Need help to diagnose problem

#41

Staging Lane

Thread Starter

iTrader: (2)

Join Date: Mar 2008

Location: Mansfield, OH

Posts: 60

Likes: 0

Received 0 Likes

on

0 Posts

lol. Been there my friend. Good job making sure the car was stable and safe before getting under there. Why take a chance just to save a few minutes...

I'd bet anything the coolant sensor is your problem and good luck!

Please do post back when you do get it fixed. So many times I've found a similar problem to one I've had by searching and the person will get it fixed in the end but never post back on here what the solution was. Frustrating to say the least.

I'd bet anything the coolant sensor is your problem and good luck!

Please do post back when you do get it fixed. So many times I've found a similar problem to one I've had by searching and the person will get it fixed in the end but never post back on here what the solution was. Frustrating to say the least.

Well more updates and more mixed results. I got the coolant temp sensor swapped out and the car seems to idle much better but still does not give a reading on the temp gauge.

I also did the one spark plug right under the sensor first since I was in there. So I guess it could be the plug that made the difference and not the sensor? I am not real sure.

At any rate the idle is a lot better and smoothe and I don't seem to be getting the sputter while idling anymore. Car also smells less rich. Exhaust smells fairly normal now. Figure that may be due to the new coolant temp sensor?

Took it for a couple short drives. About a mile each. First drive I didn't notice anything till I went about 1/4 mile and stopped at a stop sign. When taking off it sort of sputtered once pretty hard then seemed fine. Had my lights on the whole time and did not notice them flickering or anything like I would with the constant sputtering that was goin on before the fuel filter, coolant temp sensor and one plug.

Second drive it was pretty much the same thing. Sputtering on one take off after about 1/4 mile. One pretty defined hard sputter but seemed fine afterwards.

To be honest the whole car felt like it ran a lot better. I still however have no fuel gauge which I believe may be an unrelated issue with the fuel level sensor and no temp gauge which I'm kind of stumped on at this point. Anyone have ideas why the temp gauge still wouldn't register at all?

I don't know a lot about plugs so here is what my old one looked like? How bad is it? LOL Are the other 7 that look like this or worse the rest of my sputtering problem?

#42

TECH Fanatic

iTrader: (1)

you are going in the wrong direction, and not understanding what the DTC's were telling you. The initial ones were P0102 and P1635 and P1639.

whenever you have DTC's stored, all you have to do is type them into google and 95% of the time you can read them on obd-codes.com and find out everything.

P0102 is MAF circuit low input as in lower than expected voltage.

P1635 is 5v reference circuit #1 low.

P1639 is 5v reference circuit #2 low.

you also got P0452 which looks like fuel tank pressure sensor circuit low voltage.

Not sure if you posted any other codes, but just from these you need to understand what the root cause is and that some codes like P0102 and P0452 are the result of some underlying problem which may or may not be a code by itself. But in this case it seems like the 2 big codes are P1635 and P1639.

The 5v reference circuit is big time, that's a 5v signal that supplies a bunch of electronic sensors on the car like your MAF which you got a code for, like your fuel tank sender which you got a code for. So you don't go concluding you have a bad MAF or a bad fuel pump when you have P1635 & P1639 because the whole system cannot be trusted because it's not getting a good 5v reference signal to work from.

The fact that you got P1635 & P1639 both circuit 1 & 2 means you have some electrical problem related to the whole system- as opposed to it only being one of the circuits.

The only good advice anywhere in here seems to be check your grounds and electrical connections, it is an electrical problem. The spark plug pic looked fine, it's not your spark plugs, it's not your fuel filter, it's not your fuel pressure, it's not your O2 sensors.

When fuel pressure is around 50 psi engine off that is normal, and when it jumps up a few psi engine running is normal because the pump is then seeing 14 volts from the alternator outputting rather than just battery voltage of 12.5 with engine off. your fuel pressure is in normal range. you need to find out what is causing the 5v reference both circuits to go low. first thing off top of my head is bad computer but that is just a guess. i can tell you that it's not a single sensor like the coolant temp sensor because no one sensor is going to pull both 5v reference circuits low, a single sensor only runs off one 5v circuit. my suggestion is to scour the net looking for causes and solutions to the P1635 P1639 for both 5v reference circuits low.

my other suggestion is get a volt meter, preferably analog with a needle so you can see voltage bounce but a digital will get you started. a good battery engine off will read 12.5 volts or higher. with engine idling you should see battery voltage steady around 14.0 volts. i would start there and make sure you are getting reliable output from the alternator then start working your way deeper into the electrical system to find what's causing the 5v reference circuits to drop.

another thing is- disconnect battery then disconnect the two harness plugs going to the pcm and looked for bad/bent/burnt pins. also consider tracing all wire harnesses in the engine bay looking for signs of chaffing into the harness which could be shorting a wire to ground. also look under the fuse boxes in the engine bay and look for evidence of a mouse nest and chewed wires. the fact that the engine stumbles immediately after started tells me it's not really a loose or bad/intermittent connection somewhere- such as if the engine idled well but stumbled every so often then you could wiggle wires looking for one that might cause the problem. but from your description you can't do it. you should also get a handheld scanner, clear codes, then cycle the ignition without starting and look for codes thrown before engine started, then how soon after engine started, and narrow down what is causing the problem.

another thing to understand is you can unplug certain sensors like the maf, o2's, ect, or AC and still have the engine start and idle normal. in the case of a single 5v reference circuit low, what you could do is unplug a sensor and see if it fixes the stumbling due to the entire 5v reference circuit low. for example your P0102 and MAF sensor let's say that was really the cause. what you would do is clear codes, unplug the MAF and make sure the disconnected plug itself is not bad and shorting to ground then start engine and let idle. it should idle smoothly with a MAF specific code but not a 5v reference code, if this were to happen then you have some reliable info pointing to a bad MAF or wiring to it. but in your case you had both P1635 & P1639, what you need to do is get a scanner and find out when those two codes are happening and if happening simultaneously to systematically diagnose and find the problem.

whenever you have DTC's stored, all you have to do is type them into google and 95% of the time you can read them on obd-codes.com and find out everything.

P0102 is MAF circuit low input as in lower than expected voltage.

P1635 is 5v reference circuit #1 low.

P1639 is 5v reference circuit #2 low.

you also got P0452 which looks like fuel tank pressure sensor circuit low voltage.

Not sure if you posted any other codes, but just from these you need to understand what the root cause is and that some codes like P0102 and P0452 are the result of some underlying problem which may or may not be a code by itself. But in this case it seems like the 2 big codes are P1635 and P1639.

The 5v reference circuit is big time, that's a 5v signal that supplies a bunch of electronic sensors on the car like your MAF which you got a code for, like your fuel tank sender which you got a code for. So you don't go concluding you have a bad MAF or a bad fuel pump when you have P1635 & P1639 because the whole system cannot be trusted because it's not getting a good 5v reference signal to work from.

The fact that you got P1635 & P1639 both circuit 1 & 2 means you have some electrical problem related to the whole system- as opposed to it only being one of the circuits.

The only good advice anywhere in here seems to be check your grounds and electrical connections, it is an electrical problem. The spark plug pic looked fine, it's not your spark plugs, it's not your fuel filter, it's not your fuel pressure, it's not your O2 sensors.

When fuel pressure is around 50 psi engine off that is normal, and when it jumps up a few psi engine running is normal because the pump is then seeing 14 volts from the alternator outputting rather than just battery voltage of 12.5 with engine off. your fuel pressure is in normal range. you need to find out what is causing the 5v reference both circuits to go low. first thing off top of my head is bad computer but that is just a guess. i can tell you that it's not a single sensor like the coolant temp sensor because no one sensor is going to pull both 5v reference circuits low, a single sensor only runs off one 5v circuit. my suggestion is to scour the net looking for causes and solutions to the P1635 P1639 for both 5v reference circuits low.

my other suggestion is get a volt meter, preferably analog with a needle so you can see voltage bounce but a digital will get you started. a good battery engine off will read 12.5 volts or higher. with engine idling you should see battery voltage steady around 14.0 volts. i would start there and make sure you are getting reliable output from the alternator then start working your way deeper into the electrical system to find what's causing the 5v reference circuits to drop.

another thing is- disconnect battery then disconnect the two harness plugs going to the pcm and looked for bad/bent/burnt pins. also consider tracing all wire harnesses in the engine bay looking for signs of chaffing into the harness which could be shorting a wire to ground. also look under the fuse boxes in the engine bay and look for evidence of a mouse nest and chewed wires. the fact that the engine stumbles immediately after started tells me it's not really a loose or bad/intermittent connection somewhere- such as if the engine idled well but stumbled every so often then you could wiggle wires looking for one that might cause the problem. but from your description you can't do it. you should also get a handheld scanner, clear codes, then cycle the ignition without starting and look for codes thrown before engine started, then how soon after engine started, and narrow down what is causing the problem.

another thing to understand is you can unplug certain sensors like the maf, o2's, ect, or AC and still have the engine start and idle normal. in the case of a single 5v reference circuit low, what you could do is unplug a sensor and see if it fixes the stumbling due to the entire 5v reference circuit low. for example your P0102 and MAF sensor let's say that was really the cause. what you would do is clear codes, unplug the MAF and make sure the disconnected plug itself is not bad and shorting to ground then start engine and let idle. it should idle smoothly with a MAF specific code but not a 5v reference code, if this were to happen then you have some reliable info pointing to a bad MAF or wiring to it. but in your case you had both P1635 & P1639, what you need to do is get a scanner and find out when those two codes are happening and if happening simultaneously to systematically diagnose and find the problem.

Last edited by 1 FMF; 05-06-2013 at 08:33 AM.

#43

Staging Lane

Thread Starter

iTrader: (2)

Join Date: Mar 2008

Location: Mansfield, OH

Posts: 60

Likes: 0

Received 0 Likes

on

0 Posts

1 FMF I'm not quoting to save post size but this is in reply to your above post.

I was kind of afraid that this was going to be an electrical issue after reading a little about the codes and what some others have mentioned as possible cause.

Codes

Right now I have 3 codes.

P1635

P1639

P0452

Code P0102 I believe came about from having the MAF unplugged while running the car early on during testing to see if it ran better with the MAF unplugged. After clearing that code once it never did come back.

I haven't tried clearing codes since getting P0452 so I will try that tonight and see if it comes back. P1635 & P1639 always seem to be present so I'm guessing at least those are going to still be there.

Not sure if it will make a difference or not but I recently replaced my gas cap with an aftermarket locking cap. Not sure if this could possibly be the reason for the P0452 or if it's related to the other two. Timing of seeing that code seemed to be about that time. I'll try my OEM cap after clearing codes to make sure.

I'll start tracking down wires and such in hope that I find something that looks messed up. I kind of stopped with the electrical direction hoping it could be something else since I got stuck on a few things. Mainly with grounding on the back of the head. I have no idea how to get to that. I can barely touch it with my hand and that's the one closest to the edge. Can't find much info out there about how to get at these either.

Not sure if it matters but my battery is brand new. Like a week old. I'll still test voltage but I don't think there will be any issue there. Maybe if the alternator is having a problem but how can you tell if the alternator is having issues?

Regarding the PCM and wiring. Why are there torque specs on that? How specific are they? I was going to take it out and look at it closer before but was afraid of not getting it back in right with the correct torque and whatnot. I know some stuff is a lot less critical than other things and wasn't sure on this.

Any logic or reason to the car idling and running much better than it was after doing the fuel filter, one plug, and the coolant temperature sensor? After about 10-15 min of idle the car seemed fine. Didn't appear to sputter or miss even once till I drove it. Also, exhaust didn't smell as rich.

I guess codes will tell me more once I clear them out and see what's still coming back. I'll try to get more info tonight and start checking the things you suggested.

I was kind of afraid that this was going to be an electrical issue after reading a little about the codes and what some others have mentioned as possible cause.

Codes

Right now I have 3 codes.

P1635

P1639

P0452

Code P0102 I believe came about from having the MAF unplugged while running the car early on during testing to see if it ran better with the MAF unplugged. After clearing that code once it never did come back.

I haven't tried clearing codes since getting P0452 so I will try that tonight and see if it comes back. P1635 & P1639 always seem to be present so I'm guessing at least those are going to still be there.

Not sure if it will make a difference or not but I recently replaced my gas cap with an aftermarket locking cap. Not sure if this could possibly be the reason for the P0452 or if it's related to the other two. Timing of seeing that code seemed to be about that time. I'll try my OEM cap after clearing codes to make sure.

I'll start tracking down wires and such in hope that I find something that looks messed up. I kind of stopped with the electrical direction hoping it could be something else since I got stuck on a few things. Mainly with grounding on the back of the head. I have no idea how to get to that. I can barely touch it with my hand and that's the one closest to the edge. Can't find much info out there about how to get at these either.

Not sure if it matters but my battery is brand new. Like a week old. I'll still test voltage but I don't think there will be any issue there. Maybe if the alternator is having a problem but how can you tell if the alternator is having issues?

Regarding the PCM and wiring. Why are there torque specs on that? How specific are they? I was going to take it out and look at it closer before but was afraid of not getting it back in right with the correct torque and whatnot. I know some stuff is a lot less critical than other things and wasn't sure on this.

Any logic or reason to the car idling and running much better than it was after doing the fuel filter, one plug, and the coolant temperature sensor? After about 10-15 min of idle the car seemed fine. Didn't appear to sputter or miss even once till I drove it. Also, exhaust didn't smell as rich.

I guess codes will tell me more once I clear them out and see what's still coming back. I'll try to get more info tonight and start checking the things you suggested.

#44

TECH Fanatic

iTrader: (1)

it is not your gas cap, you can run any car without a gas cap and it will idle and run fine.

with the alternator you get a volt meter and hook that up to battery + and -. engine off should be 12.5 volts or higher. engine idling meter should read over 13.5 volts, if it doesn't go much above 12.5 or whatever you measured with engine off then there is a problem with alternator charging. with a analog volt meter with a needle you can see voltage bounce, it should be steady. depending on how unsteady the voltage is may indicate bad alternator.

the pcm harness torque spec is not a big deal, you don't want to over tighten it and crack the plastic. after inserting the harness plugs to the pcm, push them evenly so they are snug then finger tighten the nut using a socket, then with a ratchet finger tighten.

first a fuel filter never fixes anything. only time ever a fuel filter may be the cause of a problem is when running wide and high rpm's where engine needs lots of fuel and fuel filter is restrictive then that would result in loss of pressure at the injectors. otherwise if it were that restrictive engine would just die whenever you tried to accelerate.

when you start a cold engine for the first couple minutes it runs in open loop mode- it knows this based on coolant temp being below 100°F and a few other parameters. open loop means it's not relying on the O2 sensors, and possibly not the MAF sensor and some other sensors to make it run ideal regarding emissions and efficiency. because of your P1635 & P1639 codes that means all those sensors relying on that are now reporting bad causing the engine to run bad when in closed loop... maybe. but i thought you said initially that you first start the engine and it was instantly idling bad. if the engine is warm, the computer can go into closed loop under 10 seconds. so without seeing first hand and without more detailed info i couldn't say for sure. i also don't remember reading if you've done anything to the car or if it's completely stock. you need to at least get a scanner on the car and systematically diagnose- start engine when completely cold and verify when it's in open loop then closed loop and note when the problems occur.

you may also try unplugging all 4 O2 sensor plugs and make sure none of the plug wires are shorting or grounding, clear codes then start engine. you'll get O2 sensor codes but your goal is to find out what is causing the P1635/9 codes. there are some bulletins that water in plug harnesses could cause it along with the harness plug going to the computer (see link below). have you washed your engine bay or had rain storms or driven through puddles? any aftermarket accessories on car or anyone else perform work on the car that could have caused pinch wires?

http://gmcowners.com/gmc-forum/showthread.php?t=7

http://www.underhoodservice.com/issu...ntentid=103222

with the alternator you get a volt meter and hook that up to battery + and -. engine off should be 12.5 volts or higher. engine idling meter should read over 13.5 volts, if it doesn't go much above 12.5 or whatever you measured with engine off then there is a problem with alternator charging. with a analog volt meter with a needle you can see voltage bounce, it should be steady. depending on how unsteady the voltage is may indicate bad alternator.

the pcm harness torque spec is not a big deal, you don't want to over tighten it and crack the plastic. after inserting the harness plugs to the pcm, push them evenly so they are snug then finger tighten the nut using a socket, then with a ratchet finger tighten.

Any logic or reason to the car idling and running much better than it was after doing the fuel filter, one plug, and the coolant temperature sensor? After about 10-15 min of idle the car seemed fine. Didn't appear to sputter or miss even once till I drove it.

when you start a cold engine for the first couple minutes it runs in open loop mode- it knows this based on coolant temp being below 100°F and a few other parameters. open loop means it's not relying on the O2 sensors, and possibly not the MAF sensor and some other sensors to make it run ideal regarding emissions and efficiency. because of your P1635 & P1639 codes that means all those sensors relying on that are now reporting bad causing the engine to run bad when in closed loop... maybe. but i thought you said initially that you first start the engine and it was instantly idling bad. if the engine is warm, the computer can go into closed loop under 10 seconds. so without seeing first hand and without more detailed info i couldn't say for sure. i also don't remember reading if you've done anything to the car or if it's completely stock. you need to at least get a scanner on the car and systematically diagnose- start engine when completely cold and verify when it's in open loop then closed loop and note when the problems occur.

you may also try unplugging all 4 O2 sensor plugs and make sure none of the plug wires are shorting or grounding, clear codes then start engine. you'll get O2 sensor codes but your goal is to find out what is causing the P1635/9 codes. there are some bulletins that water in plug harnesses could cause it along with the harness plug going to the computer (see link below). have you washed your engine bay or had rain storms or driven through puddles? any aftermarket accessories on car or anyone else perform work on the car that could have caused pinch wires?

http://gmcowners.com/gmc-forum/showthread.php?t=7

http://www.underhoodservice.com/issu...ntentid=103222

#45

Staging Lane

Thread Starter

iTrader: (2)

Join Date: Mar 2008

Location: Mansfield, OH

Posts: 60

Likes: 0

Received 0 Likes

on

0 Posts

Ok good to know about the cap. I'll not bother with that one.

I will run the voltage test when I get home tonight. I don't have volt meter with a needle but I can borrow one. I'll test on my digital one tonight and see how it looks.

Can there be issues with the alternator that are minor and don't affect other functionaltiy? I've only ever had an issue with one where it completely died.

If I have enough daylight today when I get home I'll pull the PCM too and check it out. I have read some stuff about a screw underneath there somewhere that someone had a cover fall off of and rub wires. I'll check the pins as well for anything out of the ordinary assuming I can tell what I'm looking at lol

As far as the idle, the car ran like complete **** at idle and the exhaust smelled rich but not like gas, it was more carbon/ sulfur/ chemical. I replaced the fuel filter and checked it again and it was a little better but still missing pretty hard. Sitting in the car running at night you could see the blips in power from the backlight on the gauges. It would flicker pretty good every 30 or so seconds. Exhaust smell was about the same.

I changed out the coolant temperature sensor and the spark plug underneath it. Started it back up and burped the air bubbles out and the idle was smoothe. No blips or anything and exhaust smelled normal too. Was the best it had ran at idle in quite awhile. I still had no temp gauge activity even after 10-15 minutes of running the car and the fuel gague was still dead. So it does idle a LOT better but I still have issues elsewhere.

Only mods to the car is a lid which i'm pretty sure wouldn't be messing with anything. I had it off yesterday also and double checked the air filter. Other than that it's stock.

Never have driven it through any water. We get the occasional rain storm here in Ohio but nothing really I would see an issue with. That and it hasn't rained in a few days. Might have today a bit. I haven't washed down the engine bay. It's a tad dirty but not terrible.

Do you by chance know right off what all is tied into that 5v reference circuit?

I will run the voltage test when I get home tonight. I don't have volt meter with a needle but I can borrow one. I'll test on my digital one tonight and see how it looks.

Can there be issues with the alternator that are minor and don't affect other functionaltiy? I've only ever had an issue with one where it completely died.

If I have enough daylight today when I get home I'll pull the PCM too and check it out. I have read some stuff about a screw underneath there somewhere that someone had a cover fall off of and rub wires. I'll check the pins as well for anything out of the ordinary assuming I can tell what I'm looking at lol

As far as the idle, the car ran like complete **** at idle and the exhaust smelled rich but not like gas, it was more carbon/ sulfur/ chemical. I replaced the fuel filter and checked it again and it was a little better but still missing pretty hard. Sitting in the car running at night you could see the blips in power from the backlight on the gauges. It would flicker pretty good every 30 or so seconds. Exhaust smell was about the same.

I changed out the coolant temperature sensor and the spark plug underneath it. Started it back up and burped the air bubbles out and the idle was smoothe. No blips or anything and exhaust smelled normal too. Was the best it had ran at idle in quite awhile. I still had no temp gauge activity even after 10-15 minutes of running the car and the fuel gague was still dead. So it does idle a LOT better but I still have issues elsewhere.

Only mods to the car is a lid which i'm pretty sure wouldn't be messing with anything. I had it off yesterday also and double checked the air filter. Other than that it's stock.

Never have driven it through any water. We get the occasional rain storm here in Ohio but nothing really I would see an issue with. That and it hasn't rained in a few days. Might have today a bit. I haven't washed down the engine bay. It's a tad dirty but not terrible.

Do you by chance know right off what all is tied into that 5v reference circuit?

#46

TECH Fanatic

iTrader: (1)

from my 2002 service manual,

P1635 = 5v reference circuit for MAP sensor and EGR pintle position sensor for 3.8L v6, and TP sensor and MAP sensor for 5.7L v8. This DTC set if pcm sees circuit out of tolerance more than 10 seconds. The dash light illuminates on the 2nd consecutive ignition cycle that this diagnostic runs and fails, and the light will turn off automatically after 3 consecutive ignition cycles that the diagnostic test passes. when the dash light is turned on, freeze frame data is stored in the computer and you need a handheld that can show that information which helps you diagnose what caused the problem. freeze frame data automatically clears after 40 consecutive warm up cycles.

P1639 = AC pressure sensor and fuel tank pressure sensor for 5.7L v8, and only lists AC sensor for 3.8L v6.

you would want to figure out when both DTC's were setting if both happened at the same time. It seems like they are which tends to rule out a specific sensor causing this. for both circuits to go low or high, it needs to be something common to both circuits like a battery cable or engine ground. but for a single circuit problem it would go like this: unplug all sensors on circuit such as map & TP sensor for circuit 1. use volt meter to probe one connector plug, with ignition on engine off measure 5v reference pin to engine ground. if within range and no DTC set, but when connector for other sensor is plugged in the reference circuit goes out of range then you know that sensor you plugged in is bad and needs replacing. if with all sensors unplugged and reference circuit is out of range immediately when ignition turned on then you know cause is something upstream of the sensors. and if both circuits are doing this it's unlikely to have 2 simultaneously failed sensors, more likely a wiring problem common to both circuits wherever that may be. manual in it's procedure states this for both sensors and if both sensors check out good and no wiring problems found next step is replace PCM.

i do remember reading on here that one of the sheet metal type screws that holds the pcm harness on or the pcm in it's bracket could be bending the case of the pcm or protuding into a circuit board causing pcm problems.

yes the alternator can not be 100% but still function and cause zero problems and no DTC's. if the alternator were a significant problem you would have a related DTC and notice a significant voltage drop when engine running.

looking deeper into engine control schematics engine data sensors 5v & low reference:

5v reference connected to MAP, fuel tank pressure, AC pressure, and throttle position sensors and accelerator and servo control module (ASM). the wires from these sensors goes back to the PCM as the low reference which is the sensor signal. a second diagram shows ECT sensor, MAP, IAT, and TP sensors getting 5v from the PCM, not sure if all these are on the 5v reference circuit that would set a DTC.

from the looks of it, 5v reference to map is pin 48 on pcm, pin 46 for fuel tank pressure sensor, pin 8 for throttle position sensor and ASM. pin 74 for ect, pin 25 for IAT.

P1635 = 5v reference circuit for MAP sensor and EGR pintle position sensor for 3.8L v6, and TP sensor and MAP sensor for 5.7L v8. This DTC set if pcm sees circuit out of tolerance more than 10 seconds. The dash light illuminates on the 2nd consecutive ignition cycle that this diagnostic runs and fails, and the light will turn off automatically after 3 consecutive ignition cycles that the diagnostic test passes. when the dash light is turned on, freeze frame data is stored in the computer and you need a handheld that can show that information which helps you diagnose what caused the problem. freeze frame data automatically clears after 40 consecutive warm up cycles.

P1639 = AC pressure sensor and fuel tank pressure sensor for 5.7L v8, and only lists AC sensor for 3.8L v6.

you would want to figure out when both DTC's were setting if both happened at the same time. It seems like they are which tends to rule out a specific sensor causing this. for both circuits to go low or high, it needs to be something common to both circuits like a battery cable or engine ground. but for a single circuit problem it would go like this: unplug all sensors on circuit such as map & TP sensor for circuit 1. use volt meter to probe one connector plug, with ignition on engine off measure 5v reference pin to engine ground. if within range and no DTC set, but when connector for other sensor is plugged in the reference circuit goes out of range then you know that sensor you plugged in is bad and needs replacing. if with all sensors unplugged and reference circuit is out of range immediately when ignition turned on then you know cause is something upstream of the sensors. and if both circuits are doing this it's unlikely to have 2 simultaneously failed sensors, more likely a wiring problem common to both circuits wherever that may be. manual in it's procedure states this for both sensors and if both sensors check out good and no wiring problems found next step is replace PCM.

i do remember reading on here that one of the sheet metal type screws that holds the pcm harness on or the pcm in it's bracket could be bending the case of the pcm or protuding into a circuit board causing pcm problems.

yes the alternator can not be 100% but still function and cause zero problems and no DTC's. if the alternator were a significant problem you would have a related DTC and notice a significant voltage drop when engine running.

looking deeper into engine control schematics engine data sensors 5v & low reference:

5v reference connected to MAP, fuel tank pressure, AC pressure, and throttle position sensors and accelerator and servo control module (ASM). the wires from these sensors goes back to the PCM as the low reference which is the sensor signal. a second diagram shows ECT sensor, MAP, IAT, and TP sensors getting 5v from the PCM, not sure if all these are on the 5v reference circuit that would set a DTC.

from the looks of it, 5v reference to map is pin 48 on pcm, pin 46 for fuel tank pressure sensor, pin 8 for throttle position sensor and ASM. pin 74 for ect, pin 25 for IAT.

#47

Staging Lane

Thread Starter

iTrader: (2)

Join Date: Mar 2008

Location: Mansfield, OH

Posts: 60

Likes: 0

Received 0 Likes

on

0 Posts

I tested the battery with a volt meter and everything looked fine. Right about 12.5 engine off and around 14.5 engine on at idle so sounds like alternator should be ok?

I pulled the PCM and checked out the pins. Everything looked really good and clean. None of the wires had been cut or damaged from anything. I didn't open the actual PCM box up just pulled it from the car and made sure the pins looked good from the outside. Wires running underneath and around the PCM all looked fine as well. Screw that was talked about didn't appear to have gone through the PCM housing. I covered it with electrical tape before putting PCM back in to be safe.

After looking at wires around the fuse box, I thought I found the isse. See pics attached.

Found a mouse house right under the fuse box where you said to check. About 3of the wires were showing some bare wire. None of them were into the wire but one was pretty bare. I cleaned out all the stuff the mouse put in there and taped up the wires with some electrical tape.

I went over everything extremely well to make sure there were no other issues with any wires in that area or any other area that I could see. . Everything else looked good and I was confident I had found my issue. Not so much.

I started the car up and it was acting all kinds of crazy again at first start. That may have been idle relearn again? I did that procedure and it seemed to be ok at idle on the next start.

Drove it again and had the same damn hard stumble several times after going a little over a mile. I believe I was mid way through second or third gear this time. First couple passes through those gears were fine. No issues out of first from a stop.

I suppose next would be testing voltage on the 5v sensors and the PCM? Also, nothing with the wires I taped up did anything for the fuel gauge or the temp gauge. I suppose I expected the stumble to be fixed before the gauges since one of the messed up wires was for the fuel pump.

I also still have those elusive ground wires on the back of the driver's side head I've been dreading. Still stumped how to get to those. Maybe I could follow a head removal write up and get at it once I get all the other stuff off. That may be a rather large time consuming job for a newbie

Last summer my AC compressor died. From what you said the AC pressure sensor ties into this but I'm not sure that the compressor dying would mess with anything else besides the AC not working? Also where are the MAP and EGR sensors? Not familiar with either one of those or where they might be.

I pulled the PCM and checked out the pins. Everything looked really good and clean. None of the wires had been cut or damaged from anything. I didn't open the actual PCM box up just pulled it from the car and made sure the pins looked good from the outside. Wires running underneath and around the PCM all looked fine as well. Screw that was talked about didn't appear to have gone through the PCM housing. I covered it with electrical tape before putting PCM back in to be safe.

After looking at wires around the fuse box, I thought I found the isse. See pics attached.

Found a mouse house right under the fuse box where you said to check. About 3of the wires were showing some bare wire. None of them were into the wire but one was pretty bare. I cleaned out all the stuff the mouse put in there and taped up the wires with some electrical tape.

I went over everything extremely well to make sure there were no other issues with any wires in that area or any other area that I could see. . Everything else looked good and I was confident I had found my issue. Not so much.

I started the car up and it was acting all kinds of crazy again at first start. That may have been idle relearn again? I did that procedure and it seemed to be ok at idle on the next start.

Drove it again and had the same damn hard stumble several times after going a little over a mile. I believe I was mid way through second or third gear this time. First couple passes through those gears were fine. No issues out of first from a stop.

I suppose next would be testing voltage on the 5v sensors and the PCM? Also, nothing with the wires I taped up did anything for the fuel gauge or the temp gauge. I suppose I expected the stumble to be fixed before the gauges since one of the messed up wires was for the fuel pump.

I also still have those elusive ground wires on the back of the driver's side head I've been dreading. Still stumped how to get to those. Maybe I could follow a head removal write up and get at it once I get all the other stuff off. That may be a rather large time consuming job for a newbie

Last summer my AC compressor died. From what you said the AC pressure sensor ties into this but I'm not sure that the compressor dying would mess with anything else besides the AC not working? Also where are the MAP and EGR sensors? Not familiar with either one of those or where they might be.

#49

Staging Lane

Thread Starter

iTrader: (2)

Join Date: Mar 2008

Location: Mansfield, OH

Posts: 60

Likes: 0

Received 0 Likes

on

0 Posts

I did find a write up on for intake removal on ls1howto.com from another thread. It doesn't look too bad but I'm curious if anything that most would consider common knowlege was left out of the write up? They mentioned in the thread that I found the link in to not disconnect the fuel lines as shown? There any particular reason not to do that? Are they hard to reconnect or something? Was something in the write up not correct? Here's a link to it.

http://www.ls1howto.com/index.php?article=5

Mostly wanting to know if there is anything not shown that I will need to have to get this done properly? Or anything tricky for a newb that may not be shown in detail? I thought I read something about needing some new gaskets when doing this?

Any specific tools that are needed that are out of the norm? Anything going to gush some kind of fluid at me when i disconnect certain things?

Just want to make sure I do this correctly and don't jack anything up. Seems like a rather large deal compared to the other stuff I've done to this point.

Just want to make sure I do this correctly and don't jack anything up. Seems like a rather large deal compared to the other stuff I've done to this point.Any fairly basic mods or other maintenance to do while this is out?

#50

Staging Lane

Thread Starter

iTrader: (2)

Join Date: Mar 2008

Location: Mansfield, OH

Posts: 60

Likes: 0

Received 0 Likes

on

0 Posts

OK so I want to eliminate a couple of things before I go trying to pull off the Intake and tackling engine grounds. If anyone could help answer these questions it would be a big help and I can hopefully make more progress on this issue.

My A/C system has a dead compressor. Died last summer. Would this cause the car to throw any codes? Was wondering if it would have anything to do with the P1639 code? I want to try and figure out if the P1639 and P1635 codes are related or separate. Given the A/C issue from last summer, I was thinking there is a chance they could be separate.

Also, I'm not sure I'm going to replace the compressor yet. Until I decide to replace / remove it or whatever, does anything need to be unplugged to not throw any codes? Any connectors? Could this be in any way messing with my FTP sensor?

Would anyone be able to take a picture of the A/C pressure sensor / switch? I am not real sure where it is. I've seen pictures of the pigtail connector but haven't found it on the car yet. At the very least I want to test the voltage on it and ground if I can figure that out.

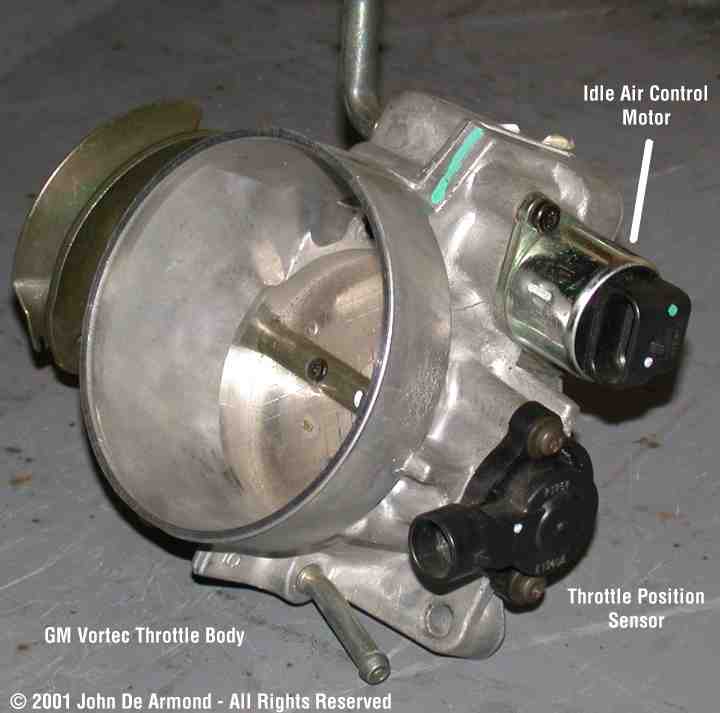

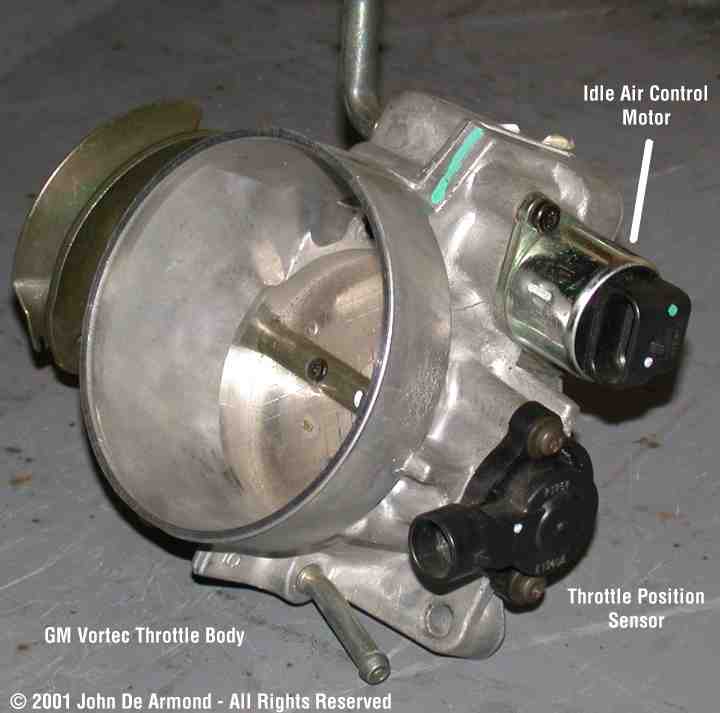

TP sensor - Is this on the top or the bottom of the throttle body? I know there are two of them on the throttle body (IAC and TP) but wasn't sure which was which.

My A/C system has a dead compressor. Died last summer. Would this cause the car to throw any codes? Was wondering if it would have anything to do with the P1639 code? I want to try and figure out if the P1639 and P1635 codes are related or separate. Given the A/C issue from last summer, I was thinking there is a chance they could be separate.

Also, I'm not sure I'm going to replace the compressor yet. Until I decide to replace / remove it or whatever, does anything need to be unplugged to not throw any codes? Any connectors? Could this be in any way messing with my FTP sensor?

Would anyone be able to take a picture of the A/C pressure sensor / switch? I am not real sure where it is. I've seen pictures of the pigtail connector but haven't found it on the car yet. At the very least I want to test the voltage on it and ground if I can figure that out.

TP sensor - Is this on the top or the bottom of the throttle body? I know there are two of them on the throttle body (IAC and TP) but wasn't sure which was which.

#51

TECH Fanatic

iTrader: (1)

IAC is top on throttle body, position sensor is bottom in line with the throttle blade shaft

IAT is in the lid above the air filter unless you have modified things.

unless you or a previous owner has wrenched on the car and modified stuff, you are probably wasting your time going after the main ground strap on the back of the head. if you can tug on it and it does not pull out, then it's good. it's not something anyone can easily get to to screw up.

IAT is in the lid above the air filter unless you have modified things.

unless you or a previous owner has wrenched on the car and modified stuff, you are probably wasting your time going after the main ground strap on the back of the head. if you can tug on it and it does not pull out, then it's good. it's not something anyone can easily get to to screw up.

Last edited by 1 FMF; 05-14-2013 at 08:16 PM.

#52

TECH Fanatic

iTrader: (1)

the AC compressor and it's clutch would not cause the codes you have. The ac compressor clutch is a battery voltage feed from the PCM that activates it, it is not on the 5v circuit. But your AC high pressure sensor is on the 5v circuit so you should unplug that, it is located in the attached pic. I don't remember off hand where the low pressure sensor is, i think it's on the accumulator which is the big metal canister that would be wet and cold if the AC were working, it's in the lower right of attached pic. I would unplug that sensor also. But the clutch wire going to the compressor, if it's easy to get to then unplug otherwise it would not cause your 5v low codes.

Last edited by 1 FMF; 05-14-2013 at 08:23 PM.

#53

Staging Lane

Thread Starter

iTrader: (2)

Join Date: Mar 2008

Location: Mansfield, OH

Posts: 60

Likes: 0

Received 0 Likes

on

0 Posts

the AC compressor and it's clutch would not cause the codes you have. The ac compressor clutch is a battery voltage feed from the PCM that activates it, it is not on the 5v circuit. But your AC high pressure sensor is on the 5v circuit so you should unplug that, it is located in the attached pic. I don't remember off hand where the low pressure sensor is, i think it's on the accumulator which is the big metal canister that would be wet and cold if the AC were working, it's in the lower right of attached pic. I would unplug that sensor also. But the clutch wire going to the compressor, if it's easy to get to then unplug otherwise it would not cause your 5v low codes.

I'm seriously thinking about just buying a new PCM to test with. I'll just throw it up for sale or hang on to it for a tune later on maybe if it's not that.

Do you know can the PCM once you have it out of the car be opened up to inspect the board? I had it out once and started to do that and got a bit of a hissing sound out of the housing when I took the 4 hex screws out of it. I stopped thinking it was something I was going to mess up.

Is there any good way to test the PCM to see if it's doing what it's supposed to?

Still making some progress at least so I'll keep at it till I figure it out. Once I get this damn thing fixed I can start modding!

#54

Staging Lane

Thread Starter

iTrader: (2)

Join Date: Mar 2008

Location: Mansfield, OH

Posts: 60

Likes: 0

Received 0 Likes

on

0 Posts

OK more info

I disconnected the A/C high pressure sensor / switch and the A/C clutch connector. I read that there isn't a low pressure sensor / switch. Is that accurate? I cleared the codes on the car and put the ignition to the run position and scanned codes again. Only getting P0452. Did this several times to be sure the P1635 and P1639 were not going to show up again. They did not.

I started the car and scanned codes again and still get P0452. I now am also getting P1635 and P1639 again. Seems these codes are only triggered when the car is running now.

I also tested the voltage of the throttle position sensor while the key was in the on position and was getting 5v from the gray (reference) wire. Can this be tested while the car is running? If so how? Doesn't appear you can back probe this one.

While doing tests I noticed that the temperature gauge which still appeared to be broken seems to be working when the key is in the on position. It starts off looking dead then when the fuel pump stops humming it goes up to what looks to be the current position it should be (based on roughly how long the car has been running). It instantly pegs to the left like it's dead when you start the car.

The fuel gauge is still dead and has been in pretty much all phases. It jitters when you turn the key to the on position and the fuel pump starts but it doesn't really move up, just kind of shakes for a second. I remember that this was one of the first things to go out on me and I was pretty sure I would need to drop the tank and put it off. Before the gauge died completely I remember it would every so often come up to around half to 3/4 of a tank. I was never really sure if it was accurate though. Eventually it pegged all the way to the left with the needle below the E and it never came back. Then the a/c compressor died a month or so later, then the issue with the sputtering shortly before putting the car away for winter.

I have a replacement PCM on order and should be arriving in the next few days. I will swap it with the original once I get it and see what happens.

I'm starting to lean towards fuel pump? I know that was suggested before and one of the possibly failing sensor's as well as the level sensor for the gauge is also there. Then again there could be the EGR or MAP sensor still giving issues which is going to be Intake removal. I can reach the MAP sensor but not sure what good that's going to do? I had my arm back in there last night and could disconnect the connector if I really wanted to. No chance of getting a multimeter on it though.

Any other ideas for the direction this could be heading based on this info? Seems really odd that the temperature gauge would seem to work at key on but not when running.

I disconnected the A/C high pressure sensor / switch and the A/C clutch connector. I read that there isn't a low pressure sensor / switch. Is that accurate? I cleared the codes on the car and put the ignition to the run position and scanned codes again. Only getting P0452. Did this several times to be sure the P1635 and P1639 were not going to show up again. They did not.

I started the car and scanned codes again and still get P0452. I now am also getting P1635 and P1639 again. Seems these codes are only triggered when the car is running now.

I also tested the voltage of the throttle position sensor while the key was in the on position and was getting 5v from the gray (reference) wire. Can this be tested while the car is running? If so how? Doesn't appear you can back probe this one.

While doing tests I noticed that the temperature gauge which still appeared to be broken seems to be working when the key is in the on position. It starts off looking dead then when the fuel pump stops humming it goes up to what looks to be the current position it should be (based on roughly how long the car has been running). It instantly pegs to the left like it's dead when you start the car.

The fuel gauge is still dead and has been in pretty much all phases. It jitters when you turn the key to the on position and the fuel pump starts but it doesn't really move up, just kind of shakes for a second. I remember that this was one of the first things to go out on me and I was pretty sure I would need to drop the tank and put it off. Before the gauge died completely I remember it would every so often come up to around half to 3/4 of a tank. I was never really sure if it was accurate though. Eventually it pegged all the way to the left with the needle below the E and it never came back. Then the a/c compressor died a month or so later, then the issue with the sputtering shortly before putting the car away for winter.

I have a replacement PCM on order and should be arriving in the next few days. I will swap it with the original once I get it and see what happens.

I'm starting to lean towards fuel pump? I know that was suggested before and one of the possibly failing sensor's as well as the level sensor for the gauge is also there. Then again there could be the EGR or MAP sensor still giving issues which is going to be Intake removal. I can reach the MAP sensor but not sure what good that's going to do? I had my arm back in there last night and could disconnect the connector if I really wanted to. No chance of getting a multimeter on it though.

Any other ideas for the direction this could be heading based on this info? Seems really odd that the temperature gauge would seem to work at key on but not when running.

#55

TECH Fanatic

iTrader: (10)

Join Date: Aug 2002

Location: Danville,PA

Posts: 1,109

Likes: 0

Received 0 Likes

on

0 Posts

Well, someone correct me if I'm wrong here, but I believe there isn't a direct wire from the temp sensor to the gauge cluster. The temp sensor signal goes through either the PCM or BCM or maybe both, before heading to the gauge cluster. So, you might have an issue in that link.

#56

TECH Fanatic

iTrader: (1)

all cars with AC will have an AC low pressure sensor. That's needed in order to know if the system is low on refrigerant to shut off the compressor before wrecking it. Some compressors will have the sensor built into it and have the connector coming off the rear of it... the AC clutch wires come off the front of the compressor from the pulley. otherwise the low pressure sensor will be somewhere on the return line from the evaporator located behind the firewall to the compressor.

the temp sender wires go to the pcm and the pcm interprets that signal into a temperature. The pcm sends a serial data feed to the gauge cluster to tell the gauges what to do, the gauge cluster is basically a little computer.

your temp gauge is screwing up because the temp sender uses the 5v reference signal. when key on but engine off, everything is fine no P1635/9 code which is 5v circuit low. so the temp sender works, the pcm reads a valid temp, and tells the gauge cluster to report it. from what you said only when your engine is running do you get the P1635/9 codes which the 5v reference circuit goes bad, so your temp sender then does not function and the PCM sees this and it does not tell the gauge cluster a temperature to report.

with being sure you don't get P1635/9 with key on engine off and you only get P0452,

http://www.ls2.com/boggs/dtcs/DTC%20P0452.htm

that is fuel tank pressure sensor low voltage. that sensor is on the 5v circuit so from this tells me the fuel pump assembly may be bad. i know the fuel pump and fuel gauge sensor are all part of the unit, i am not sure about the pressure sensor you'll need to look that up. but you said the fuel gauge has always been useless (not working) so this further points to a bad fuel pump assembly. Fuel pump assemblies needing replacement on these cars and on all of GM's cars are not uncommon.

if you know no one has worked on the car where the electrical plug connections and wires would themselves be suspect, then all you need to do is unplug them from the sensor. you can leave all the AC electrical connections unplugged. I would try to unplug all others to rule things out, don't assume. you should be able to unplug the EGR & MAP sensor electrical connections. just keep clearing codes, turn key off, unplug sensors, turn key on, read codes, and diagnose till the point you have to start the engine. then do the same thing with starting the engine and seeing what codes pop up. with things unplugged you will get a lot more codes but remember you're looking to make sense of what is causing the P1635/9 codes and when.

but the fact that you seemed to say your fuel gauge never works means you need a new fuel pump assembly regardless.

the temp sender wires go to the pcm and the pcm interprets that signal into a temperature. The pcm sends a serial data feed to the gauge cluster to tell the gauges what to do, the gauge cluster is basically a little computer.

your temp gauge is screwing up because the temp sender uses the 5v reference signal. when key on but engine off, everything is fine no P1635/9 code which is 5v circuit low. so the temp sender works, the pcm reads a valid temp, and tells the gauge cluster to report it. from what you said only when your engine is running do you get the P1635/9 codes which the 5v reference circuit goes bad, so your temp sender then does not function and the PCM sees this and it does not tell the gauge cluster a temperature to report.

with being sure you don't get P1635/9 with key on engine off and you only get P0452,

http://www.ls2.com/boggs/dtcs/DTC%20P0452.htm

that is fuel tank pressure sensor low voltage. that sensor is on the 5v circuit so from this tells me the fuel pump assembly may be bad. i know the fuel pump and fuel gauge sensor are all part of the unit, i am not sure about the pressure sensor you'll need to look that up. but you said the fuel gauge has always been useless (not working) so this further points to a bad fuel pump assembly. Fuel pump assemblies needing replacement on these cars and on all of GM's cars are not uncommon.

if you know no one has worked on the car where the electrical plug connections and wires would themselves be suspect, then all you need to do is unplug them from the sensor. you can leave all the AC electrical connections unplugged. I would try to unplug all others to rule things out, don't assume. you should be able to unplug the EGR & MAP sensor electrical connections. just keep clearing codes, turn key off, unplug sensors, turn key on, read codes, and diagnose till the point you have to start the engine. then do the same thing with starting the engine and seeing what codes pop up. with things unplugged you will get a lot more codes but remember you're looking to make sense of what is causing the P1635/9 codes and when.

but the fact that you seemed to say your fuel gauge never works means you need a new fuel pump assembly regardless.

#57

TECH Fanatic

iTrader: (1)

the tank pressure sensor can be purchased separate from the fuel pump assembly for less than $50. it mounts on top of the fuel pump assembly.

so it looks like your options are either drop the fuel tank or cut a hole in the trunk deck to access things like in the pic. I would do one of these first and unplug that pressure sensor before buying anything and before buying/trying a new PCM which you probably don't need. also check those tank pressure sensor wires as much as possible looking for nick that could be shorting to ground.

#58

Staging Lane

Thread Starter

iTrader: (2)

Join Date: Mar 2008

Location: Mansfield, OH

Posts: 60

Likes: 0

Received 0 Likes

on

0 Posts

Should I be splitting open the black ribbed tubing even if it looks fine on the outside and inspecting the actual wires inside the tubing? I suppose it wouldn't be a bad idea although it's a bit frail due to the age. I can't imagine there being something wrong with a wire inside of there if the tubing is not disturbed at all on the outside, but crazier things have happened.

Has anyone done a racetronix pump kit install? I feel like I could probably do this with the trap door method but am not real sure what all I need to buy for the swap. Honstly I don't know **** about the fuel pump and have only watched a video and read some threads / posts about the replacement options and how to. I want to make sure I have everything I am going to need before I get started. I believe it all comes in one kit? Is that something that would come straight from racetronix or from somewhere else? What sites do you guys use to get your parts through aside from the autoparts store sites? I could use a couple good resources.

I'll double check all the wiring and swap the PCM since I'll have the spare here tomorrow, but would really like to know what all I need if I end up going the replacement pump assembly route. If I have all the stuff I need I'm pretty sure I can get it done. I read a lot last night on cutting the trap door and watched a video on pulling the pump. Fuel line disconnect and reconnect sounds like the hardest part aside from cutting the hole and not cutting up crap underneath it I think I can handle that though.

I think I can handle that though.

Has anyone done a racetronix pump kit install? I feel like I could probably do this with the trap door method but am not real sure what all I need to buy for the swap. Honstly I don't know **** about the fuel pump and have only watched a video and read some threads / posts about the replacement options and how to. I want to make sure I have everything I am going to need before I get started. I believe it all comes in one kit? Is that something that would come straight from racetronix or from somewhere else? What sites do you guys use to get your parts through aside from the autoparts store sites? I could use a couple good resources.

I'll double check all the wiring and swap the PCM since I'll have the spare here tomorrow, but would really like to know what all I need if I end up going the replacement pump assembly route. If I have all the stuff I need I'm pretty sure I can get it done. I read a lot last night on cutting the trap door and watched a video on pulling the pump. Fuel line disconnect and reconnect sounds like the hardest part aside from cutting the hole and not cutting up crap underneath it

#59

Staging Lane

Thread Starter

iTrader: (2)

Join Date: Mar 2008

Location: Mansfield, OH

Posts: 60

Likes: 0

Received 0 Likes

on

0 Posts

Thanks for the pic and the info on the sensor. From what I've seen / read in other threads is the car in the picture a 98? I think the 98s have the assembly closer to the top and 99-02 closer to the bottom?

I'll try making my hole and checking out the sensor first before I spend the money on a new pump. If that turns out to be it that would be awesome to have the door for when the pump does eventually give out! Plus I'll save a few bucks.

I probably shouldn't have bought the replacement PCM but meh $100 bucks and I'll have a spare for tuning when I get around to doing a few mods I guess. Or I can sell one to some poor bastard like me for a good price

If I end up needing to do the whole assembly do the kits generally include a new sensor? How fun is it to follow the sensor wire past the tank area underneath? Ever heard of the wire being messed up half way to the other side or is that fairly uncommon in the middle section between the tank and the front?

I'll try making my hole and checking out the sensor first before I spend the money on a new pump. If that turns out to be it that would be awesome to have the door for when the pump does eventually give out! Plus I'll save a few bucks.

I probably shouldn't have bought the replacement PCM but meh $100 bucks and I'll have a spare for tuning when I get around to doing a few mods I guess. Or I can sell one to some poor bastard like me for a good price

If I end up needing to do the whole assembly do the kits generally include a new sensor? How fun is it to follow the sensor wire past the tank area underneath? Ever heard of the wire being messed up half way to the other side or is that fairly uncommon in the middle section between the tank and the front?