Log Manifold Builders Step Inside

#21

TECH Fanatic

iTrader: (7)

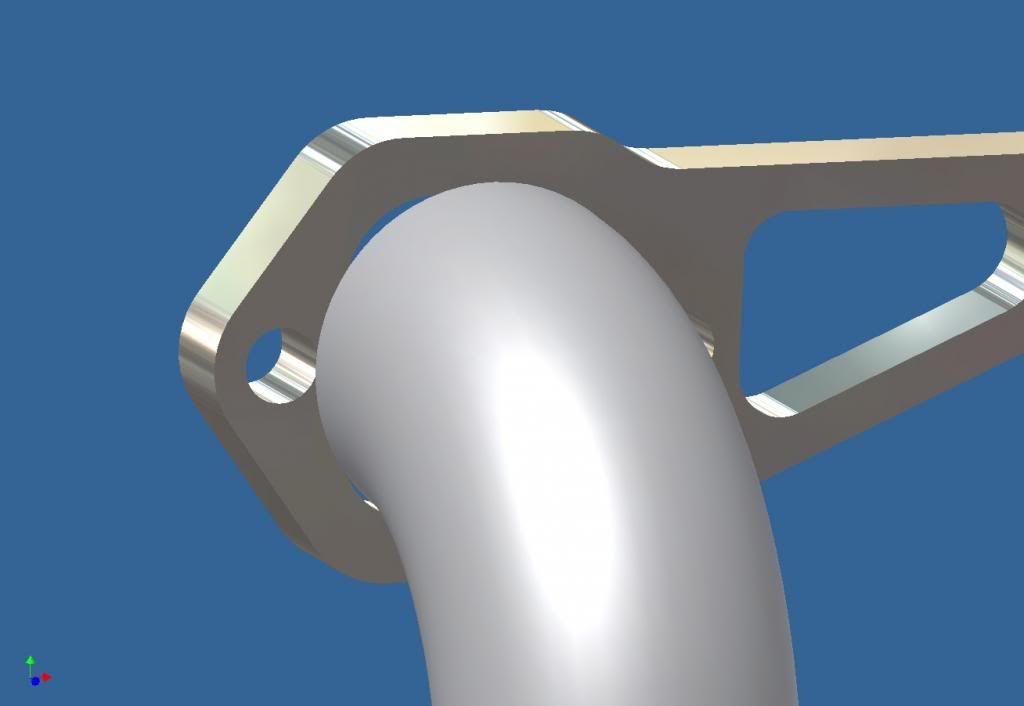

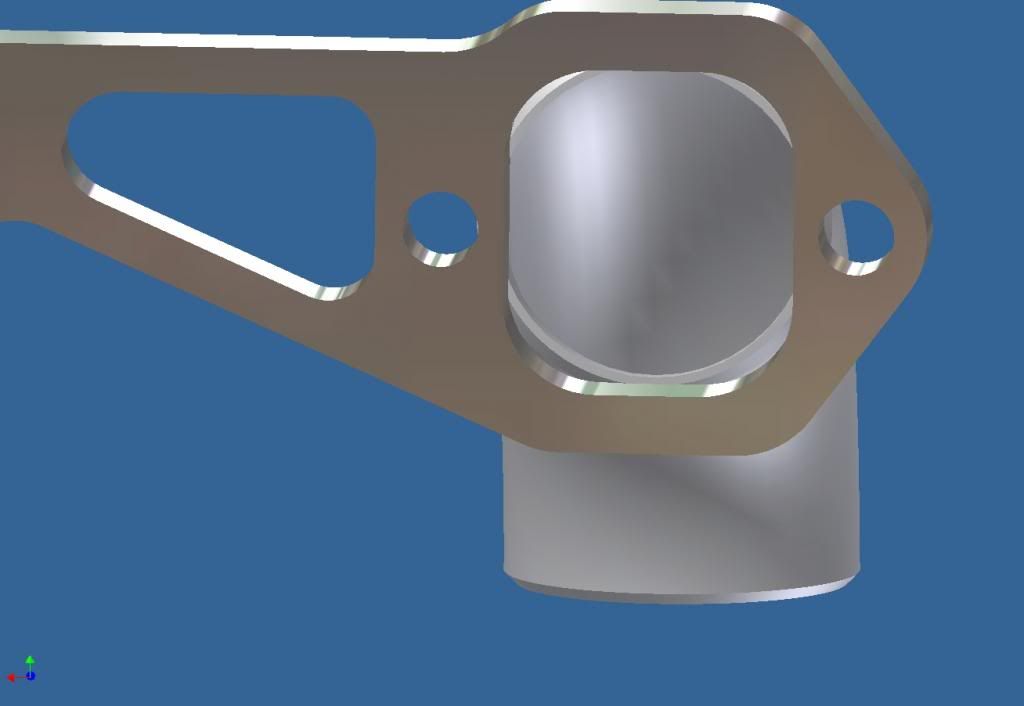

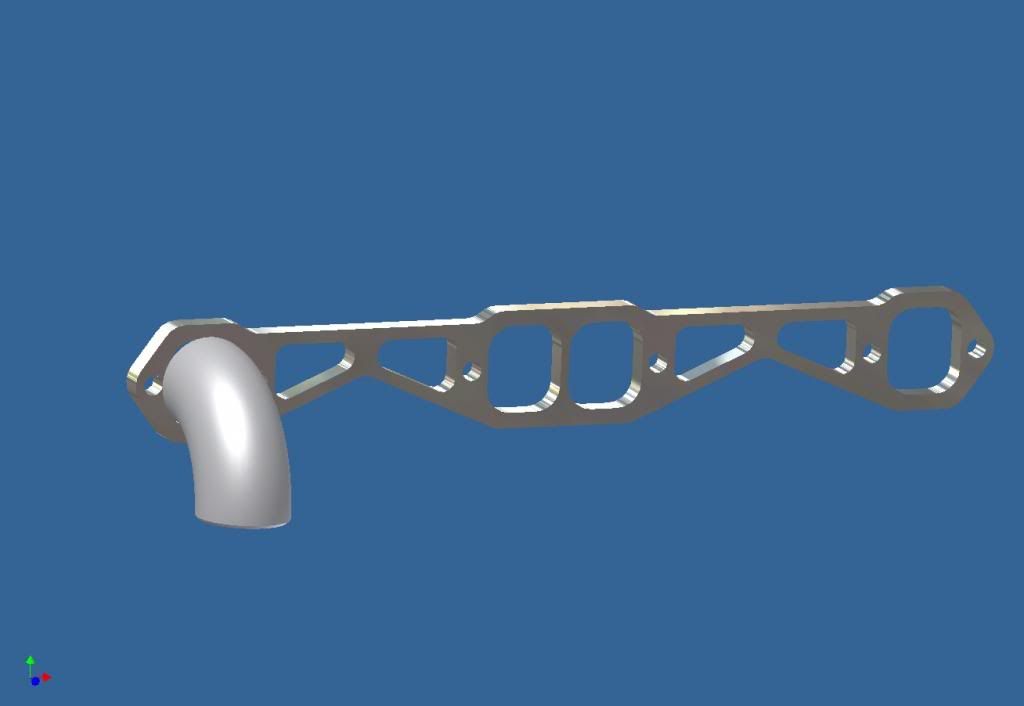

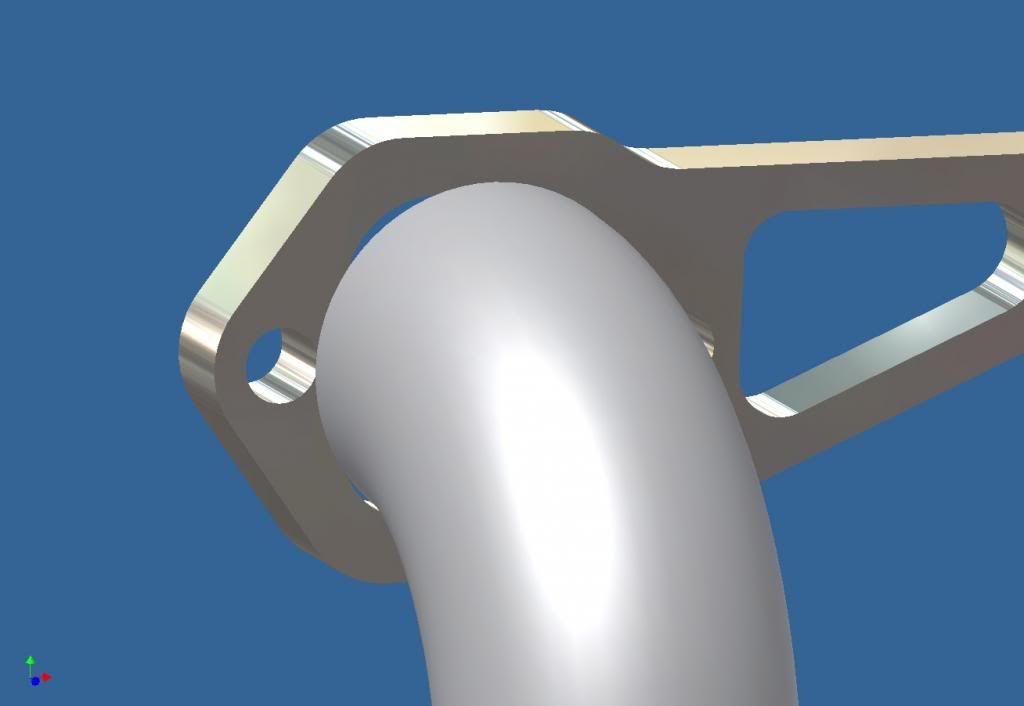

This gives you one way of fish cutting the elbows. He made a tapered log but you can use a straight log and a single reducer on the end too.

http://forum.miata.net/vb/showthread...=423624&page=2

Bear in mind he did not have a counter sunk flange but relatively but welded the elbows to the flange. Counter sinking the elbow gives a cleaner weld and better looking appearance.

He did not use a thick enough flange and it warped and then had to machine it flat after final testing.

http://forum.miata.net/vb/showthread...=423624&page=2

Bear in mind he did not have a counter sunk flange but relatively but welded the elbows to the flange. Counter sinking the elbow gives a cleaner weld and better looking appearance.

He did not use a thick enough flange and it warped and then had to machine it flat after final testing.

Last edited by aknovaman; 04-07-2014 at 09:43 PM.

#22

Here is a link to a thread I posted in a few weeks back on log manifolds.

There are a few pic's posted of some very nice manifolds in this thread.

Tig ask about offering kits.

It is hard to find a inside deal on the el's to afford to stock them and offer them at a competitive price.

About the best I can do for you right now is show you where to buy the parts you'd need to build a set of manifolds.

Thanks for the complements guys.

I should have these posted to the site by the end of the week.

There are a few pic's posted of some very nice manifolds in this thread.

Tig ask about offering kits.

It is hard to find a inside deal on the el's to afford to stock them and offer them at a competitive price.

About the best I can do for you right now is show you where to buy the parts you'd need to build a set of manifolds.

Thanks for the complements guys.

I should have these posted to the site by the end of the week.

#23

This gives you one way of fish cutting the elbows. He made a tapered log but you can use a straight log and a single reducer on the end too.

http://forum.miata.net/vb/showthread...=423624&page=2

Bear in mind he did not have a counter sunk flange but relatively but welded the elbows to the flange. Counter sinking the elbow gives a cleaner weld and better looking appearance.

He did not use a thick enough flange and it warped and then had to machine it flat after final testing.

http://forum.miata.net/vb/showthread...=423624&page=2

Bear in mind he did not have a counter sunk flange but relatively but welded the elbows to the flange. Counter sinking the elbow gives a cleaner weld and better looking appearance.

He did not use a thick enough flange and it warped and then had to machine it flat after final testing.

Has anyone got a cut away of a cast log? be interesting to see the internals of one.

#27

#28

TECH Addict

iTrader: (8)

Excellent! When I had my latest tubular manifold hotside made, I'd bought some beautiful mild steel 1/2" flanges but I *assumed* they were going to be "D" shaped since the gent knew that's what I had with my LT1. Imagine my frown when I pulled them from the package to see they were all round. The mismatch between port opening and flange must produce quite the turbulence. When I replace the header gaskets from time to time, the blackened area on the flange shows I need to address this.

#29

Here you go Dave.

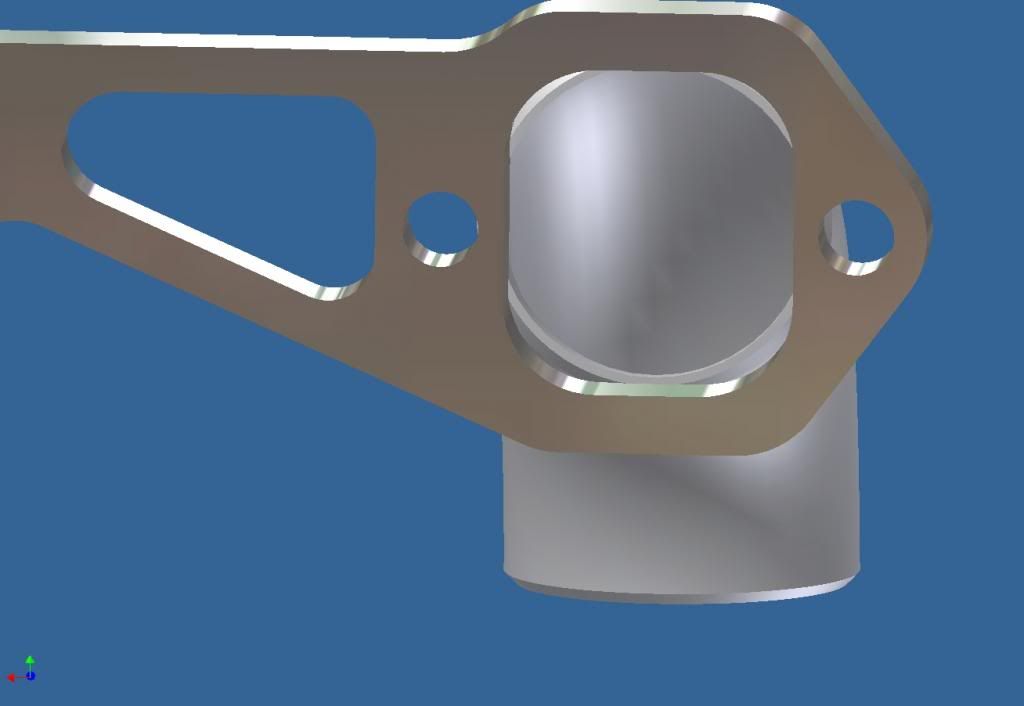

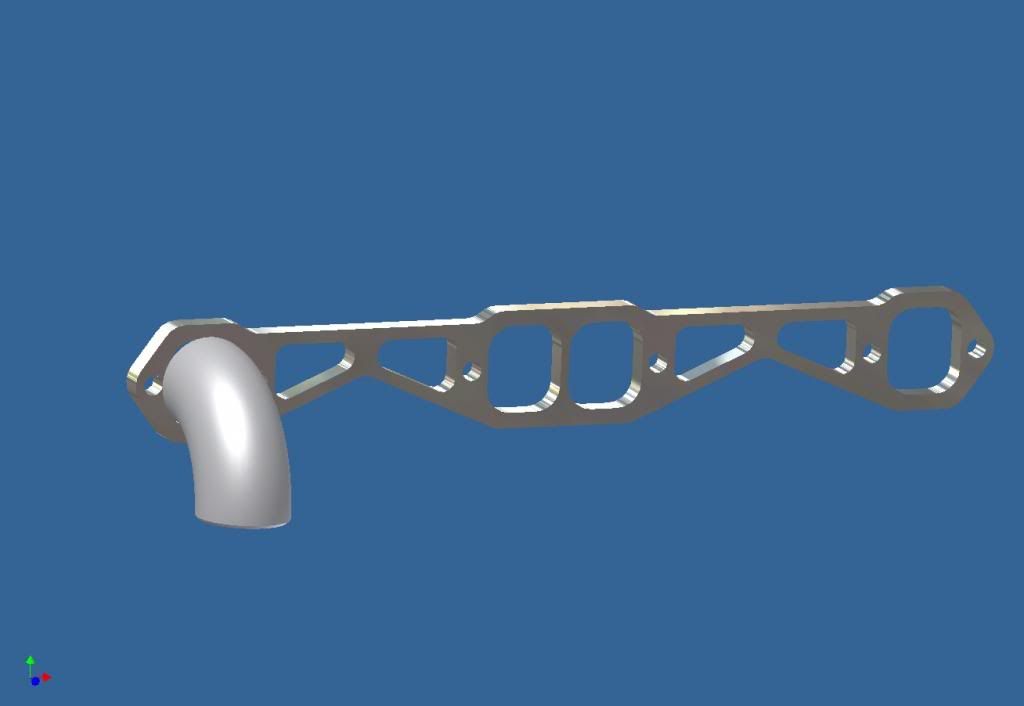

I put a 1-1/2 long radi weld el up to the flange in my cad program to see how it would fit between bolts. It's not a D shaped LT1 Port but it will work well enough to get an idea of how it will fit. I don't think the SBC style flange will benefit from a pocket like the LS type flange does. However, 1-1/4 weld els could be used as the SBC flange could have a step that would fit between the bolts. 1-1/4 weld els are 1.660 OD but the ID for SCH 10 is 1.442". That would be like using 1-1/2 header tubing. Guys are not going to buy that, it ant big enough.

I have used 1-1/2 weld els for SBC headers in the past but bolt stands have to be used and that limits you 10-15 degrees of the vertical plane so header planing will be a little more challenging.

As far as the "D" port thing goes I don't think it matters that much in a turbo build.

If you where very dependent on exhaust efficiency like a full buggy N/A deal it may buy you a few pony's.

I put a 1-1/2 long radi weld el up to the flange in my cad program to see how it would fit between bolts. It's not a D shaped LT1 Port but it will work well enough to get an idea of how it will fit. I don't think the SBC style flange will benefit from a pocket like the LS type flange does. However, 1-1/4 weld els could be used as the SBC flange could have a step that would fit between the bolts. 1-1/4 weld els are 1.660 OD but the ID for SCH 10 is 1.442". That would be like using 1-1/2 header tubing. Guys are not going to buy that, it ant big enough.

I have used 1-1/2 weld els for SBC headers in the past but bolt stands have to be used and that limits you 10-15 degrees of the vertical plane so header planing will be a little more challenging.

As far as the "D" port thing goes I don't think it matters that much in a turbo build.

If you where very dependent on exhaust efficiency like a full buggy N/A deal it may buy you a few pony's.

Last edited by Chris@CBR; 04-11-2014 at 10:43 PM.

#32

Good morning guys.

It have the flanges up on the site, here's the link.

http://www.cbrperformanceproducts.co...s1hfss.500.htm

It have the flanges up on the site, here's the link.

http://www.cbrperformanceproducts.co...s1hfss.500.htm

#33

Launching!

Join Date: May 2012

Location: Arlington, Tx

Posts: 218

Likes: 0

Received 0 Likes

on

0 Posts

Good morning guys.

It have the flanges up on the site, here's the link.

http://www.cbrperformanceproducts.co...s1hfss.500.htm

It have the flanges up on the site, here's the link.

http://www.cbrperformanceproducts.co...s1hfss.500.htm