melling 10296 without shims making it fit, the $150 experiment

#1

Well, I want to post this because I seen nothing like it in all my searches on making the melling fit with a double roller. I bought the pump and put it on with the shims, clearance behind the pump was great, alot of room actually, I have a rollmaster cahin. So I thought since there was alot of clearance with the shims what would it be like without the shims, It was close to mounting So I figured that I would try to remove a little to see what it would take to make it fit, after about 8 times of spraying the back of the pump with dykem, and then mounting the pump, turning the engine over, removing the pump and grinding where the rubbing was I had the pump bolted up to the engine with out the shims, actually fit. I decided to to push the chain toward the pump a little with a smooth bent punch I had, and turn the motor over to simulate chain movement. I removed the pump once again, and grinded the little area where the chain rubbed. I put the pump back on the motor and had plenty of clearance behind the pump could see between every area. I was thinking cool, it worked.

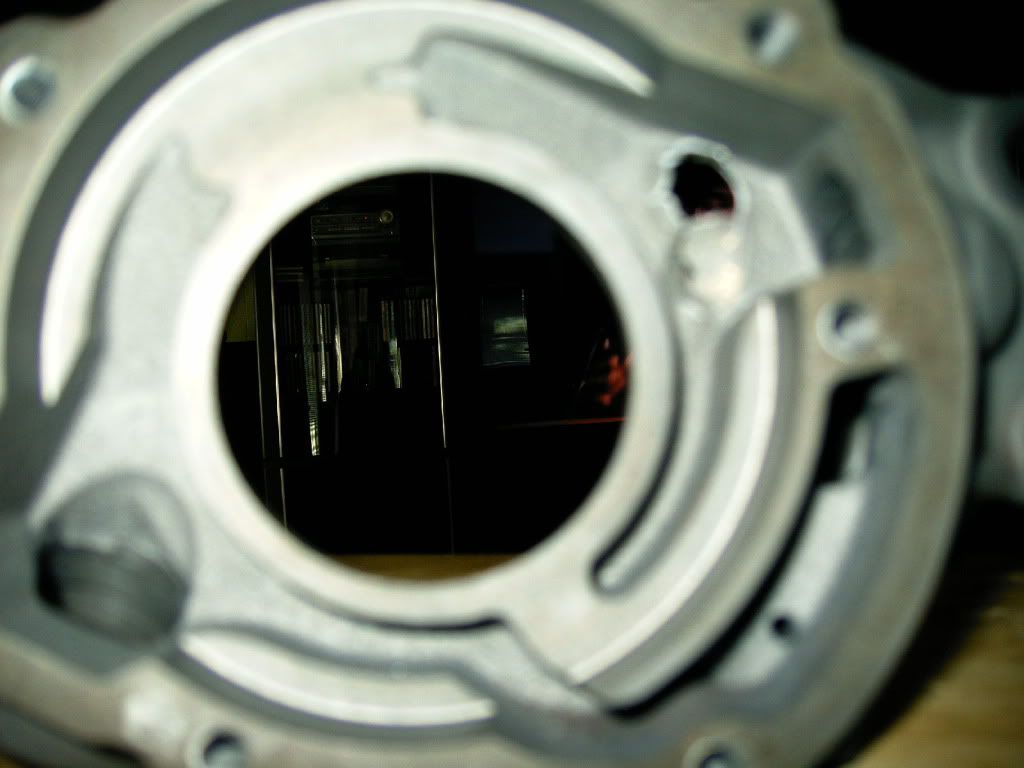

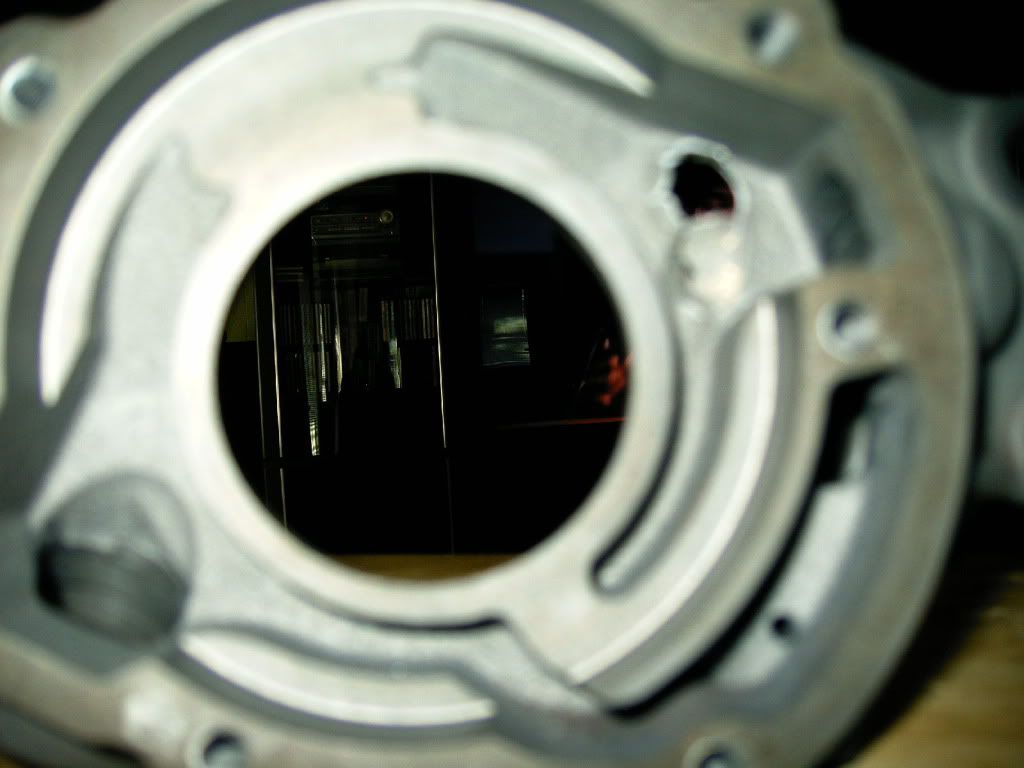

I was looking at the one area where I had to take the most out of, didnt really like how much it took So I took a set of micrometers to measure the thickness of the housing where I knew it was thinnest. Came up with .025 thousandths, Way too thin for my comfort especially considering that where the most had to be removed is in the pressure port of the pump not the suction side. After realizing I had just ruined my new pump I started thinking about just how thin .025 is and pushed on the area by hand, I believe I felt movement, Now I know that the pump is not going anywhere near my engine. I took a brass puch and just tapped it int he thin area and guess what, It left an indentation, I gave it another tap and bingo, a crack, with a little hole in the pump, then I push hard on the puch and it goes all the way thru. SO now the new pump is absolute garbage. I have purchased a new pump and will use the shims, clearance my timing cover and balancer. The point of this post is to let anyone who considers trying this see the consequences of the work. IT looked fine and fit fine, but I would never trust it on my engine. Use this post for what it is, a very informative experience from someone who tried it, learn from my 150$ BIG DUMMY mistake. Sometimes curiousity helps solve problems sometimes it creates them. the only thing this pump is good for now is to help others learn so here ya go.

I was looking at the one area where I had to take the most out of, didnt really like how much it took So I took a set of micrometers to measure the thickness of the housing where I knew it was thinnest. Came up with .025 thousandths, Way too thin for my comfort especially considering that where the most had to be removed is in the pressure port of the pump not the suction side. After realizing I had just ruined my new pump I started thinking about just how thin .025 is and pushed on the area by hand, I believe I felt movement, Now I know that the pump is not going anywhere near my engine. I took a brass puch and just tapped it int he thin area and guess what, It left an indentation, I gave it another tap and bingo, a crack, with a little hole in the pump, then I push hard on the puch and it goes all the way thru. SO now the new pump is absolute garbage. I have purchased a new pump and will use the shims, clearance my timing cover and balancer. The point of this post is to let anyone who considers trying this see the consequences of the work. IT looked fine and fit fine, but I would never trust it on my engine. Use this post for what it is, a very informative experience from someone who tried it, learn from my 150$ BIG DUMMY mistake. Sometimes curiousity helps solve problems sometimes it creates them. the only thing this pump is good for now is to help others learn so here ya go.