Dorman TRUCK intake..any results?

#101

Home depot sells the pcv plumbing caps, yes. You don't necessarily need to use the valve stem; it depends on the test. In a high pressure test, it would be more important to have a self-sealing valve. But in a low pressure test (For an NA engine) You wouldn't need the valve stem as much. Like I did in my example video, just use a hose and put your finger on it.

First let me say that I've tested hundreds of engines from mild to wild in a variety of applications (4, 6, 8 cylinder) and NEVER had an issue with valves being open causing a problem with the pressure test. For example the LSx at the end of my video has an enormous cam- something like 244/244 @ .050, it pulls 6" Hg at idle. And I didn't even glance at the position of the engine, just fill the plumbing with air and find the leaks.

Second, most throttle body are water tight, and practically air tight. If you block the IACV line (or remove it) and leave the throttle body closed, air should stop in the intercooler plumbing and raise pressure there, avoiding the intake manifold.

Third, even if valves are open, it would have to be during an overlap period, and the amount of flow is insignificant compared to the flow rate of traditional air compressors. It depends on the air compressor of course. If you are trying to use a gas station tire pump or hand-operated tire pump then you will have a problem. On the other hand, a sufficient size air compressor tank will be able to overcome the loss of air through an overlapped valve/cylinder and still give you a chance to find leaks elsewhere (listen for the leaks) in a worst case scenario pressure test. Try turning the engine away from that sequence slightly and you will find that when the exhaust valve closes as the piston is moving down the air pressure will push it the rest of the way down and stop at some point, allowing you to complete the test.

It sounds like you have not tried much, if at all this method. You are guessing about the performance of a test never performed? I suggest you give it a try.

The only thing you need to "block off" Is the PCV fresh air tube which supplies the crank case. This is to avoid pressurizing the crankcase during the pressure test.

The test is mandatory for forced induction setups. There is always a leak somewhere. A boost leak raises compressor wheel speed, raises IAT, and increases exhaust gas backpressure. In worst case situation it can blow the engine (high IAT) or turbo (over speed). At least it is a detriment to performance.

First let me say that I've tested hundreds of engines from mild to wild in a variety of applications (4, 6, 8 cylinder) and NEVER had an issue with valves being open causing a problem with the pressure test. For example the LSx at the end of my video has an enormous cam- something like 244/244 @ .050, it pulls 6" Hg at idle. And I didn't even glance at the position of the engine, just fill the plumbing with air and find the leaks.

Second, most throttle body are water tight, and practically air tight. If you block the IACV line (or remove it) and leave the throttle body closed, air should stop in the intercooler plumbing and raise pressure there, avoiding the intake manifold.

Third, even if valves are open, it would have to be during an overlap period, and the amount of flow is insignificant compared to the flow rate of traditional air compressors. It depends on the air compressor of course. If you are trying to use a gas station tire pump or hand-operated tire pump then you will have a problem. On the other hand, a sufficient size air compressor tank will be able to overcome the loss of air through an overlapped valve/cylinder and still give you a chance to find leaks elsewhere (listen for the leaks) in a worst case scenario pressure test. Try turning the engine away from that sequence slightly and you will find that when the exhaust valve closes as the piston is moving down the air pressure will push it the rest of the way down and stop at some point, allowing you to complete the test.

It sounds like you have not tried much, if at all this method. You are guessing about the performance of a test never performed? I suggest you give it a try.

The only thing you need to "block off" Is the PCV fresh air tube which supplies the crank case. This is to avoid pressurizing the crankcase during the pressure test.

The test is mandatory for forced induction setups. There is always a leak somewhere. A boost leak raises compressor wheel speed, raises IAT, and increases exhaust gas backpressure. In worst case situation it can blow the engine (high IAT) or turbo (over speed). At least it is a detriment to performance.

how is the TB air/water tight? My stock and other LS TBs have a 5/32" drilled hole in them... seems like a big "air" leak to me. You would have to Cap the TB or just test from the pressure source (turbo compressor tubing start) and test the whole cold side and motor. Or cap both ends of the cold side and test, then test the motor side. I still feel that other variables can change what "checks" out in this test. What would be the differences between a hot and cold engine? Would the intake (2 peice or equivalent) be more likely to leak when hot or cold? Did you know that the TB shaft seal will NOT seal fully when its pressurized? The seal is designed to be sucked close against the shaft and doesnt seal well when pressure is introduced and thus most will get a slight boost leak around the TB shaft throttle cable side.

You would have to block both the valve cover PCV vent as well as the PCV valve (I have never seen one completely seal as they have such loose tolerances).

I'm not saying the test is invalid... but how far do you have to go to verify and intake doesnt leak. It used to be just spray starting fluid at gasket points or use propane. Personally I'm not comfortable pressurizing the crankcase as it should never see pressure and I would hate to push a seal our or create a leak that wasn't there. By not sealing the PCV and not pressurizing the crankcase I will have blowby/leak that will then require a visual leak testing method as you should hear the blow by. I can hear my blowby my cranking the motor over by hand. A compressor running or pushing air into something creates its own noise... i wouldnt be able to hear a "leak" more than likely I would need a visual source of identification.

"A boost leak raises compressor wheel speed, raises IAT, and increases exhaust gas backpressure." This is strickly turbo... has nothing to do with my supercharger. Also compressor wheel speed doesn't greatly affect IAT temps... compressing the the air is what causes the heat. If your not compressing the air then your not creating much heat, boost is a measure of restriction... less boost = less heat. I'm sure the physical impeller spinning faster prob has more to do with a turbo as your requiring more rpm/exhaust to produce the same boost and that relates to slightly more heat but in a supercharger application impeller wheel speed is directly related to crank speed via the pulleys. So bleeding boost just means you produce less boost in a supercharger application. Again your exhaust backpressure statement doesn't relate to a supercharger.

"In worst case situation it can blow the engine (high IAT) or turbo (over speed)" This is an alittle over zealous statement. You would have to have crazy IAT temps with no fail safes. Worst case is you loose boost and thus peformance directly related to the size of the boost leak. Every stock LS PCM has an IAT temp retard table. People with 1/2 a brain on a boosted motor will have some form of logging/viewing IAT temps and will be taking the appropriate measures to keep the engine out of the danger zone. A tiny intake leak will not cause a crazy amount of turbo over speed. A faulty BOV or WG will cause engine damage.

I'm sure this test is valid and has some uses but lets not make it personal. How many people perform this test when not many people know about it? Intakes are usually pretty fool proof, you bolt them down and go... LS motors make it even more easy with the new gaskets. Your saying its necessary doesn't mean it is, your reputation proceeds you btw and I'm aware of what you say has to be taken with a grain of salt. But I do feel this test has some validity and depending on time I might try to test this theory out. I have just sorta finished up a water/air intercooler setup and I'm probably going to test the cold side piping for leaks... I might just leave it all intact and pressurize the engine as well. Although I already know my stock intake isn't leaking.

But moving forward lets keep the thread focus on the dorman intake and peoples results relating to this intake.

#102

Banned

iTrader: (1)

You would have to Cap the TB or just test from the pressure source (turbo compressor tubing start) and test the whole cold side and motor. Or cap both ends of the cold side and test, then test the motor side. I still feel that other variables can change what "checks" out in this test. What would be the differences between a hot and cold engine? Would the intake (2 peice or equivalent) be more likely to leak when hot or cold? Did you know that the TB shaft seal will NOT seal fully when its pressurized? The seal is designed to be sucked close against the shaft and doesnt seal well when pressure is introduced and thus most will get a slight boost leak around the TB shaft throttle cable side.

You would have to block both the valve cover PCV vent as well as the PCV valve (I have never seen one completely seal as they have such loose tolerances).

I'm not saying the test is invalid... but how far do you have to go to verify and intake doesnt leak. It used to be just spray starting fluid at gasket points or use propane.

Personally I'm not comfortable pressurizing the crankcase as it should never see pressure and I would hate to push a seal our or create a leak that wasn't there. By not sealing the PCV and not pressurizing the crankcase I will have blowby/leak that will then require a visual leak testing method as you should hear the blow by. I can hear my blowby my cranking the motor over by hand. A compressor running or pushing air into something creates its own noise... i wouldnt be able to hear a "leak" more than likely I would need a visual source of identification.

"A boost leak raises compressor wheel speed, raises IAT, and increases exhaust gas backpressure." This is strickly turbo... has nothing to do with my supercharger. Also compressor wheel speed doesn't greatly affect IAT temps... compressing the the air is what causes the heat. If your not compressing the air then your not creating much heat, boost is a measure of restriction... less boost = less heat. I'm sure the physical impeller spinning faster prob has more to do with a turbo as your requiring more rpm/exhaust to produce the same boost and that relates to slightly more heat but in a supercharger application impeller wheel speed is directly related to crank speed via the pulleys. So bleeding boost just means you produce less boost in a supercharger application. Again your exhaust backpressure statement doesn't relate to a supercharger.

"In worst case situation it can blow the engine (high IAT) or turbo (over speed)" This is an alittle over zealous statement. You would have to have crazy IAT temps with no fail safes. Worst case is you loose boost and thus peformance directly related to the size of the boost leak. Every stock LS PCM has an IAT temp retard table. People with 1/2 a brain on a boosted motor will have some form of logging/viewing IAT temps and will be taking the appropriate measures to keep the engine out of the danger zone. A tiny intake leak will not cause a crazy amount of turbo over speed. A faulty BOV or WG will cause engine damage.

I'm sure this test is valid and has some uses but lets not make it personal. How many people perform this test when not many people know about it? Intakes are usually pretty fool proof, you bolt them down and go... LS motors make it even more easy with the new gaskets. Your saying its necessary doesn't mean it is, your reputation proceeds you btw and I'm aware of what you say has to be taken with a grain of salt. But I do feel this test has some validity and depending on time I might try to test this theory out. I have just sorta finished up a water/air intercooler setup and I'm probably going to test the cold side piping for leaks... I might just leave it all intact and pressurize the engine as well. Although I already know my stock intake isn't leaking.

The following users liked this post:

Plus_Ultra_Cars (12-04-2019)

#104

TECH Senior Member

iTrader: (25)

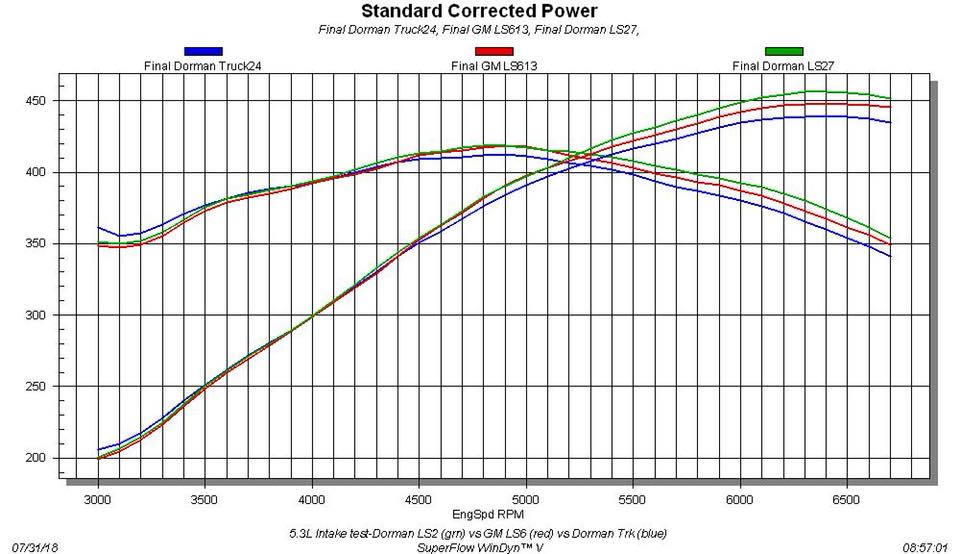

realistically, those of us spending $250 on an intake are probably not gonna have it flow tested. my comparison isn't really a fair one since I cammed and increased compression at the same time as the intake swap. but there's more blabbing about it here:

https://ls1tech.com/forums/generatio...3x-intake.html

https://ls1tech.com/forums/generatio...3x-intake.html

#105

I'm interested in numbers but like truckdoug said I won't be shelling out the cash for a Dyno session. I would have no issues sharing logs that give you all the data you need to calculate performance.

I'm honestly surprised that some of the popular car mags haven't jumped on something like this. They tested factory intakes vs aftermarket but no stock replacement aftermarkets.

#106

They make their money by pimping for manufacturers that will pay for ad space, I almost never see best-value pieces being reviewed by magazines.

The following users liked this post:

billsnogo (03-06-2023)

The following users liked this post:

billsnogo (03-06-2023)

#109

Unfortunately the few posts I could find on this intake scared me away from trying it as they complained about symptoms which could very well have been related to the install and other aspects of their setup. I went on to a tbss/nnbs intake manifold instead however these Dorman truck intakes do still look like they have potential for high rpm fun

#110

TECH Senior Member

You did well going with the tbss/nnbs manifold. But yeah, Dorman is doing some interesting stuff with their replacement manifolds. Using old FAST tooling sure can't hurt...

#111

TECH Fanatic

iTrader: (7)

Haha this is what kingtalon is known for. I've read about him on this forum before and I most ignore him.

I'm interested in numbers but like truckdoug said I won't be shelling out the cash for a Dyno session. I would have no issues sharing logs that give you all the data you need to calculate performance.

I'm honestly surprised that some of the popular car mags haven't jumped on something like this. They tested factory intakes vs aftermarket but no stock replacement aftermarkets.

I'm interested in numbers but like truckdoug said I won't be shelling out the cash for a Dyno session. I would have no issues sharing logs that give you all the data you need to calculate performance.

I'm honestly surprised that some of the popular car mags haven't jumped on something like this. They tested factory intakes vs aftermarket but no stock replacement aftermarkets.

your tuning issue that you were having ?

#113

But I did want to clarify that the Forman was not leaking apparently. My vacuum is just poor with this custom cam. I was told 16-19Ē and Iím pulling 13-14.5Ē. I swapped it out for a GM stocker old style truck intake. My vacuum went unchanged. So apparently the dorman wasnít leaking and wasnít at fault, but didnít really have a tuning issue... it was just low vacuum. I got the idle AFR squared away but I had some surge etc which was caused by the custom cam and ported stock TB which I had to mess with the idle airflow tables... still never got that at 100% but I yanked my plugs and they all looked amazing.

Iíve just swapped a NNBS intake onto this same motor and going turbo 12+psi so I didnít want to put the dorman on with the higher boost pressures. I will leave it for something that will max out around 9psi.

#114

TECH Fanatic

iTrader: (7)

Nope, basically itís sitting on the shelf. Iím thinking about using it on another project that will use the same supercharger that was run with this intake even if it was just idle.

But I did want to clarify that the Forman was not leaking apparently. My vacuum is just poor with this custom cam. I was told 16-19Ē and Iím pulling 13-14.5Ē. I swapped it out for a GM stocker old style truck intake. My vacuum went unchanged. So apparently the dorman wasnít leaking and wasnít at fault, but didnít really have a tuning issue... it was just low vacuum. I got the idle AFR squared away but I had some surge etc which was caused by the custom cam and ported stock TB which I had to mess with the idle airflow tables... still never got that at 100% but I yanked my plugs and they all looked amazing.

Iíve just swapped a NNBS intake onto this same motor and going turbo 12+psi so I didnít want to put the dorman on with the higher boost pressures. I will leave it for something that will max out around 9psi.

But I did want to clarify that the Forman was not leaking apparently. My vacuum is just poor with this custom cam. I was told 16-19Ē and Iím pulling 13-14.5Ē. I swapped it out for a GM stocker old style truck intake. My vacuum went unchanged. So apparently the dorman wasnít leaking and wasnít at fault, but didnít really have a tuning issue... it was just low vacuum. I got the idle AFR squared away but I had some surge etc which was caused by the custom cam and ported stock TB which I had to mess with the idle airflow tables... still never got that at 100% but I yanked my plugs and they all looked amazing.

Iíve just swapped a NNBS intake onto this same motor and going turbo 12+psi so I didnít want to put the dorman on with the higher boost pressures. I will leave it for something that will max out around 9psi.

#115

If anyone cares, I have been running the Dorman intake almost a year, 800 + miles, I don't know yet if its quicker by feel, but with a poor launch it still ran out the same MPH on top. Hard to tell. I don't think it could make less power, I pulled the plugs and they look better/ more consistent than they ever did with the Stock truck intake. I run 21.5 lbs normally. No vac leaks, nothing. My setup has a less than ideal size Intercooler and even with higher Intake temps, no issues..

I did not split the intake. I smoothed the ramps in the runner down like was mentioned, and I put large fender washers under the main bolts holding the intake down, some requiring shaping to fit. I was hoping it would distribute the clamping load. I have changed my combo through the years and would not be able to re- dyno it to see an accurate comparison. I do plan on pushing it higher boost, probably next year.

I did not split the intake. I smoothed the ramps in the runner down like was mentioned, and I put large fender washers under the main bolts holding the intake down, some requiring shaping to fit. I was hoping it would distribute the clamping load. I have changed my combo through the years and would not be able to re- dyno it to see an accurate comparison. I do plan on pushing it higher boost, probably next year.

#116

If anyone cares, I have been running the Dorman intake almost a year, 800 + miles, I don't know yet if its quicker by feel, but with a poor launch it still ran out the same MPH on top. Hard to tell. I don't think it could make less power, I pulled the plugs and they look better/ more consistent than they ever did with the Stock truck intake. I run 21.5 lbs normally. No vac leaks, nothing. My setup has a less than ideal size Intercooler and even with higher Intake temps, no issues..

I did not split the intake. I smoothed the ramps in the runner down like was mentioned, and I put large fender washers under the main bolts holding the intake down, some requiring shaping to fit. I was hoping it would distribute the clamping load. I have changed my combo through the years and would not be able to re- dyno it to see an accurate comparison. I do plan on pushing it higher boost, probably next year.

I did not split the intake. I smoothed the ramps in the runner down like was mentioned, and I put large fender washers under the main bolts holding the intake down, some requiring shaping to fit. I was hoping it would distribute the clamping load. I have changed my combo through the years and would not be able to re- dyno it to see an accurate comparison. I do plan on pushing it higher boost, probably next year.

#118

TECH Senior Member

#120

The following users liked this post:

Plus_Ultra_Cars (12-04-2019)