Solid motor mount question

Trending Topics

#12

6 & 8 Second Club

Join Date: Aug 2006

Location: Illinois, RT 66 dragway area

Posts: 2,284

Likes: 0

Received 0 Likes

on

0 Posts

.

I've welded my front plate & block saver, never had a problem with either one.

I would be much more concerned with changing the angle of the motor,

as I mentioned. 1/4" at the motor mount could be an issue,

by the time you get to the rear end.

If welding the mounts makes everything fit, I wouldn't stress out over it. Good luck.

.

I've welded my front plate & block saver, never had a problem with either one.

I would be much more concerned with changing the angle of the motor,

as I mentioned. 1/4" at the motor mount could be an issue,

by the time you get to the rear end.

If welding the mounts makes everything fit, I wouldn't stress out over it. Good luck.

.

#13

I've welded my front plate & block saver, never had a problem with either one.

I would be much more concerned with changing the angle of the motor,

as I mentioned. 1/4" at the motor mount could be an issue,

by the time you get to the rear end.

If welding the mounts makes everything fit, I wouldn't stress out over it. Good luck.

I would be much more concerned with changing the angle of the motor,

as I mentioned. 1/4" at the motor mount could be an issue,

by the time you get to the rear end.

If welding the mounts makes everything fit, I wouldn't stress out over it. Good luck.

Since the mounts sit on the k-member @ 45 degrees, If i cut the mounts down 1/4" each, shouldn't it lower LESS than 1/4"?

#14

TECH Addict

iTrader: (1)

Join Date: Nov 2001

Location: Michigan

Posts: 2,161

Likes: 0

Received 0 Likes

on

0 Posts

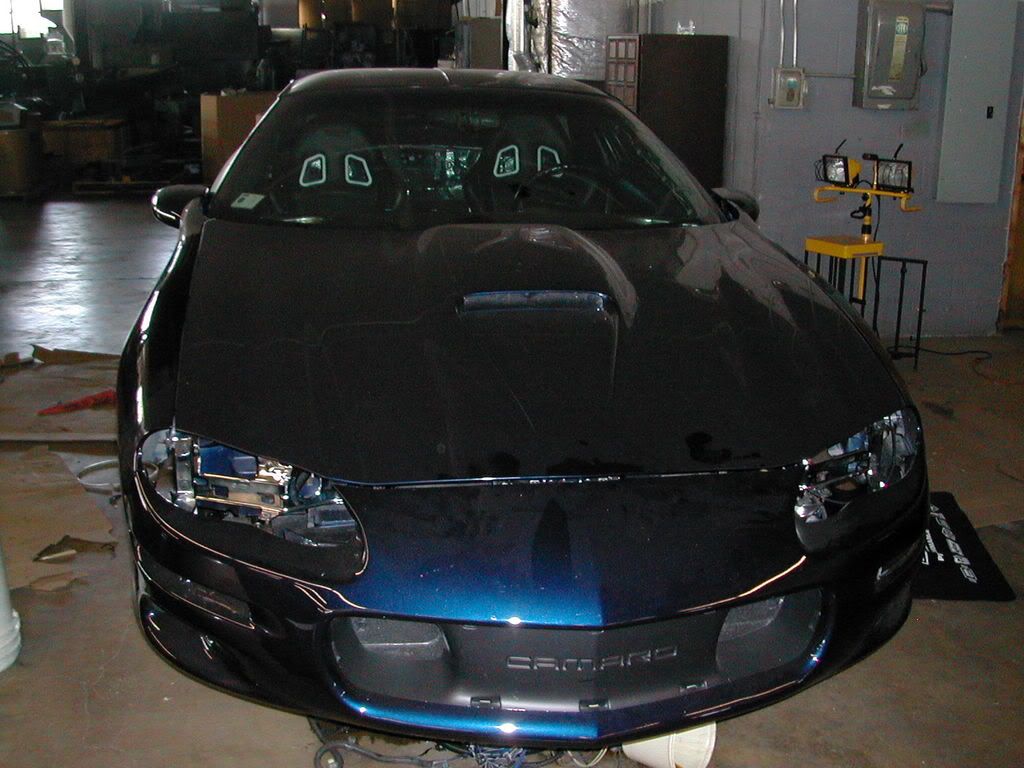

You should be able to cut it down & weld, I have the Madman solid mounts, and they are just a little shorter than the Spohn. I have a pic of the 2 somewhere, when I compared the 2. Let me see if I can find it.