Pushrod length checking questions

#22

TECH Resident

Thread Starter

iTrader: (10)

Join Date: May 2008

Location: Faribault, MN

Posts: 882

Likes: 0

Received 0 Likes

on

0 Posts

To be honest I can't figure out how to use the Trickflow one. The Comp one has a distinctive mark and an exact measurement for each full turn. It seems much easier to measure. I would definitely recommend that anyone looking for a length checker goes with a Comp one.

#23

11 Second Club

iTrader: (18)

Ok I just got my pushrod length checker in and was going to try it out, but read something about having to "set" the wipe pattern first and from there things started going over my head talking about calipers, test valvesprings, etc.

I was under the impression all I needed both now to make sure what I'm running is ok, and when my ported/milled heads go on was to get this Comp tool and check pushrod length.

I was under the impression all I needed both now to make sure what I'm running is ok, and when my ported/milled heads go on was to get this Comp tool and check pushrod length.

#29

11 Second Club

iTrader: (10)

Join Date: Mar 2006

Location: Hilliard fl.

Posts: 536

Likes: 0

Received 0 Likes

on

0 Posts

Can you do this method with a pushrod checker?Just use the checker and adjust it till you get the right size for your turns on the torque wrench.That should tell you the size you need?

#30

TECH Senior Member

iTrader: (4)

You can only change the pattern by moving the rocker base up and down. To move it up you shim the rocker, to move it down you need an aftermarket support that then is milled to reduce height. The pushrod will not change the wipe pattern unless you use a stud mounted rocker, which are not as stable.

#31

TECH Senior Member

iTrader: (39)

I used this method checking my car tonight. Using a 7.4 pushrod I have two full turns till the bolt gets snug. Not to 22ft lbs, snug.

If I have done the math right my lifter preload is about .094. I am using stock GM lifters with 49,xxx miles on them.

Thanks for any advice.

Good thread OP!

#32

TECH Senior Member

iTrader: (4)

Shane,

I used this method checking my car tonight. Using a 7.4 pushrod I have two full turns till the bolt gets snug. Not to 22ft lbs, snug.

If I have done the math right my lifter preload is about .094. I am using stock GM lifters with 49,xxx miles on them.

Thanks for any advice.

Good thread OP!

I used this method checking my car tonight. Using a 7.4 pushrod I have two full turns till the bolt gets snug. Not to 22ft lbs, snug.

If I have done the math right my lifter preload is about .094. I am using stock GM lifters with 49,xxx miles on them.

Thanks for any advice.

Good thread OP!

#34

TECH Senior Member

iTrader: (4)

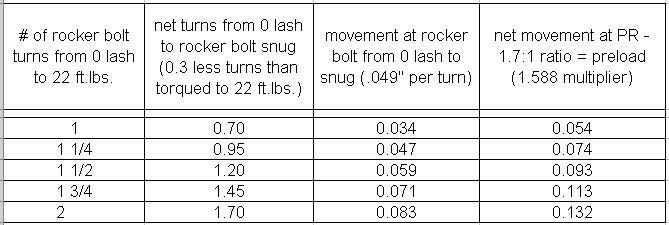

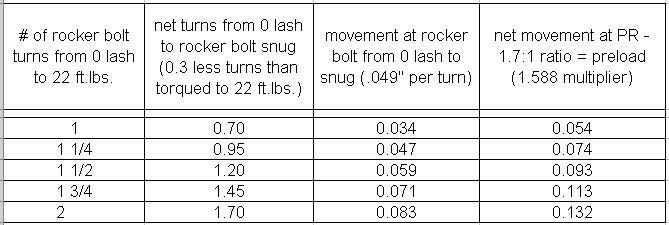

I checked Shanes method against mine and against a dial indicator. He states 1 turn from zero lash is 0.047" preload. I found the same thing. However, 1/3 turn of the one turn is to tighten the bolt after it bottoms. I found this to be pretty consistant. So, any number of turns you count, you have to remove the 1/3 turn that isn't providing preload.

If you have two turns from zero lash, subtract 1/3 turn and you have 1-2/3 turns total that is actually moving the rocker down and depressing the pushrod into the lifter.

1.667 turns X 1.25 mm per turn = 2.084mm

To convert to inches devide by 25.4 = 0.082"

Now you have to correct for the rocker ratio: 0.082 X 2.7/1.7 = 0.130"

Hope that makes sense.

If you have two turns from zero lash, subtract 1/3 turn and you have 1-2/3 turns total that is actually moving the rocker down and depressing the pushrod into the lifter.

1.667 turns X 1.25 mm per turn = 2.084mm

To convert to inches devide by 25.4 = 0.082"

Now you have to correct for the rocker ratio: 0.082 X 2.7/1.7 = 0.130"

Hope that makes sense.

#36

TECH Fanatic

iTrader: (35)

vettenuts is the guru on this but I made this spreadsheet a while back to tell you preload based on the number of turns from zero lash to 22 ft.lbs. (Shane's method). You factor in rocker ratio because - as you tighten the bolt the rocker arm is pivoting with the valve tip end fixed so the pushrod end moves more than the bolt.