Back to back testing of AI CNCd LS7 Cylinder Heads Vs Stock LS7.. Results Inside!!!

#1

There is quite a bit of debate within the LS community as to whether or not CNC porting GM LS7 cylinder heads offers any benefit over the stock porting. Vengeance Racing recently had the opportunity to conduct an A/B test to determine what the real world gains would be (if any) on a cam only combination.

The vehicle: 2007 C6 Z06

Modifications upon arrival: (Previously completed by Vengeance Racing)

Vararam Induction

Vengeance Racing "Annihilator" Camshaft

Comp 26926 Dual Spring Kit with Ti Retainers

Comp hardened pushrods

Comp Trunion Upgrade

Katech C5R Timing Chain

American Racing 1 7/8 Longtubes/X pipe

This particular C6 Z06 produced 575RWHP/525RWTQ. Our first step was to baseline the car on our DynoJet 224X to confirm the #s were in line with our intial results. After confirming the dyno #s we removed the cylinder heads and shipped them to Advanced Inductions for CNC work.

We have worked with Phil from Advanced Inductions several times in the past with excellent results. Phil disassembled the LS7 cylinder heads/Removed & replaced all valve guides/completed a full CNC port job on all intake & exhaust runners/complete competition valve job/hot tank and assembled the cylinder heads. Turn around time was less than 2 weeks from start to finish.

As soon as the cylinder heads were returned we prepped the C6 Z06 for install. After an initial heat cycle/fluid change it was back on the dyno to determine if all the work would be beneficial.

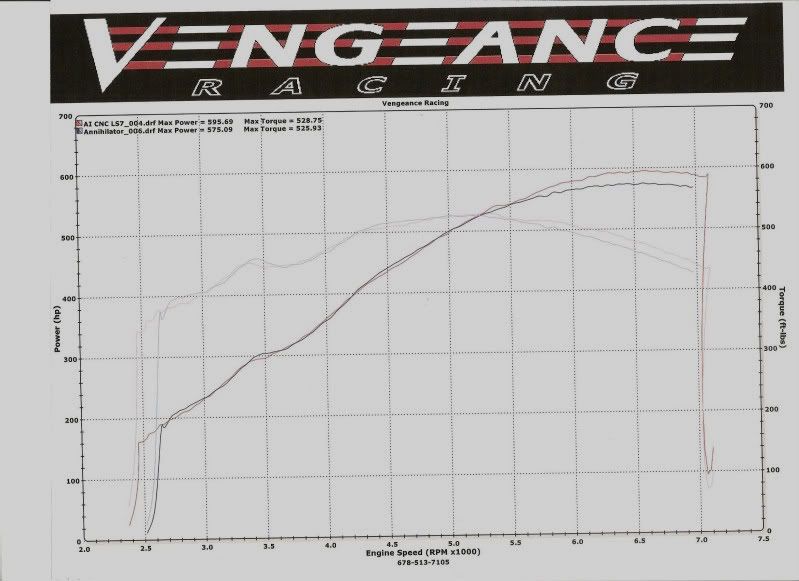

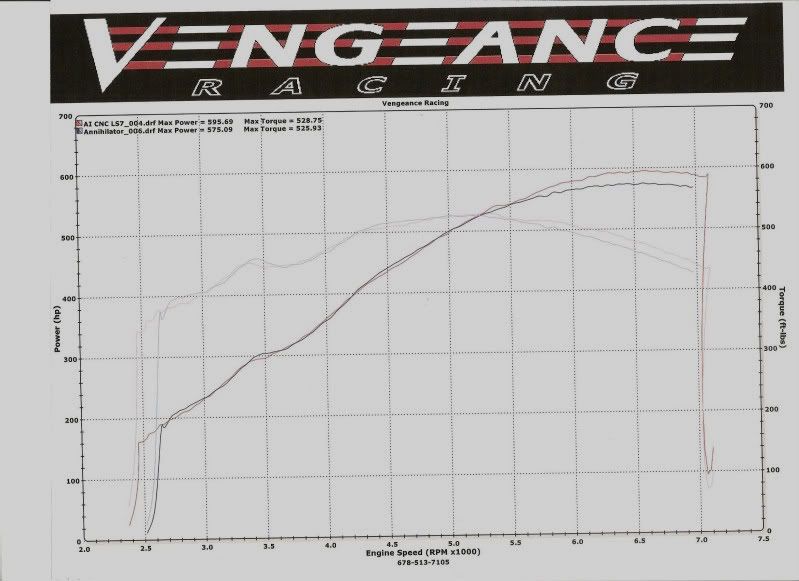

Here is the dyno graph:

As you can see the CNC work netted 20RWHP/3RWTQ from 5500rpm tp redline. The power also hangs on a bit longer up top. After speaking with Phil we both believe more power could be had if the camshaft had been replaced with something that was more suited to the flow characteristics of the cylinder heads. Unfortunately that would have negated our A/B testing. We will spec a camshaft that matches the CNCd heads on our next build and see if 600+ LEGIT rwhp is attainable.

I would say for the price of the CNC work that this is a worthwhile modification. Vengeance Racing offers CNC porting from Advanced Induction/Total Engine Airflow & West Coast Cylinder Heads for anyone interested.

The vehicle: 2007 C6 Z06

Modifications upon arrival: (Previously completed by Vengeance Racing)

Vararam Induction

Vengeance Racing "Annihilator" Camshaft

Comp 26926 Dual Spring Kit with Ti Retainers

Comp hardened pushrods

Comp Trunion Upgrade

Katech C5R Timing Chain

American Racing 1 7/8 Longtubes/X pipe

This particular C6 Z06 produced 575RWHP/525RWTQ. Our first step was to baseline the car on our DynoJet 224X to confirm the #s were in line with our intial results. After confirming the dyno #s we removed the cylinder heads and shipped them to Advanced Inductions for CNC work.

We have worked with Phil from Advanced Inductions several times in the past with excellent results. Phil disassembled the LS7 cylinder heads/Removed & replaced all valve guides/completed a full CNC port job on all intake & exhaust runners/complete competition valve job/hot tank and assembled the cylinder heads. Turn around time was less than 2 weeks from start to finish.

As soon as the cylinder heads were returned we prepped the C6 Z06 for install. After an initial heat cycle/fluid change it was back on the dyno to determine if all the work would be beneficial.

Here is the dyno graph:

As you can see the CNC work netted 20RWHP/3RWTQ from 5500rpm tp redline. The power also hangs on a bit longer up top. After speaking with Phil we both believe more power could be had if the camshaft had been replaced with something that was more suited to the flow characteristics of the cylinder heads. Unfortunately that would have negated our A/B testing. We will spec a camshaft that matches the CNCd heads on our next build and see if 600+ LEGIT rwhp is attainable.

I would say for the price of the CNC work that this is a worthwhile modification. Vengeance Racing offers CNC porting from Advanced Induction/Total Engine Airflow & West Coast Cylinder Heads for anyone interested.

#2

LS1 Tech Administrator

iTrader: (14)

Good report Ron. That's a strong running C6. How would you recommend modifying the cam valve events to better serve the flow characteristics of the new cylinder heads?

__________________

2013 Corvette Grand Sport A6 LME forged 416, Greg Good ported TFS 255 LS3 heads, 222/242 .629"/.604" 121LSA Pat G blower cam, ARH 1 7/8" headers, ESC Novi 1500 Supercharger w/8 rib direct drive conversion, 747rwhp/709rwtq on 93 octane, 801rwhp/735rwtq on race fuel, 10.1 @ 147.25mph 1/4 mile, 174.7mph Half Mile.

2016 Corvette Z51 M7 Magnuson Heartbeat 2300 supercharger, TSP LT headers, Pat G tuned, 667rwhp, 662rwtq, 191mph TX Mile.

2009.5 Pontiac G8 GT 6.0L, A6, AFR 230v2 heads. 506rwhp/442rwtq. 11.413 @ 121.29mph 1/4 mile, 168.7mph TX Mile

2000 Pewter Ram Air Trans Am M6 heads/cam 508 rwhp/445 rwtq SAE, 183.092 TX Mile

2018 Cadillac Escalade 6.2L A10 Pat G tuned.

LS1,LS2,LS3,LS7,LT1 Custom Camshaft Specialist For custom camshaft help press here.

Custom LSX tuning in person or via email press here.

2013 Corvette Grand Sport A6 LME forged 416, Greg Good ported TFS 255 LS3 heads, 222/242 .629"/.604" 121LSA Pat G blower cam, ARH 1 7/8" headers, ESC Novi 1500 Supercharger w/8 rib direct drive conversion, 747rwhp/709rwtq on 93 octane, 801rwhp/735rwtq on race fuel, 10.1 @ 147.25mph 1/4 mile, 174.7mph Half Mile.

2016 Corvette Z51 M7 Magnuson Heartbeat 2300 supercharger, TSP LT headers, Pat G tuned, 667rwhp, 662rwtq, 191mph TX Mile.

2009.5 Pontiac G8 GT 6.0L, A6, AFR 230v2 heads. 506rwhp/442rwtq. 11.413 @ 121.29mph 1/4 mile, 168.7mph TX Mile

2000 Pewter Ram Air Trans Am M6 heads/cam 508 rwhp/445 rwtq SAE, 183.092 TX Mile

2018 Cadillac Escalade 6.2L A10 Pat G tuned.

LS1,LS2,LS3,LS7,LT1 Custom Camshaft Specialist For custom camshaft help press here.

Custom LSX tuning in person or via email press here.

Trending Topics

#10

TECH Apprentice

iTrader: (1)

Join Date: Oct 2006

Location: NJ

Posts: 374

Likes: 0

Received 0 Likes

on

0 Posts

How much were the heads milled and what was the baseline static cr, and what was the static cr with the AI heads?

I haven't seen a stock cube ls7 make 600rwhp (or very close) without a bump in compression no matter who did the cnc work. At least not with a plastic front mount intake.

I'm not doubting you, but I would like to know the before and after compression ratio.

Either way 595rwhp is a nice result.

I haven't seen a stock cube ls7 make 600rwhp (or very close) without a bump in compression no matter who did the cnc work. At least not with a plastic front mount intake.

I'm not doubting you, but I would like to know the before and after compression ratio.

Either way 595rwhp is a nice result.

#11

Stage,

Before compression= stock

After compression= stock

Had the cylinder heads been milled for added compression I believe we would have seen a nice jump in power thru more of the RPM range and not just above 5000rpm.

I agree with you. We have not built and/or seen many stock LS7s go 600rwhp legit. We are actually considering adding a FAST LSXR 102mm intake to this combo so we could actually crack the 600HP barrier

Before compression= stock

After compression= stock

Had the cylinder heads been milled for added compression I believe we would have seen a nice jump in power thru more of the RPM range and not just above 5000rpm.

I agree with you. We have not built and/or seen many stock LS7s go 600rwhp legit. We are actually considering adding a FAST LSXR 102mm intake to this combo so we could actually crack the 600HP barrier

#12

TECH Apprentice

iTrader: (1)

Join Date: Oct 2006

Location: NJ

Posts: 374

Likes: 0

Received 0 Likes

on

0 Posts

Stage,

Before compression= stock

After compression= stock

Had the cylinder heads been milled for added compression I believe we would have seen a nice jump in power thru more of the RPM range and not just above 5000rpm.

I agree with you. We have not built and/or seen many stock LS7s go 600rwhp legit. We are actually considering adding a FAST LSXR 102mm intake to this combo so we could actually crack the 600HP barrier

Before compression= stock

After compression= stock

Had the cylinder heads been milled for added compression I believe we would have seen a nice jump in power thru more of the RPM range and not just above 5000rpm.

I agree with you. We have not built and/or seen many stock LS7s go 600rwhp legit. We are actually considering adding a FAST LSXR 102mm intake to this combo so we could actually crack the 600HP barrier

Wow, that's incredible and in my eyes a game changer. Congrats to you and AI on those results. I haven't seen anything close to that with 427ci, 11:1cr, stock ls7 castings, and a plastic intake (I'm not saying it's never happened, but I haven't seen it).

I'm looking forward to seeing what it will do with a FAST across the curve.

#17

Wow, that thing's gotta absolutely fly! I had the chance to line up against a stock C6 Z06 at the track and it was way too close for comfort, so I can't even imagine one with 150 more rwhp

Last edited by ScreaminRedZ; 02-23-2011 at 07:57 PM.

#18

FormerVendor

iTrader: (2)

Ron,

Nice work, thanks for posting!

Depends on what you're after, we have options from $995-1395 for the GM LS7 head.

We can provide a grind that emphasizes whichever part of the power band the customer desires. While the head will make power with any grind, it won't run to potential w/o something better suited for both its characteristics and a specific RPM range goal. For instance we can increase the area under the curve from as low as 3-3500rpm depending on goals, desired spring life, rpm headroom requirement, etc. I'll have to abstain from posting details beyond that for a couple of obvious reasons - that's a service we provide, and it would also serve to provide info on VRD's grinds that obviously work great for the stock long block guys.

Making 600rwhp with a stock short block LS7 is about as hard as falling off a log. However, to increase the probability that the head will be run to its potential we need to have a set goal from the outset. If a guy wants 600, 630, 650rwhp, that is all doable, but we need to control the entire top-end. As we've proven, with minimal inlet restriction the GM LS7 intake will support 700rwhp NA, and 600rwhp is only ~1.6Xhp/cid. In this instance I believe the gentleman was primarily concerned with simply freshening the head, and if he gained anything in the process then it was simply a bonus.

I must admit, I find the focus on compression curious. The majority of the gains are invariably from the altered port design. Beyond that, if a suite of machine work includes milling to any volume or valve location, then it would seem a bit silly to attempt to break down the net gain by machining operation. For instance, we wouldn't really care to determine what portion of a gain was attributable to tightening up guide clearances or precision valve grinding.

For reference, the potential difference on an LS7 between the stock cnc work and our cnc work is on the order of 40-45hp. However, that presupposes both a cam grind better suited to our design, as well as minimal inlet and exhaust restrictions.

Thanks for the kind words, Guys!

-Phil

Nice work, thanks for posting!

How much were the heads milled and what was the baseline static cr, and what was the static cr with the AI heads?

I haven't seen a stock cube ls7 make 600rwhp (or very close) without a bump in compression no matter who did the cnc work. At least not with a plastic front mount intake.

I'm not doubting you, but I would like to know the before and after compression ratio.

Either way 595rwhp is a nice result.

I haven't seen a stock cube ls7 make 600rwhp (or very close) without a bump in compression no matter who did the cnc work. At least not with a plastic front mount intake.

I'm not doubting you, but I would like to know the before and after compression ratio.

Either way 595rwhp is a nice result.

I must admit, I find the focus on compression curious. The majority of the gains are invariably from the altered port design. Beyond that, if a suite of machine work includes milling to any volume or valve location, then it would seem a bit silly to attempt to break down the net gain by machining operation. For instance, we wouldn't really care to determine what portion of a gain was attributable to tightening up guide clearances or precision valve grinding.

For reference, the potential difference on an LS7 between the stock cnc work and our cnc work is on the order of 40-45hp. However, that presupposes both a cam grind better suited to our design, as well as minimal inlet and exhaust restrictions.

Thanks for the kind words, Guys!

-Phil

#19

TECH Apprentice

iTrader: (1)

Join Date: Oct 2006

Location: NJ

Posts: 374

Likes: 0

Received 0 Likes

on

0 Posts

Making 600rwhp with a stock short block LS7 is about as hard as falling off a log. However, to increase the probability that the head will be run to its potential we need to have a set goal from the outset. If a guy wants 600, 630, 650rwhp, that is all doable, but we need to control the entire top-end. As we've proven, with minimal inlet restriction the GM LS7 intake will support 700rwhp NA, and 600rwhp is only ~1.6Xhp/cid. In this instance I believe the gentleman was primarily concerned with simply freshening the head, and if he gained anything in the process then it was simply a bonus.

I must admit, I find the focus on compression curious. The majority of the gains are invariably from the altered port design. Beyond that, if a suite of machine work includes milling to any volume or valve location, then it would seem a bit silly to attempt to break down the net gain by machining operation. For instance, we wouldn't really care to determine what portion of a gain was attributable to tightening up guide clearances or precision valve grinding.

For reference, the potential difference on an LS7 between the stock cnc work and our cnc work is on the order of 40-45hp. However, that presupposes both a cam grind better suited to our design, as well as minimal inlet and exhaust restrictions.

Thanks for the kind words, Guys!

-Phil

Compression has been proven time and time again the differentiating factor between the 560-570rwhp c6 z06 and the 590-610rwhp z06. That .5-.9+ jump in compression is the difference every time without fail until this. There have been a ton of claims from vendors peddling their wares, but every independent test has shown much different than their claims. In fact there have been more than a few people who've hit 590rwhp with a cam, and a $100 mill job on the heads with the ports untouched.

I hear you on unrestricting the intake and exhaust. That's why I love itb's.

You and I need to talk as one of my builds has to pass a stringent visual state inspection and I will need a plastic intake for this build at least for the time being.

Congrats again on the results. You call it easy, but I see it as a game changer. No one else is TRULY doing this with bone stock compression, and a plastic intake on stock 427 cubes.

There is a lot of smoke and mirrors out there though.

Edit: I'm not being sarcastic either. I am seriously impressed and will be in touch...

Last edited by Stage7; 02-24-2011 at 01:04 PM.