s476r slow to spool or not.

#21

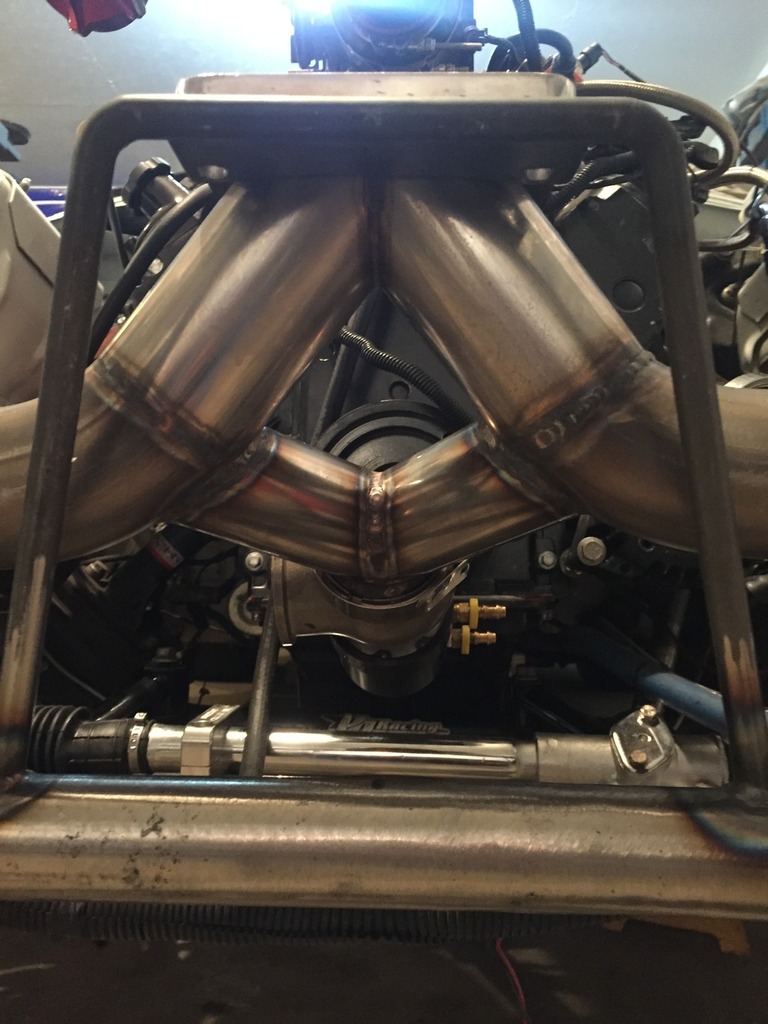

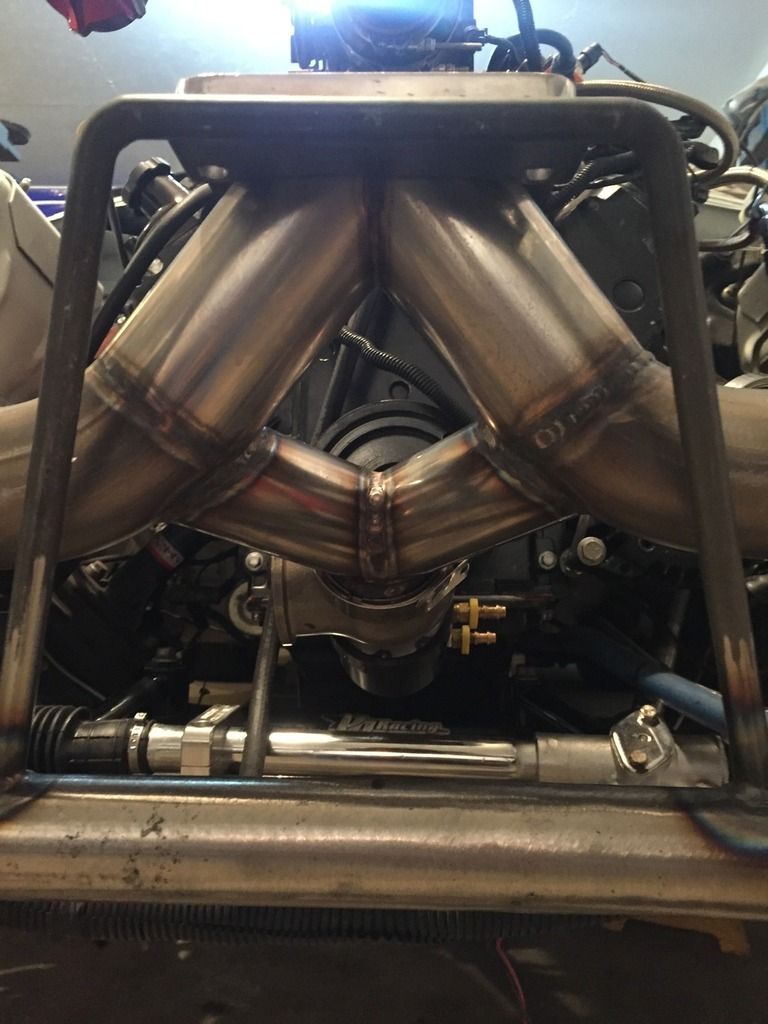

yes the piping is 2 1/4 single merge. the first few I built I used 2 1/2 pipe and they have been working great. my nova has a 2 1/2 and has gone 9.90 on 14 psi boost and seems to work well. the 2 1/4 is an effert to gain a little lowend spoolup. and as of yet I don't see any issue once in boost.

one of the hot sides I built is on my buddys Camaro with 2 1/2 to a single 2 1/2 looks exactly like the truck setup and has ran 9.40s on a 5.3 at 3550 raceweight with a on3 78/75 turbo @ 20 psi boost. I'm not seeing the big restriction at that power level yet. and i'll tell you the truck 2 1/4 setup pulls very good up stairs we have ran it to 7000 rpm on the ls2 370" engine and ljms stage 2 and it keeps pulling up there. thanks.

one of the hot sides I built is on my buddys Camaro with 2 1/2 to a single 2 1/2 looks exactly like the truck setup and has ran 9.40s on a 5.3 at 3550 raceweight with a on3 78/75 turbo @ 20 psi boost. I'm not seeing the big restriction at that power level yet. and i'll tell you the truck 2 1/4 setup pulls very good up stairs we have ran it to 7000 rpm on the ls2 370" engine and ljms stage 2 and it keeps pulling up there. thanks.

#23

The 5.3s with smaller turbos might manage to work.....does not mean it is right.

A 370 feeding a bigger turbine needs more volume to spin the turbine while the car is at the starting line......not a merge pipe the same size as the primaries. If you want 2.125" or 2.25" then they need to stay divided all the way to the turbine wheel.

A 370 feeding a bigger turbine needs more volume to spin the turbine while the car is at the starting line......not a merge pipe the same size as the primaries. If you want 2.125" or 2.25" then they need to stay divided all the way to the turbine wheel.

#24

8 Second Club

iTrader: (4)

Iím not sure thatís a fact. Do you know the scroll exit diameter of a T4 1.25 housing? If itís collectively smaller than a 2.25Ē pipe than the pipe isnít a bottle neck. The 1.32 T6 is about 1.5Ē per scroll Iím told. Iím sure the T4 is significantly smaller, but I donít know exactly. Stuff some clay in that sucker and find out for us!

Also the smaller pipes increased velocity will have a greater impact spool speed than additional volume. Question is if the piping is small enough to be a choke point at his 370s current power level. Which I doubt.

Also the smaller pipes increased velocity will have a greater impact spool speed than additional volume. Question is if the piping is small enough to be a choke point at his 370s current power level. Which I doubt.

Last edited by Forcefed86; 04-19-2017 at 09:58 AM.

#25

the 2.5 pipe is very close to the inside diameter of the t4 flange . meening if you hammer a round 2.5 pipe square it is not to far off of the t4 flange size. the 2.1/4 is a little bit smaller but still larger than if you look at the inside of the turbine housing it necks way down before getting to the wheel itself.

my idea with single 2 .5 or 2.25 pipe is to gain velocity entering the turbo. I have seen no evidence showing the pipe is to small. in a week or so we will do some track testing and I will let you know how it works. I know the 2.5 single pipe works great . thanks.

my idea with single 2 .5 or 2.25 pipe is to gain velocity entering the turbo. I have seen no evidence showing the pipe is to small. in a week or so we will do some track testing and I will let you know how it works. I know the 2.5 single pipe works great . thanks.

#31

Have you done a back to back on something to show this? I asked about this a while back, and we met with a bunch on internet scientist saying that "it work work right" since its basically impossible to "pair" the cylinders "correctly".

But, in practice I cant see how it wouldn't be a benefit.

But, in practice I cant see how it wouldn't be a benefit.

the motor was 500 RPM quicker to get to 105 kpa, 5 psi , 10 psi.

The hotside was the only change.

#33

TECH Fanatic

Thank you sir! Not sure how hard that set up was pushed but did you see any differences up top?