School me on blow off valves...

#21

look at the tial qr valve which uses the recirculating head instead of the wide open head with the q. i have yet to test out the recirculating head, which i plan to do this summer but i imagine you won't have a street sweeper going down the road like with the full open head. tial makes 2 supercharger springs which you could choose to use, a 2 lb and 3 lb spring. the heavier the spring, the quicker the diaphragm will close and allow you to go into boost. a softer spring will not have as much wapoosh (you know what i'm talking about!). personally, i use a 6 lb spring because i like having a quicker transition into boost.

to better explain the spring weights, consider this:

2lb spring = 4 in/vacuum

3lb spring = 6 in/vacuum

6lb spring = 12 in/vacuum

The transition from the diaphragm being open to closed will depend on your spring weight with the chart above based on your boost gauge (hopefully you have a gauge with vacuum and boost). Turbos work just the opposite where you want to keep the diaphragm closed at all times until the throttle body closes. That is why you always choose a spring based on the inches of vacuum at idle which matches the spring weight (ie: idle @21inchs vacuum would require an 11 lb spring).

to better explain the spring weights, consider this:

2lb spring = 4 in/vacuum

3lb spring = 6 in/vacuum

6lb spring = 12 in/vacuum

The transition from the diaphragm being open to closed will depend on your spring weight with the chart above based on your boost gauge (hopefully you have a gauge with vacuum and boost). Turbos work just the opposite where you want to keep the diaphragm closed at all times until the throttle body closes. That is why you always choose a spring based on the inches of vacuum at idle which matches the spring weight (ie: idle @21inchs vacuum would require an 11 lb spring).

Last edited by directnosfogger; 12-22-2013 at 10:16 PM.

#23

Thanks for all the replies guys. I definitely think my Proflo is leaking at higher rpms. I'm getting some fluctuation in my map readings, and I know I'm not getting belt slip, so it's time to do a pressure test.

I like what Detoxx is doing with a 6lb spring and having the boost started sooner. So I think a Tial QR (or Q) is in my future.

I like what Detoxx is doing with a 6lb spring and having the boost started sooner. So I think a Tial QR (or Q) is in my future.

#25

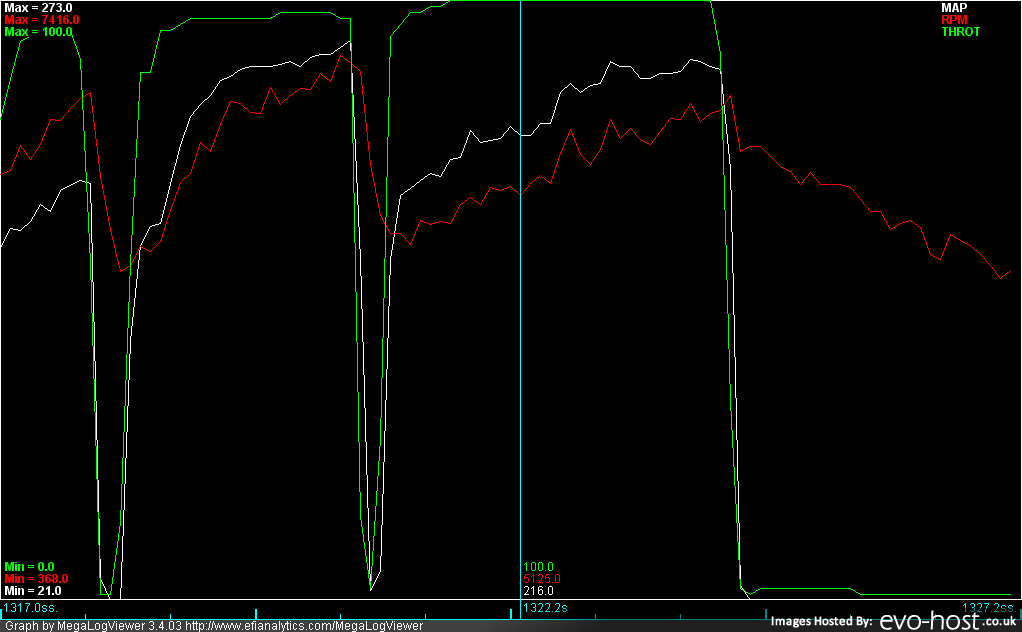

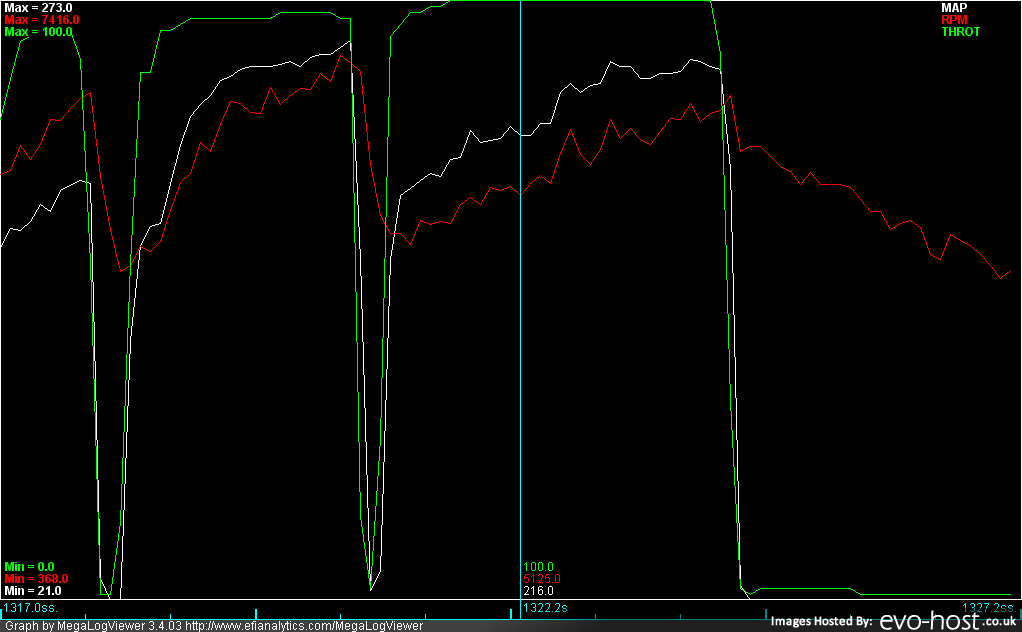

Well, here's my data log from my dyno run:

FYI, that's only 0.8 degrees of knock, and come to find out it's burst knock which I need to tune out.

As you can see, my map sensor starts to fluctuate above 5000 rpm. I watch the tensioner and it never hit the stop point, so in theory, the belt is still being held with good tension. I checked for any signs of the belt being eaten or any dust and there was none. So am I 100% certain, no, but I have a good feeling that with a 3.4", 8-rib pulley, with a new belt, Aster's bracket, and only a D1SC, that belt slip wasn't a factor. So that leads me to think that I have a boost leak, or an airflow restriction leading to the manifold, perhaps the intercooler is a restriction, who knows.

My next step is to pressurize the system and see if I have any leaks. I suspect the Proflo valve is leaking, and who knows, my FAST 90 might be as well.

Before anyone jumps down my throat about the afr being off, I know. I decided the week before my dyno session to change to ID1000 injectors and swap pulleys. I wasn't 100% of how much fuel to add, and erred on the side of caution and added too much as you can see. With some more data logging, I'll get my afr's back into the mid 11 range.

FYI, that's only 0.8 degrees of knock, and come to find out it's burst knock which I need to tune out.

As you can see, my map sensor starts to fluctuate above 5000 rpm. I watch the tensioner and it never hit the stop point, so in theory, the belt is still being held with good tension. I checked for any signs of the belt being eaten or any dust and there was none. So am I 100% certain, no, but I have a good feeling that with a 3.4", 8-rib pulley, with a new belt, Aster's bracket, and only a D1SC, that belt slip wasn't a factor. So that leads me to think that I have a boost leak, or an airflow restriction leading to the manifold, perhaps the intercooler is a restriction, who knows.

My next step is to pressurize the system and see if I have any leaks. I suspect the Proflo valve is leaking, and who knows, my FAST 90 might be as well.

Before anyone jumps down my throat about the afr being off, I know. I decided the week before my dyno session to change to ID1000 injectors and swap pulleys. I wasn't 100% of how much fuel to add, and erred on the side of caution and added too much as you can see. With some more data logging, I'll get my afr's back into the mid 11 range.

#27

9 Second Club

The boost line doesnt look that bad really. It's never going to be a completely smooth line, unless you're applying lots of filtering to the sensor or signal line.

And there are no major signs of a boost drop off as you would see with a leak or belt slip.

And there are no major signs of a boost drop off as you would see with a leak or belt slip.

#28

I need a gauge for that

iTrader: (37)

I have a very light spring in my BOV so it is open at idle, not sure what it does at cruise, but it closes in boost. The longer you keep it open the faster you will get into boost because it allows the turbo speed to get up without it having to spend a lot of work compressing air.

#29

Well, that's good to hear. One of the reasons I waited so long to dyno the car is because I really didn't want to know what it was making. As a scientist, I over analyze data routinely. So looking at the data, I was expecting to make more boost, but it is what it is. It also nosed over at around 6300, which I thought was due to the boost not continuing to rise. Honestly, the car drives great on the street, and rarely do I see north of 5500rpm.

#30

9 Second Club

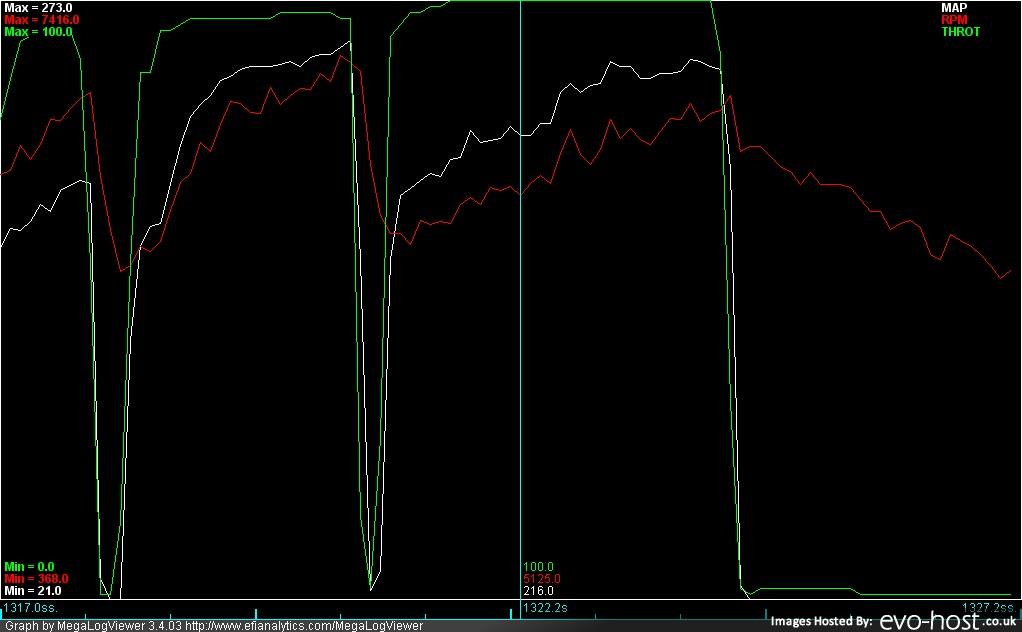

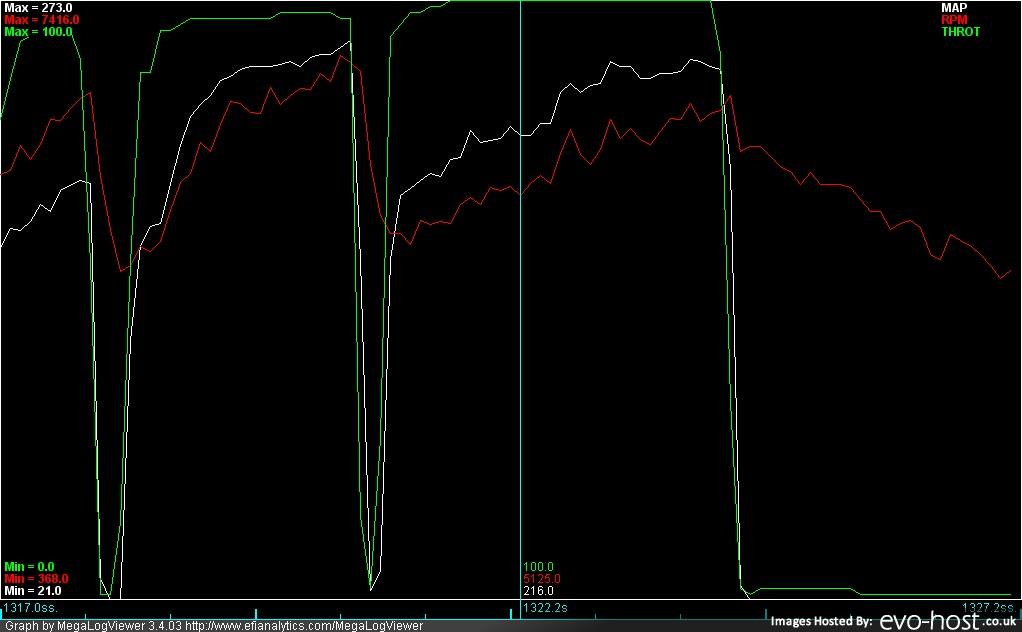

this a screenshot of a log of mine, thru the end of 2nd, 3rd and 4th gear at a race a year or so ago.

85/28T cogs with my YSi, so no slip. Logging rate is 10Hz with no filtering.

Green = TPS

Red = RPM

White = MAP

85/28T cogs with my YSi, so no slip. Logging rate is 10Hz with no filtering.

Green = TPS

Red = RPM

White = MAP

#31

9 Second Club

this a screenshot of a log of mine, thru the end of 2nd, 3rd and 4th gear at a race a year or so ago.

85/28T cogs with my YSi, so no slip. Logging rate is 10Hz with no filtering.

Green = TPS

Red = RPM

White = MAP

85/28T cogs with my YSi, so no slip. Logging rate is 10Hz with no filtering.

Green = TPS

Red = RPM

White = MAP

#32

I have a very light spring in my BOV so it is open at idle, not sure what it does at cruise, but it closes in boost. The longer you keep it open the faster you will get into boost because it allows the turbo speed to get up without it having to spend a lot of work compressing air.

#33

TECH Enthusiast

Join Date: Apr 2008

Location: Dickinson, Tx

Posts: 654

Likes: 0

Received 0 Likes

on

0 Posts

Well, here's my data log from my dyno run:

FYI, that's only 0.8 degrees of knock, and come to find out it's burst knock which I need to tune out.

As you can see, my map sensor starts to fluctuate above 5000 rpm. I watch the tensioner and it never hit the stop point, so in theory, the belt is still being held with good tension. I checked for any signs of the belt being eaten or any dust and there was none. So am I 100% certain, no, but I have a good feeling that with a 3.4", 8-rib pulley, with a new belt, Aster's bracket, and only a D1SC, that belt slip wasn't a factor. So that leads me to think that I have a boost leak, or an airflow restriction leading to the manifold, perhaps the intercooler is a restriction, who knows.

My next step is to pressurize the system and see if I have any leaks. I suspect the Proflo valve is leaking, and who knows, my FAST 90 might be as well.

Before anyone jumps down my throat about the afr being off, I know. I decided the week before my dyno session to change to ID1000 injectors and swap pulleys. I wasn't 100% of how much fuel to add, and erred on the side of caution and added too much as you can see. With some more data logging, I'll get my afr's back into the mid 11 range.

FYI, that's only 0.8 degrees of knock, and come to find out it's burst knock which I need to tune out.

As you can see, my map sensor starts to fluctuate above 5000 rpm. I watch the tensioner and it never hit the stop point, so in theory, the belt is still being held with good tension. I checked for any signs of the belt being eaten or any dust and there was none. So am I 100% certain, no, but I have a good feeling that with a 3.4", 8-rib pulley, with a new belt, Aster's bracket, and only a D1SC, that belt slip wasn't a factor. So that leads me to think that I have a boost leak, or an airflow restriction leading to the manifold, perhaps the intercooler is a restriction, who knows.

My next step is to pressurize the system and see if I have any leaks. I suspect the Proflo valve is leaking, and who knows, my FAST 90 might be as well.

Before anyone jumps down my throat about the afr being off, I know. I decided the week before my dyno session to change to ID1000 injectors and swap pulleys. I wasn't 100% of how much fuel to add, and erred on the side of caution and added too much as you can see. With some more data logging, I'll get my afr's back into the mid 11 range.

If you're not spraying meth it must be really cold there to only get to 84* during that run. What did it put down on that rich AFR?

#34

At 10.2-10.4, with only 16.5 degrees of timing, it made 742/688. Once the tune gets squared away, I'll redyno this spring and pull the inlet hat to see what it makes. I'm sure with just pulling the AFR up to 11.5 or so, and adding 2 degrees of timing, it'll make a solid 800rwhp.

#35

TECH Enthusiast

#37

So you are saying the lighter the spring, the faster you will get into boost? Your supercharger has one job compress air. The only way to make boost is to allow compression of air, and not expelling air to atmosphere. The sooner that is done, the quicker you can build on that. Please explain why you think waiting on a lighter spring to close the diaphragm in turn spends less energy building boost?

So for example, with a 2lb spring, at lets say 3000 rpm, it might require you to be at 40% throttle before the vacuum of the motor drops enough to close the valve and start to build boost. Granted, it might be only 1-2psi at that rpm, but 1-2psi is a lot more airflow than -1 to -2psi if the valve were open. Now with a 4lb spring, and the same 3000rpm, it might only be 30% throttle before the valve closes and you go from -3 to -4 psi to the same 1-2psi of boost since the blower is still spinning the same rpm, and moving the same amount of air.

So if you want more low end throttle response, I'm guessing going with a higher tension spring will help it snap into a positive airflow scenario. I'm figuring that the tuning will need to be adjusted as well since the parts of the VE table at different rpms will be different, so keep that in mind.

#39

FormerVendor

During the transition the valve will either be closed at 73kpa(-4) or 87kpa(-2).

Not going to make one bit of difference in terms of perceptible or measurable transition. It's still going to 99% come down to actual throttle position and it wouldn't take a 10% difference in throttle position at a specific rpm for it to change 15kpa.

Even with the spring cut down to the lightest possible value that would still close the valve, it would still close nearly instantly at enough throttle input (and not leak) because the diaphragm area is much larger than the valve area.

If the valve seals at low boost it should do the same at high boost. (No reason it would be more likely to leak at high boost because of the aforementioned difference in diaphragm vs valve area). Only reason for leakage would be a damaged seat/valve or ruptured diaphragm which would cause leakage at any boost level.

VE table is not going to change vs spring pressure either, it's just manifold pressure vs rpm which is still managed by throttle position, even if you pulled off the bypass valve and blocked it off. (2000rpm and 45kpa is the same regardless if the supercharger is in a surge condition).

Not going to make one bit of difference in terms of perceptible or measurable transition. It's still going to 99% come down to actual throttle position and it wouldn't take a 10% difference in throttle position at a specific rpm for it to change 15kpa.

Even with the spring cut down to the lightest possible value that would still close the valve, it would still close nearly instantly at enough throttle input (and not leak) because the diaphragm area is much larger than the valve area.

If the valve seals at low boost it should do the same at high boost. (No reason it would be more likely to leak at high boost because of the aforementioned difference in diaphragm vs valve area). Only reason for leakage would be a damaged seat/valve or ruptured diaphragm which would cause leakage at any boost level.

VE table is not going to change vs spring pressure either, it's just manifold pressure vs rpm which is still managed by throttle position, even if you pulled off the bypass valve and blocked it off. (2000rpm and 45kpa is the same regardless if the supercharger is in a surge condition).

#40

I wasn't using the throttle percentages as definitive, just random numbers as a point of reference to demonstrate the concept. I certainly haven't experimented, so I can't comment on how each would react. Thank you for adding some real life experience.