NXS Spring Loaded Manual Boost Controller Question

#21

TECH Addict

iTrader: (2)

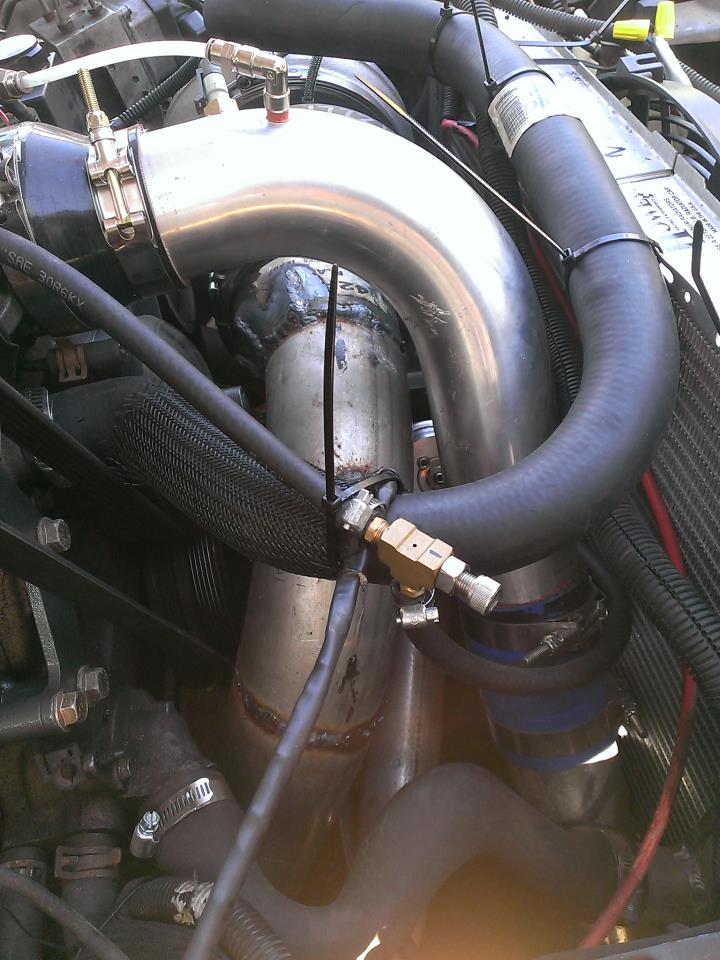

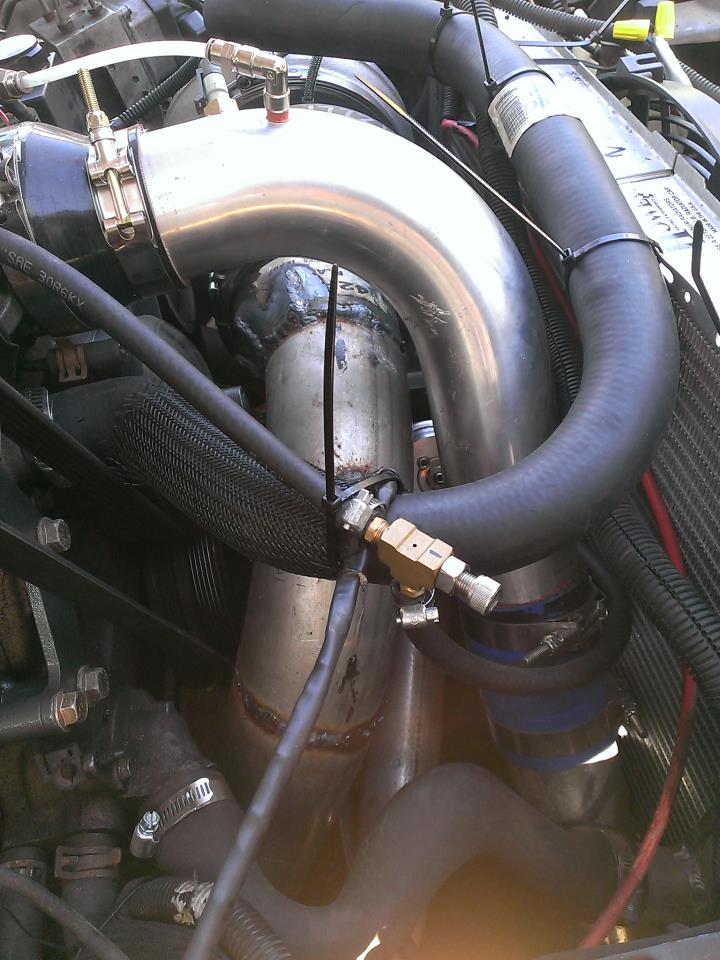

and done lol its retarded simple lol i just couldnt wrap my head around how simple it really is to hook up lol after all the other complicated crap ive done to get this rear mounted turbo setup going, i thought this would be just another thing that would be a PITA lol

#24

10 Second Club

iTrader: (33)

If not using a controller, bottom line hooked up with make wg spring boost, both top and bottom hooked up will make around double the spring, no lines hooked up at all to wg, will make around double the spring. If you run a MBC on bottom with nothing on top, and you max it out, it'll make around double the spring again.

#25

TECH Addict

iTrader: (6)

did some digging around yesterday and it seems using the top can really load up the wastegate. A company called Perrin has a dual controller set up where you can get 30 psi out of a 5 psi spring using their controller with one controller on top and one on the bottom. Never really looked into it, we just always used the bottom port.

#27

TECH Addict

iTrader: (2)

had a question on where to place the MBC on a rear mount.. do I have it as close to the turbo as possible or close to the intake manifold or does it even matter? Since rear mounts need little more attention to detail on where you place things, was wondering if this did too.

#28

TECH Veteran

iTrader: (17)

Join Date: Mar 2009

Location: Indy

Posts: 4,220

Likes: 0

Received 0 Likes

on

0 Posts

had a question on where to place the MBC on a rear mount.. do I have it as close to the turbo as possible or close to the intake manifold or does it even matter? Since rear mounts need little more attention to detail on where you place things, was wondering if this did too.

I would...

1.,,run MBC from source off compressor...

2... Put it in cabin... Small lines do not take long to fill.

3. Use a rigid line.

4.. Have fine.

You run intake to bottom port and air source (compressor) to top of gate...

#29

TECH Addict

iTrader: (6)

Not sure what you are saying but the way I have always hooked them up is intake to one side and wastegate to the other. Never heard of hooking intake to one side and compressor to the other. But I always hope to learn something new. I disagree with running off the compressor as you want the final boost to be intake boost, not what it is after intercooler and any restrictions. Rigid line is awesome. The push to connect stuff is awesome.

#30

TECH Veteran

iTrader: (17)

Join Date: Mar 2009

Location: Indy

Posts: 4,220

Likes: 0

Received 0 Likes

on

0 Posts

Not sure what you are saying but the way I have always hooked them up is intake to one side and wastegate to the other. Never heard of hooking intake to one side and compressor to the other. But I always hope to learn something new. I disagree with running off the compressor as you want the final boost to be intake boost, not what it is after intercooler and any restrictions. Rigid line is awesome. The push to connect stuff is awesome.

Think of it like CO2... Especially, on a rearmount, there will be a pressure drop through the system, IE< the compressor will have more "boost" then the intake... Atleast from what i've seen on street style cars, there will be a pressure drop.

So consider the compressor, a mile away, the co2 source... IE, it takes more pressure on top of the gate the manifold plus spring to keep it closed.

so, you run the compressor, which is farther away and will most likely read higher, to the top of the gate, with a bleeder (boost controller) to add pressure to the top of the gate to keep it closed. This will allow higher then "spring" pressure...

Im a little drunk so i hope i explained that well.

yes, i agree on the push-to-lock stuff, its all over my car, i love it! and its cheap

#31

TECH Addict

iTrader: (6)

I admit that my experience with manuals is less than with electronic as the cars I tuned the most were Subarus with EBCS from the factory, but we always just ran a line from intake to BCS to the bottom port. When we tried using the top port it always seemed to boost too high if a spring was used on the wastegate that was close to desired boot. Have you found this to be true?

#32

TECH Veteran

iTrader: (17)

Join Date: Mar 2009

Location: Indy

Posts: 4,220

Likes: 0

Received 0 Likes

on

0 Posts

Not real sure, as i've always hooked them up per instructions i had at the time and just done it that way since.

The manifold to the bottom port and added pressure to the top port, i've not seen it done other ways. Unless someone is using a real light spring in the bottom and only using Co2 to control the boost pressure desired.

EDIT" Remmeber, every system is different, and a system on 2:1 backpressure with a "14lb" spring might only make 7lbs of boost in the manifold and a 1:1 system with the same spring might make the desired and rated "14lbs" of boost.

So in a situation where you wanna control boost really low, or overcome higher back pressure, or head loss, you would add pressure to the top of the gate to make more or less or control the advance.

The manifold to the bottom port and added pressure to the top port, i've not seen it done other ways. Unless someone is using a real light spring in the bottom and only using Co2 to control the boost pressure desired.

EDIT" Remmeber, every system is different, and a system on 2:1 backpressure with a "14lb" spring might only make 7lbs of boost in the manifold and a 1:1 system with the same spring might make the desired and rated "14lbs" of boost.

So in a situation where you wanna control boost really low, or overcome higher back pressure, or head loss, you would add pressure to the top of the gate to make more or less or control the advance.

#33

9 Second Club

I admit that my experience with manuals is less than with electronic as the cars I tuned the most were Subarus with EBCS from the factory, but we always just ran a line from intake to BCS to the bottom port. When we tried using the top port it always seemed to boost too high if a spring was used on the wastegate that was close to desired boot. Have you found this to be true?

There are multiple ways to configure boost plumbing, to achieve different things and to accommodate different setups.

You need to understand why you'd use the various plumbing methods in order for them to do what you would expect.

Applying boost to the top port of the gate ( ie helping to blow the gate shut + spring ) would always yield much higher boost pressure than base spring, unless EGBP was astronomically high. Which is usually fairly rare.

So yes what you describe would be true...because it's exactly what you'd expect from that method.

Unless intending to run lots of boost or you expected insane EGBP at lower boosts, you wouldnt really choose that method though.

Or unless you wanted to use a very very light spring, and rely on the boost signal to keep the gate shut instead of the spring.

With a rear mount, given the potentially long pipe runs involved...I'd only use an EBC. They just give more flexibility and versatility over control, and a basic one is pretty cheap.

#35

9 Second Club

The best bit about using a solenoid or solenoids and electronic control.

You can just as easily use both top and/or bottom port if needed. So best of both worlds.

Keep it simple and just use bottom port

Confuse a little and only use top port.

Mix it up for a wider range of control, and use both ports. You've the low boost level of using bottom only and high boost level of using top port only, or anything in between.

Or some controllers will let you have independent control over both ports for even more flexibility, usually requiring one solenoid per chamber.

And no, you dont need CO2 for any of that, but I guess using a form of high pressure air does add more options again.

But on top of that, not all controllers are the same. Some are just basic open loop, no feedback control, others have full feedback control and boost targeting.. And some even within those modes are just better than others.

Just depends what you need of any controller to do. If it's just a simple boost level, with some adjustability, then yes a cheap mechanical bleed setup can work well for many applications. The further you want to deviate from that, or from base spring pressure, is where the electronic controllers make life easier.

Plus the fact they're so easy to adjust from the cabin.

You can just as easily use both top and/or bottom port if needed. So best of both worlds.

Keep it simple and just use bottom port

Confuse a little and only use top port.

Mix it up for a wider range of control, and use both ports. You've the low boost level of using bottom only and high boost level of using top port only, or anything in between.

Or some controllers will let you have independent control over both ports for even more flexibility, usually requiring one solenoid per chamber.

And no, you dont need CO2 for any of that, but I guess using a form of high pressure air does add more options again.

But on top of that, not all controllers are the same. Some are just basic open loop, no feedback control, others have full feedback control and boost targeting.. And some even within those modes are just better than others.

Just depends what you need of any controller to do. If it's just a simple boost level, with some adjustability, then yes a cheap mechanical bleed setup can work well for many applications. The further you want to deviate from that, or from base spring pressure, is where the electronic controllers make life easier.

Plus the fact they're so easy to adjust from the cabin.

#36

TECH Resident

iTrader: (2)

Join Date: Jun 2013

Location: Wichita, KS

Posts: 755

Likes: 0

Received 0 Likes

on

0 Posts

coming out of the intake manifold, into the bottom of the boost controller, **** up, then coming out of the side, to the bottom port on an external gate.

the spring pushes down on a ceramic ball, and that adds artificial pressure to your wastegate spring basically limiting the boost it sees, before opening.

when you crank in your boost goes up. these do work great we use them on everything.

the spring pushes down on a ceramic ball, and that adds artificial pressure to your wastegate spring basically limiting the boost it sees, before opening.

when you crank in your boost goes up. these do work great we use them on everything.