STS - separate turbo oil system Qs

#21

TECH Resident

Thread Starter

iTrader: (7)

Join Date: Dec 2008

Location: CT

Posts: 796

Likes: 0

Received 0 Likes

on

0 Posts

Care to go a little deeper than that? lol.

It sounds like I can just have a cooler, 2 pumps, and a tank in the trunk. I can check the oil level by hand - so i dont really think id need a sensor for that. also, if there is a thermostat way of cooling that sounds like a great idea.. but trying to do a search on that i am coming up empty handed.

On the plus side my friend is a very good mechanic, so we can change things on the fly so to speak. lol

It sounds like I can just have a cooler, 2 pumps, and a tank in the trunk. I can check the oil level by hand - so i dont really think id need a sensor for that. also, if there is a thermostat way of cooling that sounds like a great idea.. but trying to do a search on that i am coming up empty handed.

On the plus side my friend is a very good mechanic, so we can change things on the fly so to speak. lol

#23

10 Second Club

iTrader: (2)

1. not one, but two pumps to fail

2. Have to get the oil up to working temp

3. if feed pump fails kiss your CHRA bearings good bye.

4. extra tank, one more thing to check constantly

5. all the extra cost involved

6. extra weight

Pump failure is the biggest reason not to do this setup. The KISS method really should apply to the scavange pump/feed setup as it is a critical component. The mechanical setup from the engine is much more reliable.

2. Have to get the oil up to working temp

3. if feed pump fails kiss your CHRA bearings good bye.

4. extra tank, one more thing to check constantly

5. all the extra cost involved

6. extra weight

Pump failure is the biggest reason not to do this setup. The KISS method really should apply to the scavange pump/feed setup as it is a critical component. The mechanical setup from the engine is much more reliable.

#28

TECH Apprentice

iTrader: (5)

Join Date: Oct 2003

Location: Glendale,AZ

Posts: 382

Likes: 0

Received 0 Likes

on

0 Posts

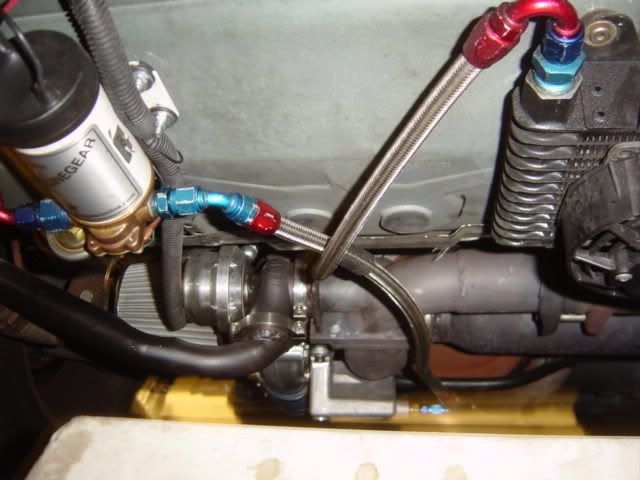

Heres the system I built more than three years ago, and around 10,000 miles of driving.

1. Oil drain pan/resovior is from a porsche 996 turbo

2. Oil pump is a brass gear driven pump similar to what you get for the return pump from STS

3. oil pressure guage running in my center vent

4. Oil goes into a B&M cooler with a thermostat controlled fan.

5 Oil goes to the turbo inlet which also has a small needle and seat bypass to adjust pressure.

6. The little Black box is a PWM DC motor controller. It has two speeds that switch at .5 psi. On a cold morning the oil pressure is about 30psi, when it warms up it sits around 15-20, which i have been told is plenty for a turbo thats not spooling. at .5 psi the PWM kicks up the voltage and give around 40psi when the system is warm.

The whole system was a little pricey about $1000.00 but the only part that has ever failed was the PWM, and that was because I used one only intended for 10A max, the new one is designed for 24A and have not had any other issues.

Also I just checked my MP t-70 has no shaft play

1. Oil drain pan/resovior is from a porsche 996 turbo

2. Oil pump is a brass gear driven pump similar to what you get for the return pump from STS

3. oil pressure guage running in my center vent

4. Oil goes into a B&M cooler with a thermostat controlled fan.

5 Oil goes to the turbo inlet which also has a small needle and seat bypass to adjust pressure.

6. The little Black box is a PWM DC motor controller. It has two speeds that switch at .5 psi. On a cold morning the oil pressure is about 30psi, when it warms up it sits around 15-20, which i have been told is plenty for a turbo thats not spooling. at .5 psi the PWM kicks up the voltage and give around 40psi when the system is warm.

The whole system was a little pricey about $1000.00 but the only part that has ever failed was the PWM, and that was because I used one only intended for 10A max, the new one is designed for 24A and have not had any other issues.

Also I just checked my MP t-70 has no shaft play

#31

Teching In

Join Date: Jul 2008

Location: southeast of indy

Posts: 12

Likes: 0

Received 0 Likes

on

0 Posts

I'm doing a "butt mount" Holset HX50 with absoultly no scavenging pump. This is my theory; and hopefully it will work.

I've installed a 15 gallon aluminum fuel cell in my trunk and eliminated my stock gas tank. "My theory" is that if I mount the turbo high enough giving me enough downward pitch back to the bottom of the pan, then no problem.

Go ahead, Im ready for feedback (neg or pos)

I've installed a 15 gallon aluminum fuel cell in my trunk and eliminated my stock gas tank. "My theory" is that if I mount the turbo high enough giving me enough downward pitch back to the bottom of the pan, then no problem.

Go ahead, Im ready for feedback (neg or pos)

#32

Teching In

Join Date: Jul 2008

Location: southeast of indy

Posts: 12

Likes: 0

Received 0 Likes

on

0 Posts

I just wanted to show you guys my surgical procedure that I went through so far. With the stock gas tank removed I've gained 12 inches, thats right 12 inches without the use of pills, creams, or streneous exercises. (of clearance I mean) LOL!

#33

Teching In

Join Date: Jul 2008

Location: southeast of indy

Posts: 12

Likes: 0

Received 0 Likes

on

0 Posts

This is my new intake port for my hx55 the old filler door was removed and i fabbed up a new semi-attractive looking screened intake. The best part is that this is the only one I've seen like this and I have a straight shot from the opening to the turbo through a conical air filter and 4 inch pipe.

#36

Teching In

Join Date: Jul 2008

Location: southeast of indy

Posts: 12

Likes: 0

Received 0 Likes

on

0 Posts

Im curious to hear other thoughts to.

#37

10 Second Club

iTrader: (2)

I'm doing a "butt mount" Holset HX50 with absoultly no scavenging pump. This is my theory; and hopefully it will work.

I've installed a 15 gallon aluminum fuel cell in my trunk and eliminated my stock gas tank. "My theory" is that if I mount the turbo high enough giving me enough downward pitch back to the bottom of the pan, then no problem.

Go ahead, Im ready for feedback (neg or pos)

I've installed a 15 gallon aluminum fuel cell in my trunk and eliminated my stock gas tank. "My theory" is that if I mount the turbo high enough giving me enough downward pitch back to the bottom of the pan, then no problem.

Go ahead, Im ready for feedback (neg or pos)

#38

Teching In

Join Date: Jul 2008

Location: southeast of indy

Posts: 12

Likes: 0

Received 0 Likes

on

0 Posts

Im thinking if I trapped the line at some point of return and installed the discharge into the side of the pan or front rather than the rear I should be ok. (I hope) Im going to mock it up with a roll of soft 3/8 aluminum tubing just to see what kind of foward pitch I can get. If Im not satisfied I just might consider a seperate oiling system, kinda like that idea.

#39

Back to the orig post, you shouldn't separate the oiling since mainly because of heat. Your oil should be no less than 160 degrees before you load the engine and turbos of course are no exception. If you separate the systems you have a very difficult time regulating heat and making sure heat is maintained and flow isn't interrupted. Also if you want a bullet proof setup go with a drysump pump system, like one sized for a rear end, single stage should be fine. Drive it off the motor and be done with it. If the motor turns the pump turns. DONE! RELIABLE! FORGET ABOUT IT! Also anything can fail anytime. Run steel lines from front to back, secure them well and nothing will happen. How many times has your exhaust system been torn off? Let me guess not one time, right? So what are your chances for your oiling lines getting torn off? Most likely none. I have been reading Zombie's posts and he right, use the K.I.S.S. method and enjoy.

#40

Now to the gravity drain post from the rear. I don't want to be a downer but I feel you will be buying some sort of scavenge pump in order to make this work. Draining from that far back will be difficult. Since it isn't a pressurized line back to the motor or a vacuum system in the engines sump(drysump) it is going to be difficult to get the oil to reliably get back to the engine sump. Of course liquids will seek level so as long as the turbo is a decent height above the oil level in the engine it technically should drain. But here is the rub, its oil and things don't always work the way you think they should. Oil doesn't flow as freely as water. As you accelerate it will back up in the line since the whole system is open to the same atmospheric pressure and you will be applying acceleration force to the mass of oil. Think of a drink in your cup holder when you accelerate. But the other side, if you think you can make it with enough fall to get to the engine and drain go for it. If it doesn't work you know you need to by a scavenge pump. One thing also you may want to look at adding an accumulation tank to handle increase oil volume if you do encounter intermittent draining issues. This may help your gravity drain system by allowing it to build volume so it doesn't back up the line as quickly if it even becomes a problem. Actually most systems should have an accumulation tank as a buffer for these kind of setups.