Exhaust drone with engine swaps - solved

#41

Smithy, Good point, 16 pages of some substance and hypothesizing. I found the same thing with the mopar guys.

Most corral people have not scientifically analyzed it mathematically using sound physics calculations, only physical experimentation with much discussion and debate. Accept the fact that physics properties and their calculation all never change, only the variables change.

My original intent was and is to educate folks so they don't waste time guessing. I never guess, or wonder. I measure, analyze and calculate to come to real world conclusions

Most corral people have not scientifically analyzed it mathematically using sound physics calculations, only physical experimentation with much discussion and debate. Accept the fact that physics properties and their calculation all never change, only the variables change.

My original intent was and is to educate folks so they don't waste time guessing. I never guess, or wonder. I measure, analyze and calculate to come to real world conclusions

After more thinking i think the only way to get it right on would be to have a slip fit pipe over the exhaust outlet at back bumper(turbo car with one exit for all 8 cylinders, idk if itd work on dual pipes) then get it to the drone rpm (i dont remember if mine would drone without load on engine, if it needed a load you would have to do this on a chassis dyno) then slowly extend the pipe out and once it drones again that length you extended it would be the length of 1 pulse. (like dude does in last vid on the 1st page) but im pretty sure you would make the length of resonator 3/4s (or maybe 1/2, idk) the length you figured each pulse to be. due to jpipe changing it from open pipe to a closed pipe, Idk have to check the info again.

Also like i said right off, this is how I comprehend this, but i might not be understanding it at all.

#42

The only real variable that should change in the calculation from setup to setup is the drone RPM.

Mustangs typically have a 2000RPM drone given their engine/muffler location/exhaust routing.

All you need to do is drive your car, determine where you want to kill some interior resonance, then use that RPM value in the calculation.

You COULD do a trombone sliding feature to "dial in" the length. But after you find it, you won't need adjustability anymore. UNLESS you swap mufflers or change your exhaust from single to duals etc.

And yes you need to drive the car to do this with load on the engine.

Again, if you are off in length by 1/4" or so it won't matter. BUT given a 4" cutoff wheel, flux core welder and a string (to measure the centerline of the pipe to get the length right) I go damn close to my required 29" got my old GTO.

Mustangs typically have a 2000RPM drone given their engine/muffler location/exhaust routing.

All you need to do is drive your car, determine where you want to kill some interior resonance, then use that RPM value in the calculation.

You COULD do a trombone sliding feature to "dial in" the length. But after you find it, you won't need adjustability anymore. UNLESS you swap mufflers or change your exhaust from single to duals etc.

And yes you need to drive the car to do this with load on the engine.

Again, if you are off in length by 1/4" or so it won't matter. BUT given a 4" cutoff wheel, flux core welder and a string (to measure the centerline of the pipe to get the length right) I go damn close to my required 29" got my old GTO.

#44

Some will say "just pick the right muffler....my Borla Pro XS mufflers don't drone". (Just picked a muffler I keep reading doesn't drone). My LT's/catless/Borla adjustable CB with passenger tip capped off (everything flowing through muffler) did not drone.

Yes well, if you run a duals system then that's 2 mufflers you need to buy. You can kill drone A LOT cheaper than going through different mufflers to see what one reduces drone.

Yes well, if you run a duals system then that's 2 mufflers you need to buy. You can kill drone A LOT cheaper than going through different mufflers to see what one reduces drone.

#45

you cant calculate x+x=x, without 2 of the x's. You guys are doing x+x(plus or minus y) = your length. and ignoring that your answer is actually " (length) +/-y". So your in the ballpark, which is good enough for me, but claiming a homerun would be BS.

this seems, logically speaking = or > than your solution to problem

#46

For a basic street car and using this generic calculation to get you in the "ballpark" of of the right length...yes the EGT's are the same.

If you have a crazy setup with higher EGT's then measure the temp and plop it in...simple.

If you keep looking for loopholes in this then you will never get anywhere. Why haven't you complained about the fact that the SOS is not accurate because we assume it's in air and not the ACTUAL exhaust gas composition???

Some people wayyyy over think this kind of stuff. Like any design/analysis there are known assumptions in anything to get the ball rolling... X+Y=Z Assume X, you know Y you can get Z. Make an assumption, generate theoretical values or answers and test your theory.

Hell error on the long side of the resonator pipe so you can cut some off and keep experimenting.

And what happens when you buy a Borla muffler at $100+ and it doesn't drone but you HATE the tone? Is the muffler selection option really the better solution? Since a lot of the time people will say "I like the sound I have but hate the drone". What makes selecting the right muffler the "better" solution?

If you have a crazy setup with higher EGT's then measure the temp and plop it in...simple.

If you keep looking for loopholes in this then you will never get anywhere. Why haven't you complained about the fact that the SOS is not accurate because we assume it's in air and not the ACTUAL exhaust gas composition???

Some people wayyyy over think this kind of stuff. Like any design/analysis there are known assumptions in anything to get the ball rolling... X+Y=Z Assume X, you know Y you can get Z. Make an assumption, generate theoretical values or answers and test your theory.

Hell error on the long side of the resonator pipe so you can cut some off and keep experimenting.

And what happens when you buy a Borla muffler at $100+ and it doesn't drone but you HATE the tone? Is the muffler selection option really the better solution? Since a lot of the time people will say "I like the sound I have but hate the drone". What makes selecting the right muffler the "better" solution?

#49

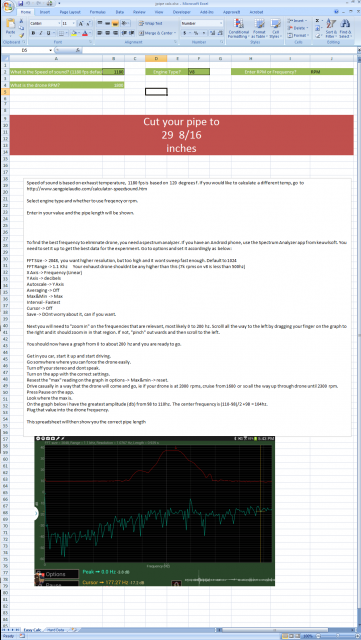

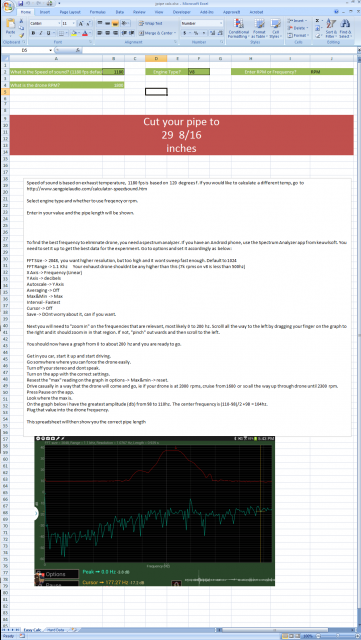

I posted up an excel that people can use to find the pipe length exactly. You can choose whether to enter in the frequency to eliminate directly (has a guide to find that frequency) or enter in the engine type and rpm to find it. You can also change the speed of sound based on the exhaust temperature.

the excel sheet is here

the excel sheet is here

#50

I posted up an excel that people can use to find the pipe length exactly. You can choose whether to enter in the frequency to eliminate directly (has a guide to find that frequency) or enter in the engine type and rpm to find it. You can also change the speed of sound based on the exhaust temperature.

the excel sheet is here

the excel sheet is here

so the speed of sound could be measured by pointing a surface temp laser at inner of exhaust pipe a few inches from the exit? cause that should be equal to the air temp if everything is warmed up. Or does the speed need to be known at the point which you mount the j pipe? cause i know speed increase's the farther up the pipe, so distance between each pulse is tighter youd need a smaller j? Or since were trying to cancel out the noise exiting, does only speed there matter?

smitty-when i do mine im just gonna try whatever fits really, but im not gonna make guesses then tell people i calculated that shitt dead on using e=mc(2). Im definitely not "that" guy.

#51

TECH Resident

iTrader: (2)

Join Date: Apr 2004

Location: The Back Door...

Posts: 796

Likes: 0

Received 0 Likes

on

0 Posts

Who said anything about exact? I'm guessing that by "dead on using e=mc(2)" you mean "e=mc^(2)"? At the risk of sounding like an ******* (I am, don't worry... I'll own it) I just did to you what you were doing to him. I don't recall anyone stating some 9th place past the decimal accuracy. Maybe it's just me but you come off condescending about accuracy and exactness yet you can't use basic punctuation to express your thoughts to someone else so they don't have to decrypt what the hell you're trying to say.

#52

10 Second Club

iTrader: (8)

It's a SWAG, buddy. Scientific Wild *** Guesses are done every-day to get engineers into the ballpark when experimenting to solve problems that are overly complicated or have too many variables. Some variables in every-day, really critical calculations are still only guesses, but they're close enough they work just fine. And **** doesn't fall apart, blow up or kill people. Mostly.

#53

TECH Enthusiast

iTrader: (25)

Join Date: Nov 2011

Location: Milwaukee, WI

Posts: 547

Likes: 0

Received 0 Likes

on

0 Posts

Someone mentioned using a cutout before and it made me think. Would it be possible, or work, to have one tuned length of pipe before the cutout, say for 2000RPM, then after the cutout an additional length of pipe to eliminate drone in another range? Then you could specify different frequencies and eliminate them with the flick of a switch when you are in that range.

#54

see that method seems very reasonable to me, I like equations that dont include "best guess" or "@"

so the speed of sound could be measured by pointing a surface temp laser at inner of exhaust pipe a few inches from the exit? cause that should be equal to the air temp if everything is warmed up. Or does the speed need to be known at the point which you mount the j pipe? cause i know speed increase's the farther up the pipe, so distance between each pulse is tighter youd need a smaller j? Or since were trying to cancel out the noise exiting, does only speed there matter?

smitty-when i do mine im just gonna try whatever fits really, but im not gonna make guesses then tell people i calculated that shitt dead on using e=mc(2). Im definitely not "that" guy.

so the speed of sound could be measured by pointing a surface temp laser at inner of exhaust pipe a few inches from the exit? cause that should be equal to the air temp if everything is warmed up. Or does the speed need to be known at the point which you mount the j pipe? cause i know speed increase's the farther up the pipe, so distance between each pulse is tighter youd need a smaller j? Or since were trying to cancel out the noise exiting, does only speed there matter?

smitty-when i do mine im just gonna try whatever fits really, but im not gonna make guesses then tell people i calculated that shitt dead on using e=mc(2). Im definitely not "that" guy.

Who said anything about exact? I'm guessing that by "dead on using e=mc(2)" you mean "e=mc^(2)"? At the risk of sounding like an ******* (I am, don't worry... I'll own it) I just did to you what you were doing to him. I don't recall anyone stating some 9th place past the decimal accuracy. Maybe it's just me but you come off condescending about accuracy and exactness yet you can't use basic punctuation to express your thoughts to someone else so they don't have to decrypt what the hell you're trying to say.

It's a SWAG, buddy. Scientific Wild *** Guesses are done every-day to get engineers into the ballpark when experimenting to solve problems that are overly complicated or have too many variables. Some variables in every-day, really critical calculations are still only guesses, but they're close enough they work just fine. And **** doesn't fall apart, blow up or kill people. Mostly.

Someone mentioned using a cutout before and it made me think. Would it be possible, or work, to have one tuned length of pipe before the cutout, say for 2000RPM, then after the cutout an additional length of pipe to eliminate drone in another range? Then you could specify different frequencies and eliminate them with the flick of a switch when you are in that range.

You can simply see that the lower RPM's need longer pipes since the frequency wave is longer. Higher rpm's require shorter pipes. The pic below was what I used for my GTO. I made the pipe 29" long to keep it simple and worked as planned. The cabin noise was like a flip of a switch when the rpms rose to 1750rpm...it would cut out then come back to normal noise. But would not drone. 1750 was where I would cruise at 70mph on the highway.

This is how my calculation broke down:

Last edited by smitty2919; 04-21-2014 at 11:13 AM.

#55

TECH Enthusiast

iTrader: (25)

Join Date: Nov 2011

Location: Milwaukee, WI

Posts: 547

Likes: 0

Received 0 Likes

on

0 Posts

Well, think about where you want to kill drone and why. Typically you hate "constant" drone in a common operating rpm range. Meaning anything sustained while cruising. If you have a 2000rpm drone then I would make a pipe based off of that rpm. Something to consider is that these pipes don't work in "multiples". You can't make a pipe made to a 4000rpm drone and also plan to kill 2000rpm drone. The other main issue will be available space.

#56

Smitty,

Are you using 1125 as the speed of sound. I reversed the math and came up with 75 degree F exhaust gas temps. I doubt any exhaust gassses are 75 degrees F. 120 is more realistic.

If so, this would change the length by 3 inches (longer) compared to my spreadsheet. Either that or are my calculations off, thus significantly changing the actual resonant freq and drone reduction.

Are you using 1125 as the speed of sound. I reversed the math and came up with 75 degree F exhaust gas temps. I doubt any exhaust gassses are 75 degrees F. 120 is more realistic.

If so, this would change the length by 3 inches (longer) compared to my spreadsheet. Either that or are my calculations off, thus significantly changing the actual resonant freq and drone reduction.

#57

I know you can't use one pipe to get both. Guess it didn't come across that way ha. What I meant was that you could use the two separate lengths to eliminate drone at two distinct RPM. So say you are city driving at 2000RPM you use the longer pipe by having the cutout open. Then you are on the highway and say your at 2800 or something and you close the cutout to eliminate the drone at that speed since the lower RPM drone is no longer there. Not specifically those RPM numbers but just trying to portray what is in my head

A way to do this is be chugging along at 30mph in say 4th gear (a gear that can handle low to higher mph) then gradually increase rpm/speed in the same gear. You may start at 1500rpm then climb up to 5000rpm all in 4th gear you should hear the drone go "in and out" at maybe 2000rpm then again at maybe 3800rpm (guessing at numbers). But you won't care about the 3800rpm because the only time you daily drive that rpm is going WOT for short periods of time. Where as you will see 2000rpm A LOT more often normal driving through the gears and even cruising on the highway.

I would like to see what this exhaust routing setup would be like lol. It would be a variable/tune-able resonant pipe. Cutout closed it handles 2000rpm drone. Cutout open it handles 3800rpm drone.

FWIW...when I did this on my GTO for 1750 rpm drone, I never hit another rpm resonant frequency to bother me.

Smitty,

Are you using 1125 as the speed of sound. I reversed the math and came up with 75 degree F exhaust gas temps. I doubt any exhaust gassses are 75 degrees F. 120 is more realistic.

If so, this would change the length by 3 inches (longer) compared to my spreadsheet. Either that or are my calculations off, thus significantly changing the actual resonant freq and drone reduction.

Are you using 1125 as the speed of sound. I reversed the math and came up with 75 degree F exhaust gas temps. I doubt any exhaust gassses are 75 degrees F. 120 is more realistic.

If so, this would change the length by 3 inches (longer) compared to my spreadsheet. Either that or are my calculations off, thus significantly changing the actual resonant freq and drone reduction.

#58

Actually, I just calculated it out as 68 degrees F with your 1125 figure. We are looking at he exhaust gas temp not the pipe temp.

The actual resonant freq should be measured with a spectrum analyzer so you can see the levels of the fundamental resonant freq and the levels of the subordinant harmonics.

The actual resonant freq should be measured with a spectrum analyzer so you can see the levels of the fundamental resonant freq and the levels of the subordinant harmonics.

#59

TECH Enthusiast

iTrader: (25)

Join Date: Nov 2011

Location: Milwaukee, WI

Posts: 547

Likes: 0

Received 0 Likes

on

0 Posts

I got ya. You COULD, but then you will run into issues of room to do all this piping. BUT, if you have 2000rpm city drone, I doubt you will have drone at a different rpm while cruising. Meaning the rpm range in which you would DAILY operate in is narrower than the range of the drone resonant frequencies. Ex: If you drone city driving at 2000rpm, your next drone rpm may be 4200rpm. I don't see a DD car cruising anywhere near 4200rpm for a sustained period of time.

A way to do this is be chugging along at 30mph in say 4th gear (a gear that can handle low to higher mph) then gradually increase rpm/speed in the same gear. You may start at 1500rpm then climb up to 5000rpm all in 4th gear you should hear the drone go "in and out" at maybe 2000rpm then again at maybe 3800rpm (guessing at numbers). But you won't care about the 3800rpm because the only time you daily drive that rpm is going WOT for short periods of time. Where as you will see 2000rpm A LOT more often normal driving through the gears and even cruising on the highway.

I would like to see what this exhaust routing setup would be like lol. It would be a variable/tune-able resonant pipe. Cutout closed it handles 2000rpm drone. Cutout open it handles 3800rpm drone.

A way to do this is be chugging along at 30mph in say 4th gear (a gear that can handle low to higher mph) then gradually increase rpm/speed in the same gear. You may start at 1500rpm then climb up to 5000rpm all in 4th gear you should hear the drone go "in and out" at maybe 2000rpm then again at maybe 3800rpm (guessing at numbers). But you won't care about the 3800rpm because the only time you daily drive that rpm is going WOT for short periods of time. Where as you will see 2000rpm A LOT more often normal driving through the gears and even cruising on the highway.

I would like to see what this exhaust routing setup would be like lol. It would be a variable/tune-able resonant pipe. Cutout closed it handles 2000rpm drone. Cutout open it handles 3800rpm drone.

#60

I found this in that corral forum:

More on the speed of sound in exhaust

--------------------------------------------------------------------------------

This site (specifically, the matlab link near the bottom) has the speed of sound in car exhaust listed at 486 m/s at 600 F. At that temperature, the speed of sound in air is 524 m/s. Assuming a simple linear transfer function between the two, that would mean that the speed of sound in exhaust would be 92.7% of that in air.

Now, 600F is way more than we are going to see in this resonator. There is no actual flow through the resonator, for one thing, and the exhaust at the point of the resonator junction with the tailpipe will have cooled anyway. I have seen estimates of 150 F as the terminal temp of the exhaust... this is 65.6 C, which results in 371.5 m/s according to this site's calculator.

371.5 m/s is 1219 fps. So, if this is the correct speed of sound, one can simply divide this by 4 (its a quarter wave tube) to get 304.75; 305 is more than precise enough since the speed of sound is an estimate anyway. Simply divide 305 by the desired frequency of attenuation to get the length of the tube you need in feet.

We could get a more accurate speed of sound if we knew the temperature inside the resonator tube. Since there is no actual flow inside the tube, I would think that the gas temp inside the tube is pretty close to the temperature of the outside of the tube. I do not have an infrared temp gun, but I do have a multimeter with a thermocouple... I might be able to get a decent reading with that. Anyone else think that this is/is not a reasonable estimate of the gas temp within the tube?

Where I assumed the 1125 for SOS:

Well, the objective is to calculate the wavelength of the exhaust sound pulses at the engine speed corresponding to the drone. In my case, 2500 rpm yields 167 Hz in each exhaust pipe:

2500 rev per minute * 4 pulses per rev / 60 seconds per minute = 167 pulses per second

The speed of sound in air depends upon the temperature. I assumed 1125 feet per second.

To find the wavelength of each sound pulse:

1125 feet per second / 167 pulses per second = 6.74 feet

You want the quarter-wave tube to be 1/4 of the wavelength, or 20.2 inches, in my case.

Since building mine, I found a reasearch paper where this was done under laboratory conditions. They found that the air in the quarter-wave tube reached a steady-state temperature around 95 deg. C, which yields a speed of sound around 1260 feet per second. Had I used this number, my tubes would need to be 22.4 inches long. Of course, beneath a moving car is not laboratory conditions, so there's no guarantee that temperature is any better than 70 deg. F, like I used. Besides, I didn't have any more room. There is about 3/8 in. space between the end of each quarter-wave tube and the transmission crossmember. I guess mine might be tuned for a higher frequency than I thought, but it works well due to the broad range of effectiveness.

One last thing. The attenuator works for all odd multiples of the tuned frequency, as well. So, if yours are tuned for 2000 rpm, they will have an effect at 6000 rpm, too.

More on the speed of sound in exhaust

--------------------------------------------------------------------------------

This site (specifically, the matlab link near the bottom) has the speed of sound in car exhaust listed at 486 m/s at 600 F. At that temperature, the speed of sound in air is 524 m/s. Assuming a simple linear transfer function between the two, that would mean that the speed of sound in exhaust would be 92.7% of that in air.

Now, 600F is way more than we are going to see in this resonator. There is no actual flow through the resonator, for one thing, and the exhaust at the point of the resonator junction with the tailpipe will have cooled anyway. I have seen estimates of 150 F as the terminal temp of the exhaust... this is 65.6 C, which results in 371.5 m/s according to this site's calculator.

371.5 m/s is 1219 fps. So, if this is the correct speed of sound, one can simply divide this by 4 (its a quarter wave tube) to get 304.75; 305 is more than precise enough since the speed of sound is an estimate anyway. Simply divide 305 by the desired frequency of attenuation to get the length of the tube you need in feet.

We could get a more accurate speed of sound if we knew the temperature inside the resonator tube. Since there is no actual flow inside the tube, I would think that the gas temp inside the tube is pretty close to the temperature of the outside of the tube. I do not have an infrared temp gun, but I do have a multimeter with a thermocouple... I might be able to get a decent reading with that. Anyone else think that this is/is not a reasonable estimate of the gas temp within the tube?

Where I assumed the 1125 for SOS:

Well, the objective is to calculate the wavelength of the exhaust sound pulses at the engine speed corresponding to the drone. In my case, 2500 rpm yields 167 Hz in each exhaust pipe:

2500 rev per minute * 4 pulses per rev / 60 seconds per minute = 167 pulses per second

The speed of sound in air depends upon the temperature. I assumed 1125 feet per second.

To find the wavelength of each sound pulse:

1125 feet per second / 167 pulses per second = 6.74 feet

You want the quarter-wave tube to be 1/4 of the wavelength, or 20.2 inches, in my case.

Since building mine, I found a reasearch paper where this was done under laboratory conditions. They found that the air in the quarter-wave tube reached a steady-state temperature around 95 deg. C, which yields a speed of sound around 1260 feet per second. Had I used this number, my tubes would need to be 22.4 inches long. Of course, beneath a moving car is not laboratory conditions, so there's no guarantee that temperature is any better than 70 deg. F, like I used. Besides, I didn't have any more room. There is about 3/8 in. space between the end of each quarter-wave tube and the transmission crossmember. I guess mine might be tuned for a higher frequency than I thought, but it works well due to the broad range of effectiveness.

One last thing. The attenuator works for all odd multiples of the tuned frequency, as well. So, if yours are tuned for 2000 rpm, they will have an effect at 6000 rpm, too.