Rod Bolt Replacement Lesson if your thinking about doing this come in.....

#43

ModSquad

iTrader: (6)

Once the rod goes out of round, it must be re-machined.

#44

UNDER PRESSURE MOD

iTrader: (19)

Che70velle, my machinist said the said thing. That's why he measured rod bolts with a stretch gauge rather than a torque wrench, it yeilds far greater accuracy, his words, not mine. Hence why he torque mine down, measured stretch, then measured the rod journal and sized as needed. He also said any bolt clamping down on a bearing is a critical measurement. Changing those loads, means changing how oil moves through the motor, and change that and bad things are bound to happen.

#45

Staging Lane

Join Date: Sep 2004

Location: arlington, wash

Posts: 59

Likes: 0

Received 0 Likes

on

0 Posts

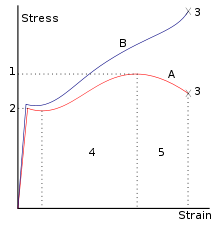

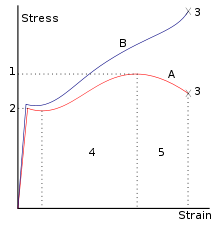

Does anyone know the yield stress or modulus of elasticity of either Arp Katech or GM bolts? Torque values of either? Material properties of stock GM rods? I understand rod distortion, but if all bolts are torqued to same clamping force.. it would provide that each rod should be equally distorted (+-) some statistics on material properties.

#46

Staging Lane

Join Date: Sep 2004

Location: arlington, wash

Posts: 59

Likes: 0

Received 0 Likes

on

0 Posts

http://arp-bolts.com/pages/technical.shtml

Katech's material properties: http://www.matweb.com/search/DataShe...458bb22&ckck=1

Are Katechs effective diameter (root or shank) smaller than ARP's? Essentially reducing clamping force, negating distortion of the rod, and still yielding (stretching to .006) the bolt?

Katech's material properties: http://www.matweb.com/search/DataShe...458bb22&ckck=1

Are Katechs effective diameter (root or shank) smaller than ARP's? Essentially reducing clamping force, negating distortion of the rod, and still yielding (stretching to .006) the bolt?

#47

Launching!

iTrader: (1)

I tested every one of mine. I tested, checked, retested, remeasured, and re-torqued and re-measured. Exactly the same in every way, clamping force and roundness. The ARP bolts did not put ANY more clamping force than the stock bolt. They aren't meant to. They are meant to retain strength and not fatigue like the stock one's. Like I said, not meant for more clamping force. - which explains any lack of ovaling or distorting. They're just meant to be stronger when higher revs try to pull it apart and not stretch. There is a difference. Keep in mind I am only talking about the ARP complete hi perf 8740 kit number 134-6006 NO other kit. There are 3 kits that will "fit" in the Stock cracked cap. The one I mentioned was meant for stock rod duty. 134-6006

my conclusion is not flawed, there is a much higher wear in the specific spot that would be affected by the bolts compared to the rest of the bearing which exhibited normal wear the only thing that would cause that type of bearing damage is an out of round housing.....and the rate at which it appeared to be wearing was not on par with the rest of the bearing.....find a GOOD performance machine shop and they will tell you the same thing......this is not the first time i have seen this......but it is the first time im sharing my find to try and save people some headaches............whether you chose to take the info or throw it out there is no sweat off of my back.......im merely stating a fact.......according to your theory then we can freely swap bolts in and out with no problem, interesting......do YOU have any data to back up your claims?

How is this conclusion not flawed? Just because, "that type of bearing damage is an out of round housing." will be said by reputable people still does not place blame on the ARP bolts. Do you know every bit of history with these rods and bearings? Did YOU install them and measure them before and after using the ARP? If so, then we have more validity, but you did not mention this in your original Post. If YOU did indeed do all this measuring and installing before running in the motor, are you sure you followed proper torque procedures? The answer is a definite no. Otherwise you would have caught any out of round you claim the ARP did cause and are at fault. So it is safe to say, you definitely don't know the full story of the motor before you pulled it apart and therefore cannot make ANY claim as to who or what is to blame, including oiling issues or whatever the hell else could have gone wrong in conjunction with distortion. Were the bearings changed once already before you got to them? Were those bearings the proper size? Too many variables to use this as a great example. Once again, if you do know the full history, which I've proven you don't first hand, you need to include all data before making such a huge blanket statement placing blame. In this case you don't, and you truly have no business posting this blame.

Last edited by 95ONE; 05-06-2012 at 09:00 PM.

#49

12 Second Club

iTrader: (49)

Not exactly. Given the variances in machining of a mass produced product, a simple change in rod bolts could put the bearing in proper crush on a rod with a greater clearance, and distort the one next to it with lesser clearance...

I can only speak from experience, as have others in this thread. With stock rods, it seems hit or miss and the only thing a can pin it to is mass production.

Maybe someone should test a set of aftermarket rods between 8740's and 2000's and try to either prove or disprove this. But even then, mass production would play a part as well...albeit smaller because of the fact less are produced, it will still play some part.

I can only speak from experience, as have others in this thread. With stock rods, it seems hit or miss and the only thing a can pin it to is mass production.

Maybe someone should test a set of aftermarket rods between 8740's and 2000's and try to either prove or disprove this. But even then, mass production would play a part as well...albeit smaller because of the fact less are produced, it will still play some part.

#51

to validate claims i have "no buisness" making............yes every single rod in the motor was worn EXACTLY the same on both TOP and BOTTOM......so what you are telling me is the person that installed the bolts before me somehow over torqued every one of them exactly the same......ok i can buy that........ yet when i measured the bolt coming out with my stretch gauge it returned excatly the amount it should have for that particular bolt, this unvalidates that overtorquing claim.....i am not "blaming" arp at all.....ARP makes a fantastic product and i will continue to run them for years to come.......i do blame improper procedure upon installing the rod bolts.....the housing went out of round and it should have been corrected........that is it........stock gm rods with stock bolts ive seen almost .0013 out of round before.....take an issue like that with a tight stock clearance and then add the rod bolt issue and you run into a problem..........as previously stated will ALL do this, no they will not, but will some do this if you have other issues working against you, YES.......personally i would not take the chance......

for the LS1 tech crowd and experienced people that have been here and understand what happend here im glad i could show it.........and i hope you can distinguish from real world experience and correct infortmation in this thread vs. incorrect infortmation i have read in some posts over the past couple pages.......

again.....i resign

(for real this time )

)

for the LS1 tech crowd and experienced people that have been here and understand what happend here im glad i could show it.........and i hope you can distinguish from real world experience and correct infortmation in this thread vs. incorrect infortmation i have read in some posts over the past couple pages.......

again.....i resign

(for real this time

Last edited by quik95lt1; 05-07-2012 at 07:39 AM.

#53

TECH Junkie

iTrader: (1)

Thanks for the explanations.

This sheds some light on the destruction on my #7 rod bearing, & trashing of the crank.

Upon engine reassembly, I have a .0007 (or so) clearance on #7. Although plastigauge was used at four 90deg points in the rod, the clearances were the same. So, although the hole seems to be round, it is definitely on the small side. I went to an 'x' bearing to compensate.

This sheds some light on the destruction on my #7 rod bearing, & trashing of the crank.

Upon engine reassembly, I have a .0007 (or so) clearance on #7. Although plastigauge was used at four 90deg points in the rod, the clearances were the same. So, although the hole seems to be round, it is definitely on the small side. I went to an 'x' bearing to compensate.

#54

Staging Lane

Join Date: Jan 2009

Location: Adelaide, South Australia

Posts: 77

Likes: 0

Received 0 Likes

on

0 Posts

I replaced the rod bolts in my old 99' LS1 with the ARP High perf bolts, one at a time to 40nm, and never had an issue with that engine. Ive jut done the same with my 03' LS1 but i havent run it yet. I bet it will be fine.

Heaps down here in AUS have done the one at a time method with success.

But this thread certainly is an interesting read.

Heaps down here in AUS have done the one at a time method with success.

But this thread certainly is an interesting read.

#55

TECH Addict

iTrader: (1)

Apparently, I was extremely wrong in my assessment. I was just going off of observations from past conversations. I am not a metallurgist, do not want anybody making decisions on what I said (despite having a few thought on why it may work out), and so I will bow out.

Last edited by SSCamaro99_3; 05-07-2012 at 12:32 PM.

#56

TECH Enthusiast

Thanks quik95lt1, these are the types of posts I find very educational. You explained it well, with nice photos. I had considered doing the rod bolt swap in the car at one time, using the Katech bolts, because I had seen many others doing it. I was at least smart enough to ask the question of a couple professional race engine builders. They told me I was far better off leaving it alone with an inferior factory bolt in there than trying to swap the bolts to a better bolt without resizing the rods. They said it would cause an oor problem and could wear the bearings our rapidly, if the oor condition was significant enough. One told me that he wouldn't even bother swapping out the stock bolt unless I was considering exceeding 7K rpm, he said better ones wouldn't hurt if I were resizing, but were really somewhat overkill. He said that the rod bolts are not as fragile as the internet claims, there are several other limitations that you will have failures at before the rod bolts.

Your post here just demonstrates what other respected builders had told me, but you were able to explain it better with photos. Very constructive thread. I think the nay sayers were constructive too, in vetting your data. Although some have had good "luck" with it, they have not been able to put together any real solid reason to support changing the rod bolts, without a proper resize.

Thanks dude!

Your post here just demonstrates what other respected builders had told me, but you were able to explain it better with photos. Very constructive thread. I think the nay sayers were constructive too, in vetting your data. Although some have had good "luck" with it, they have not been able to put together any real solid reason to support changing the rod bolts, without a proper resize.

Thanks dude!

#57

and just to validate what you said about the rod bolts i completely agree........there are far weaker spots in a stock shortblock than the bolts......ive seen two stock bottom end ls1's come in that ive rebuilt with bent rods.....the top bearing shell had signs of detonation and the bottom were fine but the rods had an s bend in them......one was a naturally aspirated motor that saw 7000rpm and detonated to bend the rod......with stock rod bolts.....that motor would've ran much longer if it werent for the poor tune..........the second was a turbo application that made over 500 at the wheel through a 200r4.....same deal stock bolts with a bent rod.......again detonation.......not saying they dont break bolts but the overwhelming majority of broken ones ive seen come through are all due to detonation, broken ring landings, shrunken pistons, bent rods, spun bearings from detonation beatings and oiling issues........hell i had a close friend of mine that literally broke a rod in half....yet the cap was still bolted on the crank and was slinging around smashing the block to bits.......whole motor was junk but when i pulled the pan and saw that i was impressed lol

Last edited by quik95lt1; 05-07-2012 at 01:23 PM.

#58

Launching!

iTrader: (1)

That said, the remainder of what you said in the quote is indeed something for everyone to consider.

Last edited by 95ONE; 05-07-2012 at 01:26 PM.

#59

I would love to learn something from anyone. But posting this as fact is making readers dumber, not smarter. It does not invalidate the over torque claim. Just because it wasn't stretched beyond permanent distortion does not prove that it wasn't over torqued for the spec on this rod. I'm damn sure these bolts can go higher torque (also read in stretch) before they don't return to their original length. So yes, they could be over torqued FOR THE ROD SPECS and return to their original length. .. .. .. ..

that makes about as much sense as a screen door on a submarine im sorry lol

Last edited by quik95lt1; 05-07-2012 at 01:43 PM.