My motor is seized. Shit.

#121

UPDATE 12-7-07:

THINGS ARE JUST GETTING WORSE

The motor is all torn apart now. At least 4 pistons are VERY skortched. A few others are questionable. The rod bearings have some premature wear on them....nothing serious, but should probably replace them too. The crank is BRIGHT BLUE. The line hone was wayyyyy off and all chewed up from the mains spinning. ****.

So now it looks like TSP's machining error is going to cost me:

1. main bearings

2. rod bearings

3. New block

4. New pistons

5. Rings

6. Cam bearings

7. 6.0 Crank

8. Gaskets

9. Machine work

10. Assembly

3. cam bearings for new block

THINGS ARE JUST GETTING WORSE

The motor is all torn apart now. At least 4 pistons are VERY skortched. A few others are questionable. The rod bearings have some premature wear on them....nothing serious, but should probably replace them too. The crank is BRIGHT BLUE. The line hone was wayyyyy off and all chewed up from the mains spinning. ****.

So now it looks like TSP's machining error is going to cost me:

1. main bearings

2. rod bearings

3. New block

4. New pistons

5. Rings

6. Cam bearings

7. 6.0 Crank

8. Gaskets

9. Machine work

10. Assembly

3. cam bearings for new block

#122

Well finally got the whole motor apart and checkedOUCH.

block crank and pistons are fucked.

the mains spun bad enough that the block is toast,also with all the debris from the bearings it scuffed 3 skirts bad enough that the pistons are junk.Also turned the crank BLUE.

Also to the fellow who said water in the oil or no oil pressure.

HAd zero coolant in the oil and it always had oil pressure as the rod bearings look good along with the cam bearings,i mean they dont have signs of failure just signs of debris going threw the oiling system.Again imo it was a assembly error or machinest error.

block crank and pistons are fucked.

the mains spun bad enough that the block is toast,also with all the debris from the bearings it scuffed 3 skirts bad enough that the pistons are junk.Also turned the crank BLUE.

Also to the fellow who said water in the oil or no oil pressure.

HAd zero coolant in the oil and it always had oil pressure as the rod bearings look good along with the cam bearings,i mean they dont have signs of failure just signs of debris going threw the oiling system.Again imo it was a assembly error or machinest error.

#123

UPDATE 12-7-07:

THINGS ARE JUST GETTING WORSE

The motor is all torn apart now. At least 4 pistons are VERY skortched. A few others are questionable. The rod bearings have some premature wear on them....nothing serious, but should probably replace them too. The crank is BRIGHT BLUE. The line hone was wayyyyy off and all chewed up from the mains spinning. ****.

So now it looks like TSP's machining error is going to cost me:

1. main bearings

2. rod bearings

3. New block

4. New pistons

5. Rings

6. Cam bearings

7. 6.0 Crank

8. Gaskets

9. Machine work

10. Assembly

3. cam bearings for new block

THINGS ARE JUST GETTING WORSE

The motor is all torn apart now. At least 4 pistons are VERY skortched. A few others are questionable. The rod bearings have some premature wear on them....nothing serious, but should probably replace them too. The crank is BRIGHT BLUE. The line hone was wayyyyy off and all chewed up from the mains spinning. ****.

So now it looks like TSP's machining error is going to cost me:

1. main bearings

2. rod bearings

3. New block

4. New pistons

5. Rings

6. Cam bearings

7. 6.0 Crank

8. Gaskets

9. Machine work

10. Assembly

3. cam bearings for new block

#124

Still don't have a clue do ya!...bad mouthing a company without really knowing what's going on...The bearings would have gone 2500 miles ago if it was machine error...you say you need a new block..is it cracked in the main saddles..should be able to be line bored to clear up the spun bearings...crank could probably be turned...

i feel your sorrow...but live and learn. Speed costs...Most engine builders building race..and yes at the power levels you are makeing yo dam sure would be considered race IMO, don't have no stinking warranties due to things out of there control!

Riddicule me, but this is way things really work!

72 cuda

895 rwhp

small-block mopar

i feel your sorrow...but live and learn. Speed costs...Most engine builders building race..and yes at the power levels you are makeing yo dam sure would be considered race IMO, don't have no stinking warranties due to things out of there control!

Riddicule me, but this is way things really work!

72 cuda

895 rwhp

small-block mopar

#125

Teching In

Join Date: Oct 2005

Location: College Station, TX

Posts: 3

Likes: 0

Received 0 Likes

on

0 Posts

I lurk here a lot but don't post much... I hate to hear your problems and would be equally upset. However I'd be careful with your preliminary analysis of the situation. I used to work for a shop that saw a fair share of these issues, and there could be more going on here than machine work or short block assembly.

First thing is it was obviously not a problem with the power level, or the tuning (rod bearings and piston tops would show that). So we know that is not an option. Secondly based on the pictures you posted the main's were only damaged on the crank side....I highly doubt that the block suffered any damage in that area. Also, I don't think the bore/pistons could have been damaged as a secondary effect from this minimal amount of metal in the oil.

I DO NOT doubt the bores are shot along with the pistons, I am just saying that they were not caused by the main's going out and then that causing the piston/bore damage. Other items in your short block are more prone to damage due to metal in the oil than your pistons.

Your rod and cam bearings would have went first….I just don’t see the main’s going as the root cause.

I can give you a very pessimistic interpretation of the issue right now based on the experience I have... It looks like a poor short block install with an incorrect break-in procedure that lead to initial scoring of the main's and bores/pistons (poor pre-lube or lack thereof). This initial scoring would have opened up clearances on the affected mains thereby causing the problem to exasperate itself and eventually lead to complete seizure.

Like others have said here, incorrect machining or assembly of the engine will be spotted within the first 100mi or so. I’m not sure who did the short block install, or even if this is definitely the issue without personally inspecting the short block, but I have seen all kinds of failures and this really looks like assembly/machining was ok (based on the pictures provided).

Is it possible this could this be poor assembly or machining, of course. However it is not very probable. The visual evidence is just leading me away from this point of view initially, along with TSP’s exceptional previous track record… However anybody can make mistakes and someone might have just had a bad day. I’m just trying to provide you with another possible viewpoint to your problem.

I know I’m not an established poster and my opinion may not have any weight, but it might give you something else to consider.

EDITED INFORMATION FOLLOWS:

There are 3rd party shops that do engine failure analysis, we used to send suspect items to Jasper Engines so we could have an unbiased expert opinion that help validate both the customer's and our analysis. I'm sure there are other shops that would do this as well if you called around. If you are absolutely certain this was TSP's fault, they may agree that an unbiased 3rd pary decision would bear more weight on their decision.

First thing is it was obviously not a problem with the power level, or the tuning (rod bearings and piston tops would show that). So we know that is not an option. Secondly based on the pictures you posted the main's were only damaged on the crank side....I highly doubt that the block suffered any damage in that area. Also, I don't think the bore/pistons could have been damaged as a secondary effect from this minimal amount of metal in the oil.

I DO NOT doubt the bores are shot along with the pistons, I am just saying that they were not caused by the main's going out and then that causing the piston/bore damage. Other items in your short block are more prone to damage due to metal in the oil than your pistons.

Your rod and cam bearings would have went first….I just don’t see the main’s going as the root cause.

I can give you a very pessimistic interpretation of the issue right now based on the experience I have... It looks like a poor short block install with an incorrect break-in procedure that lead to initial scoring of the main's and bores/pistons (poor pre-lube or lack thereof). This initial scoring would have opened up clearances on the affected mains thereby causing the problem to exasperate itself and eventually lead to complete seizure.

Like others have said here, incorrect machining or assembly of the engine will be spotted within the first 100mi or so. I’m not sure who did the short block install, or even if this is definitely the issue without personally inspecting the short block, but I have seen all kinds of failures and this really looks like assembly/machining was ok (based on the pictures provided).

Is it possible this could this be poor assembly or machining, of course. However it is not very probable. The visual evidence is just leading me away from this point of view initially, along with TSP’s exceptional previous track record… However anybody can make mistakes and someone might have just had a bad day. I’m just trying to provide you with another possible viewpoint to your problem.

I know I’m not an established poster and my opinion may not have any weight, but it might give you something else to consider.

EDITED INFORMATION FOLLOWS:

There are 3rd party shops that do engine failure analysis, we used to send suspect items to Jasper Engines so we could have an unbiased expert opinion that help validate both the customer's and our analysis. I'm sure there are other shops that would do this as well if you called around. If you are absolutely certain this was TSP's fault, they may agree that an unbiased 3rd pary decision would bear more weight on their decision.

Last edited by dyezak; 12-07-2007 at 10:30 PM. Reason: Adding information about 3rd party analysis...

#126

I appreciate everyones 2 cents, and maybe it came off harsh. My opinion is based on the opinion of several local engine builders who have been building race motors for years (3rd parties, if you will DYEZAK). Again, OPINIONS. The mains were REALLY chewed up, and I do believe the debris in the oil could have scored the pistons. There was ZERO water in the oil, and the pressure was always perfect. The oil pump was a TSP piece as well.

As far as break-in, I followed TSP's strict instructions TO THE "T". I used their specified oil, and make SEVERAL changes the first 1,000 miles. No WOT for the first 1k either.

I am not trying to BASH TSP. They have always treated me well and seem like they are gonna take care of me in this situation. I do, on the other hand, feel it is ethical to report the findings of my block failure......and educated opinions on the cause. You all can make up your own minds.

As far as break-in, I followed TSP's strict instructions TO THE "T". I used their specified oil, and make SEVERAL changes the first 1,000 miles. No WOT for the first 1k either.

I am not trying to BASH TSP. They have always treated me well and seem like they are gonna take care of me in this situation. I do, on the other hand, feel it is ethical to report the findings of my block failure......and educated opinions on the cause. You all can make up your own minds.

#127

Still don't have a clue do ya!...bad mouthing a company without really knowing what's going on...The bearings would have gone 2500 miles ago if it was machine error...you say you need a new block..is it cracked in the main saddles..should be able to be line bored to clear up the spun bearings...crank could probably be turned...

i feel your sorrow...but live and learn. Speed costs...Most engine builders building race..and yes at the power levels you are makeing yo dam sure would be considered race IMO, don't have no stinking warranties due to things out of there control!

Riddicule me, but this is way things really work!

72 cuda

895 rwhp

small-block mopar

i feel your sorrow...but live and learn. Speed costs...Most engine builders building race..and yes at the power levels you are makeing yo dam sure would be considered race IMO, don't have no stinking warranties due to things out of there control!

Riddicule me, but this is way things really work!

72 cuda

895 rwhp

small-block mopar

#128

I lurk here a lot but don't post much... I hate to hear your problems and would be equally upset. However I'd be careful with your preliminary analysis of the situation. I used to work for a shop that saw a fair share of these issues, and there could be more going on here than machine work or short block assembly.

First thing is it was obviously not a problem with the power level, or the tuning (rod bearings and piston tops would show that). So we know that is not an option. Secondly based on the pictures you posted the main's were only damaged on the crank side....I highly doubt that the block suffered any damage in that area. Also, I don't think the bore/pistons could have been damaged as a secondary effect from this minimal amount of metal in the oil.

I DO NOT doubt the bores are shot along with the pistons, I am just saying that they were not caused by the main's going out and then that causing the piston/bore damage. Other items in your short block are more prone to damage due to metal in the oil than your pistons.

Your rod and cam bearings would have went firstÖ.I just donít see the mainís going as the root cause.

I can give you a very pessimistic interpretation of the issue right now based on the experience I have... It looks like a poor short block install with an incorrect break-in procedure that lead to initial scoring of the main's and bores/pistons (poor pre-lube or lack thereof). This initial scoring would have opened up clearances on the affected mains thereby causing the problem to exasperate itself and eventually lead to complete seizure.

Like others have said here, incorrect machining or assembly of the engine will be spotted within the first 100mi or so. Iím not sure who did the short block install, or even if this is definitely the issue without personally inspecting the short block, but I have seen all kinds of failures and this really looks like assembly/machining was ok (based on the pictures provided).

Is it possible this could this be poor assembly or machining, of course. However it is not very probable. The visual evidence is just leading me away from this point of view initially, along with TSPís exceptional previous track recordÖ However anybody can make mistakes and someone might have just had a bad day. Iím just trying to provide you with another possible viewpoint to your problem.

I know Iím not an established poster and my opinion may not have any weight, but it might give you something else to consider.

EDITED INFORMATION FOLLOWS:

There are 3rd party shops that do engine failure analysis, we used to send suspect items to Jasper Engines so we could have an unbiased expert opinion that help validate both the customer's and our analysis. I'm sure there are other shops that would do this as well if you called around. If you are absolutely certain this was TSP's fault, they may agree that an unbiased 3rd pary decision would bear more weight on their decision.

First thing is it was obviously not a problem with the power level, or the tuning (rod bearings and piston tops would show that). So we know that is not an option. Secondly based on the pictures you posted the main's were only damaged on the crank side....I highly doubt that the block suffered any damage in that area. Also, I don't think the bore/pistons could have been damaged as a secondary effect from this minimal amount of metal in the oil.

I DO NOT doubt the bores are shot along with the pistons, I am just saying that they were not caused by the main's going out and then that causing the piston/bore damage. Other items in your short block are more prone to damage due to metal in the oil than your pistons.

Your rod and cam bearings would have went firstÖ.I just donít see the mainís going as the root cause.

I can give you a very pessimistic interpretation of the issue right now based on the experience I have... It looks like a poor short block install with an incorrect break-in procedure that lead to initial scoring of the main's and bores/pistons (poor pre-lube or lack thereof). This initial scoring would have opened up clearances on the affected mains thereby causing the problem to exasperate itself and eventually lead to complete seizure.

Like others have said here, incorrect machining or assembly of the engine will be spotted within the first 100mi or so. Iím not sure who did the short block install, or even if this is definitely the issue without personally inspecting the short block, but I have seen all kinds of failures and this really looks like assembly/machining was ok (based on the pictures provided).

Is it possible this could this be poor assembly or machining, of course. However it is not very probable. The visual evidence is just leading me away from this point of view initially, along with TSPís exceptional previous track recordÖ However anybody can make mistakes and someone might have just had a bad day. Iím just trying to provide you with another possible viewpoint to your problem.

I know Iím not an established poster and my opinion may not have any weight, but it might give you something else to consider.

EDITED INFORMATION FOLLOWS:

There are 3rd party shops that do engine failure analysis, we used to send suspect items to Jasper Engines so we could have an unbiased expert opinion that help validate both the customer's and our analysis. I'm sure there are other shops that would do this as well if you called around. If you are absolutely certain this was TSP's fault, they may agree that an unbiased 3rd pary decision would bear more weight on their decision.

i agree with you on most of what you said,as i asked sean the same questions about break in.he said he did as the said.And as i have stated like 14 times in this thread the block is junk now because it spun the main in the BLOCK again it spun 3 out of the 5 mains in the BLOCK but the other 2 mains did not and actually were not horrible.As you stated and as i stated the tune looked good,the tops of the pistons and top rod bearings along with the fire ring in the gasket looked great and there was ZERO water in the oil.I agree that the rod bearing should have gonealong witht he mains but all of the mains should have went also.most of the time i see spun rod bearings before i see spun mains when its a oil pressure issue for the simple fact that the mains get oiled first and there is less surface area of bearing so it holds less oil and will hold less load.Anyway i need to check the ebaring to crank size and make sure they put the right bearing in it.I thought there motors came with new stock blocks and new stock cranks but it had .020 rod bearings and .010 mains in it so who knows.

#129

Also at this point the parts that are here are so beat to **** its hard to say what caused the whole thing.Again not bad mouthing any shop just showing what we came up with and letting everyone know.Now the important thing is to get him a new bullet built to have ready for this coming race season.

#134

LS1Tech Co-Founder

iTrader: (34)

Good luck either way. I don't know what to think in these situations because I know jack about engine failures, like how long bearings can go etc. Remember that bluing can = heat can = a secondary result. I had to have my turbo redone and the bearing damage was largely felt to be secondary.

#136

Restricted User

Join Date: Feb 2007

Location: oakland ca

Posts: 35

Likes: 0

Received 0 Likes

on

0 Posts

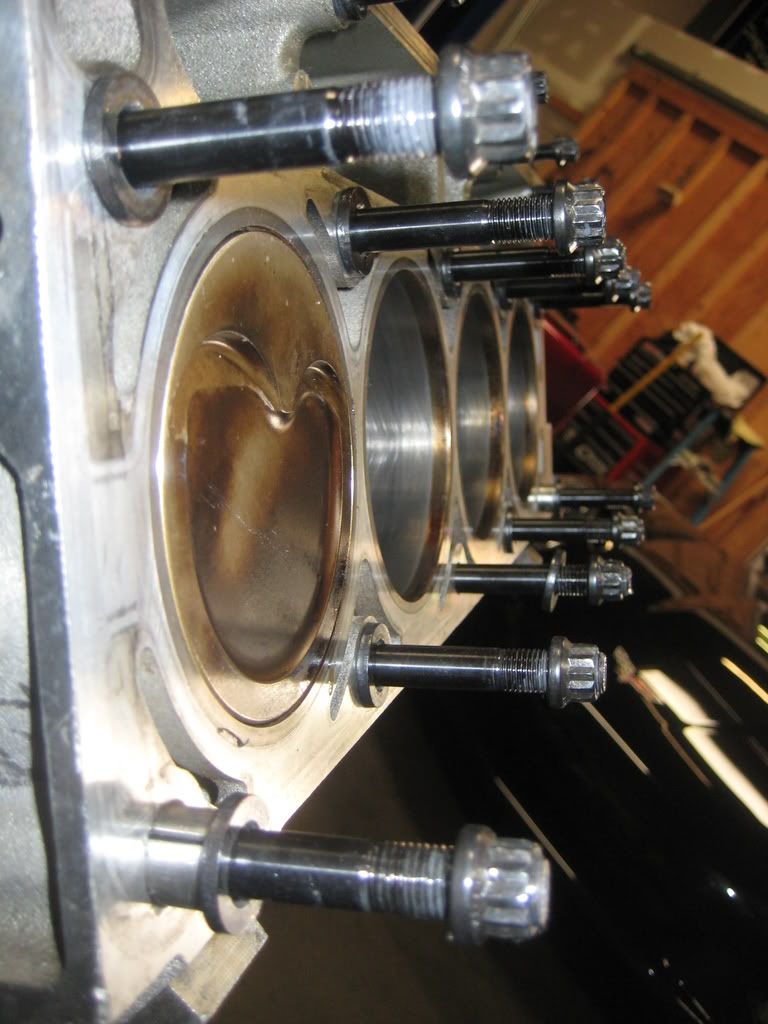

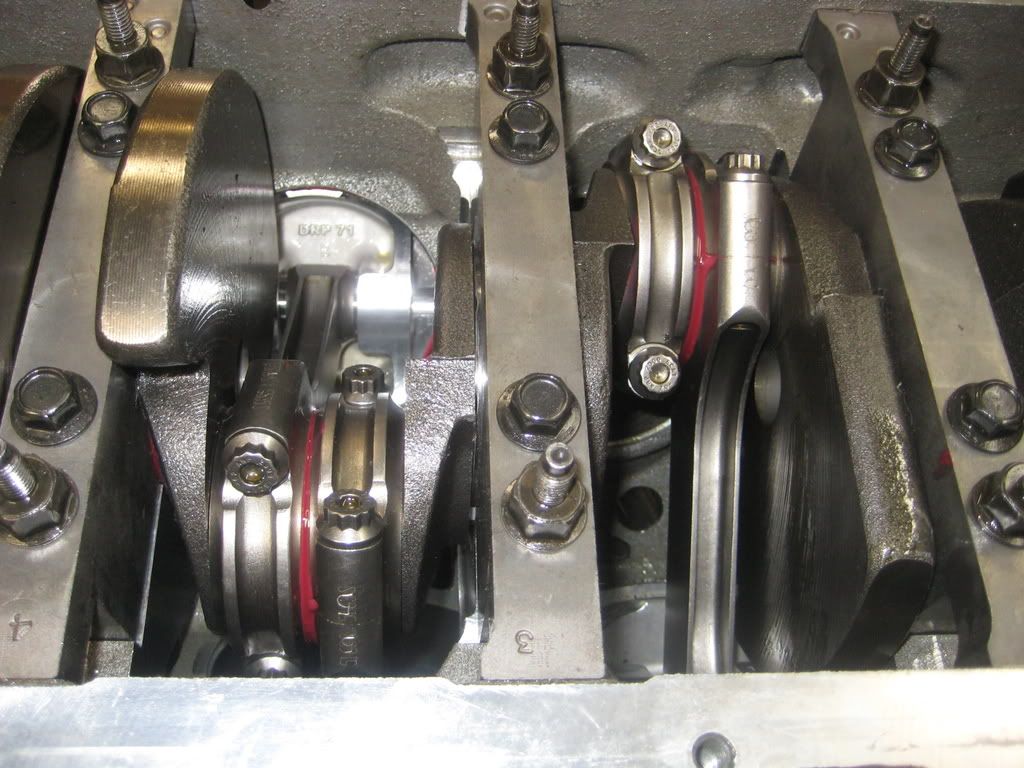

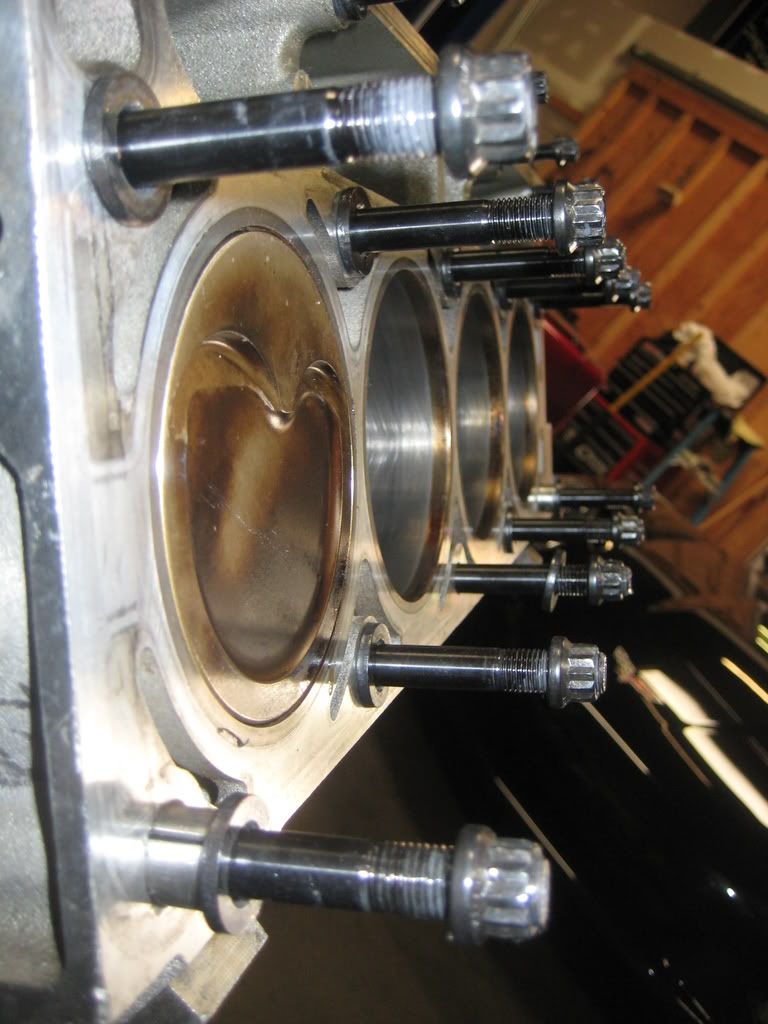

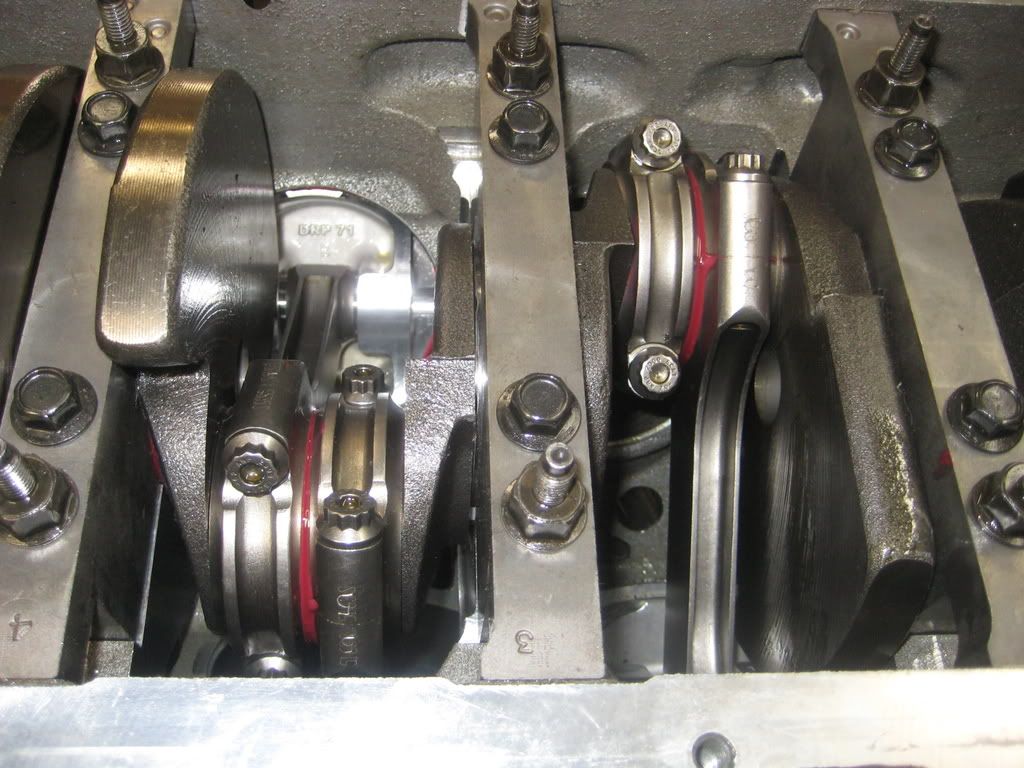

i bought a tsp 347 from a guy at the shop i work at and he had nothing but problems with the tsp engine. first they sent it without the oil plug in the front behind the timing cover. he fixed that after noticing after startup that it had no oil pressure. then 500 miles later he starts to hear knocking and decides to take the car back to stock. well i bought the engine assuming i was going to find a bad rod or main bearing but was surprised when i found that the number 1 cam bearing had spun so bad it was hanging on to the cam lobes. luckily there wasnt much damage and i was able to replace all of the bearings and basically overhaul the engine myself and since i put the engine in my car i havent had any problems and its putting out 680rwhp on 13.5 psi. but as fas as tsp engines go i have seen at least 4 of them blow with very low mileage!!! the pics below are after i put this thing back together. it was never hot tanked this is how low the mileage was when it failed. it was still brand new!