Install Of Aps Twin Turbo!!! Kwikss

#122

TECH Apprentice

Thread Starter

iTrader: (15)

Join Date: Apr 2007

Location: Fort Worth, TX

Posts: 351

Likes: 0

Received 0 Likes

on

0 Posts

Well I'm wondering how I can tighten it with the K member in place. I'm not going to drop it again to tighten one fitting. Has to be another way. How tight do the fittings need to get???

#124

Launching!

iTrader: (2)

Join Date: Jan 2007

Location: Los Lunas NM

Posts: 234

Likes: 0

Received 0 Likes

on

0 Posts

well not to be a jerk, or state the obvious but the instructions from APS clearly do not have you install the k-member before tightening this line.

You'll just need to find a tool to make it happen, or drop the k-member.

You'll just need to find a tool to make it happen, or drop the k-member.

#125

TECH Apprentice

Thread Starter

iTrader: (15)

Join Date: Apr 2007

Location: Fort Worth, TX

Posts: 351

Likes: 0

Received 0 Likes

on

0 Posts

Well I know that they dont have the K member installed first. But I was thinking from a stand point of what if the person already had a K member installed. Would APS really make you drop it out and then install it again. ????

#126

Launching!

iTrader: (2)

Join Date: Jan 2007

Location: Los Lunas NM

Posts: 234

Likes: 0

Received 0 Likes

on

0 Posts

Well I am going to be installing this kit as well, I will not be rebuilding my engine or removing it from the engine bay. I also do not have the K-member yet either.

Do you have any room at all? I mean we all know how hard it is to get the #8 spark plug out of the car but it can be done.

I hope you can get it done, but the right tool for the job may end up being making more room by removing the K-Member one last time or at least removing a few bolts and loosening some on the other side to kinda tweak it around to just get some more clearance.

Do you have any room at all? I mean we all know how hard it is to get the #8 spark plug out of the car but it can be done.

I hope you can get it done, but the right tool for the job may end up being making more room by removing the K-Member one last time or at least removing a few bolts and loosening some on the other side to kinda tweak it around to just get some more clearance.

#127

12 Second Club

iTrader: (4)

Ok guys have lots of questions. First one is how in the hell do you tighten the coolant hoses on the turbos once there mounted up in the car???? Use a wrench that is open at the end???? I cut my closed end and I still didn't have enough room to turn it. Second is the passerenside knock sensor in a good spot? Also I'm installing my ASP underdrive pulley. Will that work for FI.??????The first location would not work due to the starter being in the way. And for the people doing the install. INSTALL THE K MEMBER LAST. Damnittttt.!!!!!!!!!!!! first I took the oil pan loose thinking it would give me room to fit the driver turbo in the car. That was a joke. So I had to take the motor mount bolt out which is not easy to get in, in the first place. Hold the engine up and lower the K member about 6 inch to clear the turbo. And tonight I was the only one working on the car. So it made things twice as hard. Tonight I got about half of what I really wanted to get done.

Here are alot of pictures from tonight and the other night. Also can you spot the BUD LIGHT IN THE PICTURE. No I didn't drink it all tonight. I wish after the **** my car just put me threw.

Here are alot of pictures from tonight and the other night. Also can you spot the BUD LIGHT IN THE PICTURE. No I didn't drink it all tonight. I wish after the **** my car just put me threw.

Here are alot of pictures from tonight and the other night. Also can you spot the BUD LIGHT IN THE PICTURE. No I didn't drink it all tonight. I wish after the **** my car just put me threw.

Here are alot of pictures from tonight and the other night. Also can you spot the BUD LIGHT IN THE PICTURE. No I didn't drink it all tonight. I wish after the **** my car just put me threw. You may also want to really consider a torque arm relocation bracket. My newfound power caused the rear tailshaft seal to leak again and I had just replaced that seal last spring. Got my bracket on and no more drips, but my fluid level could also be low. Gotta get under there and check that this week. Over 1,000 miles on the kit now and having a blast with it!

Last edited by Hugger Z; 10-08-2007 at 08:25 AM.

#129

TECH Apprentice

Thread Starter

iTrader: (15)

Join Date: Apr 2007

Location: Fort Worth, TX

Posts: 351

Likes: 0

Received 0 Likes

on

0 Posts

Ok finally got the balancer bolt off with a 3 foot breaker bar. I didn't have to undo anything last night. Everything went as planed for once. Got the power steering rack on, Finished running all the lines for the turbos.

But I do have a question about my cam sensor. Since I'm using a new Ls2 motor the sensor is in the front, so I bought a harness but I seen that some have a bracket that moves it down next to the crank, but as for mine(in the Picture below) its above everything. And the harness will not clip in due to a notch in the sensor on the motor. I can make the new harness work I just want to find out what the piont of the lower brakcet I've seen on other cars is for.Picture of the bracket is below(found a pic) Thanks Jordan

But I do have a question about my cam sensor. Since I'm using a new Ls2 motor the sensor is in the front, so I bought a harness but I seen that some have a bracket that moves it down next to the crank, but as for mine(in the Picture below) its above everything. And the harness will not clip in due to a notch in the sensor on the motor. I can make the new harness work I just want to find out what the piont of the lower brakcet I've seen on other cars is for.Picture of the bracket is below(found a pic) Thanks Jordan

Last edited by KWIKKAR; 10-09-2007 at 10:39 AM.

#130

TT-TECH Veteran

iTrader: (29)

You can remove the bracket unpin the plug which is the same as a stock LS1 cam sensor plug and unpin the one on your harness and use the correct plug from that jumper harness I hope that sounded right LOL! I just used a paper clip the small one and insert it into the plug you will see a very small notch in it and that is where you slide the paper clip in and then just gently pull on the wire it should come right out. Oh yeah don't forget to take the plastic keeper off of the back of the plug first. Sorry if it sounded a little confusing it is hard to explain it in a typed message.

#131

TECH Apprentice

Thread Starter

iTrader: (15)

Join Date: Apr 2007

Location: Fort Worth, TX

Posts: 351

Likes: 0

Received 0 Likes

on

0 Posts

Well thats the thing I have the first picture not the second one. So I have no bracket. I think thats my problem. What year models did those come with. Thanks

#134

TECH Apprentice

Thread Starter

iTrader: (15)

Join Date: Apr 2007

Location: Fort Worth, TX

Posts: 351

Likes: 0

Received 0 Likes

on

0 Posts

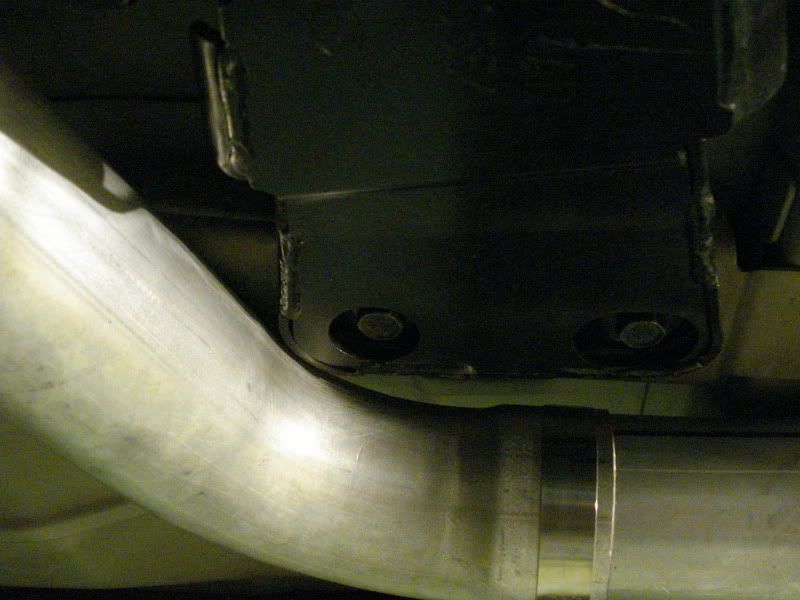

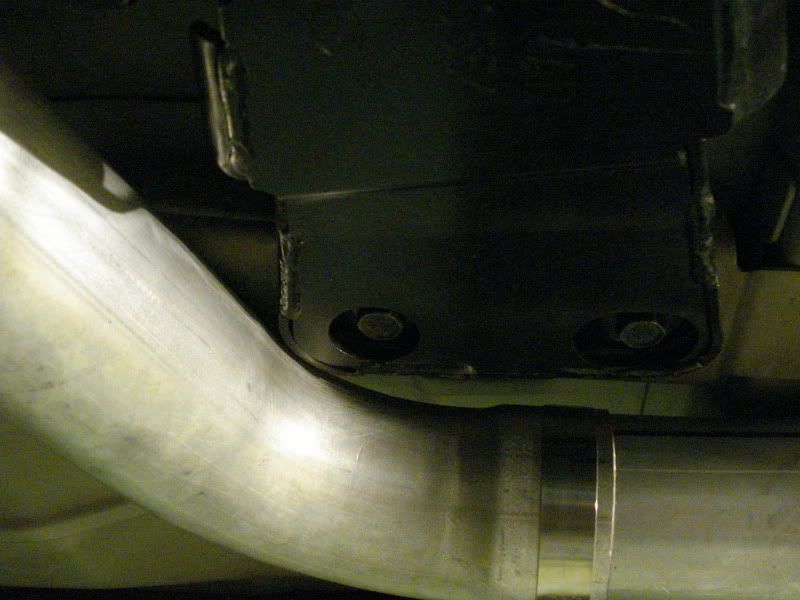

Alright guys, been working really hard to get this done. Got the WP,PS,Alt,A/C everything put back on. Everything is going pretty good, but there is a few issues I need help with. First the BRAKE LINES. Gzzzzz there has to be a better way to run these things. Second. When drilling the hole for the RHS pipe coming from the compressor side, why did they have us put the Coolant tank and other pipe on first. Theres no way to get a drill in there.(see pic) So I had to take the tank off and then reinstall. I got some T Bolt clamps but there are a few tight spots where I couldn't use those clamps so I used the stock ones that came with it. Third. Since its an LS2 the sensor in the third picture will not plug into my Ls1 harness, do I just take my LS1 sensor off the old motor and put it on this one or what do I do.?????? Fourth... Look how close the Hooker Y pipe is to the tranny brace and floor??? With the new motor mounts is it going to move any????? Also I haven't got my fuel system from LPA, but where do I run the fuel lines, Its a pretty tight fit in there. Anyone have pictures of the underneath where the lines are ran. Heres the pictures from the last few days. AIR FILTERS, DID APS not look into a camaro for fitmit???? Should I remove my fog lights and have air filters there or how did you camaro guys get them in there. Also the tube coming out of the front of the valley cover, what is it and what do I do with it. Also had some fitmit issues with battary tray, holes wouldn't line up.Thanks I'm sure I left something out.

Last edited by KWIKKAR; 10-17-2007 at 10:02 AM.

#137

TECH Apprentice

iTrader: (2)

can't help ya with a lot but i'll tell ya what i did on a couple things:

1) the bracket on the rhs pipe should be drilled in as low as possible and as you said, aps should have you do this before installing that coolant can. i broke at least 1 bit trying to squeeze my drill in there.

2) on my camaro i bent the fog light bracket near the top where it extends down from the main light bracket forward a good 1/2 to 3/4 inch (so it sloped to the front) and then bent the lower part back vertical (obviously - otherwise the light would be pointing upwards!) i then used a 3/4 inch or so nylon spacer and a longer bolt that i think i stole from the air pump removal and used that to attach the fog light to the stock lower bracket that attaches to the bolt where the fascia bolts to the fender (i think.) i also loosened the adjusting bolt on the fog light and slid the light down as far as it would go so it would fit back in the fascia. gave me just enough room to get that darn filter in there on both sides without rubbing/bending the filter.

i'll try to get pics this weekend when i'm back home.

1) the bracket on the rhs pipe should be drilled in as low as possible and as you said, aps should have you do this before installing that coolant can. i broke at least 1 bit trying to squeeze my drill in there.

2) on my camaro i bent the fog light bracket near the top where it extends down from the main light bracket forward a good 1/2 to 3/4 inch (so it sloped to the front) and then bent the lower part back vertical (obviously - otherwise the light would be pointing upwards!) i then used a 3/4 inch or so nylon spacer and a longer bolt that i think i stole from the air pump removal and used that to attach the fog light to the stock lower bracket that attaches to the bolt where the fascia bolts to the fender (i think.) i also loosened the adjusting bolt on the fog light and slid the light down as far as it would go so it would fit back in the fascia. gave me just enough room to get that darn filter in there on both sides without rubbing/bending the filter.

i'll try to get pics this weekend when i'm back home.

#138

TT-TECH Veteran

iTrader: (29)

On the oil presure sensor use you LS1 stocker the new LS2's don't work I tried and they will not work just use the stock LS1 sensor, and the tube in the front of the valley cover is your PVC hook up I don't know what APS is doing with it , but I ran mine to the inlet of the turbo with a catch can in line with it so no oil could possibly get in to the inlet of my turbos and a Metco breather on the valve cover etc... Looks good your almost there.

Jeff

Jeff

#139

12 Second Club

iTrader: (4)

Alright guys, been working really hard to get this done. Got the WP,PS,Alt,A/C everything put back on. Everything is going pretty good, but there is a few issues I need help with. First the BRAKE LINES. Gzzzzz there has to be a better way to run these things. Second. When drilling the hole for the RHS pipe coming from the compressor side, why did they have us put the Coolant tank and other pipe on first. Theres no way to get a drill in there.(see pic) So I had to take the tank off and then reinstall. I got some T Bolt clamps but there are a few tight spots where I couldn't use those clamps so I used the stock ones that came with it. Third. Since its an LS2 the sensor in the third picture will not plug into my Ls1 harness, do I just take my LS1 sensor off the old motor and put it on this one or what do I do.?????? Fourth... Look how close the Hooker Y pipe is to the tranny brace and floor??? With the new motor mounts is it going to move any????? Also I haven't got my fuel system from LPA, but where do I run the fuel lines, Its a pretty tight fit in there. Anyone have pictures of the underneath where the lines are ran. Heres the pictures from the last few days. AIR FILTERS, DID APS not look into a camaro for fitmit???? Should I remove my fog lights and have air filters there or how did you camaro guys get them in there. Also the tube coming out of the front of the valley cover, what is it and what do I do with it. Also had some fitmit issues with battary tray, holes wouldn't line up.Thanks I'm sure I left something out.

Yeah I ran into the same issue with the RHS bracket hole. I had to drop the coolant reservoir in order to get in there with a drill. No biggie but still sucks to undo work.

I had the same clearance problem on the battery tray. I had to open up the center hole (I believe I made mention of that in my install thread as well).

For the Air Filters, just clock them around. I spun them so they angled back a little and would fit behind the foglights. Luckily they have an angled neck on them so you can actually get some movement there for clearance.

You are getting close! Good luck with the final stretch.

#140

TECH Apprentice

Thread Starter

iTrader: (15)

Join Date: Apr 2007

Location: Fort Worth, TX

Posts: 351

Likes: 0

Received 0 Likes

on

0 Posts

Well on the red crossbrace, I thought the same thing, but the bolt holes will not line up the other way around. Its atleast 1 inch off. So its on right. thanks for the oil sensor, I thought that would work. I'll just do that. And as for the air filters I'll just wait till you post up pictures so everyone can see. Still trying to figure out what I'm going to do for a PCV set-up, I know I want to run a catch can, but not sure about the hoses coming from the turbo piping where to hook or put those at. I saw the other thread about PCV's, but with two hoses(twin turbo) do I run them both in the same place or two different spots. Thanks.