Discussion about turbo cams, overlap, boost and reversion

#81

I don't think Zombie is as interested in what cams work well as he is why a cam is designed a certain way.

For instance, it's easy to say, "Joe Bob has a cam that's 240/230-114, +4 and his car runs 8's." Despite the fact that this is basically worthless information since there is no frame of reference, it also isn't helpful because there is no discussion about why particular specs work or don't work.

For instance, take one aspect of cam design, say EVO. An average high performance NA engine with a reasonable E/I head flow balance will work well with an EVO around 60 deg BBDC. Now, add 30-50 psi of exhaust pressure, a compression ratio of 8.5/1, and 2x the mass in the cylinder, and which way should the EVO move, how much, and why? Just an example...

For instance, it's easy to say, "Joe Bob has a cam that's 240/230-114, +4 and his car runs 8's." Despite the fact that this is basically worthless information since there is no frame of reference, it also isn't helpful because there is no discussion about why particular specs work or don't work.

For instance, take one aspect of cam design, say EVO. An average high performance NA engine with a reasonable E/I head flow balance will work well with an EVO around 60 deg BBDC. Now, add 30-50 psi of exhaust pressure, a compression ratio of 8.5/1, and 2x the mass in the cylinder, and which way should the EVO move, how much, and why? Just an example...

#83

Most turbo cars will not be operating at or near1:1 intake to exhaust ratio.I built a 4cyl car that was 1:1 even with dual bb super badass turbo and fairly high compression it was way to slow to spool. (why don't more people monitor back pressure? just a thought)

I can see where having no overlap in a high pressure differential (3:1+) of drive pressure to supplied intake pressure (back pressure vs boost) might be beneficial by not allowing the exhaust gas to revert into the combustion chamber polluting the intake charge during overlap, but it's a very short time duration.

Starting with IVO, I believe should happen just before TDC in order to get the valve open enough to flow well as the pistons starts done the bore.

the next event would be EVC, Which I would think @.050 should happen very close if not at TDC

These two number will control your over lap. I think what we will be trying to do is get as much exhaust out with out letting too much in the intake valve and getting the intake valve ready to start moving as much air as possible in. Aggressive cam profiles will help here.

the next event is IVC I don't see a lot a reason to move this compared to a NA cam. FI or NA the goal is still to trap as much air as possible. I will say this though a late close may help keep the heads down on four bolt cars. (this would lead to a reverse split that looks a little different than what I have seen) (if your heads lift at 1000hp whats the point of a cam thats capable of getting you to 1500hp?)

Now that we have burned our fuel when do you open the exhaust valve? conventional thinking says about anywhere it won't effect power much. (thats what I've heard at least) In a turbo engine we have the problem of a high back pressure. I believe that a strong exhaust pulse will not do much good so why not a late open and try to take advantage of all of the power stoke? Yes we will have more pumping loss but either way the piston will have to go through the exhaust stroke pushing against exhaust pressure. (I don't see scavenging working effectively under pressure with manifolds or short tube headers My thought is get that valve open before btc but no sooner than you have to to get the valve open enough to flow well, get it open enough to flow well as the pistons starts up.

The more I look this the more I see that a set heads that flow well will greatly help the cam do its job. Aggressive cam profiles seem like they will help control the negatives (exhaust try to go backwards) that we are working against.

I think to spec a cam properly we would need more than at .050 duration of a cam, we need every .100. then we could look at head flow and see cross over points/ where intake and exhaust flows during over lap and get a better idea of how they would interact in the combustion chamber. we could then also better predict when to open the exhaust valve, I'm concerned what the valve is doing

TDC and BDC, We seem be guessing based on what we know about the cam profile and duration.

Interesting thread.

Vizard once wrote that turbo motor cams should "forget about the dynamics, and worry about the pressures", or something like that. His turbo cam was all about managing the pressures in the cylinder. In other words, you basically hold the intake valve closed until the piston moves down enough in the cylinder to expand the exhaust gasses down below boost pressure. This totally prevents reversion into the intake port. The result was something like 200/234-124 LSA, 10 deg retarded.

However...consider that the amount of exhaust gas remaining in the chamber is the amount you're stuck with. Whether or not it stays in the cylinder or reverses into the intake port seems irrelevant because it's all going to wind up in the cylinder anyway. The advantage to opening the intake valve early is that when flow INTO the cylinder does actually start, the valve is far open and out of the way so the restriction is minimized.

Validating this 2nd theory was INTMD8, who tested at least 4 cams in his twin turbo LTx. His conclusion was something like, "everytime I added overlap, I got more power". In all fairness I don't think he went as high as even 10 deg @ .050, but I think he did invalidate the theory that 35 deg of negative overlap is good. Furthermore, I have NEVER heard anyone say that they added overlap on a turbo car and lost power.

Mike

Vizard once wrote that turbo motor cams should "forget about the dynamics, and worry about the pressures", or something like that. His turbo cam was all about managing the pressures in the cylinder. In other words, you basically hold the intake valve closed until the piston moves down enough in the cylinder to expand the exhaust gasses down below boost pressure. This totally prevents reversion into the intake port. The result was something like 200/234-124 LSA, 10 deg retarded.

However...consider that the amount of exhaust gas remaining in the chamber is the amount you're stuck with. Whether or not it stays in the cylinder or reverses into the intake port seems irrelevant because it's all going to wind up in the cylinder anyway. The advantage to opening the intake valve early is that when flow INTO the cylinder does actually start, the valve is far open and out of the way so the restriction is minimized.

Validating this 2nd theory was INTMD8, who tested at least 4 cams in his twin turbo LTx. His conclusion was something like, "everytime I added overlap, I got more power". In all fairness I don't think he went as high as even 10 deg @ .050, but I think he did invalidate the theory that 35 deg of negative overlap is good. Furthermore, I have NEVER heard anyone say that they added overlap on a turbo car and lost power.

Mike

I think alot of what I said mimics what Mike said, but gives the reasons

I think once I have figured out target power and engine displacement I would figure out what pressure ratio I will be working with. (intake and exhaust) figure in static compression to figure out dynamic compression. use that to determine IVC. from there use this info to figure how much duration I need on the intake.

Next I'd try to figure out when to open the exhaust valve based on flow as the piston starts up the bore.

Next id get the exhaust closed @.050 at or around TDC

These are my thoughts, I love to hear people thoughts on this. I think we really need to hash out the cam selection thing. it comes up way too much, with people going all different directions and no rhyme or reason why.

Btw I have never had anyone on this board not answer my question, or at least hint or point me in the right direction, thanks to all.

Last edited by Professor_speed; 06-28-2009 at 06:25 PM.

#85

TECH Fanatic

iTrader: (10)

This thread needs to be put up top with all the other good stuff. Good reading for those that are new to FI and choosing a cam, even NA guys could learn a thing or two from reading this.

Here is some food for thought for the person who wanted a 1000hp and asked comp to spec them a cam that was something like the one below.

383 cubic inch, stroked LS6. Twin, low mounted, 54mm Precision ball bearing turbos

225cfm Trickflow heads

Cam size: 228/232 .588/.595 116 LSA

Power output: 968 rwhp / 886 ft-lbs at 16 pounds of boost

Here is some food for thought for the person who wanted a 1000hp and asked comp to spec them a cam that was something like the one below.

383 cubic inch, stroked LS6. Twin, low mounted, 54mm Precision ball bearing turbos

225cfm Trickflow heads

Cam size: 228/232 .588/.595 116 LSA

Power output: 968 rwhp / 886 ft-lbs at 16 pounds of boost

Last edited by Fb0dy0nly; 06-28-2009 at 08:31 AM.

#86

How do I change this text

iTrader: (26)

Join Date: Jan 2005

Location: Behind the TIG welder

Posts: 7,279

Likes: 0

Received 0 Likes

on

0 Posts

Mine set-up is this... 10.2:1 370 with a Budget Borg Warner, 5" down pipe. I also kept my exhaust separated to the split scroll... My cam is a SUPER baby cam at 218 214 on a 114. I have NO power before 4,000 even with 5-6 psi of boost.... My thoughts are my ivc event is too late for a stock converter. A interesting fact is the same engine with a STS GT-67 had a near 3:1 ratio. and a best of 2:1.

#87

TECH Resident

iTrader: (7)

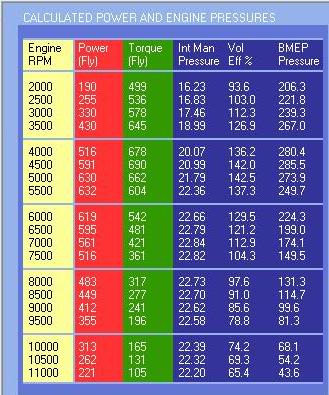

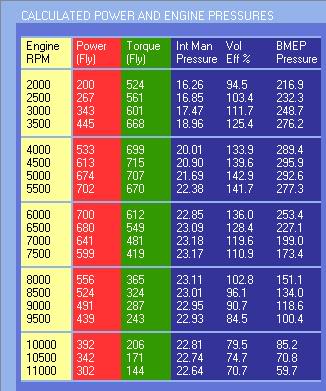

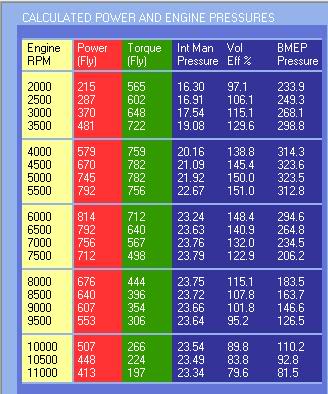

ok after reading through this i decided to do a little test to see what desktop dyno 2003 would come up with using a 370 lsx with different compression ratios and cams keeping the same heads same turbo and intercooler efficiency rating (150%)

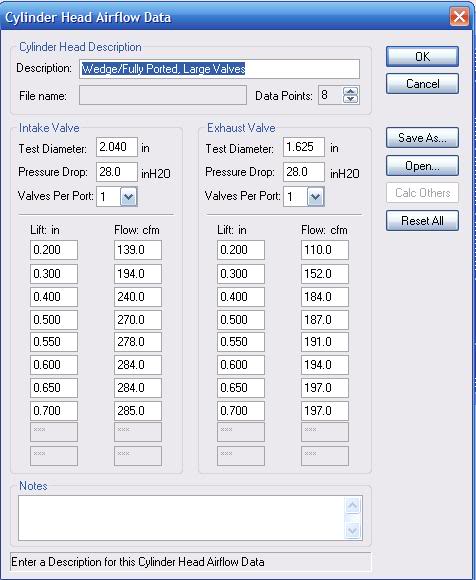

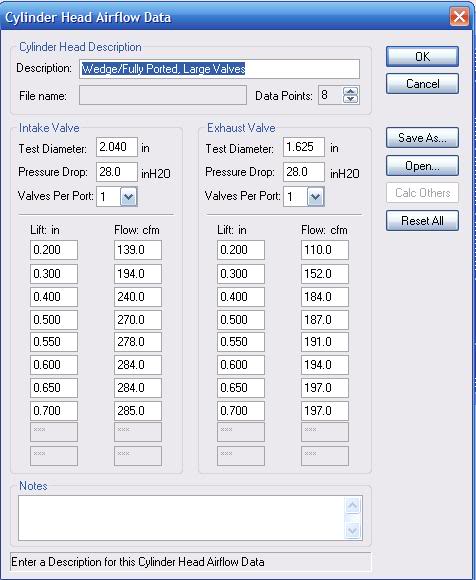

the head flow looks is like this for all tests

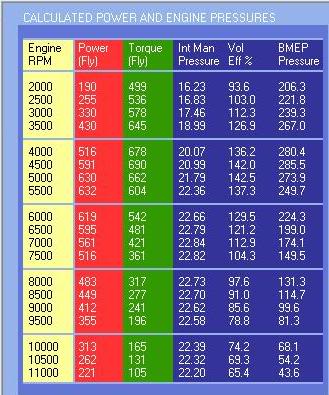

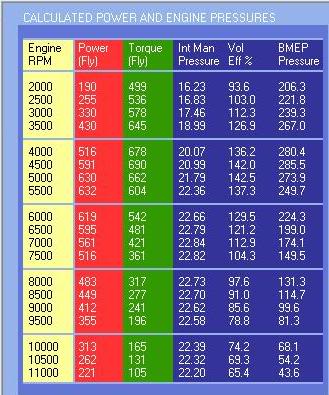

first test was 8:1 comp with speed inc 225/225 .581/.581 113lsa (632hp at 5500rpm / 690tq at 4500rpm)

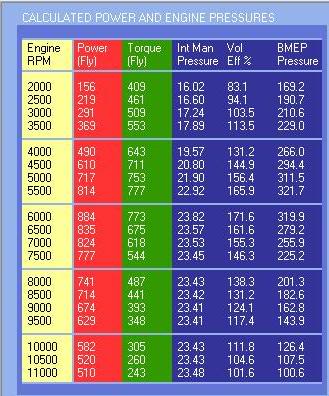

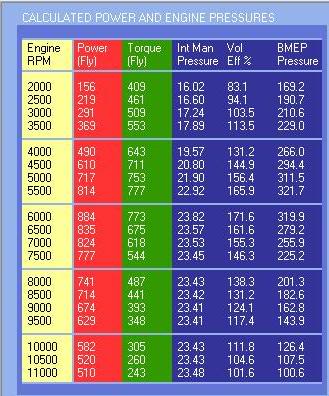

next was a custom cam (245/253 .612/.656 113lsa) same 8:1 comp (884hp at 6000rpm / 777tq at 5500rpm)

from the speed inc cam to the custom cam we picked up 252hp/87tq with nothing but a cam swap

if we use the same 2 cams and bump the compression up to 10:1 we get results like this

just by increasing the compression to 10:1 we picked up 99hp/81tq (731hp at 5500rpm /771tq at 4500rpm)

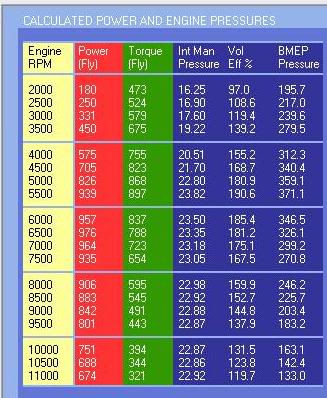

and with the custom cam we picked up 86hp/88tq ( 970hp at 6000rpm / 865tq at 5500rpm)

so with the bump of compression the tq on the speed inc cam comes to about the same as the custom cam before the compression bump now the question is would you rather have that baby cam that will idle just fine with -1* overlap with 10:1 compression and make 771tq at 4500rpm or would you like to have the custom cam that will have a hard time idling with 23* overlap with 8:1 compression that makes 777tq at 5500rpm a full 1000rpm later

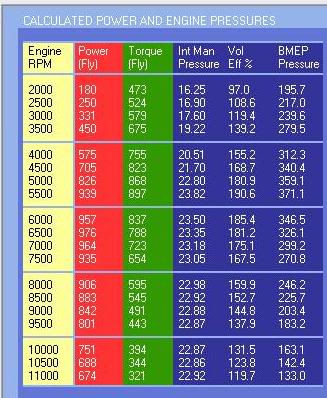

now my last test i took the same motor left the 10:1 compression ratio and came up with a new custom cam (weird i know) 229/269 .571/.624 114lsa 21*overlap and picked up another 6hp/32tq (976hp at 6500rpm / 897 at 5500rpm)

out of these 3 cams which would you "cam experts" rather run?

the head flow looks is like this for all tests

first test was 8:1 comp with speed inc 225/225 .581/.581 113lsa (632hp at 5500rpm / 690tq at 4500rpm)

next was a custom cam (245/253 .612/.656 113lsa) same 8:1 comp (884hp at 6000rpm / 777tq at 5500rpm)

from the speed inc cam to the custom cam we picked up 252hp/87tq with nothing but a cam swap

if we use the same 2 cams and bump the compression up to 10:1 we get results like this

just by increasing the compression to 10:1 we picked up 99hp/81tq (731hp at 5500rpm /771tq at 4500rpm)

and with the custom cam we picked up 86hp/88tq ( 970hp at 6000rpm / 865tq at 5500rpm)

so with the bump of compression the tq on the speed inc cam comes to about the same as the custom cam before the compression bump now the question is would you rather have that baby cam that will idle just fine with -1* overlap with 10:1 compression and make 771tq at 4500rpm or would you like to have the custom cam that will have a hard time idling with 23* overlap with 8:1 compression that makes 777tq at 5500rpm a full 1000rpm later

now my last test i took the same motor left the 10:1 compression ratio and came up with a new custom cam (weird i know) 229/269 .571/.624 114lsa 21*overlap and picked up another 6hp/32tq (976hp at 6500rpm / 897 at 5500rpm)

out of these 3 cams which would you "cam experts" rather run?

#89

TECH Resident

iTrader: (7)

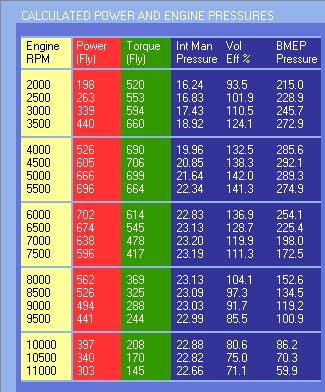

ok here is vizards specs on the same motor only change was the cam

i used these cam lobes

intake: comp cams lobe number 3473

exhaust: cam motion lobe number X-2023

200/234 .546/.612 126lsa 9* retarded

(702hp at 6000rpm / 706tq at 4500rpm)

so i did some more playing around with his specs and i found if you retard it only 8* you come out making same hp only 500rpm sooner and 9tq more at the same rpm

and if you took the above cam specs (still at 9* retarded) and bumped it to 10:1 comp you picked up another 112hp at the same rpm and 76tq at the same rpm heres the graph

#93

12 Second Truck Club

iTrader: (4)

Join Date: Nov 2004

Location: Jacksonville FL.

Posts: 6,273

Likes: 0

Received 0 Likes

on

0 Posts

i am currently in the market for a cam also. i'm trying to learn as much as i can about turbo cams before i buy. i've recieved spec's from alot of people so far any where from a striaght 214 to a striaght 228. one thing i have to note and keeps coming to mind though is a build i did on a buddy's truck. it was a extended cab silberado with a 4.3l. the motor was built and had low 8:1 compression. he wanted the truck to lope. i told him that it might not be best for the turbo, but thats what he wanted. so we went with a 224 525 on a 110lsa. heads were vortecs that were p&p'd. due to the low compression it felt about stock out of boost. but when boost cam on it ran hard!! i mean hard hard. 6psi broke the clutch into pieces. on 6psi we were walking away from a ext cab dodge ram with a bolt ons (lt, cai, 3"dual exhaust, tune) 5.7 hemi. due to fuel we had to short shift the 4.3l at 4500 rpm.

we fixed the fuel and clutch, took it to the track and it ran 103-104 mph on 14ish psi. it popped out of gear on launch so he had a very bad time. turbo was a mpt70 and i put a .84a/r housing on it. it sat on a stock set of syty manifolds. nothing like seeing a extcab v6 truck pull away from a v6 350z with a 75 shot!

back to the point. this thing loped like you wouldn't believe in a v6 and ran hard. so this is where i get confused. you have guys that run huge cams and make big power and guys that run smaller ones and make good power. i would love to learn more on this.

we fixed the fuel and clutch, took it to the track and it ran 103-104 mph on 14ish psi. it popped out of gear on launch so he had a very bad time. turbo was a mpt70 and i put a .84a/r housing on it. it sat on a stock set of syty manifolds. nothing like seeing a extcab v6 truck pull away from a v6 350z with a 75 shot!

back to the point. this thing loped like you wouldn't believe in a v6 and ran hard. so this is where i get confused. you have guys that run huge cams and make big power and guys that run smaller ones and make good power. i would love to learn more on this.

Last edited by 4.8T; 11-02-2009 at 05:42 PM.

#94

9 Second Club

iTrader: (37)

my combo is 10.3 c/r 408 etp heads..s488...3.08 gear..3960 raceweight,,ls6 intake

I asked for a cam to do this:

good driveability off idle for the street with my tight converter and 3.08 gears and 4095# street weight

dont want to shift over 6000 rpms

allow me to make 1000rwhp

under 600 lift

here are the cam specs I was given

0.006 0.050 0.200

Intake Duration - ID 283 230 147

Exhaust Duration - ED 287 234 150

Lobe Center Angle - LSA 113 113 113

Intake Centerline - ICL 112 112 112

Intake Valve opens - IVO 29.5 3 -38.5 BTDC (- indicates ATDC)

Intake Valve closes - IVC 73.5 47 5.5 ABDC

Exhaust Valve Opens - EVO 77.5 51 9 BBDC

Exhaust Valve Closes - EVC 29.5 3 -39 ATDC (- indicates BTDC)

Exhaust Centerline - ECL 114 114 114

Overlap 59 6 -77.5 degrees

i think the lift is in the .58x

I dont know why those numbers were chosen but it does what I have asked for

9.39@ 145 on 14.5 psi

I have since cleaned up my tune and went 145mph on 12psi and 147 on 14psi. I wasnt looking for the most power that could be made.....just a cam to fit my requirements

I asked for a cam to do this:

good driveability off idle for the street with my tight converter and 3.08 gears and 4095# street weight

dont want to shift over 6000 rpms

allow me to make 1000rwhp

under 600 lift

here are the cam specs I was given

0.006 0.050 0.200

Intake Duration - ID 283 230 147

Exhaust Duration - ED 287 234 150

Lobe Center Angle - LSA 113 113 113

Intake Centerline - ICL 112 112 112

Intake Valve opens - IVO 29.5 3 -38.5 BTDC (- indicates ATDC)

Intake Valve closes - IVC 73.5 47 5.5 ABDC

Exhaust Valve Opens - EVO 77.5 51 9 BBDC

Exhaust Valve Closes - EVC 29.5 3 -39 ATDC (- indicates BTDC)

Exhaust Centerline - ECL 114 114 114

Overlap 59 6 -77.5 degrees

i think the lift is in the .58x

I dont know why those numbers were chosen but it does what I have asked for

9.39@ 145 on 14.5 psi

I have since cleaned up my tune and went 145mph on 12psi and 147 on 14psi. I wasnt looking for the most power that could be made.....just a cam to fit my requirements

Last edited by cablebandit; 11-02-2009 at 08:40 PM. Reason: i cant spell

#96

FormerVendor

iTrader: (7)

Its been a while, but Im bumping this thread for data.

Ive had a little more data to add. Just data, no theory, and some of this stems from other 4 stroke turbo stuff as well, not just LSx. Take this for what its worth, and simply use my data points for your use.

Turbo technology has come a LONG way in the last 2 years. Drive pressure is important.

2:1 backpressure to manifold pressure is the most you would ever like to see, Ideally. In a dream world, 1:1 is the magical number. On the larger turbo, big turbine wheel 2JZs, Im right at 1:1 Pressure ratio, and the graphs, power, and curve prove that.

I dynoed an FI98x like Fireball had, today, and it had roughly 1.2:1 P/R at 17 psi. This was a 366, 224/224, C16, 20* advance, 10.6:1 Compression, AFR 225s, LS6 intake, thru chance driven glide. 21 psi back pressure, 16.7 psi boost. It is 1:1 at 12 psi. I can imagine Fireball was 2:1, or more, at 30+ psi, but there are a lot of things to take into consideration too- Cam, heads, intake, RPM. All play a role on that pressure ratio.

It barely makes 4 psi at 4k, under load, itll make 8 psi at 4700 under load, if you can imagine that curve.

It made roughly 750 rwhp thru the glide at that level, but shutting down at 5800, just when it starts to sing. 500 more RPM, it would have picked up another 100 hp. I have no clue where it would have gone, If I could have spun it to 8500.

A big single DOES NOT spool AT ALL like a set of smaller twins.

Higher compression helps get them lit

Spinning them higher nets faster ETs, mainly due to the fact that these turbos really need RPM, as there is no cubic inch pushing them. Its not like a single 76 behind a 346, were talking a 100mm turbo behind a 366.

They behave like supras. Really dont do much till 4k, and the curve isnt a street car curve at all.

You need to take into consideration a lot of things, and if you are doing a big HP build, you are doing to have to change, update, refine your setup. You are not going to buy a turn key 2000hp setup on the cheap

Like I Told Vee8 a few years ago, go with your best foot forward, test, see where you have issues ( Spooling, getting the car to 330, transient boost response, etc,) and then refine your package from there.

Its all about research and development, if you take the time and have the know how to do it right, you will be on a good path.

Ive got the Twin 66mm and smaller cam stuff down pat, but big turbo, small cubic inch, even big turbo, medium cubic inch is a totally different ball game.

Louis

Ive had a little more data to add. Just data, no theory, and some of this stems from other 4 stroke turbo stuff as well, not just LSx. Take this for what its worth, and simply use my data points for your use.

Turbo technology has come a LONG way in the last 2 years. Drive pressure is important.

2:1 backpressure to manifold pressure is the most you would ever like to see, Ideally. In a dream world, 1:1 is the magical number. On the larger turbo, big turbine wheel 2JZs, Im right at 1:1 Pressure ratio, and the graphs, power, and curve prove that.

I dynoed an FI98x like Fireball had, today, and it had roughly 1.2:1 P/R at 17 psi. This was a 366, 224/224, C16, 20* advance, 10.6:1 Compression, AFR 225s, LS6 intake, thru chance driven glide. 21 psi back pressure, 16.7 psi boost. It is 1:1 at 12 psi. I can imagine Fireball was 2:1, or more, at 30+ psi, but there are a lot of things to take into consideration too- Cam, heads, intake, RPM. All play a role on that pressure ratio.

It barely makes 4 psi at 4k, under load, itll make 8 psi at 4700 under load, if you can imagine that curve.

It made roughly 750 rwhp thru the glide at that level, but shutting down at 5800, just when it starts to sing. 500 more RPM, it would have picked up another 100 hp. I have no clue where it would have gone, If I could have spun it to 8500.

A big single DOES NOT spool AT ALL like a set of smaller twins.

Higher compression helps get them lit

Spinning them higher nets faster ETs, mainly due to the fact that these turbos really need RPM, as there is no cubic inch pushing them. Its not like a single 76 behind a 346, were talking a 100mm turbo behind a 366.

They behave like supras. Really dont do much till 4k, and the curve isnt a street car curve at all.

You need to take into consideration a lot of things, and if you are doing a big HP build, you are doing to have to change, update, refine your setup. You are not going to buy a turn key 2000hp setup on the cheap

Like I Told Vee8 a few years ago, go with your best foot forward, test, see where you have issues ( Spooling, getting the car to 330, transient boost response, etc,) and then refine your package from there.

Its all about research and development, if you take the time and have the know how to do it right, you will be on a good path.

Ive got the Twin 66mm and smaller cam stuff down pat, but big turbo, small cubic inch, even big turbo, medium cubic inch is a totally different ball game.

Louis

#97

TECH Fanatic

iTrader: (1)

Join Date: Jul 2006

Location: Washington DC

Posts: 1,444

Likes: 0

Received 0 Likes

on

0 Posts

i dont know if anyone saw, but theres a fairly decent article in car craft. it could be alot better, and alot more in depth, but kurt urban (427) and kenny duttweiler chimed in. ^ like you said lou, backpressure is vastly different now than it was 10-20 years ago, and LSA's are too. the trends are going away from wide lsa's to tighter ones, ie: 109, etc. though lsa isnt a part of cam design, merely a product of it, you get the point. ken or kurt mentioned the cams are looking more and more like mild N/A cams. interesting...

#99

TECH Veteran

iTrader: (17)

Join Date: Mar 2009

Location: Indy

Posts: 4,220

Likes: 0

Received 0 Likes

on

0 Posts

I dont know much of anything about valve events and overlap, and all that cam mumbo jumbo, but im learning, and its funny that the short amount of time ive been around this world, the way the data, or thought processes have changed from one extreme to another.

Its def hard to understand from a novices point of view, and i thank each and every one of the builders and designers and the guys testing stuff for your time and write ups.

Please, by all means carry on