Wsss6 - MPT70 Front Mount Build

#41

Teching In

Thread Starter

iTrader: (2)

Join Date: Jun 2008

Location: Saint Charles, MO

Posts: 44

Likes: 0

Received 0 Likes

on

0 Posts

The pipes are supporting the turbo for now, its in my near future plans to make some sort of bracket off of the holes originally used for the stock alt pulley. We'll see how far that gets.

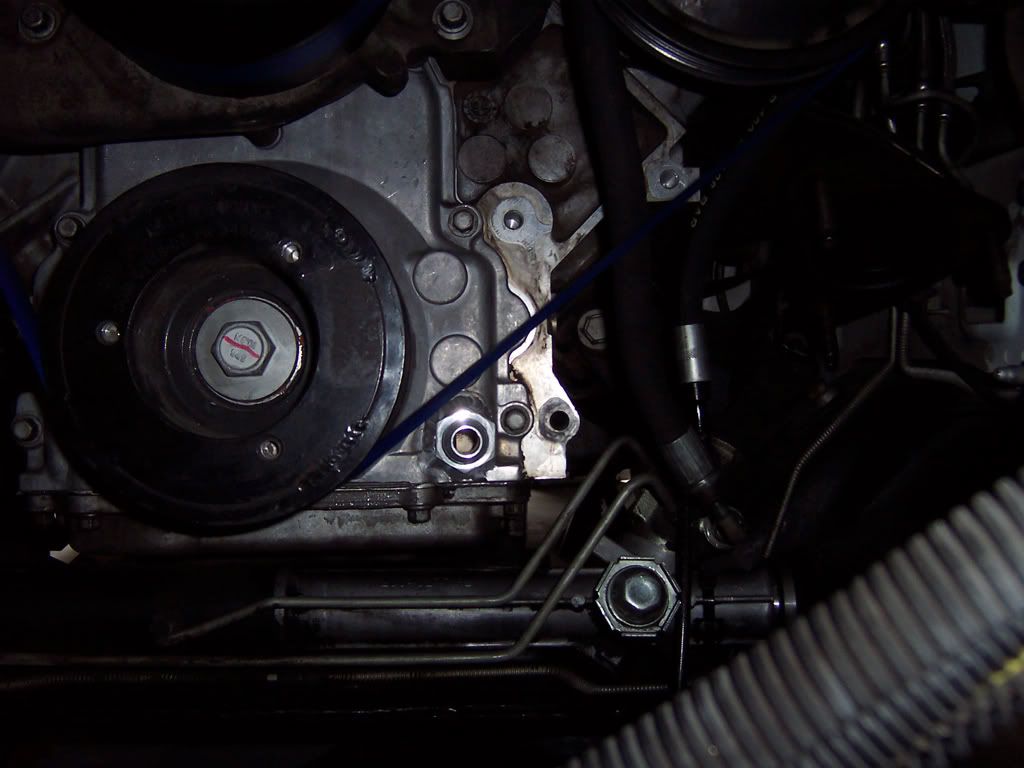

So I bought the drain system off my buddy's MR2 and started modifying it. I welded a 45 degree AN fitting on the timing cover. Has great clearance with the stock crank pulley but looks like its going to interfere with the drivers side crossover. To remedy this I'm hacked up the stock alt pulley (so the belt goes straight up when it wraps around the crank) and plan on cutting of the 45 fitting and rotating it 90 degrees so it points up.

I'm going to be out of town for a while so updates over the week may be non-existent.

I also had a problem getting the drain flange to fit onto the turbo. The flange meets up fine but I have a -10AN 90 degree fitting coming off the flange that wont fit between the compressor and turbine housings...

I think I may do some more hacking up and install 5/8 aluminum tube hard lines, maybe with an inch or so of hose in case anything flexes. Anyone ever tried this? Is it legit?

Anyway, I'm starting to get really excited. I want this thing to be finished pretty bad.

So I bought the drain system off my buddy's MR2 and started modifying it. I welded a 45 degree AN fitting on the timing cover. Has great clearance with the stock crank pulley but looks like its going to interfere with the drivers side crossover. To remedy this I'm hacked up the stock alt pulley (so the belt goes straight up when it wraps around the crank) and plan on cutting of the 45 fitting and rotating it 90 degrees so it points up.

I'm going to be out of town for a while so updates over the week may be non-existent.

I also had a problem getting the drain flange to fit onto the turbo. The flange meets up fine but I have a -10AN 90 degree fitting coming off the flange that wont fit between the compressor and turbine housings...

I think I may do some more hacking up and install 5/8 aluminum tube hard lines, maybe with an inch or so of hose in case anything flexes. Anyone ever tried this? Is it legit?

Anyway, I'm starting to get really excited. I want this thing to be finished pretty bad.

#42

Teching In

Thread Starter

iTrader: (2)

Join Date: Jun 2008

Location: Saint Charles, MO

Posts: 44

Likes: 0

Received 0 Likes

on

0 Posts

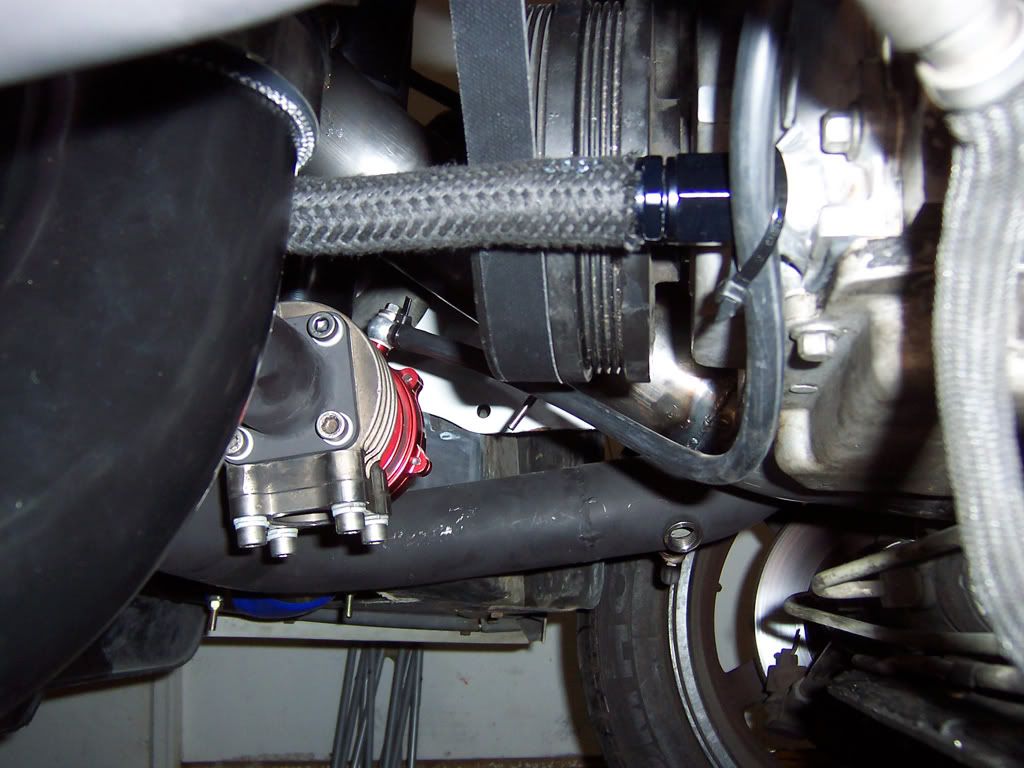

I redid the oil drain into the timing cover and the drain flange on the turbo. Space was tight everywhere so I had to get creative.

I couldn't put the 45 degree AN fitting on there to point straight up without hitting the crank pulley so I compromised. This time I just tacked it on so if it still doesn't work I'll cut it off, put it on straight up, and cough up the cash for an underdrive pulley.

The problem with the drain flange on the turbo was that the -10 90 degree fitting was too big just about everywhere, and it was especially too tall. Easy fix I guess.

I also got the cold pipes from the turbo to intercooler done but for some reason (probably because it was after midnight and I was a walking zombie) I forgot to take a picture. I plan on everything being welded that can be, and only using silicone couplers where I need them. I'll try and get pictures of those up later.

I couldn't put the 45 degree AN fitting on there to point straight up without hitting the crank pulley so I compromised. This time I just tacked it on so if it still doesn't work I'll cut it off, put it on straight up, and cough up the cash for an underdrive pulley.

The problem with the drain flange on the turbo was that the -10 90 degree fitting was too big just about everywhere, and it was especially too tall. Easy fix I guess.

I also got the cold pipes from the turbo to intercooler done but for some reason (probably because it was after midnight and I was a walking zombie) I forgot to take a picture. I plan on everything being welded that can be, and only using silicone couplers where I need them. I'll try and get pictures of those up later.

#43

Teching In

Thread Starter

iTrader: (2)

Join Date: Jun 2008

Location: Saint Charles, MO

Posts: 44

Likes: 0

Received 0 Likes

on

0 Posts

Got a picture of the cold side from turbo to intercooler. The intercooler to throttle body side is mocked up and marked but not welded yet, probably get to that tomorrow afternoon. I feel good now that all my piping is done but I still have a lot of little things to work out.

1) Need to make new power steering lines

2) Oil return is still not working out, not sure yet what I'm going to do

3) Re-install cooling system and figure out what to do about the upper radiator hose

4) Fab exhaust to connect downpipe to catback

5) Install new injectors

I got really pissed off tonight when I went to put on the t clamps that came with the ebay intercooler kit; they're too small!!! Did anyone else have this problem? I tried all sorts of things but I can't figure it out. I doubt the company I got them from has any sort of worth while customer service and I really doubt they would send me bigger clamps but I guess I can try. If you have any good input please enlighten me.

Anyway...

1) Need to make new power steering lines

2) Oil return is still not working out, not sure yet what I'm going to do

3) Re-install cooling system and figure out what to do about the upper radiator hose

4) Fab exhaust to connect downpipe to catback

5) Install new injectors

I got really pissed off tonight when I went to put on the t clamps that came with the ebay intercooler kit; they're too small!!! Did anyone else have this problem? I tried all sorts of things but I can't figure it out. I doubt the company I got them from has any sort of worth while customer service and I really doubt they would send me bigger clamps but I guess I can try. If you have any good input please enlighten me.

Anyway...

#47

TECH Fanatic

iTrader: (19)

Join Date: Sep 2007

Location: houston TX

Posts: 1,497

Likes: 0

Received 0 Likes

on

0 Posts

the general concensus of the ebay kits seems to be they really dont work and you need new clamps. Frost posted in another thread (concerning the exact same problem ) that there is no standard sizes of clamps, t or vband.

#48

12 Second Club

iTrader: (91)

That statement was referring to the width or where the flanges sit. The t-bands should fit fine. Try totally unbolting them then wrapping it over the pipe. All mine fit great and i have some extra if you need them. Kits coming along great! I'm waiting on v-bands to finish mine.

#50

Teching In

Thread Starter

iTrader: (2)

Join Date: Jun 2008

Location: Saint Charles, MO

Posts: 44

Likes: 0

Received 0 Likes

on

0 Posts

I tried unbolting them and wrapping it over the pipe, I had a buddy and myself both squeezing and we weren't even close. He found a stamp on the clamp that reads "2.25". What a bunch of bastards sending me tiny clamps. Oh well, I bought new ones. I think I've sorted out just about all my current problems, I need this thing to be done so I can drive home for winter break, lol. We'll see if I can make it.

To answer the question about the tig welder, its a square waves tig 175 pro. I only did a small amount of welding on this so far and it was all on pieces that won't be visible, for all the nice stuff I've had my buddy Doug do it.

To answer the question about the tig welder, its a square waves tig 175 pro. I only did a small amount of welding on this so far and it was all on pieces that won't be visible, for all the nice stuff I've had my buddy Doug do it.

#52

Teching In

Thread Starter

iTrader: (2)

Join Date: Jun 2008

Location: Saint Charles, MO

Posts: 44

Likes: 0

Received 0 Likes

on

0 Posts

In response to KnightmareLS1, sure thing man. I'm pretty sure you'll smoke the crap out me though. I've been wanting to learn how to (putting on flame suit) drift more than anything, just seems more interesting from a driving perspective than drag racing anything in my budget right now. I've got some plans for next semester that include safety and suspension pieces.

Anywho, I've got all my piping done now, here's some pictures of the progress.

The blow off valve I'm using is an oem Toyota unit, and I've got two reasons for it. First, its designed to be closed at idle and I like that. Second, it was $30.

I scrapped the idea of using braided line for the return, I'm sick of messing with it. I chose instead to use aluminum hard line. The ID of the pipe is the equivelant of -12 or so. Its got better clearance with the crank pulley and the cross over pipe it goes over, though its still very close. I haven't finished it yet, I'll post up pictures when I'm done.

Anywho, I've got all my piping done now, here's some pictures of the progress.

The blow off valve I'm using is an oem Toyota unit, and I've got two reasons for it. First, its designed to be closed at idle and I like that. Second, it was $30.

I scrapped the idea of using braided line for the return, I'm sick of messing with it. I chose instead to use aluminum hard line. The ID of the pipe is the equivelant of -12 or so. Its got better clearance with the crank pulley and the cross over pipe it goes over, though its still very close. I haven't finished it yet, I'll post up pictures when I'm done.

#54

Teching In

Thread Starter

iTrader: (2)

Join Date: Jun 2008

Location: Saint Charles, MO

Posts: 44

Likes: 0

Received 0 Likes

on

0 Posts

The intercooler is that standard ebay unit. Maybe it looks bigger because I'm using 2.5 inch piping instead of 3 inch that most people seem to use. Dunno.

The oil drain is really irritating me. I checked all my clearances but I guess something moved during welding because now it contacts the crank pulley. Its very close, like if the crank pulley was 1/4 inch smaller I would have almost 1/4 inch of clearance, but its definitely touching. I know this is a no go and I'm not sure what to do. This is the only part of the project holding me up and it seems like its been kicking my *** forever. I could get an underdrive pulley and call it good, but I think a cheaper alternative would be to plug the hole in my timing cover and put the drain in the side of my oil pan.

Let me know your thoughts on it.

The oil drain is really irritating me. I checked all my clearances but I guess something moved during welding because now it contacts the crank pulley. Its very close, like if the crank pulley was 1/4 inch smaller I would have almost 1/4 inch of clearance, but its definitely touching. I know this is a no go and I'm not sure what to do. This is the only part of the project holding me up and it seems like its been kicking my *** forever. I could get an underdrive pulley and call it good, but I think a cheaper alternative would be to plug the hole in my timing cover and put the drain in the side of my oil pan.

Let me know your thoughts on it.

#56

11 Second Club

iTrader: (43)

The intercooler is that standard ebay unit. Maybe it looks bigger because I'm using 2.5 inch piping instead of 3 inch that most people seem to use. Dunno.

The oil drain is really irritating me. I checked all my clearances but I guess something moved during welding because now it contacts the crank pulley. Its very close, like if the crank pulley was 1/4 inch smaller I would have almost 1/4 inch of clearance, but its definitely touching. I know this is a no go and I'm not sure what to do. This is the only part of the project holding me up and it seems like its been kicking my *** forever. I could get an underdrive pulley and call it good, but I think a cheaper alternative would be to plug the hole in my timing cover and put the drain in the side of my oil pan.

Let me know your thoughts on it.

The oil drain is really irritating me. I checked all my clearances but I guess something moved during welding because now it contacts the crank pulley. Its very close, like if the crank pulley was 1/4 inch smaller I would have almost 1/4 inch of clearance, but its definitely touching. I know this is a no go and I'm not sure what to do. This is the only part of the project holding me up and it seems like its been kicking my *** forever. I could get an underdrive pulley and call it good, but I think a cheaper alternative would be to plug the hole in my timing cover and put the drain in the side of my oil pan.

Let me know your thoughts on it.

I wish I had a friend named Doug who could weld like that....

Who's the manufacturer of the tig welder?

#57

Teching In

Thread Starter

iTrader: (2)

Join Date: Jun 2008

Location: Saint Charles, MO

Posts: 44

Likes: 0

Received 0 Likes

on

0 Posts

I'll try and get up some pictures of what I had for the drain before I go berserk with a cut off wheel. I'm afraid that if I try and dent it I'll bend/dent the tube and then when I go to bolt it onto the turbo it either won't or it'll put the tube in a situation where its in constant stress. I lost a lot of sleep last night thinking about it and I think I'll just scrap the idea. Is it possible to have a hard line going to the timing cover with a stock pulley? Yep. Is it worth my time to try and figure it out? I don't think so. Its depressing when you put in so much time and don't get to see any results. At lease if I plug the hole and go into my oil pan I can put everything back together in the engine bay and not have to worry about that anymore. There's still a lot of little things to work on while I'm waiting on some new fittings to show up...

To 98Camarod: The tig welder is a Lincoln Electric unit. Doug is pretty much a bad *** when it comes to sticking two pieces of metal together. I'll owe him some work when he gets around to putting his car back together.

To 98Camarod: The tig welder is a Lincoln Electric unit. Doug is pretty much a bad *** when it comes to sticking two pieces of metal together. I'll owe him some work when he gets around to putting his car back together.

WhenI comehome on R&R we should run em

WhenI comehome on R&R we should run em