and all rust has been removed.

Then I applied 2 coats of SPI Black Epoxy... Let me tell you SPI has my business from here on out. Fantastic products and prices! Here is a picture after the filler work over the epoxy. Oh, the Wife-to-be says "HI"

After filler work was complete it went back into the booth for some slick sand. Here she is all blocked out and ready to for another 2 coats of epoxy to seal it back up.

Sealed up!

Over 24 hours later we wet sanded it and I applied 3 coats of Spies Hecker FP 2002 Blue/Black!

After I let the base sit 16 hours I cleared it this morning. 3 coats of SPI Universal Clear. This alone took over 4 hours with 30 minute flash times. I really like this clear. I have been a PPG DCU2002 Guy for years. I'm done paying for PPG's stuff!

Let me tell you this is by far the most difficult object I have ever had to paint. What a nightmare to get to every surface. Lucky me not a single area of dry spray and not a single run!

#60

Launching!

iTrader: (1)

Well this is the first time I've opened this thread and I don't quite know what to say,,,,just give me a minute.

You can actually make a Radiator? wow I thought it to be magic!

Anyway can you tell us more about your Hardlines Fuel, Steam and the like. What type of tubing do you use and more importantly what 37* Flaring Tool do you recommend . I have a 3/8 SS fuel line I would like to flare and now I can see a few more applications to use one.

A polished Manifold how am I ever going to get my car finished now!

Really nice job you are doing there.

Thanks, Tony

You can actually make a Radiator? wow I thought it to be magic!

Anyway can you tell us more about your Hardlines Fuel, Steam and the like. What type of tubing do you use and more importantly what 37* Flaring Tool do you recommend . I have a 3/8 SS fuel line I would like to flare and now I can see a few more applications to use one.

A polished Manifold how am I ever going to get my car finished now!

Really nice job you are doing there.

Thanks, Tony