Out of curiousity why does everyone use 2.5" on the crossover pipe

#201

Just general thinking here, no specifics.....It's too easy to get caught up in conventional N/A thinking when doing the piping on a turbo. You HAVE to run smaller pipe on the hot side of the turbo. A turbine operates by pressure differential. You make it small on one end and big on the other (outlet). Reason being is not just velocity but also to keep the heat in the gas. The exhaust gas expands as it cools so you want that cooling to happen on its way through the outlet of the turbine which is why a big honkin' pipe on the actual exhaust is good on a turbo car. That's what gives you the spool. The higher the difference in pressure before the inlet and outlet (hot gas little pipe, cooing gas big pipe), the harder it's going to blow through that turbine and spin it. That effect also aids in PULLING the exhaust out of the engine because the higher the velocity of the gas pulse, the bigger the vacuum pulse is behind it that is yanking the next pulse along with it. At a certain point the bigger the hot side pipe, the more chance there is for the exhaust gas that you want driving your turbine to loose energy by loosing heat, pressure, and velocity. Yeah yeah yeah backpressure and what not but don't forget the cold side is generating vacuum to yank the hot side out which isn't there in near the capacity in a N/A setup.

The reason you have to go bigger on a N/A car with higher power is that the gas starts cooling and expanding as soon as it leaves the head so you've got to give it some place to go. Problem with a street car is tuning it correctly to operate acceptably at a wide operation range rather than do good in one spot while being a bitch at another. The problem all of us have is thinking we know more than the experts. Ha ha.

The reason you have to go bigger on a N/A car with higher power is that the gas starts cooling and expanding as soon as it leaves the head so you've got to give it some place to go. Problem with a street car is tuning it correctly to operate acceptably at a wide operation range rather than do good in one spot while being a bitch at another. The problem all of us have is thinking we know more than the experts. Ha ha.

#203

TECH Resident

Join Date: Oct 2009

Location: Michigan

Posts: 793

Likes: 0

Received 0 Likes

on

0 Posts

SSellers, et al:

Interestingly, if you read up on Bernoulli's principle and the venturi effect, you will see that these things are not necessarily as you have described them here... Throw in the ideal gas law, and it gets really complicated (opposite of one thing you mentioned, SSellers).

I wonder how often it might be that the reason there is lower pressure in the hot side piping with smaller tubes is simply due to Bernoulli's principle alone, and possibly the addition of the higher flowing turbine housing just adds to the effect?....

Just thinking out loud about this complex topic. Maybe some of the actual engineers on here and the OP will chime back in about some of this stuff.

Interestingly, if you read up on Bernoulli's principle and the venturi effect, you will see that these things are not necessarily as you have described them here... Throw in the ideal gas law, and it gets really complicated (opposite of one thing you mentioned, SSellers).

I wonder how often it might be that the reason there is lower pressure in the hot side piping with smaller tubes is simply due to Bernoulli's principle alone, and possibly the addition of the higher flowing turbine housing just adds to the effect?....

Just thinking out loud about this complex topic. Maybe some of the actual engineers on here and the OP will chime back in about some of this stuff.

#204

Just general thinking here, no specifics.....It's too easy to get caught up in conventional N/A thinking when doing the piping on a turbo. You HAVE to run smaller pipe on the hot side of the turbo. A turbine operates by pressure differential. You make it small on one end and big on the other (outlet). Reason being is not just velocity but also to keep the heat in the gas. The exhaust gas expands as it cools so you want that cooling to happen on its way through the outlet of the turbine which is why a big honkin' pipe on the actual exhaust is good on a turbo car. That's what gives you the spool. The higher the difference in pressure before the inlet and outlet (hot gas little pipe, cooing gas big pipe), the harder it's going to blow through that turbine and spin it. That effect also aids in PULLING the exhaust out of the engine because the higher the velocity of the gas pulse, the bigger the vacuum pulse is behind it that is yanking the next pulse along with it. At a certain point the bigger the hot side pipe, the more chance there is for the exhaust gas that you want driving your turbine to loose energy by loosing heat, pressure, and velocity. Yeah yeah yeah backpressure and what not but don't forget the cold side is generating vacuum to yank the hot side out which isn't there in near the capacity in a N/A setup.

The reason you have to go bigger on a N/A car with higher power is that the gas starts cooling and expanding as soon as it leaves the head so you've got to give it some place to go. Problem with a street car is tuning it correctly to operate acceptably at a wide operation range rather than do good in one spot while being a bitch at another. The problem all of us have is thinking we know more than the experts. Ha ha.

The reason you have to go bigger on a N/A car with higher power is that the gas starts cooling and expanding as soon as it leaves the head so you've got to give it some place to go. Problem with a street car is tuning it correctly to operate acceptably at a wide operation range rather than do good in one spot while being a bitch at another. The problem all of us have is thinking we know more than the experts. Ha ha.

#209

9 Second Club

iTrader: (22)

Join Date: Mar 2008

Location: Lancaster,Pa.

Posts: 777

Likes: 0

Received 0 Likes

on

0 Posts

This is a new project. Sold the T/A and am putting together a 99 s10 with a 5.3 and a little tc76. Just want something fun for the street. Would love to have a low 10, high 9 second street truck..... And no that ET/MPH wasn't enough for me, but apparently it was enough or my 402

#210

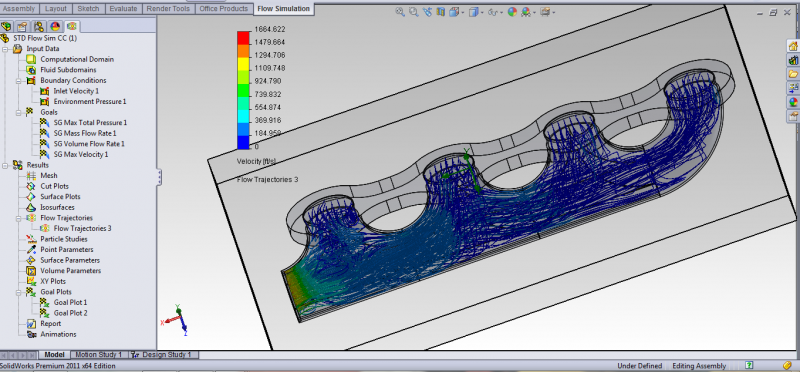

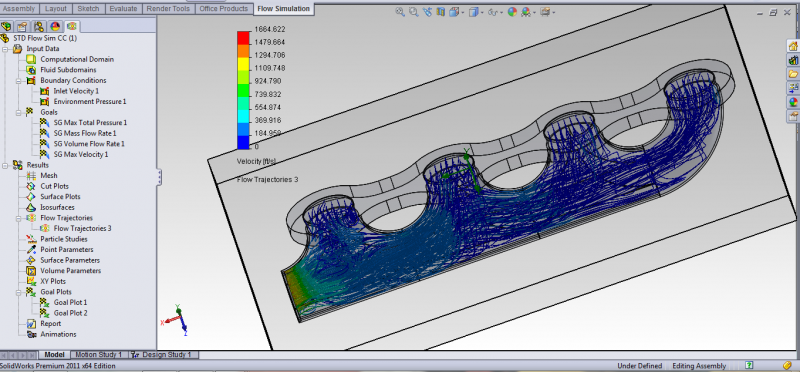

Hey guys great information here, really appreciate it! Putting a 5.3 with 76mm turbo in my MKIII Supra and and working on headers. So I did a Solidworks design and used some of Pill99Vettes numbers from the first page to do a flow simulation. The manifolds will be log style due to my tight quarters and wanting to keep all the accessories low and headers high. Also the truck headers are heavy as ****! These will weigh about 7lbs each and do the job for 650rwhp. I am using 1 1/2" SCH 5 304 which are 1.9 OD, 1.77 ID. Anyways using Phil's 300fps at the header, flow simulation says I will have about 950fps at the exit of my manifolds. I am going with a 2" cross over so the setup should spool like crazy. Anyways here is a picture of the simulation:

With all that said this does not take into account valve timing or anything else.

Thanks again,

Seth

With all that said this does not take into account valve timing or anything else.

Thanks again,

Seth

#212

Hey Mike, I probably should have looked that before! lol Anyways it says 734fps with 1 and 3 and 772fps from 2 and 4. Not really sure what all this is determining for me but it is fun! Only one way to find out if it will do the job, run it!

Seth

Seth

#213

I wonder how much power a 2 inch crossover will support on a 5.3L? At what point do you have to go larger? Or is it more due to engine size then power output when sizing the crossover?

Hope that makes sense.

Hope that makes sense.

#216

Seth

#218

Curious. I plan to toss a 5.3 in my '68 LeMans A-body using truck manifolds and a GT45 turbo. Would it be ideal to:

Reduce the natural 2.5" diameter of the pipe (after cutting off the factory flanges) to 2" on both sides

Make the crossover pipe reduce into 2" and run it to the 2-1 merge

Have it all run to a 3" outlet, 2" inlet merge to the T4 Flange with a roughly 3" hole

What is the ideal intercooler size and piping to support 800whp on Ethanol?

Reduce the natural 2.5" diameter of the pipe (after cutting off the factory flanges) to 2" on both sides

Make the crossover pipe reduce into 2" and run it to the 2-1 merge

Have it all run to a 3" outlet, 2" inlet merge to the T4 Flange with a roughly 3" hole

What is the ideal intercooler size and piping to support 800whp on Ethanol?

#219

8 Second Club

iTrader: (4)

What is the benefit of reducing the entire hotside and crossover piping diameter VS just dropping the diameter down at the turbo flange?

Assuming we are dealing with an automatic drag car and building boost on the line, is there any benefit to running smaller piping the entire length form the manifolds to the turbo flange?

Why wouldn’t necking the piping down at the turbo flange itself provide the same velocity into the turbo?

Assuming we are dealing with an automatic drag car and building boost on the line, is there any benefit to running smaller piping the entire length form the manifolds to the turbo flange?

Why wouldn’t necking the piping down at the turbo flange itself provide the same velocity into the turbo?