S10 LS1 headers from Sanderson

#21

Teching In

Join Date: Sep 2005

Location: Dearborn Heights, MI

Posts: 29

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by Bigdeezs

1) trim the bottom of the pan

2) use the f-body pan or ls2 pan and trim the crossmember

3) weld 2 inches worth of steal to the bottom of the crossmember as a skid plate

2) use the f-body pan or ls2 pan and trim the crossmember

3) weld 2 inches worth of steal to the bottom of the crossmember as a skid plate

well i have a f-body pan right now... ive been freakin out for like the last 2 hours about this.. lol do you have any idea how much i would have to notch out the crossmember

#22

TECH Enthusiast

iTrader: (11)

Join Date: Dec 2002

Location: Iowa

Posts: 529

Likes: 0

Received 0 Likes

on

0 Posts

Heres a link to the ls2 pics,you pretty much have to notch the entire top of the crossmember

https://ls1tech.com/forums/showpost....&postcount=366

I bought an ls2 pan and held it up to the fbody pan and there's very little difference....Kind of a waste of money for me.And heres a ls7(looks identical to ls2 pan) pan compared to a fbody pan.

https://ls1tech.com/forums/showpost....&postcount=366

I bought an ls2 pan and held it up to the fbody pan and there's very little difference....Kind of a waste of money for me.And heres a ls7(looks identical to ls2 pan) pan compared to a fbody pan.

#23

TECH Resident

Join Date: Oct 2004

Location: TAMPA by way of MIAMI!!!

Posts: 807

Likes: 0

Received 0 Likes

on

0 Posts

Yeah but doesn't the LS2 pan have much better baffeling as compared to the F-body pan? For a few hundred it might be worth it. I just wish Milodon or Moroso would start making pans for these things. It would give us some more options.

#24

TECH Enthusiast

iTrader: (11)

Join Date: Dec 2002

Location: Iowa

Posts: 529

Likes: 0

Received 0 Likes

on

0 Posts

Yeah,I forgot about the baffeling.With as many different applications the lsx is being used in,you'd think they would have different options by now.I swear I've seen a sheetmetal pan but it was stock dimensions  .

.

.

.

Originally Posted by firefighter

Yeah but doesn't the LS2 pan have much better baffeling as compared to the F-body pan? For a few hundred it might be worth it. I just wish Milodon or Moroso would start making pans for these things. It would give us some more options.

#28

TECH Resident

Join Date: Dec 2004

Location: Baltimore, MD.

Posts: 841

Likes: 0

Received 0 Likes

on

0 Posts

Option 4. Build your own pan out of steel.

A steel pan will be much more forgiving of contact with the pavement (it'll bend where the cast alum pan will break).

I'd also suggest looking for a "claimer" pan kit from somebody like Speedway. They've got trapdoors and such for racing purposes, with which you could make the pan wider at the bottom to increase your volume (but still be above the crossmember).

My suggestion would be 3/8" x 2" flat bar for the flange and 16 or 18 guage for the rest of the pan except the bottom. I'd suggest something heavier (like 12 ga or 1/8") for the pan bottom, since you're likely to drag it on the ground. Might even reinforce the corners with some angle iron.

'JustDreamin'

A steel pan will be much more forgiving of contact with the pavement (it'll bend where the cast alum pan will break).

I'd also suggest looking for a "claimer" pan kit from somebody like Speedway. They've got trapdoors and such for racing purposes, with which you could make the pan wider at the bottom to increase your volume (but still be above the crossmember).

My suggestion would be 3/8" x 2" flat bar for the flange and 16 or 18 guage for the rest of the pan except the bottom. I'd suggest something heavier (like 12 ga or 1/8") for the pan bottom, since you're likely to drag it on the ground. Might even reinforce the corners with some angle iron.

'JustDreamin'

#30

TECH Resident

Join Date: Dec 2004

Location: Baltimore, MD.

Posts: 841

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by firefighter

It'l sounds like thats a good idea but it sounds HEAVY you got about 40lbs of steel in that sentence. JD not giving you a hard time just saying.

I didn't think to weigh mine before I put it on. (Took some pictures of it and can't find them either.)

You're right, I chose a method that was easy (for me) and inexpensive (I think I've got $40 in materials), but not necessarily light.

Aluminum has some advantages and disadvantages.

1.) Aluminum is 1/3 the weight of steel, but also 1/3 the strength (which often means you need 3 times as much of it).

2.) Cast Aluminum (the factory pans) is brittle, which means hit it on something and its broken, not bent. (steel usually bends, wrought or forged alum will usually bend too).

3.) Aluminum in general is more difficult to weld than steel (for the amateur and professional alike), requires special equipment, and welding used cast aluminum (as you'd find in most oil pans) is Very difficult.

Given the quantity of materials I used, I would guess the pan I built actually weighs about 23 lbs. (Very roughly estimated at 9 lbs of 3/8" barstock, 12lbs of sheet, 2lbs of mig wire). You certainly could go thinner on the barstock (1/4" or 5/16") and sheet (18 or 20 ga), and mine is fully welded inside & out, so you could use less wire by picking one side and skipping the other. Weight wasn't a concern for me (it needed to clear the front diff and not leak). Since I'd already stepped up to the iron block motor & 4L80E for a variety of reason (namely cost and durability), weight wasn't that big a deal.

If weight was a big issue and you could weld alum (I can't) build it out of sheet aluminum. 5052 sheet would be an excellent alum alloy for this kind of thing. 6061 barstock for the flange would weld acceptably to 5052 and is readily available. 6061 sheet doesn't bend real well, so I'd stay away from it. At that point, you could build a pan with 3/8" barstock for the flange, and .060" or .090" for the body and still loose weight (i'd estimate my pan at around 13 lbs if I had used .090" alum, 10 lbs if I used .060" alum).

For Lowonair's situation, I would suggest steel, and probably as thick or thicker than what I used. Why, because his pan is very likely to make intimate contact with terra firma, and it is usually not very forgiving. I'd rather have 10 extra pounds of steel in the oilpan than to have to pull the motor out and repair the oilpan (but I'm just lazy).

I do think some of the aftermarket companies are working on steel or sheet alum pans. I'd suggest looking around. But don't expect them to be cheap, most of the ones I've seen were talking about street prices around $400 to $500.

'JustDreamin'

Last edited by 'JustDreamin'; 01-21-2007 at 08:39 AM.

#31

TECH Resident

iTrader: (12)

Speaking of headers though I did find a somewhat easy solution. I ended up using a set of 98-99 shorty headers. Just modified the flanges and put 3" collectors on them and it worked out real slick. The only problem is I had to relocate my steering shaft alittle. The column is in the factory spot still. Here are the pictures. www.geocities.com/jays_s10/IMG_0425.JPG www.geocities.com/jays_s10/IMG_0426.JPG www.geocities.com/jays_s10/IMG_0427.JPG

Last edited by kossuth; 01-21-2007 at 02:18 PM.

#32

TECH Resident

Join Date: Oct 2004

Location: TAMPA by way of MIAMI!!!

Posts: 807

Likes: 0

Received 0 Likes

on

0 Posts

JD you seem like you got alot of the schizz figured out for these swaps I don't think w/o ALOT of practice I can weld anything good enough to get it to not leak. I can get stuff to stick but I don't think I would trust $5-6K worth of motor to my welds. Personally I think the LS2 pan is gonna work for me I just gotta figure out the oil drain situation. I like the idea of the baffeling and the cross member will protect my pan. But I agree with your statement on the durability factor for lowonair.

Hey Kossuth those headers look good.

Hey Kossuth those headers look good.

#33

Launching!

iTrader: (17)

Join Date: May 2005

Location: Los Angeles

Posts: 228

Likes: 0

Received 0 Likes

on

0 Posts

what did you end up doing with your custom long tubes?

Originally Posted by kossuth

Speaking of headers though I did find a somewhat easy solution. I ended up using a set of 98-99 shorty headers. Just modified the flanges and put 3" collectors on them and it worked out real slick. The only problem is I had to relocate my steering shaft alittle. The column is in the factory spot still. Here are the pictures. www.geocities.com/jays_s10/IMG_0425.JPG www.geocities.com/jays_s10/IMG_0426.JPG www.geocities.com/jays_s10/IMG_0427.JPG

#35

TECH Resident

Join Date: Dec 2004

Location: Baltimore, MD.

Posts: 841

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by firefighter

I don't think w/o ALOT of practice I can weld anything good enough to get it to not leak. I can get stuff to stick but I don't think I would trust $5-6K worth of motor to my welds.

(Can't you hear Dirty Harry's voice? Man's got ta know his limitations)

I think you're probably on the right path with the LS2 pan.

'JustDreamin'

#38

Teching In

Join Date: Mar 2006

Location: Lubbock/Marshall, Texas

Posts: 17

Likes: 0

Received 0 Likes

on

0 Posts

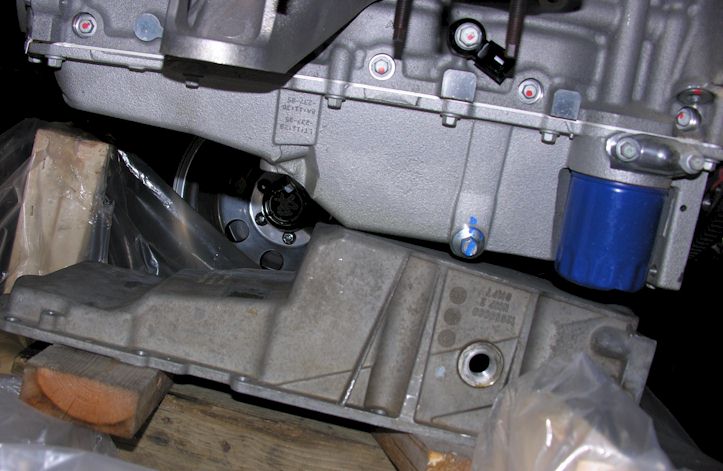

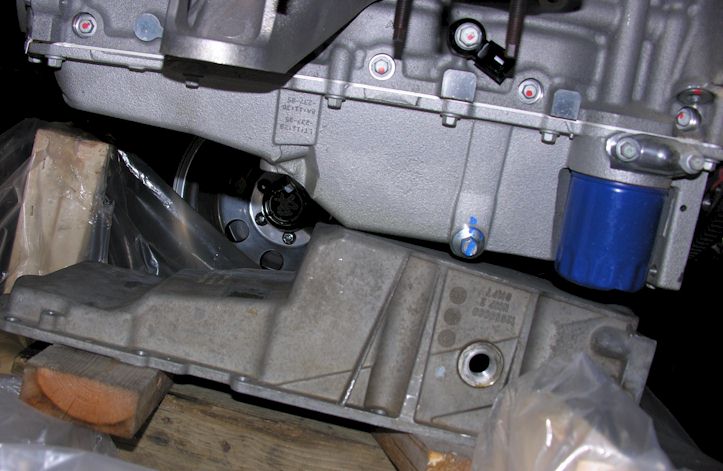

Sorry to bring this back from the dead, but does anyone know if I'll have any problems with clearance using the C5 oil pan (bottom right)?

Has anyone found any companies recently that make long-tube headers for the LS1 swap?

Has anyone found any companies recently that make long-tube headers for the LS1 swap?

#39

TECH Resident

iTrader: (148)

Join Date: Dec 2006

Location: Crete, NE & Berthoud, CO

Posts: 848

Likes: 0

Received 0 Likes

on

0 Posts

ur pretty much hosed with any pan you use. The hummer H3 pan clears on the second gen trucks without frame mods but its a tight fit (maybe 1/4" clearance).

As for headers, i used sanderson shorty swap headers and honestly i was not impressed with them. 1.5" primaries suck, welds were not very quality, had to use copper gaskets to get them to seal. I would build my own set next time around or simply wait till someone can come out with a good header for these trucks.

As for headers, i used sanderson shorty swap headers and honestly i was not impressed with them. 1.5" primaries suck, welds were not very quality, had to use copper gaskets to get them to seal. I would build my own set next time around or simply wait till someone can come out with a good header for these trucks.

#40

TECH Resident