Pushrod length checking questions

#43

11 Second Club

iTrader: (18)

I do not know, I was told they were GM Performance Parts ls1 lifters...which could mean GM was selling the ls7 lifters as such I guess.

So if that were the case and I used pushrods meant for the same setup with ls1 lifters would that mean I have way to much preload?

I didn't know to measure at the time of the cam install and everyone I ordered parts from said the 7.4 would be what I need. This just has me wondering...off to research what lifters the GMPP are I guess.

So if that were the case and I used pushrods meant for the same setup with ls1 lifters would that mean I have way to much preload?

I didn't know to measure at the time of the cam install and everyone I ordered parts from said the 7.4 would be what I need. This just has me wondering...off to research what lifters the GMPP are I guess.

#45

FormerVendor

iTrader: (2)

Join Date: Dec 2001

Location: Baton Rouge, LA, USA

Posts: 1,954

Likes: 0

Received 3 Likes

on

3 Posts

Guys, you are overthinking this. The rocker ratio has little effect on the preload measurement. I checked the actual preload over the pushrod tip of the rocker with a dial indicator to come up with this method. I didn't just calculate this based on thread pitch and rocker ratio. Also due to the pushrod side being on the opposite side of the trunion from the valve, the ratio would mean the pushrod moves LESS than the bolt... The rocker tip (longer side from the fulcrum) is the side that gets multiplied by the ratio.

2 turns is the maximum I would normally allow, I go for 3/4 to 1 and 3/4. Vettenutts is right about the some of the preload getting lost in bolt stretch. What I will tell you is that if you end up between 1 and 2 turns from 0 lash, you will be perfectly fine.

Shane

2 turns is the maximum I would normally allow, I go for 3/4 to 1 and 3/4. Vettenutts is right about the some of the preload getting lost in bolt stretch. What I will tell you is that if you end up between 1 and 2 turns from 0 lash, you will be perfectly fine.

Shane

#48

TECH Fanatic

iTrader: (35)

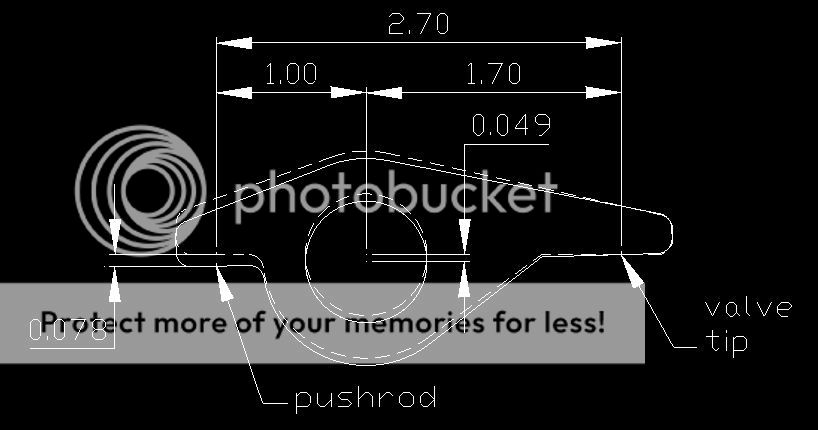

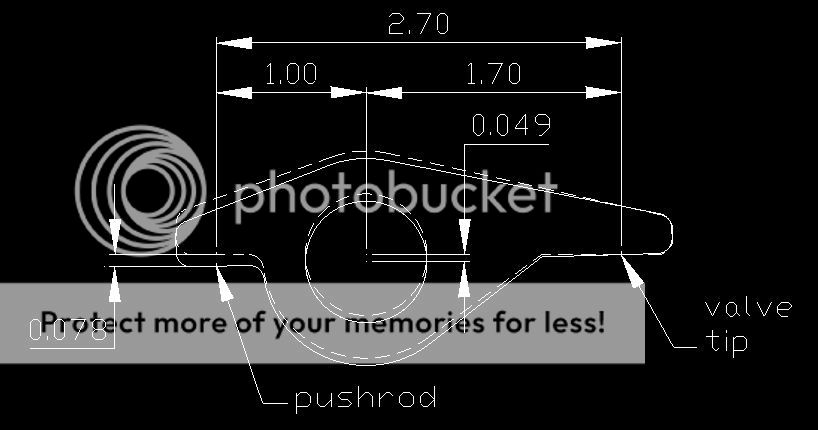

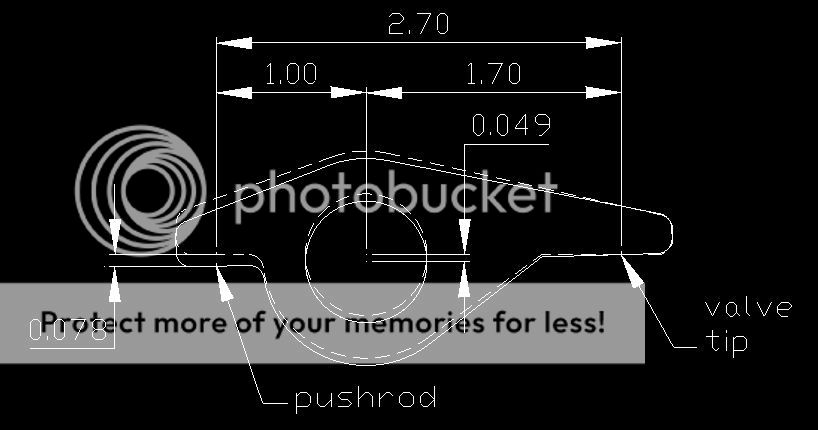

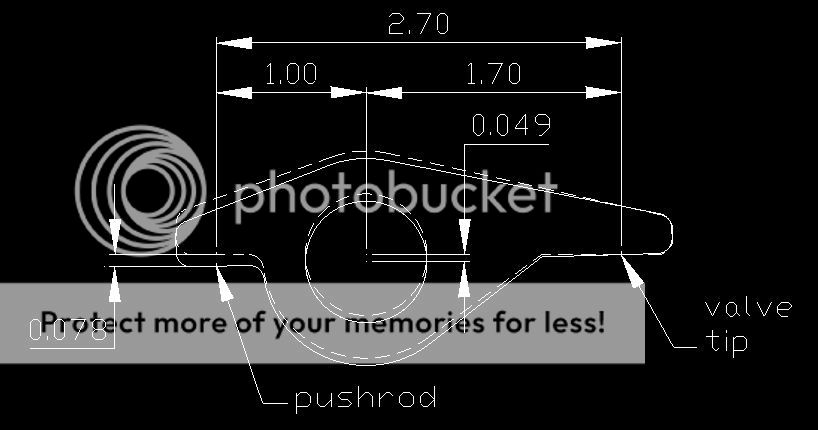

This drawing shows movement of the rocker as it is being tightened down by the trunnion bolt for pre-load checking. The rocker at the valve tip is stationary. Due to the rocker ratio the pushrod end travels down .078" for every .049" (1 turn) of the rocker bolt. The ratio = .078 / .049 = 1.59 is also calculated as 2.7 / 1.7 = 1.59 since the valve tip is the pivot point.

#49

FormerVendor

iTrader: (2)

Join Date: Dec 2001

Location: Baton Rouge, LA, USA

Posts: 1,954

Likes: 0

Received 3 Likes

on

3 Posts

Sorry guys, my bad on that one. You are correct. One thing I will tell you though, is that I physically checked the pushrod tip travel with a fixed dial indicator. For every 1 free turn of the rocker bolt, the tip of the pushrod will move right at .047". You can do all of the calculations you want but when it comes down to it in the real world and in practice, this is what really happens. Have any of you taken this measurment or are you all just doing calculations based on thread pitch and theoretical rocker ratios? Also, explain how if I add .025" of length to a pushrod, I end up with approximately 1/2 turn more preload... I do it every day day in and day out. This just goes to show you, theory and practice don't always mesh.

Also, FWIW, we did testing with a TRex cam and stock lifters. We ran preload values from well over .100" to 0". THERE WAS NO APPRECIABLE DIFFERENCE IN POWER OR VALVETRAIN STABILITY. The only difference was in noise. Now I don't claim that the stock lifters would survive very long with no preload but I know that it didn't matter from a power or stability standpoint. So what I'm saying here is that we are all splitting hairs at this point. I will tell you, if you have a preload setting between 3/4 of a turn and 1 3/4 of a turn you will have 0 issues.

Shane

Also, FWIW, we did testing with a TRex cam and stock lifters. We ran preload values from well over .100" to 0". THERE WAS NO APPRECIABLE DIFFERENCE IN POWER OR VALVETRAIN STABILITY. The only difference was in noise. Now I don't claim that the stock lifters would survive very long with no preload but I know that it didn't matter from a power or stability standpoint. So what I'm saying here is that we are all splitting hairs at this point. I will tell you, if you have a preload setting between 3/4 of a turn and 1 3/4 of a turn you will have 0 issues.

Shane

Last edited by XtraCajunSS; 05-28-2011 at 11:31 AM.

#50

TECH Senior Member

iTrader: (4)

I checked your method, my calculations and used a dial indicator to verify. All were the same within a few thousanths with my Yella Terra's. I had also done a similar thing with the Cranes I ran since these were stud mounted (different thread pitch though). What I found was that 1/3 of the turn from zero lash to 22 lb-ft on the Yella Terra rockers results on no rocker movement downward but is rather the bolt stretch. I also found this to be pretty consistent so a different pushrod length, in the same setup, would need to have this 1/3 turn accounted for if you are calculating.

Hope that helps.

Hope that helps.

#51

TECH Fanatic

iTrader: (35)

Thanks Shane. Well in my testing I found that a .025" longer / shorter pushrod gives me about 1/3 more or less turns to 22 ft.lbs. That follows with .078 x .33 = .026". Can you tell us what pre-load was the quietest in your testing with the TRex? Thanks.

Last edited by hiltsy855; 05-28-2011 at 10:04 PM.

#52

TECH Senior Member

iTrader: (4)

This drawing shows movement of the rocker as it is being tightened down by the trunnion bolt for pre-load checking. The rocker at the valve tip is stationary. Due to the rocker ratio the pushrod end travels down .078" for every .049" (1 turn) of the rocker bolt. The ratio = .078 / .049 = 1.59 is also calculated as 2.7 / 1.7 = 1.59 since the valve tip is the pivot point.

#55

TECH Addict

iTrader: (7)

alright, this thread is very informative. I'm finishing up my H/C install and measuring pushrod lenght. I have LS7 lifters and milled 2.5 ls6 heads. At 0 lash I'm getting 1 3/4 turns to 22ft lbs prettly consistantly with a 7.4 rod. Just about everyone I see go shorter with these lifters to a 7.35. Should I go shorter just to be safe? That should put me at 1 - 1.5 turns to 22 ft lbs right?

#56

I didn't see anything mentioned in this thread about lifter bleed down when you are rotating the engine by hand checking all of these things. I mention it only because I recently changed the cam in my motor and ran across the issue where I could not measure zero lash because the lifter resisted only with the internal spring and not hydraulic pressure. I was too lazy to use a checking spring. I use LS7 lifters and a 7.350 pushrod which I had determined earlier provide the correct wipe pattern with HS 1.8 rocker arms. To set the preload I did the following (on two cylinders):

1. Put (2) .047 shims under the rocker pedestals. With this much shim (.094), the rocker are loose on the valve tip. The important part is to provide enough shim so that the rockers are obviously loose (detectable play). Torque to spec. (22ft-lbs).

2. For the intakes, rotate the engine until the exhaust valve on that cylinder just begins to close. Measure (using an old school feeler gauge) the clearance between the rocker tip and the valve.

3. Repeat on the exhaust except now rotate until the intake just begins to open.

4. Divide each of these measurements by the rocker ratio; in my case it was 1.8:1. This is the slop in the lifter to pushrod fit.

5. Calculate how much shim you need to remove to give the desired preload. In my case, I removed one .047 shim from each pedestal. The result was approximately .025 preload on the exhaust and .036 on the intake. I checked two cylinders and they were very close (like .002).

This method worked well for me. I see the logic in all of the methods desribed in this thread also. Hope this helps.

1. Put (2) .047 shims under the rocker pedestals. With this much shim (.094), the rocker are loose on the valve tip. The important part is to provide enough shim so that the rockers are obviously loose (detectable play). Torque to spec. (22ft-lbs).

2. For the intakes, rotate the engine until the exhaust valve on that cylinder just begins to close. Measure (using an old school feeler gauge) the clearance between the rocker tip and the valve.

3. Repeat on the exhaust except now rotate until the intake just begins to open.

4. Divide each of these measurements by the rocker ratio; in my case it was 1.8:1. This is the slop in the lifter to pushrod fit.

5. Calculate how much shim you need to remove to give the desired preload. In my case, I removed one .047 shim from each pedestal. The result was approximately .025 preload on the exhaust and .036 on the intake. I checked two cylinders and they were very close (like .002).

This method worked well for me. I see the logic in all of the methods desribed in this thread also. Hope this helps.

#58

TECH Senior Member

iTrader: (39)

It's been a few months since this thread has been bumped. It's a really good thread and I want others to see it.

I have two quick questions. What's preload should I be shooting for with stock LS1 lifters?

Also what bad things can happen if you run too much preload?

Thanks for the help. I have my valve covers off right now replacing some seals and I'm going to fix my **** once and for all. Well this problem anyway.

I have two quick questions. What's preload should I be shooting for with stock LS1 lifters?

Also what bad things can happen if you run too much preload?

Thanks for the help. I have my valve covers off right now replacing some seals and I'm going to fix my **** once and for all. Well this problem anyway.

#59

TECH Fanatic

iTrader: (35)

It's been a few months since this thread has been bumped. It's a really good thread and I want others to see it.

I have two quick questions. What's preload should I be shooting for with stock LS1 lifters?

Also what bad things can happen if you run too much preload?

Thanks for the help. I have my valve covers off right now replacing some seals and I'm going to fix my **** once and for all. Well this problem anyway.

I have two quick questions. What's preload should I be shooting for with stock LS1 lifters?

Also what bad things can happen if you run too much preload?

Thanks for the help. I have my valve covers off right now replacing some seals and I'm going to fix my **** once and for all. Well this problem anyway.

#60

I posted this comment in another thread here:

I think there is so much confusion regarding valve train noise it isn't funny. Everybody has an opinion...none are 100% right or wrong. But here is what I discovered. Late LS1 block (LS6) with 243 heads, 54-456-11 Comp cam, 918 Comp springs, .050 GM gaskets, stock rockers, top hat seals. This is a fairly mild cam, but has a somewhat radical lobe with over .600 lift. With the springs installed to just under 1.800 installed height, and 135 lbs on the seat, and 7.400 pushrods, this had between .090 and .100 lifter preload. Geometry was acceptable. Now, to me, this is WAY to deep in the lifter...but there are a lot of well respected builders out there and on this site who said I was just fine...that this engine likes them that deep. There are a lot of Stock Eliminator boys who are forced to run hydraulic lifters who run them just off the bottom of the lifter, but noise and driveability are not a concern...performance only. They do it to simulate a solid lifter's characteristics. Not the case here and I always felt this was wrong. Sure enough, this thing was noisy as hell. When my tuner heard it, he thought it was normal for a cammed LSx. I hated it. I know the cam lobe and other factors combine to make this noisy, but I still thought it could be better. So I went back and remeasured everything and I ordered a set of 7.350 pushrods and changed my lifter preload to around .045 on all lifters. The difference was dramatic. My tuner couldn't believe the difference when he heard it. It's almost as quiet as stock. I may even try a set of 7.325 pushrods just to see...but I may have geometry issues if I go that short. Moral of the story...don't be afraid to play with your valvetrain. You may come up with some very interesting findings.

As to the correct way to measure the preload, well, my method is to use an adjustable pushrod and with the lobe on the base circle and the rocker torqued to spec, adjust to zero preload. That can be tough on these motors as you can't really get your fingers in there to spin the push rod until you feel drag. But if you're careful, you can get it. Once you have zero lash, pull the pushrod and measure it. Add to that measurement the amount of preload you want to end up with.

Too much preload can have a lot of different issues. Lifter pump up, noise, valves that won't seat, reduced rpm, burned valves, etc etc. But I have to tell you...at .100 preload, I only had noise issues that I could tell. Comp Cams told me they like around .025 with my setup. I wish I had tried that...and I may yet. But at .045, it made a dramatic difference in noise reduction.

I think there is so much confusion regarding valve train noise it isn't funny. Everybody has an opinion...none are 100% right or wrong. But here is what I discovered. Late LS1 block (LS6) with 243 heads, 54-456-11 Comp cam, 918 Comp springs, .050 GM gaskets, stock rockers, top hat seals. This is a fairly mild cam, but has a somewhat radical lobe with over .600 lift. With the springs installed to just under 1.800 installed height, and 135 lbs on the seat, and 7.400 pushrods, this had between .090 and .100 lifter preload. Geometry was acceptable. Now, to me, this is WAY to deep in the lifter...but there are a lot of well respected builders out there and on this site who said I was just fine...that this engine likes them that deep. There are a lot of Stock Eliminator boys who are forced to run hydraulic lifters who run them just off the bottom of the lifter, but noise and driveability are not a concern...performance only. They do it to simulate a solid lifter's characteristics. Not the case here and I always felt this was wrong. Sure enough, this thing was noisy as hell. When my tuner heard it, he thought it was normal for a cammed LSx. I hated it. I know the cam lobe and other factors combine to make this noisy, but I still thought it could be better. So I went back and remeasured everything and I ordered a set of 7.350 pushrods and changed my lifter preload to around .045 on all lifters. The difference was dramatic. My tuner couldn't believe the difference when he heard it. It's almost as quiet as stock. I may even try a set of 7.325 pushrods just to see...but I may have geometry issues if I go that short. Moral of the story...don't be afraid to play with your valvetrain. You may come up with some very interesting findings.

As to the correct way to measure the preload, well, my method is to use an adjustable pushrod and with the lobe on the base circle and the rocker torqued to spec, adjust to zero preload. That can be tough on these motors as you can't really get your fingers in there to spin the push rod until you feel drag. But if you're careful, you can get it. Once you have zero lash, pull the pushrod and measure it. Add to that measurement the amount of preload you want to end up with.

Too much preload can have a lot of different issues. Lifter pump up, noise, valves that won't seat, reduced rpm, burned valves, etc etc. But I have to tell you...at .100 preload, I only had noise issues that I could tell. Comp Cams told me they like around .025 with my setup. I wish I had tried that...and I may yet. But at .045, it made a dramatic difference in noise reduction.