Quick question on pushrod size.

#41

Restricted User

Join Date: May 2006

Location: virginia

Posts: 132

Likes: 0

Received 0 Likes

on

0 Posts

OMG!!!!!

Your telling these guys what they have done, does NOT WORK. PERIOD END OF STORY... but they are all telling you they don't live in a vacuum and it does. Did that hurt your feelings?

I want my LS1tech money back now!

#42

Restricted User

Join Date: May 2006

Location: virginia

Posts: 132

Likes: 0

Received 0 Likes

on

0 Posts

There is no way in hell you can set the optimum preload with those on all valves, you can only be in a ballpark, and to add to that; unless you have a no split cam (meaning same intake and exhaust duration), you HAVE different base circles on int/exhaust and therefore different preloads if you use the same length p-rods.

1. You need to measure PR length on both intake and exhaust, in EVERY motor.

2. If your valve tip heights aren't that close to one another that you can't do this, your heads are junk. OEM heads ARE this close, then again this is just more proof showing you have never even measured this.

I did not bash anyone in this whole thread, but you guys had to, to prove your point. So I am asking: Can you prove your point with numbers and measurements (since you measured)? maybe by doing this exercise you'll find out why .030 works for ya, that would be something wouldn't it?

Seriously give up your little temper tantrum on this, I mean we all know you have enough time to make 11,000+ posts so you sound smart to the uniformed but when you bark up trees you have NO CLUE about you make yourself look dumber and dumber in the eyes of your minions who don't know better.

Jes

#48

TECH Senior Member

Ok,

So, I'm the moron here?

Time for some proof then from reputed LSX builders (one of the best I might add)

https://ls1tech.com/forums/generatio...r-preload.html

So please, this is not my post, that is KATECH

Bash them if you can. This is all I'm going to say about this anymore.

I have enjoyed all of this, thank you for the entertainment.

__________________

So, I'm the moron here?

Time for some proof then from reputed LSX builders (one of the best I might add)

https://ls1tech.com/forums/generatio...r-preload.html

Katech How-To: Check lifter preload

--------------------------------------------------------------------------------

I get asked this a lot so I thought it would be helpful to post:

1) The only way to properly check (and know where you are in the travel) is

to use a special checking lifter or completely compress a stock lifter.

a) Checking lifter consists of a lifter that has been disassembled

to install shims that lock the plunger at the top of travel in the lifter body.

If using this method you would add length to the checking pushrod to put the

final pushrods into the middle of travel of the plunger.

b) Using a stock lifter, you must make certain that you have pumped

all the oil out of the lifter. To do this leave it at valve full open (highest

spring load) for a while with an indicator on the pushrod side of the

rocker. Watch to see when the indicator stops moving (when the plunger is

fully compressed in the lifter body). Once you have compressed the lifter

rotate the engine to close the valve, extend your checking pushrod to full

length. Using this method you will subtract length from your checking

pushrod to put the final pushrods into the middle of travel of the plunger.

2) Typical plunger travel on Gen 3/4 lifters is 0.150 - 0.200 depending on

the manufacturer, year, etc. We recommend 0.075-0.100" from the bottom of

travel (using method 'b' described above) or 0.075 from the top of travel

(using method 'a' described above). That will generally put you close to

the middle of travel. While there are many different strategies for where

to put the plunger, for street use we strongly suggest that near the middle

of travel is the safest for durability.

3) The more precise method of checking is 'a' because you are not guessing

that you got all the oil out.

With this though, I do have to make the disclaimer that since we are not doing the assembly ourselves, we cannot be responsible for any misunderstandings. We recommend assembly by experienced professionals to avoid possible issues.

--------------------------------------------------------------------------------

I get asked this a lot so I thought it would be helpful to post:

1) The only way to properly check (and know where you are in the travel) is

to use a special checking lifter or completely compress a stock lifter.

a) Checking lifter consists of a lifter that has been disassembled

to install shims that lock the plunger at the top of travel in the lifter body.

If using this method you would add length to the checking pushrod to put the

final pushrods into the middle of travel of the plunger.

b) Using a stock lifter, you must make certain that you have pumped

all the oil out of the lifter. To do this leave it at valve full open (highest

spring load) for a while with an indicator on the pushrod side of the

rocker. Watch to see when the indicator stops moving (when the plunger is

fully compressed in the lifter body). Once you have compressed the lifter

rotate the engine to close the valve, extend your checking pushrod to full

length. Using this method you will subtract length from your checking

pushrod to put the final pushrods into the middle of travel of the plunger.

2) Typical plunger travel on Gen 3/4 lifters is 0.150 - 0.200 depending on

the manufacturer, year, etc. We recommend 0.075-0.100" from the bottom of

travel (using method 'b' described above) or 0.075 from the top of travel

(using method 'a' described above). That will generally put you close to

the middle of travel. While there are many different strategies for where

to put the plunger, for street use we strongly suggest that near the middle

of travel is the safest for durability.

3) The more precise method of checking is 'a' because you are not guessing

that you got all the oil out.

With this though, I do have to make the disclaimer that since we are not doing the assembly ourselves, we cannot be responsible for any misunderstandings. We recommend assembly by experienced professionals to avoid possible issues.

Bash them if you can. This is all I'm going to say about this anymore.

I have enjoyed all of this, thank you for the entertainment.

__________________

Last edited by PREDATOR-Z; 04-15-2009 at 05:14 PM.

#49

TECH Senior Member

Oh wait, 1 more post

and Jessica, baby, loosen those bra straps you are preloading those hooters way too much

and Jessica, baby, loosen those bra straps you are preloading those hooters way too much

Last edited by PREDATOR-Z; 04-15-2009 at 05:36 PM.

#50

IMO you owned yourself, just because Katech wrote it doesn't make it completely right. That's they're opinion on how it should be done. There's deff. easier ways to measure than that write up. You have owned no one in this thread other than yourself with your search skills.

#52

wow. this went from intelligent to bashing Pred.

Can noone have a discussion, even an intelligent one, without sounding like a bunch of kids on a playground?

Stop bashing each other's intelligence or say **** like "im smarter than you" and discuss the matter at hand.

Can noone have a discussion, even an intelligent one, without sounding like a bunch of kids on a playground?

Stop bashing each other's intelligence or say **** like "im smarter than you" and discuss the matter at hand.

#53

smiley.

smiley.

#54

hmmm..... ok

I am trying to actually learn something here not get in on this argument. that is why i was hoping the conversation could get back on topic. lol.

It is my experience that no matter what field (mechanics to even scientists) professionals will always dissagree with each other. That can not be avoided. But maybe someone will be able to learn from this if facts are posted.

I am trying to actually learn something here not get in on this argument. that is why i was hoping the conversation could get back on topic. lol.

It is my experience that no matter what field (mechanics to even scientists) professionals will always dissagree with each other. That can not be avoided. But maybe someone will be able to learn from this if facts are posted.

#55

TECH Junkie

iTrader: (2)

hmmm..... ok

I am trying to actually learn something here not get in on this argument. that is why i was hoping the conversation could get back on topic. lol.

It is my experience that no matter what field (mechanics to even scientists) professionals will always dissagree with each other. That can not be avoided. But maybe someone will be able to learn from this if facts are posted.

I am trying to actually learn something here not get in on this argument. that is why i was hoping the conversation could get back on topic. lol.

It is my experience that no matter what field (mechanics to even scientists) professionals will always dissagree with each other. That can not be avoided. But maybe someone will be able to learn from this if facts are posted.

#56

TECH Senior Member

Here is a VINCI wite up on rocker install (granted they are adjustable but they mention what they recommend as far as lifter preload and they do "bleed" lifters to find 0 lash; which would be option 'b' in KATECH writeup.

http://www.vincihighperformance.com/...TRUCTIONS.HTML

Look at bottom of page about 4 lines up

Originally Posted by VINCI

we recommend adjusting lifter preload to .060 -.100.” Extensive testing has shown this preload to provide the best power and performance, as well as minimizing valve train noise

#57

I'll agree that bleeding the lifters could work with finding zero lash if you can make sure that the lifter is bottomed out and it doesn't try to return any at all while your taking your measurements. It takes a little force to push the plunger down in a lifter. So if you just slide the checker pushrod in torque the rocker to spec, then turn the checker until you have zero lash. Loosen the rocker remove the checker and measure it. Add your desired preload and order your new pushrods.

This is so much simpler than Pred is trying to make it out to be.

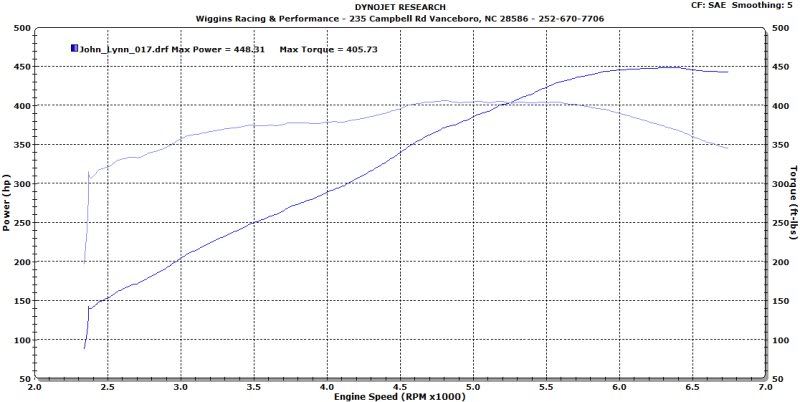

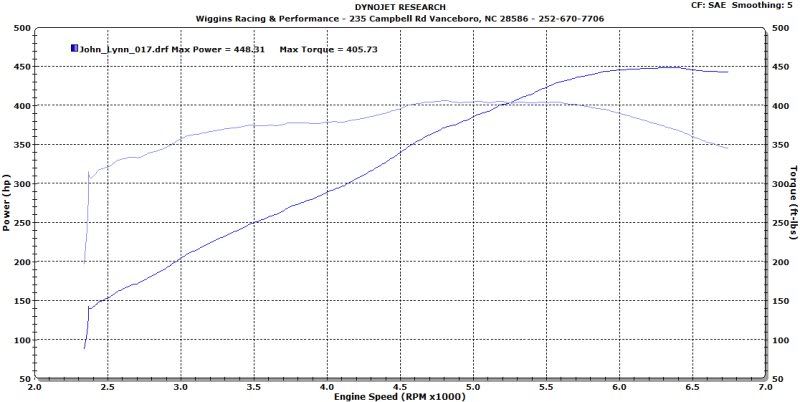

Here's a graph of a H/C, A4 car we just did with .020" preload with the stock lifters (car is a '01 SS with only 6400 miles some the stock lifters were just fine). Do you see any signs of valve train problems with with the light preload?

This is so much simpler than Pred is trying to make it out to be.

Here's a graph of a H/C, A4 car we just did with .020" preload with the stock lifters (car is a '01 SS with only 6400 miles some the stock lifters were just fine). Do you see any signs of valve train problems with with the light preload?

#58

Banned

iTrader: (10)

OK, I ca't resist any longer. I was gonna stay out, but...........

I think one of the problems here is Pred saying basically it HAS to be X amount of preload, otherwise it won't work, or "it will go to ****" or whatever.

One of the things no one seems to be talking about is all the different lifters. Personally, with the GM lifters, I've had better luck, made more power with more preload. One some of the aftermarkets, you CANNOT run the same amount, or bad things will happen. I just put shorter pushrods in a motor with Morels. Ended up about .030 on the preload. It was about .080-.100 before, and would barely run. It was actually holding the valves open.

The one thing I've learned from doing this stuff for longer than I care to remember is you cannot make blanket statements about how things will or won't work, because just when you thought you've seen it all, something else comes along, or someone does something differently.

I think one of the problems here is Pred saying basically it HAS to be X amount of preload, otherwise it won't work, or "it will go to ****" or whatever.

One of the things no one seems to be talking about is all the different lifters. Personally, with the GM lifters, I've had better luck, made more power with more preload. One some of the aftermarkets, you CANNOT run the same amount, or bad things will happen. I just put shorter pushrods in a motor with Morels. Ended up about .030 on the preload. It was about .080-.100 before, and would barely run. It was actually holding the valves open.

The one thing I've learned from doing this stuff for longer than I care to remember is you cannot make blanket statements about how things will or won't work, because just when you thought you've seen it all, something else comes along, or someone does something differently.

#59

On The Tree

iTrader: (9)

Join Date: Mar 2007

Location: Orlando,FL

Posts: 116

Likes: 0

Received 0 Likes

on

0 Posts

WOW....

I'm sorry,but this is reDICKulous."I pay attention to details,I'm a scientist,

I make drugs",blahblahblah.Then,you have a someone that likes to pretend

their female,just to post here.

It is ALL opinions.There is not one fact to back up any statement made in

this thread,from either side.And as far as these great buiders with all their

records and statistics,where are they?I'll tell ya where.They are out doing it,

not talking about it.If you have to convince folks how great you are,are you?

You hardcore guys are like a bunch of little yapping dogs that run to the

fence line,make a bunch of noise,then run back home for a pat on the head.

Boy "we sure told PRED-Z"

If TECH is so bad,why bother posting here?

I'm sorry,but this is reDICKulous."I pay attention to details,I'm a scientist,

I make drugs",blahblahblah.Then,you have a someone that likes to pretend

their female,just to post here.

It is ALL opinions.There is not one fact to back up any statement made in

this thread,from either side.And as far as these great buiders with all their

records and statistics,where are they?I'll tell ya where.They are out doing it,

not talking about it.If you have to convince folks how great you are,are you?

You hardcore guys are like a bunch of little yapping dogs that run to the

fence line,make a bunch of noise,then run back home for a pat on the head.

Boy "we sure told PRED-Z"

If TECH is so bad,why bother posting here?

#60

Restricted User

Join Date: May 2006

Location: virginia

Posts: 132

Likes: 0

Received 0 Likes

on

0 Posts

Assume it's all opinions.... assume I'm not a female.... assume I've never dyno tested these things....

That's going to make a *** out of U and ME.... well mostly you.

One thing I really think is funny about this is how when presented with an arguement based on FACTS not hearsay, people over here dance around the topic when the otherside does something TOTALLY different than their realm of knowledge allows. This is only all taken as BASHING because people being WRONG with unsupported arguements are getting their EGOs hurt.

I love how you flip-flop like your John Kerry or something...

Are you so sure about that?????

Sounds like you need a set of these!

Are you going from your own experience of testing lifter preload or are you not? It looks like your not to me, sounds like your not to me and it's more than apparent that you have never tested any of this statically in terms of measurements or dynamically on a dyno.

I've talked to Fritz, I'm pretty sure you have not and your supporting examples aren't helping your side. Their way is one way to check this, especially if you want to check sweep patterens on a rocker arm. Problem is with a shaft style rocker arm like a LS1 has stock you aren't going to change the sweep pattern with the pushrod length & you only have to measure the PR length with the pushrod on the lifter, not any other pressure. A solid lifter setup to stock pushrod cup height makes this easier but it is not needed, PLUS we are not talking about HOW to do this but what makes the most power and DOESN'T have side effects like those that are mentioned here. UNLESS YOU HAVE TESTED THIS BOTH WAYS YOU DO NOT HAVE THE EXPERIENCE TO TALK ABOUT IT LIKE IT'S THE 2nd COMING OF GOD (or ALLAH for you.)

Problem is guys don't check anything based on the advice they get here, they do internet math to determine pushrod length, and have been ADVISED to do so for YEARS on this web forum, and PRED-Z is the main culprit of that. Hence why his panties are in a bunch and he CAN'T backup his statements, and considers this bashing.... it's more about him getting his ego bruised.

If you had any stud mount rocker setup and did internet math to get pushrod length on a motor with solid lifters this advice would have trashed EVERY set of valve guides in heads this was done on by now.... just because LS motors are idiot proof doesn't mean that you can't build them properly and get more out of them.

Just because you shout the loudest and most, DOES NOT MAKE YOU CORRECT!

That's going to make a *** out of U and ME.... well mostly you.

One thing I really think is funny about this is how when presented with an arguement based on FACTS not hearsay, people over here dance around the topic when the otherside does something TOTALLY different than their realm of knowledge allows. This is only all taken as BASHING because people being WRONG with unsupported arguements are getting their EGOs hurt.

I love how you flip-flop like your John Kerry or something...

Ok,

So, I'm the moron here?

Time for some proof then from reputed LSX builders (one of the best I might add)

https://ls1tech.com/forums/generatio...r-preload.html

So please, this is not my post, that is KATECH

Bash them if you can. This is all I'm going to say about this anymore.

I have enjoyed all of this, thank you for the entertainment.

__________________

So, I'm the moron here?

Time for some proof then from reputed LSX builders (one of the best I might add)

https://ls1tech.com/forums/generatio...r-preload.html

So please, this is not my post, that is KATECH

Bash them if you can. This is all I'm going to say about this anymore.

I have enjoyed all of this, thank you for the entertainment.

__________________

Are you going from your own experience of testing lifter preload or are you not? It looks like your not to me, sounds like your not to me and it's more than apparent that you have never tested any of this statically in terms of measurements or dynamically on a dyno.

I've talked to Fritz, I'm pretty sure you have not and your supporting examples aren't helping your side. Their way is one way to check this, especially if you want to check sweep patterens on a rocker arm. Problem is with a shaft style rocker arm like a LS1 has stock you aren't going to change the sweep pattern with the pushrod length & you only have to measure the PR length with the pushrod on the lifter, not any other pressure. A solid lifter setup to stock pushrod cup height makes this easier but it is not needed, PLUS we are not talking about HOW to do this but what makes the most power and DOESN'T have side effects like those that are mentioned here. UNLESS YOU HAVE TESTED THIS BOTH WAYS YOU DO NOT HAVE THE EXPERIENCE TO TALK ABOUT IT LIKE IT'S THE 2nd COMING OF GOD (or ALLAH for you.)

Problem is guys don't check anything based on the advice they get here, they do internet math to determine pushrod length, and have been ADVISED to do so for YEARS on this web forum, and PRED-Z is the main culprit of that. Hence why his panties are in a bunch and he CAN'T backup his statements, and considers this bashing.... it's more about him getting his ego bruised.

If you had any stud mount rocker setup and did internet math to get pushrod length on a motor with solid lifters this advice would have trashed EVERY set of valve guides in heads this was done on by now.... just because LS motors are idiot proof doesn't mean that you can't build them properly and get more out of them.

Just because you shout the loudest and most, DOES NOT MAKE YOU CORRECT!