Quick turbo question

#1

On The Tree

Thread Starter

iTrader: (9)

Join Date: Sep 2012

Location: Rio Rancho, NM

Posts: 185

Likes: 0

Received 0 Likes

on

0 Posts

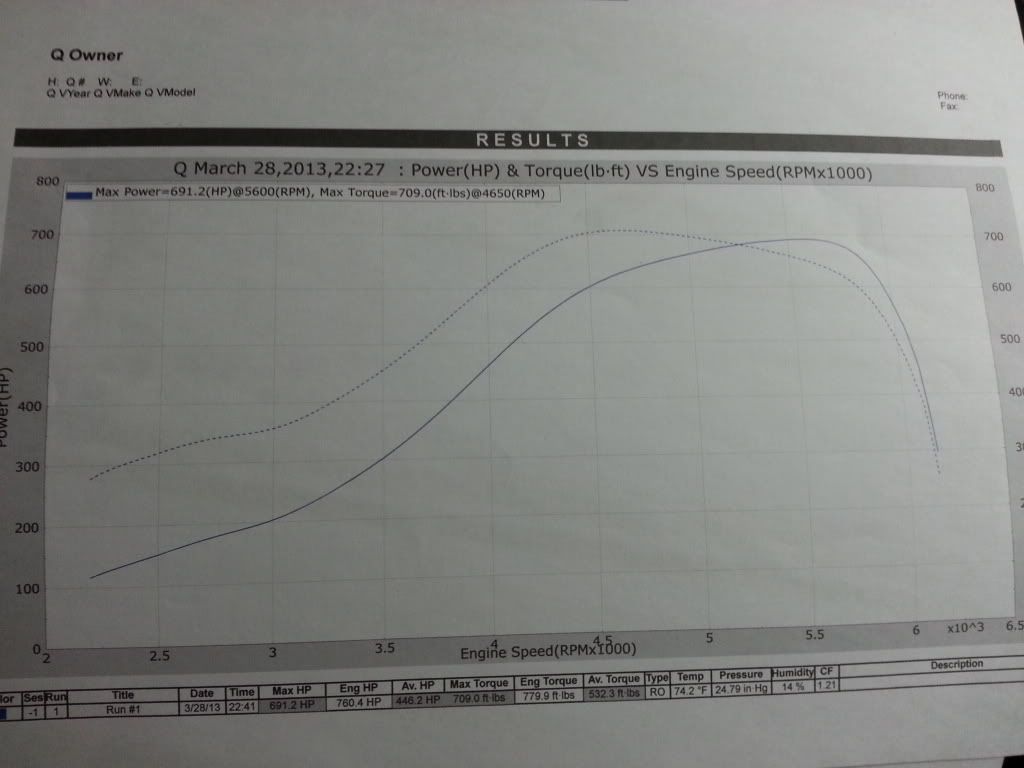

Does this dyno chart look like possible back pressure issue or maybe valve float?

LM33 aluminum 5.3 with custom spec'd turbo cam stock 799 heads ls7 lifters hardened pushrods and crane dual springs ( no idea how old they are ), ls6 intake. Turbo is precision gts 7675 with .81 ar. Car was T56 car before but I swapped in a TH400 with 3500 converter. This is 15lbs on chassis dyno car losses 50+ horse power after 5600 rpm. Could it be valve float or too much back pressure due to super small .81 at housing. I talked with precision and they offer the .96 ar housing for $229. Goal was 800ish corrected wrhp( 675ish at sea wrhp ).

Any help would be great.

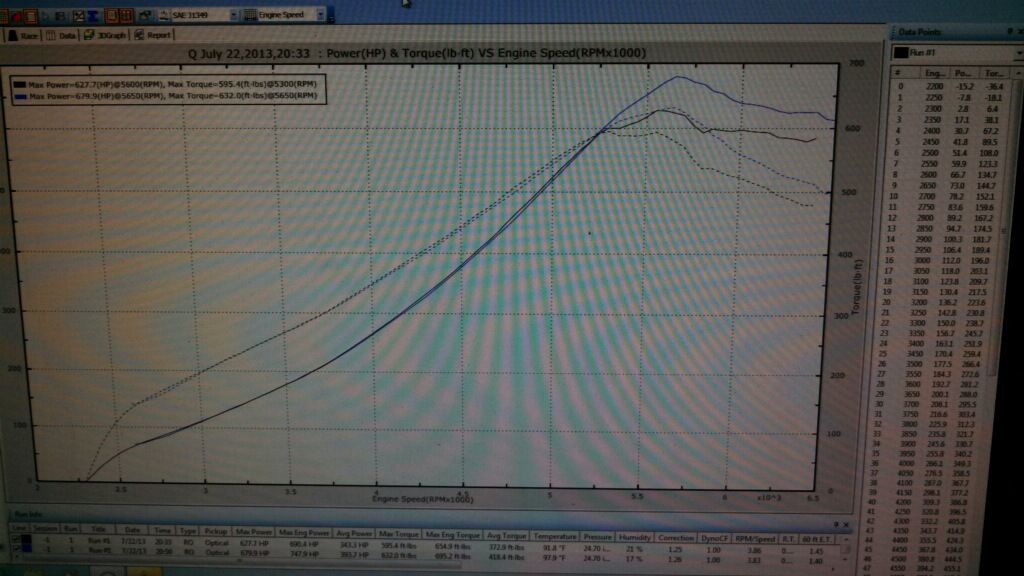

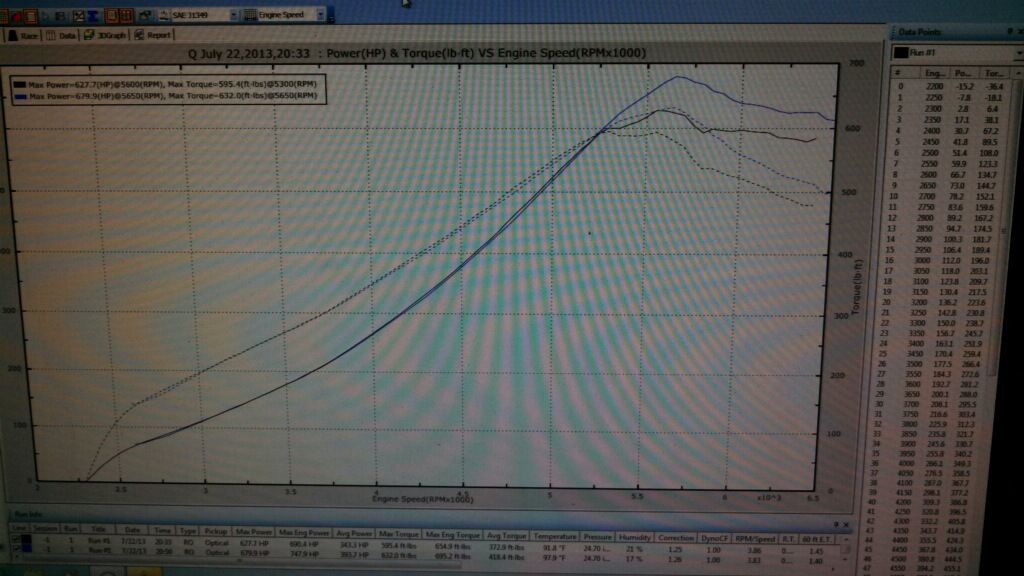

this is a before and after timing adjustment, tuner said at 11-12 lbs power doesn't drop off in the upper rpms.

LM33 aluminum 5.3 with custom spec'd turbo cam stock 799 heads ls7 lifters hardened pushrods and crane dual springs ( no idea how old they are ), ls6 intake. Turbo is precision gts 7675 with .81 ar. Car was T56 car before but I swapped in a TH400 with 3500 converter. This is 15lbs on chassis dyno car losses 50+ horse power after 5600 rpm. Could it be valve float or too much back pressure due to super small .81 at housing. I talked with precision and they offer the .96 ar housing for $229. Goal was 800ish corrected wrhp( 675ish at sea wrhp ).

Any help would be great.

this is a before and after timing adjustment, tuner said at 11-12 lbs power doesn't drop off in the upper rpms.

#2

TECH Veteran

iTrader: (11)

That is a small housing, but I wouldn't think you would see back pressure issues at only 15 psi.

Can you pull one of the springs off and get it checked for seat and open pressure

How about putting a gauge in between the engine and the turbo to see if it really is back pressure?

Can you pull one of the springs off and get it checked for seat and open pressure

How about putting a gauge in between the engine and the turbo to see if it really is back pressure?

Last edited by 87silverbullet; 07-23-2013 at 01:49 PM.

#3

On The Tree

Thread Starter

iTrader: (9)

Join Date: Sep 2012

Location: Rio Rancho, NM

Posts: 185

Likes: 0

Received 0 Likes

on

0 Posts

Yeah might have to pull a spring, before I put this motor together I called around and the shops wanted 40 bucks to check 1 spring I thought that was a bit much so I never did it.

How does one put a gauge between engine and turbo?

How does one put a gauge between engine and turbo?

#6

TECH Veteran

iTrader: (11)

That doesn't help much because both graphs are falling off in the same spot so you can't tell if its valve float or back pressure. The stock motor had a stock cam and springs so its only going to spin so high and we don't know if its valve float because those are 2 different springs.

Second, you went from a stock setup of 346 cubes down to a more efficient 325 cube setup so we don't know which motor is going to create more back pressure. It kinda put both motors on the same playing field. You need a gauge to measure back pressure or test the valve springs on your car to do a little process of elimination to diagnose this.

Second, you went from a stock setup of 346 cubes down to a more efficient 325 cube setup so we don't know which motor is going to create more back pressure. It kinda put both motors on the same playing field. You need a gauge to measure back pressure or test the valve springs on your car to do a little process of elimination to diagnose this.

Trending Topics

#10

#14

On The Tree

Thread Starter

iTrader: (9)

Join Date: Sep 2012

Location: Rio Rancho, NM

Posts: 185

Likes: 0

Received 0 Likes

on

0 Posts

I do have a manual boost controller but It was in the before with old setup.

Tuner said boost stays at 15 lbs. Power just drops off.

Not sure about spool time its got a th400 with no lock up converter.

Tuner said boost stays at 15 lbs. Power just drops off.

Not sure about spool time its got a th400 with no lock up converter.

#16

On The Tree

Thread Starter

iTrader: (9)

Join Date: Sep 2012

Location: Rio Rancho, NM

Posts: 185

Likes: 0

Received 0 Likes

on

0 Posts

Okay so swapped out the housing to the .96 ar housing and it made no change at all. Power still dropping off about 5700.

Measured backpressure and getting 36pis at 16psi of boost I know this is pretty high but is it too high? I know you want to be under 2 to 1 and im slightly over 2 to 1 .

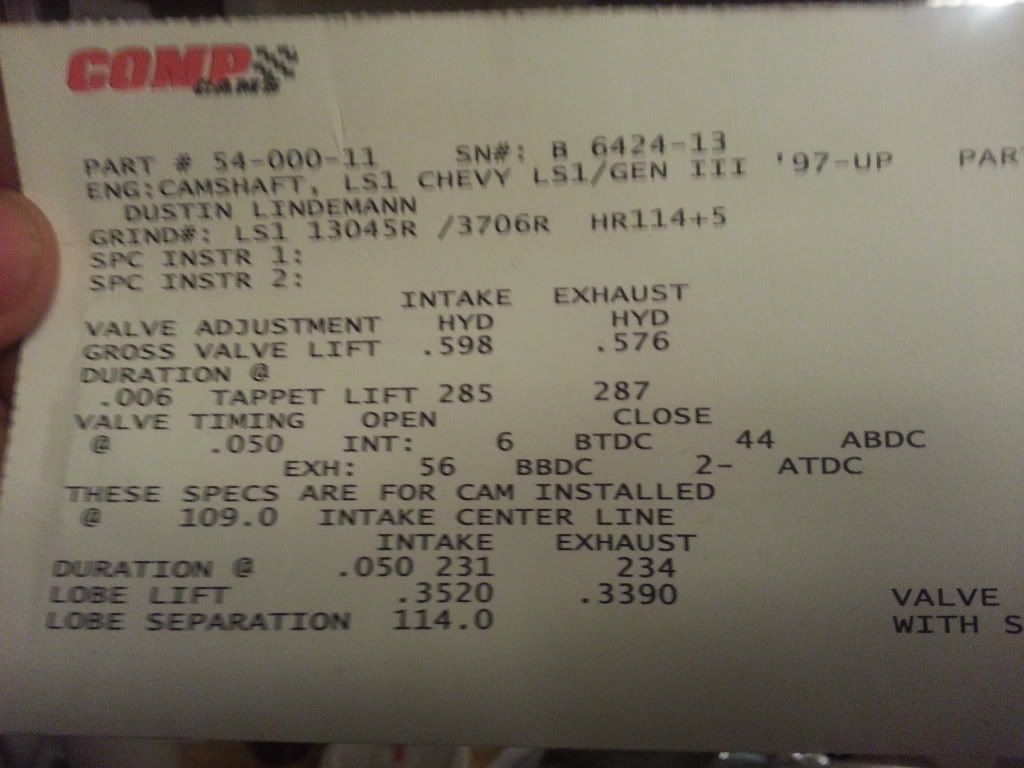

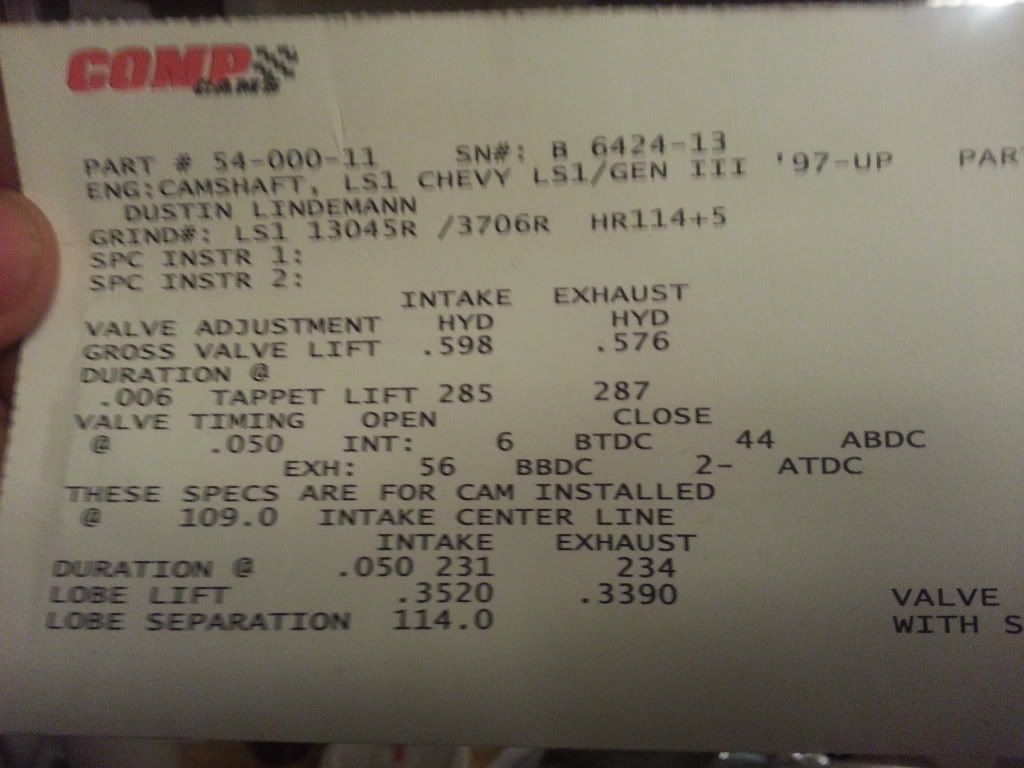

Turbo is 7675, Stock 799 heads with crane dual springs I don't know how old they are but from reading power shouldn't look that smooth on chart if it was a valve spring issue, custom spec'd Lil John motorsports cam ls6 intake, th400 with ford 9inch.

My question is what now? If anything can I change to help save this combo I know people have had great results with a 7675 and 5.3 liter why isn't mine. The turbo kit is not the typical front facing truck manifolds, It has passenger side header facing rear crossover under car 2.5 inch and forward facing driver side header where they merge then go into turbo.

Any help would be great, tuner and I are out of ideas really though changing to the bigger .96 housing instead of the .81 ar housing would make a big difference but it did NOTHING.

Cam specs are below

Measured backpressure and getting 36pis at 16psi of boost I know this is pretty high but is it too high? I know you want to be under 2 to 1 and im slightly over 2 to 1 .

Turbo is 7675, Stock 799 heads with crane dual springs I don't know how old they are but from reading power shouldn't look that smooth on chart if it was a valve spring issue, custom spec'd Lil John motorsports cam ls6 intake, th400 with ford 9inch.

My question is what now? If anything can I change to help save this combo I know people have had great results with a 7675 and 5.3 liter why isn't mine. The turbo kit is not the typical front facing truck manifolds, It has passenger side header facing rear crossover under car 2.5 inch and forward facing driver side header where they merge then go into turbo.

Any help would be great, tuner and I are out of ideas really though changing to the bigger .96 housing instead of the .81 ar housing would make a big difference but it did NOTHING.

Cam specs are below

#17

TECH Senior Member

iTrader: (17)

The turbo has to turn a lot more RPM to keep up with the airflow demands of a cam like that. So the exhaust has to push harder to keep that turbo up to speed...this contributes to back pressure. I mentioned this in another thread just yesterday...turbine radius is the biggest determining factor in back pressure. It is far less dependent on the housing AR ratio itself.

The more your cam lobes overlap, an increase in back pressure is just going to make the next cylinder charge dirtier. So your boost and/or RPM can increase....yet the usable air in the cylinder for combustion may not increase at all.

#18

On The Tree

Thread Starter

iTrader: (9)

Join Date: Sep 2012

Location: Rio Rancho, NM

Posts: 185

Likes: 0

Received 0 Likes

on

0 Posts

So bigger turbo is needed to use this cam. What about changing cam or am I just covering up the issue of turbo still being to small. I am really new to turbo stuff.