5.3L Truck Motor Cam-only

#21

How do you think the stage 1 blower cam will work in a 5.3L with flat top pistons? Looking at getting a 5.3 here soon and have some flat top pistons I may throw in it. Possibly going supercharger later on but not right away.

#23

Martin,

I can't argue the piston speed with the same stroke and rod ratio. Things I think reflect the differences and food for thought.

Although stroke/rod ratio is the same, bore is different. Which means:

There is more volume to fill for the 5.7, 6.0, 6.2

Same sized valves means the larger bore can breath more easily due to the unshrouded valve.

I believe that as the cyl volume increases (5.3 to 6.2) if the same heads are used, a bigger cam would be required to keep the same peak as there s not enough duration to fill the cyl adequately. 5.3 to 5.7 not so much. At some point the valve is not causing a restriction as bore goes bigger.

Am i wrong in saying the smaller bore motor suffers with the bigger cam in the lower rpm. The small 5.3 bore won't pull the same vacuum as a 6.2 wearing the same top end.

I can't argue the piston speed with the same stroke and rod ratio. Things I think reflect the differences and food for thought.

Although stroke/rod ratio is the same, bore is different. Which means:

There is more volume to fill for the 5.7, 6.0, 6.2

Same sized valves means the larger bore can breath more easily due to the unshrouded valve.

I believe that as the cyl volume increases (5.3 to 6.2) if the same heads are used, a bigger cam would be required to keep the same peak as there s not enough duration to fill the cyl adequately. 5.3 to 5.7 not so much. At some point the valve is not causing a restriction as bore goes bigger.

Am i wrong in saying the smaller bore motor suffers with the bigger cam in the lower rpm. The small 5.3 bore won't pull the same vacuum as a 6.2 wearing the same top end.

#25

Thread Starter

FormerVendor

iTrader: (3)

Joined: Feb 2012

Posts: 7,480

Likes: 15

From: Mount Airy, NC

Did you see the graphs I posted with the 6.0 with a 4.0" bore compared to a 5.3 with a 3.78" bore? They both have the exact same IVC event and peak at the exact same rpm for torque and horsepower. How else can you explain that?

The only affect the smaller bore drawing less vacuum and allowing less air to enter the motor has is on power output, not where the engine peaks at.

This is just some of the things I've found from doing literally over 500 cams since I've been at Tick Performance. I know some may not believe that number, but it may be even higher by now. I lost count around the 300 mark.

#28

Tigger, bore honestly doesn't play as big of a part as you would think even when the difference is more than 10%...................................Did you see the graphs I posted with the 6.0 with a 4.0" bore compared to a 5.3 with a 3.78" bore? They both have the exact same IVC event and peak at the exact same rpm for torque and horsepower. How else can you explain that?

If the smaller motor has smaller heads and/or smaller intake, your test them becomes invalid. GM put smaller heads on the smaller motors for a reason. To maintain a certain displacement to head volume/flow ratio.

An engine is a positive displacement pump. Bore to stroke ratio and rod to stroke ratios certain have an influence over torque curves and cam timing preferences, but in the end an 350 cubic inch pump still pumps 350 cubic inches of air per cycle at 100% volumetric efficiency. And when that pump changes to 320 cubic inches per cycle, it will reach optimum volumetric efficiency at a higher RPM when all other things are equal.

But, again, there is a 10% difference in displacement between a 5.7 and a 5.3. Not much to worry about IMO.

Last edited by speedtigger; 03-18-2013 at 10:47 PM.

#29

Thread Starter

FormerVendor

iTrader: (3)

Joined: Feb 2012

Posts: 7,480

Likes: 15

From: Mount Airy, NC

Did both of those motors have the same heads and intake? Same headers?

If the smaller motor has smaller heads and/or smaller intake, your test them becomes invalid. GM put smaller heads on the smaller motors for a reason. To maintain a certain displacement to head volume/flow ratio.

An engine is a positive displacement pump. Bore to stroke ratio and rod to stroke ratios certain have an influence over torque curves and cam timing preferences, but in the end an 350 cubic inch pump still pumps 350 cubic inches of air per cycle at 100% volumetric efficiency. And when that pump changes to 320 cubic inches per cycle, it will reach optimum volumetric efficiency at a higher RPM when all other things are equal.

But, again, there is a 10% difference in displacement between a 5.7 and a 5.3. Not much to worry about IMO.

If the smaller motor has smaller heads and/or smaller intake, your test them becomes invalid. GM put smaller heads on the smaller motors for a reason. To maintain a certain displacement to head volume/flow ratio.

An engine is a positive displacement pump. Bore to stroke ratio and rod to stroke ratios certain have an influence over torque curves and cam timing preferences, but in the end an 350 cubic inch pump still pumps 350 cubic inches of air per cycle at 100% volumetric efficiency. And when that pump changes to 320 cubic inches per cycle, it will reach optimum volumetric efficiency at a higher RPM when all other things are equal.

But, again, there is a 10% difference in displacement between a 5.7 and a 5.3. Not much to worry about IMO.

I've tested this numerous times. A 5.3 and a 5.7 or a 5.3 and a 6.0 will all peak within 50-100rpm's for a given intake valve close event if the manifold and cylinder head runner length is the same and cross sectional area is close to being the same.

BTW a smaller head will peak at a LOWER rpm, which a 5.3 head has a 190cc intake runner and a 1.89" intake valve. A 6.0 which is the graph I posted not a 5.7 has a 210cc intake runner and a 2.0" valve. Which means it should peak later by your reasoning. Tell me why it doesn't in this case? Both have the SAME headers and SAME intake...so why do they not peak at different rpm?

Last edited by Sales@Tick; 03-19-2013 at 03:48 PM.

#30

The 5.3 has the smaller runner 5.3 head and the 6.0 has the larger 6.0 head right? If this is the case, then the heads are proportionate to the displacement of the engine. This would lend itself to the results you have. However, put that bigger head on the small engine and the smaller engine will need to run at a higher rpm to reach optimum volumetric efficiency.

My experience with engines ranging from big block Chevies with rectangular port heads vs oval port and small block Fords with Cleveland Vs Windsor heads almost always show the same thing. A small engine with a big head wants a narrower LSA and more ICL advance to acheive optimal average power under the curve vs a bigger motor with a smaller head that most often prefers a wider LSA with less ICL advance. There is no reason this would not also be true for an LS series engine.

I think the ultimate extreme example to illustrate the point would be a comparison between and LS3 and a 5.3 with LS3 heads (if you could make em fit). They both have the same stroke and stroke to rod ratio, however I am willing to bet that the 5.3 would need a smaller cam with narrower LSA and an earlier IVC to make optimal average horsepower in the same RPM same range. This has proven true throughout time on all types on V8s.

One thing that the LS has going for it that can mask a less than optimal cam choice is the long runner LS EFI intake. That intake has allowed many guys to over cam their engines and still get acceptable results. Get the cam that wrong on a car equipped with a Victor Jr. and you will have your very own pet pig.

My experience with engines ranging from big block Chevies with rectangular port heads vs oval port and small block Fords with Cleveland Vs Windsor heads almost always show the same thing. A small engine with a big head wants a narrower LSA and more ICL advance to acheive optimal average power under the curve vs a bigger motor with a smaller head that most often prefers a wider LSA with less ICL advance. There is no reason this would not also be true for an LS series engine.

I think the ultimate extreme example to illustrate the point would be a comparison between and LS3 and a 5.3 with LS3 heads (if you could make em fit). They both have the same stroke and stroke to rod ratio, however I am willing to bet that the 5.3 would need a smaller cam with narrower LSA and an earlier IVC to make optimal average horsepower in the same RPM same range. This has proven true throughout time on all types on V8s.

One thing that the LS has going for it that can mask a less than optimal cam choice is the long runner LS EFI intake. That intake has allowed many guys to over cam their engines and still get acceptable results. Get the cam that wrong on a car equipped with a Victor Jr. and you will have your very own pet pig.

Last edited by speedtigger; 03-19-2013 at 04:25 PM.

#31

Thread Starter

FormerVendor

iTrader: (3)

Joined: Feb 2012

Posts: 7,480

Likes: 15

From: Mount Airy, NC

The 5.3 has the smaller runner 5.3 head and the 6.0 has the larger 6.0 head right? If this is the case, then the heads are proportionate to the displacement of the engine. This would lend itself to the results you have. However, put that bigger head on the small engine and the smaller engine will need to run at a higher rpm to reach optimum volumetric efficiency.

My experience with engines ranging from big block Chevies with rectangular port heads vs oval port and small block Fords with Cleveland Vs Windsor heads almost always show the same thing. A small engine with a big head wants a narrower LSA and more ICL advance to acheive optimal average power under the curve vs a bigger motor with a smaller head that most often prefers a wider LSA with less ICL advance. There is no reason this would not also be true for an LS series engine.

I think the ultimate extreme example to illustrate the point would be a comparison between and LS3 and a 5.3 with LS3 heads (if you could make em fit). They both have the same stroke and stroke to rod ratio, however I am willing to bet that the 5.3 would need a smaller cam with narrower LSA and an earlier IVC to make optimal average horsepower in the same RPM same range. This has proven true throughout time on all types on V8s.

One thing that the LS has going for it that can mask a less than optimal cam choice is the long runner LS EFI intake. That intake has allowed many guys to over cam their engines and still get acceptable results. Get the cam that wrong on a car equipped with a Victor Jr. and you will have your very own pet pig.

My experience with engines ranging from big block Chevies with rectangular port heads vs oval port and small block Fords with Cleveland Vs Windsor heads almost always show the same thing. A small engine with a big head wants a narrower LSA and more ICL advance to acheive optimal average power under the curve vs a bigger motor with a smaller head that most often prefers a wider LSA with less ICL advance. There is no reason this would not also be true for an LS series engine.

I think the ultimate extreme example to illustrate the point would be a comparison between and LS3 and a 5.3 with LS3 heads (if you could make em fit). They both have the same stroke and stroke to rod ratio, however I am willing to bet that the 5.3 would need a smaller cam with narrower LSA and an earlier IVC to make optimal average horsepower in the same RPM same range. This has proven true throughout time on all types on V8s.

One thing that the LS has going for it that can mask a less than optimal cam choice is the long runner LS EFI intake. That intake has allowed many guys to over cam their engines and still get acceptable results. Get the cam that wrong on a car equipped with a Victor Jr. and you will have your very own pet pig.

I am not arguing that cam specs need to be slightly different for each engine, I am only illustrating, in all of my testing and from all the results I've personally gathered from my camshafts that I have done that when you're dealing with port volumes that vary so little from a 190cc port to a 210cc while the stroke and rod length remains the same and the intake valve closes at the same time on each engine that the peak rpm will not change.

I'm not arguing that a 260cc runner head will need a different cam than a 190cc runner head that the 5.3 came with of course it will. BUT when you have a 6.0 and a 5.3 or a 5.7 and a 5.3 that have NEARLY IDENTICAL port volumes with the same rod and stroke length the cam and intake valve closing event will be NO different from the one used in the opposite engine. Or at least I feel it should be. I wish I had a dyno graph for every engine I've cammed. I could show you at least 10 more examples just like the two I've shown in this thread.

All I am saying, is if the 5.3 needs such an earlier intake valve closing event and shorter events in general than a 6.0 why does it peak at the same RPM. No one can answer that question....I will continue to cam my customers engines the same as I have been doing.

#33

Thread Starter

FormerVendor

iTrader: (3)

Joined: Feb 2012

Posts: 7,480

Likes: 15

From: Mount Airy, NC

I have some customers with carb'd 5.3's in the works along with some customers with carb'd 6.0's in the works with single plane intakes. 3-4 of them have the same IVC event as the other(5.3 vs. 6.0). If any of those customers put them on a dyno(most of my carb customers could care less about dyno numbers they want to race like yourself) I'll make a separate thread illustrating the similarities.

#35

So explain why would an XER lobed 223/228 106/106 in a 10.5-1cr wearing stock ls6 heads, stock ls6 intake/tb and 1 3/4 headers peaked exactly where a stock ls6 cam does.. There is a reason why I put that cam in a specific vehicle.

Last edited by LIL SS; 03-19-2013 at 09:38 PM.

#36

That is a drastically different design of a camshaft. There is a lot of variables there. It may peak at the same place but I bet it has a hell of a lot better midrange. Am I right?

#38

I am building a budget carb'd 5.3. Totally stock for now, but cam, valvetrain and head upgrades are all in the future. Everything you are posting is terrific! I would really apperciate it if you could create a carb/cam dyno thread. Seeing the real world outcomes of different combination would be a great part selection tool for all of us! Thanks Martin!

#39

Thread Starter

FormerVendor

iTrader: (3)

Joined: Feb 2012

Posts: 7,480

Likes: 15

From: Mount Airy, NC

The key element that is being displayed here is how the manipulation of exhaust timing events effect peak power after peak torque.

After peak torque, power is decaying at a certain rate depending on the ability of the 4 stroke cycle to receive fresh air and excuvate the exhaust gases. The engine that is more efficient at this process, you will see the torque curve decline at a slower rate and peak power increase. The engine less efficient at scavenging after peak torque will fall off faster.

If you were to use that exact same cam from the 5.3 in that 6.0, the curves would not be similar.

The 5.3 cam has 0* overlap

The 6.0 cam has 9* of overlap which aids past peak torque in scavenging.

Yes the IVC plays a part but with a different duration with the same camshaft timing events are different because they are happening at different times in relationship to crankshaft degrees.

Martin-

What you have found is good data for your records in "correlation" to if you are specing a cam and chosing where you want peak power to occur in comparison.

But it is stretching it to say that the controlled variables of the rod size,intake, headers, crankshaft, etc are grounds to make a correlation of this type.

After peak torque, power is decaying at a certain rate depending on the ability of the 4 stroke cycle to receive fresh air and excuvate the exhaust gases. The engine that is more efficient at this process, you will see the torque curve decline at a slower rate and peak power increase. The engine less efficient at scavenging after peak torque will fall off faster.

If you were to use that exact same cam from the 5.3 in that 6.0, the curves would not be similar.

The 5.3 cam has 0* overlap

The 6.0 cam has 9* of overlap which aids past peak torque in scavenging.

Yes the IVC plays a part but with a different duration with the same camshaft timing events are different because they are happening at different times in relationship to crankshaft degrees.

Martin-

What you have found is good data for your records in "correlation" to if you are specing a cam and chosing where you want peak power to occur in comparison.

But it is stretching it to say that the controlled variables of the rod size,intake, headers, crankshaft, etc are grounds to make a correlation of this type.

I use all the data I've gathered for future reference on all the cams I do. This is what I have found from that data nothing more. It's worked so far, I think I will keep doing it this way. Good discussion though.

I told Tooley one time that I had noticed that with identical cam timing events in identical engines other than EVC being 2 degrees later(my V.2 112lsa Polluter versus V.2 111lsa Polluter) 2 degrees more overlap carried power to a higher rpm power peak. He disagreed that it was from the overlap lol. He has told me plenty of times before that EVO, IVO and EVC have little to no effect on where power actually peaks, but how the curves are formed(i.e. plotted) and how they fall after peak. I forwarded him a link to this thread. Maybe he will grace us with his presence.

Which LS6 cam? 204 intake duration or the 207 intake duration? Everything the same on both engines? Or did you do a cam swap from the stock LS6 cam to the 223/228 106/106 cam?

#40

Thread Starter

FormerVendor

iTrader: (3)

Joined: Feb 2012

Posts: 7,480

Likes: 15

From: Mount Airy, NC

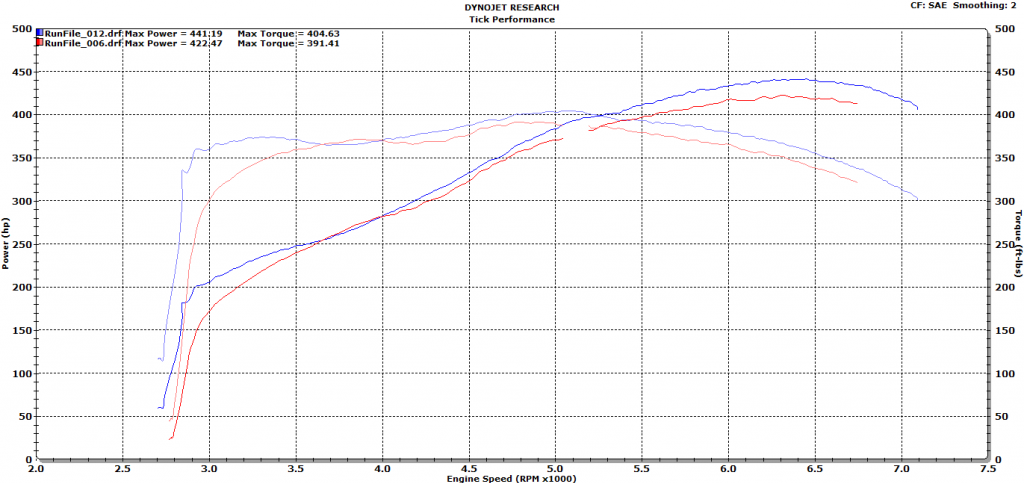

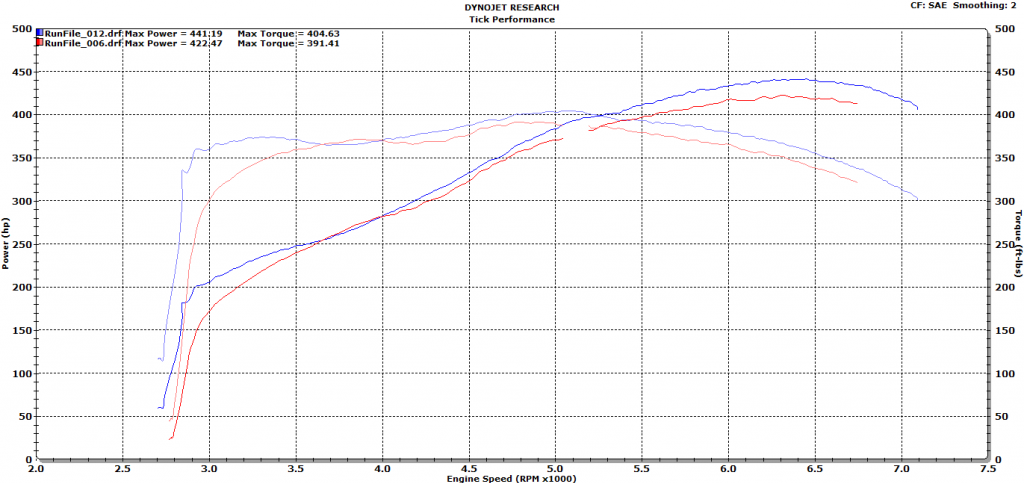

Here is a mind boggler for Lil SS and Tigger since both think that a larger engine will peak sooner and a smaller engine will peak later with identical cam timing events all other variables being identical.

This is what I noticed and mentioned to Tooley and he disagreed. I still think that just like Bozz Hawg said that overlap can help carry power further past peak, but I still am left wondering if it actually affects where power peaks and not just before peak and after peak. I mean, I can look at this graph and say, "The only different variables in this equation are a 10cc difference in port volume(from my experience not near enough to change power peak, but it's possible) and 2 degrees of overlap." That still isn't a firm enough stance for me. I'd need to see at least 4-5 more engines with these two cams in them with every other variable being the same as it was in this case to draw a conclusion. It took at least 7-8 5.3 cams for me to realize and ask myself..."Why are these 5.3's peaking so early with these cams?" So I asked an esteemed colleague of mine what he thought and his advice was, "Cam the 5.3 with the same IVC as a 5.7/6.0 and watch what happens." So I did and saw that for the same IVC event as I was using in the larger bore engines, once used in a 5.3 engine with a smaller bore, it produced the same peak power rpm as the larger bore engine did.

LS1(3.898" x 3.622") with the 239/244 112+3 V.2 Polluter. Events are:

10.5 IVO

48.5 IVC

57.0 EVO

7.0 EVC

LS2(4.0" x 3.622") with the same 239/244 V.2 Polluter but on a 111+2...events are:

10.5 IVO

48.5 IVC

55.0 EVO

9.0 EVC

Here is a graph overlay showing both cams. Blue line is the LS2, red line is the LS1. Notice that the larger bore LS2 actually peaks later(around 5100 for torque and 6450 for horsepower) and not earlier than the smaller bore LS1(around 4800 for torque and 6250-6300 for horsepower).

This is what I noticed and mentioned to Tooley and he disagreed. I still think that just like Bozz Hawg said that overlap can help carry power further past peak, but I still am left wondering if it actually affects where power peaks and not just before peak and after peak. I mean, I can look at this graph and say, "The only different variables in this equation are a 10cc difference in port volume(from my experience not near enough to change power peak, but it's possible) and 2 degrees of overlap." That still isn't a firm enough stance for me. I'd need to see at least 4-5 more engines with these two cams in them with every other variable being the same as it was in this case to draw a conclusion. It took at least 7-8 5.3 cams for me to realize and ask myself..."Why are these 5.3's peaking so early with these cams?" So I asked an esteemed colleague of mine what he thought and his advice was, "Cam the 5.3 with the same IVC as a 5.7/6.0 and watch what happens." So I did and saw that for the same IVC event as I was using in the larger bore engines, once used in a 5.3 engine with a smaller bore, it produced the same peak power rpm as the larger bore engine did.

LS1(3.898" x 3.622") with the 239/244 112+3 V.2 Polluter. Events are:

10.5 IVO

48.5 IVC

57.0 EVO

7.0 EVC

LS2(4.0" x 3.622") with the same 239/244 V.2 Polluter but on a 111+2...events are:

10.5 IVO

48.5 IVC

55.0 EVO

9.0 EVC

Here is a graph overlay showing both cams. Blue line is the LS2, red line is the LS1. Notice that the larger bore LS2 actually peaks later(around 5100 for torque and 6450 for horsepower) and not earlier than the smaller bore LS1(around 4800 for torque and 6250-6300 for horsepower).

Last edited by Sales@Tick; 03-20-2013 at 05:49 PM.