Lifter pre-load?

#23

TECH Addict

iTrader: (2)

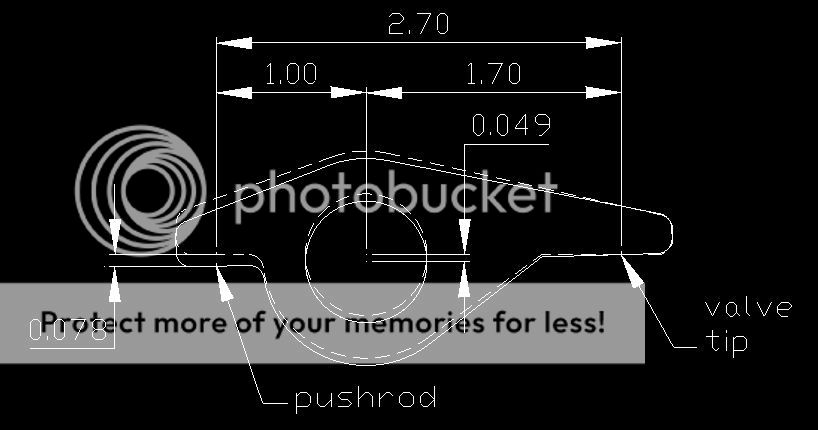

Vettenuts numbers use a formula that reduces to approximately 0.078" per turn applied to the number of turns minus the one-third turn constant. Shane uses 0.049" per turn applied to the number of turns, unadjusted. The difference in the two methods is small at low turn counts and increases as the number of turns increase. However, since the preloads being established have a large window, and pushrods come in increments of 0.025" the difference in the two methods is acceptable in many instances. See attached.

#24

https://ls1tech.com/forums/15087505-post42.html

I don't know exactly what the "2.7/1.7" factor is in Vettenuts' calculation example. The 1.7 is probably the rocker ratio, but what's the 2.7?

=====================

When the number of turns increases to 1-1/4, you still need to subtract the 1/3 bolt turn after the rocker seats in the stand.

(1.25-0.3333) X 1.25/25.4 X 2.7/1.7 = 0.071

=====================

I'm assuming he verified his math results with actual dial indicator measurements.

When Shane came up with his "1 turn = 0.049" pre-load", it may have only been checked at around 1 to 1-1/2 turns, thereby not showing that the 1 turn = 0.049 factor changes depending on how many turns are required to torque the rocker arm bolt to 22 ft-lbs.

Darkman - nice summary table.

Last edited by ZeeOSix; 02-26-2012 at 02:01 PM.

#25

TECH Addict

iTrader: (2)

#26

Not to nit-pick, but Shane's method was quoting 0.047" per turn instead of 0.049". See his attached word file.

https://ls1tech.com/forums/14930022-post24.html

It is a good exercise to try and nail these correlations down.

Here are a couple of other good posts in the same main thread [ https://ls1tech.com/forums/generatio...questions.html ]:

https://ls1tech.com/forums/14941833-post34.html

https://ls1tech.com/forums/14943159-post36.html

https://ls1tech.com/forums/14930022-post24.html

It is a good exercise to try and nail these correlations down.

Here are a couple of other good posts in the same main thread [ https://ls1tech.com/forums/generatio...questions.html ]:

https://ls1tech.com/forums/14941833-post34.html

https://ls1tech.com/forums/14943159-post36.html

#28

Looks good, except your thread calculation conversion and results columns are a decimal place off. Divide by 25.4 instead of 2.54 to convert mm to inches.

#30

TECH Fanatic

iTrader: (7)

That's because GM has already figured out the correct parts (pushrod length, etc) to give the lifter plunger the right pre-load. GM doesn't write the manual assuming people are going to be modifying and put different parts in the engine. GM assumes all the OEM parts are being used, and in that case there would be need to worry about lifter pre-load.

I agree that it's wise to check your preload if you're installing a cam or aftermarket valvetrain. But I've messed with the preload on my H/C LT1 with LS7 lifters, and noticed almost no change between 1/4, 1/2, and 3/4 turn preload.

I was merely stating what method worked for me. If OP chooses not to do that, that's fine. But I'm not looking to get into an argument over lifters. There are plenty of methods for adjusting them, and this method worked for me.

#31

#32

Not to nit-pick, but Shane's method was quoting 0.047" per turn instead of 0.049". See his attached word file.

https://ls1tech.com/forums/14930022-post24.html

It is a good exercise to try and nail these correlations down.

Here are a couple of other good posts in the same main thread [ https://ls1tech.com/forums/generatio...questions.html ]:

https://ls1tech.com/forums/14941833-post34.html

https://ls1tech.com/forums/14943159-post36.html

https://ls1tech.com/forums/14930022-post24.html

It is a good exercise to try and nail these correlations down.

Here are a couple of other good posts in the same main thread [ https://ls1tech.com/forums/generatio...questions.html ]:

https://ls1tech.com/forums/14941833-post34.html

https://ls1tech.com/forums/14943159-post36.html

#33

But ... Shane's method, and vettenuts' method were measuring the movement of the rocker just above the pushrod with a dial indicator - which is essentially measuring the push deflection which equates to lifter pre-load. They were not measuring the rocker arm bolt movement.

I also noticed that in practice between the two methods both Shane and Vettenuts said that the push rod didn't move much more than a couple thousanths over the actual bolt. The only issue I see with this is that if the lifters are not brand new (like mine) and have oil in them. They actually started moving the valve not the lifter plunger. So it stands to reason that the plunger doesn't move much if the vave does. I am just going to do it the right way tomorrow and see what I come up with.

You could probably turn the engine over a few times by hand before removing the rocker arms to help push oil out of the lifters so it would be easier to try the Shane/vettenuts method.

#34

Good points. I am going to do the correct method tomorrow and see what I get. I got on the dyno tonight and didn't have any real issues. I jus want to be sure and eak out every last bit of what I have. I didn't gain as much out of the head mods as I thought but I did run out of injector. We will see. I will post up a dyno thread tomorrow when I have time.

#35

So I pulled the rockers today and this is what I found out. My preload was .110" on the intake and .105" on the exhaust. I also checked the valve trane geometry and it wasn't bad. I ended up shimming the intakes up about .047" and the exhaust .040". The geometry didn't move much but it isn't perfect. I am going to get some 7.350" push rods and take the shims out. Funny thing is that I went from 1 3/4 turns to 3/4 turns to 22ft/lbs. So in my case it looks like Vettenuts wins. 1 3/4 turns equaled .110ish pre-load.

#36

So I pulled the rockers today and this is what I found out. My preload was .110" on the intake and .105" on the exhaust. I also checked the valve trane geometry and it wasn't bad. I ended up shimming the intakes up about .047" and the exhaust .040". The geometry didn't move much but it isn't perfect. I am going to get some 7.350" push rods and take the shims out. Funny thing is that I went from 1 3/4 turns to 3/4 turns to 22ft/lbs.

LOL ... hard to argue with applicable engineering science.

#38

Teching In

Join Date: Jun 2011

Location: LONGVIEW, TX

Posts: 44

Likes: 0

Received 0 Likes

on

0 Posts

I am glad to see this thread. I have been preaching this anti .047" bullshit over on ls1gto for a while now. I thought I was the only one measuring with a dial indicator! I came up with about .078" for one turn. People are running WAY more preload than they think and giving false info all the time because they saw a thread somewhere that said .047"

#39

Teching In

Join Date: Jun 2011

Location: LONGVIEW, TX

Posts: 44

Likes: 0

Received 0 Likes

on

0 Posts

#40

TECH Fanatic

iTrader: (35)

I am glad to see this thread. I have been preaching this anti .047" bullshit over on ls1gto for a while now. I thought I was the only one measuring with a dial indicator! I came up with about .078" for one turn. People are running WAY more preload than they think and giving false info all the time because they saw a thread somewhere that said .047"

================================================== =======================================

This drawing shows movement of the rocker as it is being tightened down by the trunnion bolt for pre-load checking. The rocker at the valve tip is stationary. Due to the rocker ratio the pushrod end travels down .078" for every .049" (1 turn) of the rocker bolt. The ratio = .078 / .049 = 1.59 is also calculated as 2.7 / 1.7 = 1.59 since the valve tip is the pivot point.