Yep, it's another "lots of valvetrain ticking" thread...

#21

I'm gonna give you some free advice, pull the heads and get them gone over properly. ALL the valves should be in the seats equally AND the heights should all be close to the same. Having the valves in the seats at different height also effects performance. That means every cylinder has a different volume. PLUS now your drive train is noisy, how do you know it isn't from loose or worn valve guides on top of everything else? Also you realize the rockers are wiping the tops of the valves all over the place, all your valve geometry in basicly gone! Go find a good set of heads or get yours done properly. Good head work is hard to find IMO, any idiot can screw a set up quickly.

Last edited by O2Form; 04-22-2011 at 10:37 AM.

#22

Thanks very much Patrick. I was hoping someone would confirm that part of my problem is excess spring pressure. I'm a little surprised to see a recommendation to go with more pre-load though. I've been reading .060 to .075 is ideal. Looks like I'll be ordering another set of pushrods - 7.400s this time - along with beehives!!!! Thanks again.

#30

Just to toss more confusion into the mix...

Comp cams 54-456-11 with 918 Beehive springs. Cam is 219/227 at .050 and 607/614. I have 1.25 to 1.5 turns of preload on brand new genuine GM lifters...which is NOT an issue according to Comp. I have a noisy valve train. These springs aren't recommended by Comp for this cam...they say they aren't enough. But lots of guys are using them and it runs to 6500 easily. However, the installed height is just a bit short of specs and using a .050 retainer was too much and would have required a shim. So I just left them. I couldn't find any thinner seals/seats. I would have used them in a heartbeat. Who makes them?

Has anyone actually measured how far the rocker bolt moves in one full turn? That should certainly be easy enough to find.

Comp cams 54-456-11 with 918 Beehive springs. Cam is 219/227 at .050 and 607/614. I have 1.25 to 1.5 turns of preload on brand new genuine GM lifters...which is NOT an issue according to Comp. I have a noisy valve train. These springs aren't recommended by Comp for this cam...they say they aren't enough. But lots of guys are using them and it runs to 6500 easily. However, the installed height is just a bit short of specs and using a .050 retainer was too much and would have required a shim. So I just left them. I couldn't find any thinner seals/seats. I would have used them in a heartbeat. Who makes them?

Has anyone actually measured how far the rocker bolt moves in one full turn? That should certainly be easy enough to find.

#31

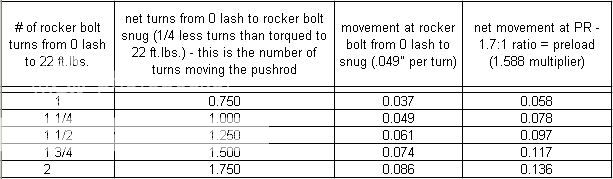

The thread pitch of the rocker screw is .049". But when you tighten the screw from zero lash the valve tip is stationary so you're using the valve tip as a pivot point and the pushrod moves down more than .049". Then you have to use the rocker arm ratio to calculate the amount the pushrod movement for every .049" at the rocker screw. For this calculation on a 1.7 rocker say the distance from the trunnion to the PR is 1" and the distance from the trunnion to the valve tip is 1.7" (giving you 1.7:1 ratio), so the overall length is 2.7". Actual dimensions don't matter since we're talking about ratios. So using simple math: .049" / 1.7 = D / 2.7 ....... so D = .078" - this is the distance the pushrod travels for every turn of the rocker screw.

But keep this in mind when you're using the "turns to 22 ft.lbs" method - Part of the rotation of the screw is used torqueing the screw, which is not pushing the pushrod down into the lifter. Thru my tests I get about 1/4 turn or a little more from when the screw is snugged up to 22 ft.lbs.

So factoring in the rocker ratio and a 1/4 turn to reach 22 ft.lbs. I get this:

I might catch all kinds of hell for overthinking this but it does help explain why the guys using 1 1/4 to 1 3/4 turns from snug to 22 ft.lbs. have minimal valvetrain noise. It's real close to Partick's recommended pre-load range of .080"-.100". I hope this makes sense.

#32

Just to toss more confusion into the mix...

Comp cams 54-456-11 with 918 Beehive springs. Cam is 219/227 at .050 and 607/614. I have 1.25 to 1.5 turns of preload on brand new genuine GM lifters...which is NOT an issue according to Comp. I have a noisy valve train. These springs aren't recommended by Comp for this cam...they say they aren't enough. But lots of guys are using them and it runs to 6500 easily. However, the installed height is just a bit short of specs and using a .050 retainer was too much and would have required a shim. So I just left them. I couldn't find any thinner seals/seats. I would have used them in a heartbeat. Who makes them?......

Comp cams 54-456-11 with 918 Beehive springs. Cam is 219/227 at .050 and 607/614. I have 1.25 to 1.5 turns of preload on brand new genuine GM lifters...which is NOT an issue according to Comp. I have a noisy valve train. These springs aren't recommended by Comp for this cam...they say they aren't enough. But lots of guys are using them and it runs to 6500 easily. However, the installed height is just a bit short of specs and using a .050 retainer was too much and would have required a shim. So I just left them. I couldn't find any thinner seals/seats. I would have used them in a heartbeat. Who makes them?......

#33

12 Second Club

iTrader: (13)

I'll try to get a video up tomorrow. What lifters are you running? Stock I assume, I followed your build thread and ordered my cam somewhat based on that. When I ordered the cam from Geoff we talked about PR length and since I had LS7 lifters (higher) and shaved heads (lower) he recommended 7.375s. They would have been spot on if my machininst would have made the valve height consistent. Some valves sit higher in the head requiring shorter pushrods.

Damn I wish I'd got PAC 1518s like you did. I think my short spring install height is caused from the steel retainers + the thick spring locator from EPS (I think they were .050 or more). With the 1518s I know I'd have 1.800 install height using stock retainers and the thinner (.040) seal/spring seat.

So my current thoery is that the noise is caused by short spring install height (added seat & open pressure), dual springs which are heavy and add pressure, and the heavy steel retainers. I have to go back thru my math but 1518s reduce seat pressure by 20#, reduce open pressure by 50#, and are lighter + allow use of lighter stock retainers.

Damn I wish I'd got PAC 1518s like you did. I think my short spring install height is caused from the steel retainers + the thick spring locator from EPS (I think they were .050 or more). With the 1518s I know I'd have 1.800 install height using stock retainers and the thinner (.040) seal/spring seat.

So my current thoery is that the noise is caused by short spring install height (added seat & open pressure), dual springs which are heavy and add pressure, and the heavy steel retainers. I have to go back thru my math but 1518s reduce seat pressure by 20#, reduce open pressure by 50#, and are lighter + allow use of lighter stock retainers.

#34

Actually, I have plenty of room there. That, along with PTV clearance, was something I was very concerned with. I wish I could remember the spec, but it was plenty safe. They really are a heck of a spring.

#35

Here's an update - I replaced the "EPS" dual springs with PAC 1518s using my stock retainers and stock replacement seals. The base of the seal is a little thinner than the EPS spring locator so the install height is closer to 1.800 than before. Also installed the Comp trunnion upgrade on the rockers and re-assembled with longer pushrods. All lifter pre-loads measure .094 to .082 except for 2 that measure .100. On the 2 that had .100 I debated going with shorter pushrods to give me .075 but I went ahead because of Patrick's recommendation of .080 - .100 preload. After all that I still have a little ticking noise but it's definitely reduced. I can't hear it from inside the car hardly at all under most conditions so I'm reasonably happy with the work & expense. I might try shorter pushrods on the two that have .100 preload to see if that eliminates the noise completely but I doubt it will make any difference.