safety harness install?

#1

On The Tree

Thread Starter

iTrader: (6)

Join Date: Oct 2007

Location: Arkansas

Posts: 111

Likes: 0

Received 0 Likes

on

0 Posts

i'm about to put a 5 point harness in my car and i have a 10 point cage, i was wondering how has everybody connected the lap part of the belt to the floor and the shoulder parts to the roll cage?

#5

Do you guys just use a single tab, sitting horizontal, facing towards the driver?

I thought the belt manufacturers prefer a "double shear" mount where the buckle is bolted between two plates, thus creating the "double shear" loading on the bolt.

I thought the belt manufacturers prefer a "double shear" mount where the buckle is bolted between two plates, thus creating the "double shear" loading on the bolt.

Trending Topics

#8

If it is the "Y" style, that is no longer legal due to conerns over stretching in an accident (i.e. all of the load being transferred to 1 piece of 3" nylon as opposed to 2).

However, wrapping the belts around the bar is a fool-proof (and preferred way by many chassis shops and belt manufacturers) means of attaching the shoulders.

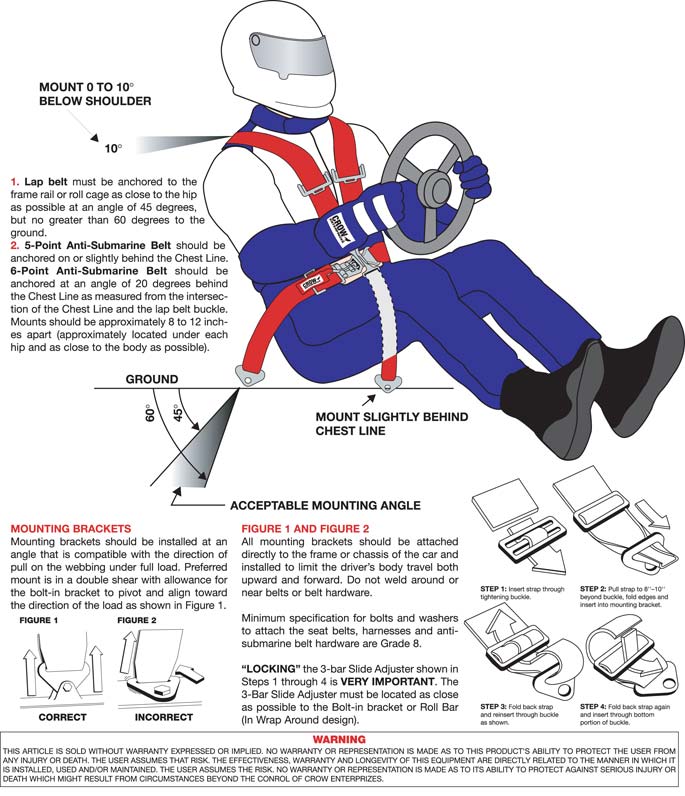

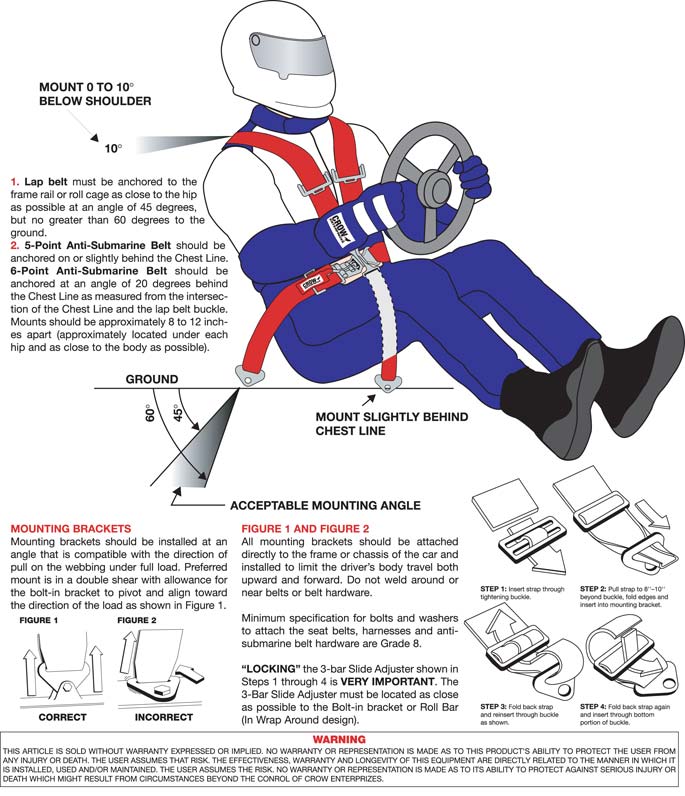

Regarding the lap belts, mine along the trans tunnel had the end laid over way to far to be safe per figure 2 in the diagram above while the rocker side was a better angle, but was obstructed by the rocker bar.

As such, we welded two .125" thick 6"x6" plates to the floor and welded a piece of .125" wall rectangular tubing between the two. In the tubing, we welded bushings so that eye bolts could be used and I switched to a "clip" style end instead of the bolt-in.

The result was a ridiculously overengineered chunk of steel welded to the floor, but the belts are sitting at my hip's width, pulling at a 45deg angle, and are pulling on the eye bolt purely in tension (i.e. no side loading) to comply with everything illustrated in my previous post.

However, wrapping the belts around the bar is a fool-proof (and preferred way by many chassis shops and belt manufacturers) means of attaching the shoulders.

Regarding the lap belts, mine along the trans tunnel had the end laid over way to far to be safe per figure 2 in the diagram above while the rocker side was a better angle, but was obstructed by the rocker bar.

As such, we welded two .125" thick 6"x6" plates to the floor and welded a piece of .125" wall rectangular tubing between the two. In the tubing, we welded bushings so that eye bolts could be used and I switched to a "clip" style end instead of the bolt-in.

The result was a ridiculously overengineered chunk of steel welded to the floor, but the belts are sitting at my hip's width, pulling at a 45deg angle, and are pulling on the eye bolt purely in tension (i.e. no side loading) to comply with everything illustrated in my previous post.

#10

How do you get the lap belts to line up correctly with the stock holes and not end up like the "incorrect" loading as shown in the picture above?

#11

From Simpson:

MOUNTING BRACKETS

Mounting brackets should be installed at an angle that is compatible with the direction of pull on the webbing under full load. Preferred mount is in a double shear with allowance for the bolt-in bracket to pivot and align toward the direction of the load as shown in Figure 1.

Figure 1 and Figure 2

All mounting brackets should be attached directly to the frame or chassis of the car and installed to limit the driver’s body travel both upward and forward. Do not weld around or near belts or belt hardware.

Minimum specification for bolts and washers to attach the seat belts, harnesses and anti-submarine belt hardware are Grade 8.

Wrap Around style mounts should have a provision to prevent lateral or side-to-side movement.

DO NOT MOUNT TO THE SHEET METAL FLOORBOARD. ALL MOUNTS SHOULD HOLD A MINIMUM OF 3,000 LBS.FORCE.

MOUNTING BRACKETS

Mounting brackets should be installed at an angle that is compatible with the direction of pull on the webbing under full load. Preferred mount is in a double shear with allowance for the bolt-in bracket to pivot and align toward the direction of the load as shown in Figure 1.

Figure 1 and Figure 2

All mounting brackets should be attached directly to the frame or chassis of the car and installed to limit the driver’s body travel both upward and forward. Do not weld around or near belts or belt hardware.

Minimum specification for bolts and washers to attach the seat belts, harnesses and anti-submarine belt hardware are Grade 8.

Wrap Around style mounts should have a provision to prevent lateral or side-to-side movement.

DO NOT MOUNT TO THE SHEET METAL FLOORBOARD. ALL MOUNTS SHOULD HOLD A MINIMUM OF 3,000 LBS.FORCE.

#12

Launching!

iTrader: (1)

Join Date: Feb 2003

Location: Huntsville, AL

Posts: 246

Likes: 0

Received 0 Likes

on

0 Posts

Here are the belts I have:

http://store.summitracing.com/partde...5&autoview=sku

You can remove the "bracket" from the two top belts and the crotch belt. Unfortunately, you can not do that with the two lap belts. The top belts are easy enough - just run them across the cross-bar on your cage/roll bar.

As far as lap belts, I wanted to keep my stock belts as well. I simply removed some material on the lap belt bracket that goes on the door-side, slid it through the stock mounting bolt, and attached the stock seatbelt normally. This seems to be what a number of people do, per the search button.

Do I trust it? Yes, I do. That being said, this DOES NOT put the bracket at the angle shown in the instructions earlier. How to get it there with these seat belts - I'm not sure. If these didn't have the sewn in brackets on the end of the lap belts, it wouldn't be an issue. Seeing as how they do, I'm not sure how to fix the situation. If anyone has pictures they'd like to share, that would be great. I'm at a bit of a loss, to be honest. Even with the eye bolt mounting kit I'm not sure how you'd make that attachment.

Finally the crotch strap - are most of you (who run it to a "cross" bar between two of the seat bolts) putting it on the rear seat bolts or the front seat bolts? Seems people have done it both ways.

Hopefully we can resolve these issues. I'll gladly rework my setup if someone can point us all in a better direction.

#13

8 Second Club

iTrader: (34)

If it is the "Y" style, that is no longer legal due to conerns over stretching in an accident (i.e. all of the load being transferred to 1 piece of 3" nylon as opposed to 2).

However, wrapping the belts around the bar is a fool-proof (and preferred way by many chassis shops and belt manufacturers) means of attaching the shoulders.

Regarding the lap belts, mine along the trans tunnel had the end laid over way to far to be safe per figure 2 in the diagram above while the rocker side was a better angle, but was obstructed by the rocker bar.

As such, we welded two .125" thick 6"x6" plates to the floor and welded a piece of .125" wall rectangular tubing between the two. In the tubing, we welded bushings so that eye bolts could be used and I switched to a "clip" style end instead of the bolt-in.

The result was a ridiculously overengineered chunk of steel welded to the floor, but the belts are sitting at my hip's width, pulling at a 45deg angle, and are pulling on the eye bolt purely in tension (i.e. no side loading) to comply with everything illustrated in my previous post.

However, wrapping the belts around the bar is a fool-proof (and preferred way by many chassis shops and belt manufacturers) means of attaching the shoulders.

Regarding the lap belts, mine along the trans tunnel had the end laid over way to far to be safe per figure 2 in the diagram above while the rocker side was a better angle, but was obstructed by the rocker bar.

As such, we welded two .125" thick 6"x6" plates to the floor and welded a piece of .125" wall rectangular tubing between the two. In the tubing, we welded bushings so that eye bolts could be used and I switched to a "clip" style end instead of the bolt-in.

The result was a ridiculously overengineered chunk of steel welded to the floor, but the belts are sitting at my hip's width, pulling at a 45deg angle, and are pulling on the eye bolt purely in tension (i.e. no side loading) to comply with everything illustrated in my previous post.

), the stock RH mounting will never really be right with an aftermarket harness. But like many others thats how mine was, with the new cage the RH side will have tabs on the bar and I will use the stock LH hole. Still really wont be 100% correct since I have the seat moved as far to the right as I can almost touching the tunnel. But with a stock floor car you start running out of room when you start adding more bars.

), the stock RH mounting will never really be right with an aftermarket harness. But like many others thats how mine was, with the new cage the RH side will have tabs on the bar and I will use the stock LH hole. Still really wont be 100% correct since I have the seat moved as far to the right as I can almost touching the tunnel. But with a stock floor car you start running out of room when you start adding more bars.I see a lot of cars with the shoulder belts mounted way too high or way too low as well, thats something thats pretty critical.

#14

10 Second Club

iTrader: (15)

Join Date: May 2004

Location: Minnesota

Posts: 652

Likes: 0

Received 0 Likes

on

0 Posts

This is all good info...

Is it legal to put a 3 inch strap through a 2 ich snap connector like under figure 5 in this link..?

http://www.schrothracing.com/main/Documents/3barSlide

Is it legal to put a 3 inch strap through a 2 ich snap connector like under figure 5 in this link..?

http://www.schrothracing.com/main/Documents/3barSlide

#15

8 Second Club

iTrader: (34)

This is all good info...

Is it legal to put a 3 inch strap through a 2 ich snap connector like under figure 5 in this link..?

http://www.schrothracing.com/main/Documents/3barSlide

Is it legal to put a 3 inch strap through a 2 ich snap connector like under figure 5 in this link..?

http://www.schrothracing.com/main/Documents/3barSlide

#16

I am not posting to sound like a jerk and start trouble. The bottom line is that the NHRA rulebook states "Check manufacturer's instructions" in the driver restrain section. For me, I run M&R belts, this is what they say:

"A. Attached to frame (roll cage) or chassis of vehicle. DO NOT mount to sheet metal floorboard.

B. Install to insure a direct line of pull when webbing and hardware are under load conditions (See Drawings)

C. Install to limit driver's movement upward or forward.

D. Attach harness to mounting bracket with grade 8 or better bolts & washers

"

"

Maybe different belts have different requirements, I don't know. After being failed at tech though for the wrong style hose clamp on my overflow tank (Midwest guys, guess which track!), I always make sure to pay attention to the details so that I cannot get tech'd out again!

"A. Attached to frame (roll cage) or chassis of vehicle. DO NOT mount to sheet metal floorboard.

B. Install to insure a direct line of pull when webbing and hardware are under load conditions (See Drawings)

C. Install to limit driver's movement upward or forward.

D. Attach harness to mounting bracket with grade 8 or better bolts & washers

"

"Maybe different belts have different requirements, I don't know. After being failed at tech though for the wrong style hose clamp on my overflow tank (Midwest guys, guess which track!), I always make sure to pay attention to the details so that I cannot get tech'd out again!

#17

Launching!

iTrader: (1)

Join Date: Feb 2003

Location: Huntsville, AL

Posts: 246

Likes: 0

Received 0 Likes

on

0 Posts

I don't think you're starting any trouble. The NHRA rules are great and all, and it makes sense to mount them with the brackets in a "straight line" with the pull of the belts when you think about it, but what people (myself included) seem to be asking for is how exactly to make an approved setup happen. Maybe someone has some actual pictures of their mounting setups that HAVE passed inspection?

#19

8 Second Club

iTrader: (34)

I dont think I ever seen NHRA check for seat belt mounting, ever. Since 99.9% of the people here use the stock belt bolts I doubt you will find any pics here.

Whether its 'right' can be debated, always best to do what you feel safe with and pay attention what the manufacture recommends. Especially with safety equipment.

Whether its 'right' can be debated, always best to do what you feel safe with and pay attention what the manufacture recommends. Especially with safety equipment.

#20

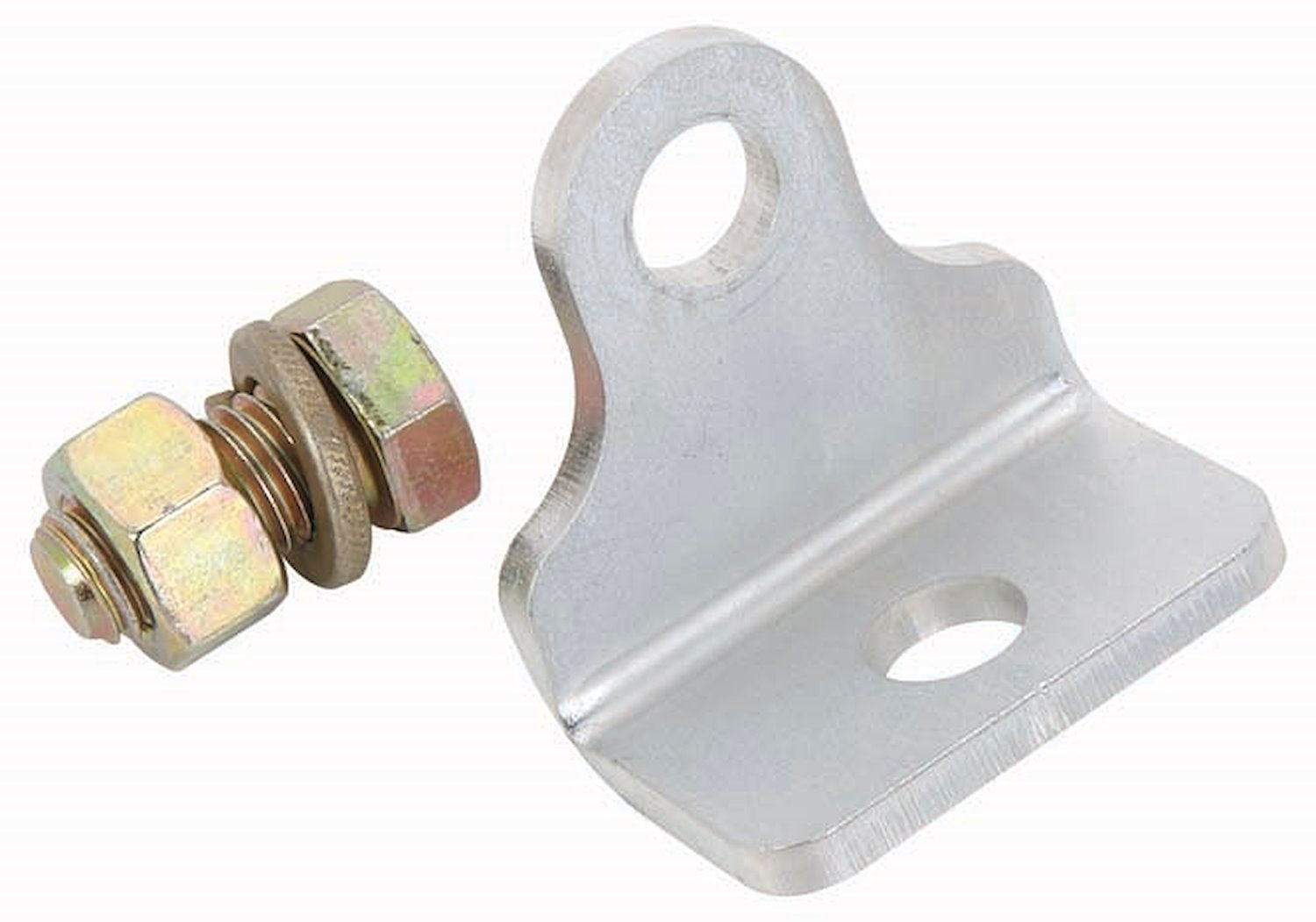

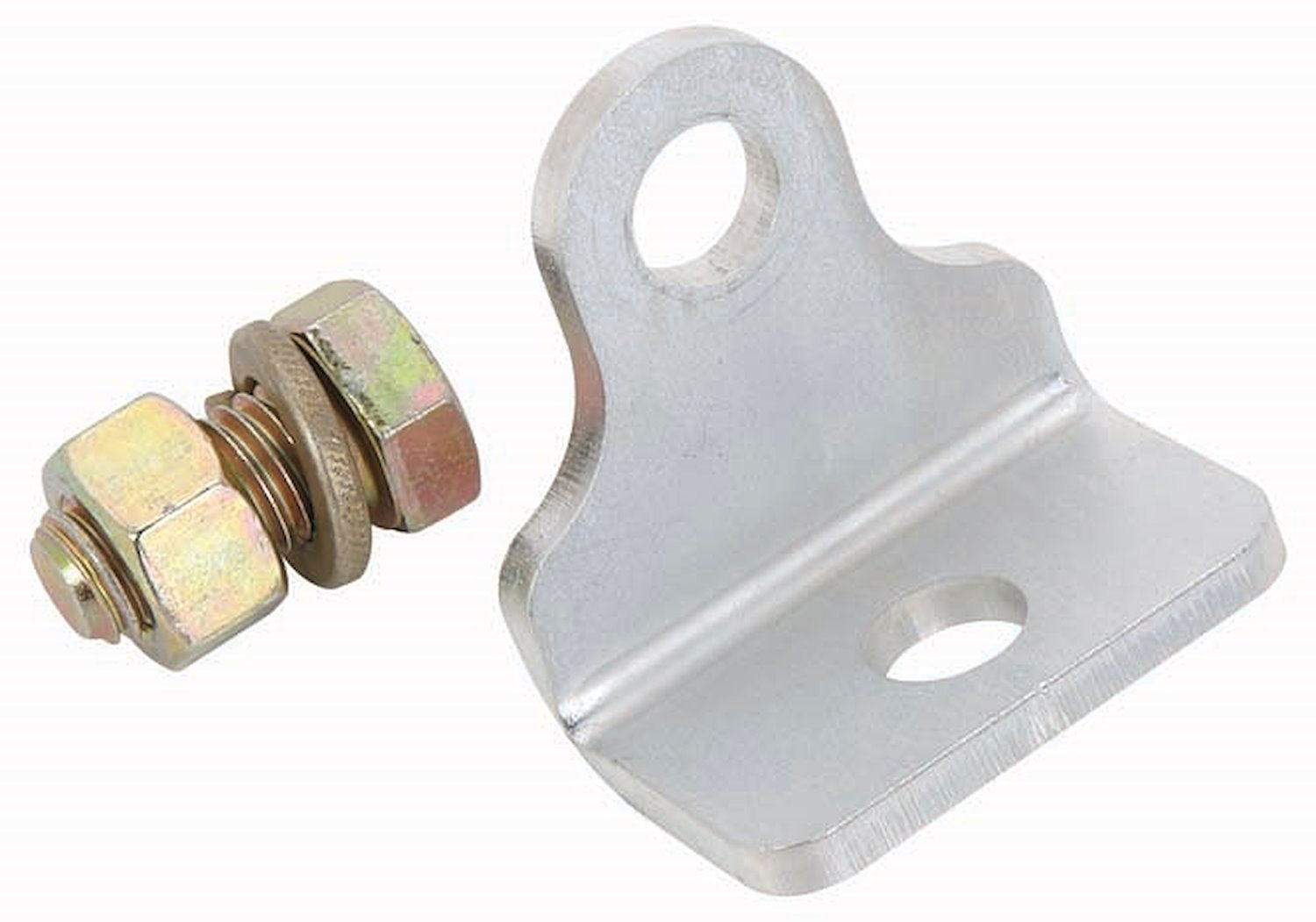

This could be another alternative to get the belt right if you do not have access to fabrication equipment:

"A must have for early style muscle cars, stockers, or any vehicle utilizing a racing harness. Save the time and money of having to fabricate and weld brackets to mount your safety harness to the floor of your vehicle. These brackets allow you to bolt the safety harness directly to the floor and have the belt loop facing the direction of the pull as many safety harness manufacturers intended. You can mount them to an existing seat belt mount on the floor or by machining a hole in the floor and using the 471-100H safety harness back up plate. Includes Grade 8 mounting hardware. Made in the USA."

http://www.jegs.com/i/JEGS/555/70015/10002/-1

Or this one...

"A must have for early style muscle cars, stockers, or any vehicle utilizing a racing harness. Save the time and money of having to fabricate and weld brackets to mount your safety harness to the floor of your vehicle. These brackets allow you to bolt the safety harness directly to the floor and have the belt loop facing the direction of the pull as many safety harness manufacturers intended. You can mount them to an existing seat belt mount on the floor or by machining a hole in the floor and using the 471-100H safety harness back up plate. Includes Grade 8 mounting hardware. Made in the USA."

http://www.jegs.com/i/JEGS/555/70015/10002/-1

Or this one...