402 Teardown, engine experts welcome

#1

Noticed low oil pressure and cut open the oil filter and saw a lot of bearing material so decided to pull the engine sooner rather than later. Roughly 3500 miles on it...granted those are hard miles  Engine was still running great! No odd sounds, no vibrations, still making great power, no smoke, no oil consumption. Just low oil pressure and bearing material. Engine was built by a very reputable shop in Houston.

Engine was still running great! No odd sounds, no vibrations, still making great power, no smoke, no oil consumption. Just low oil pressure and bearing material. Engine was built by a very reputable shop in Houston.

Anyway, on to the pics...

Just put in new plugs as well...if you notice 2 timing marks, I pulled 2 degrees out before the last time I ran it. Most timing was around 17 degrees.

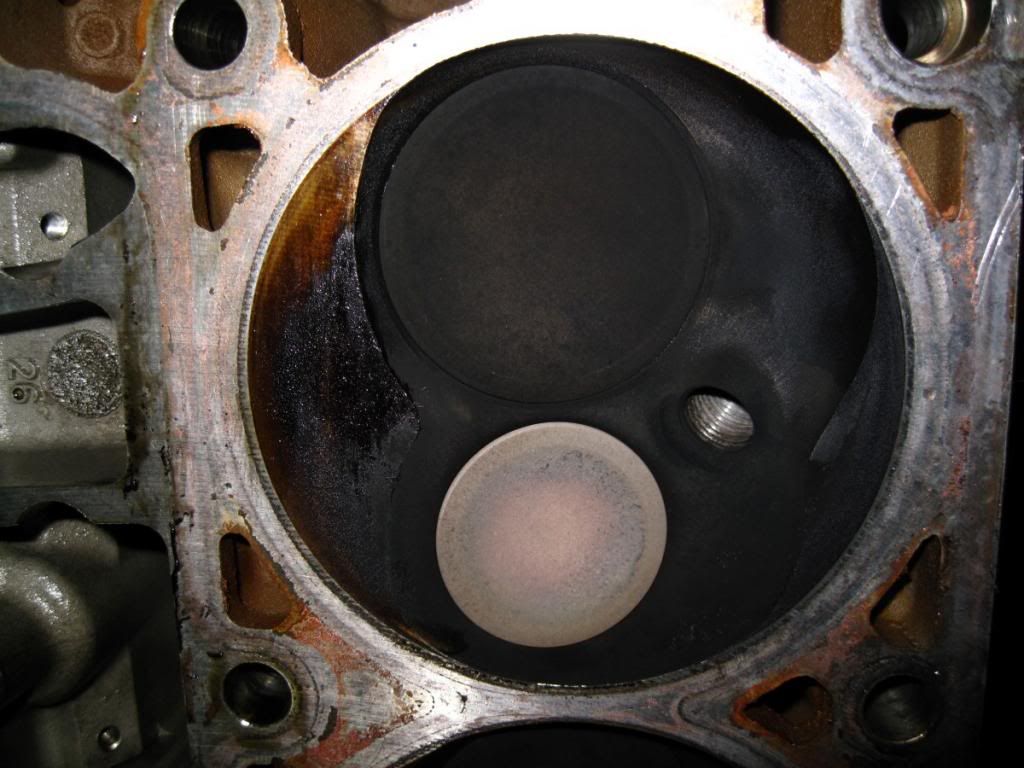

Top end looked great to me. Zero evidence of detonation.

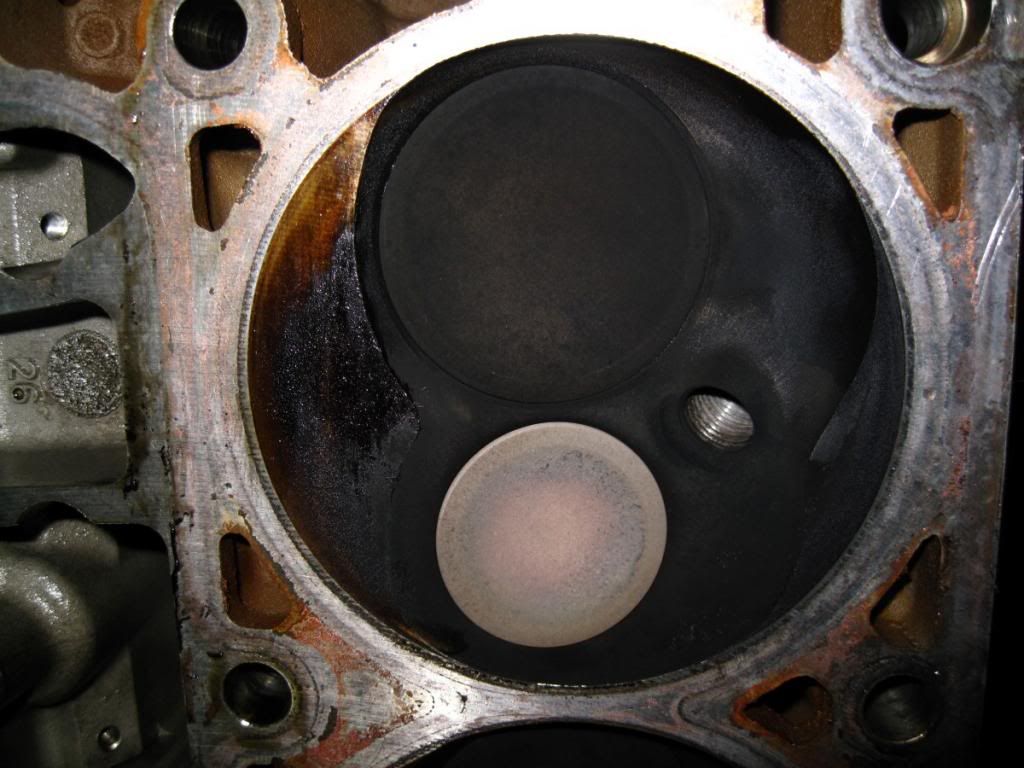

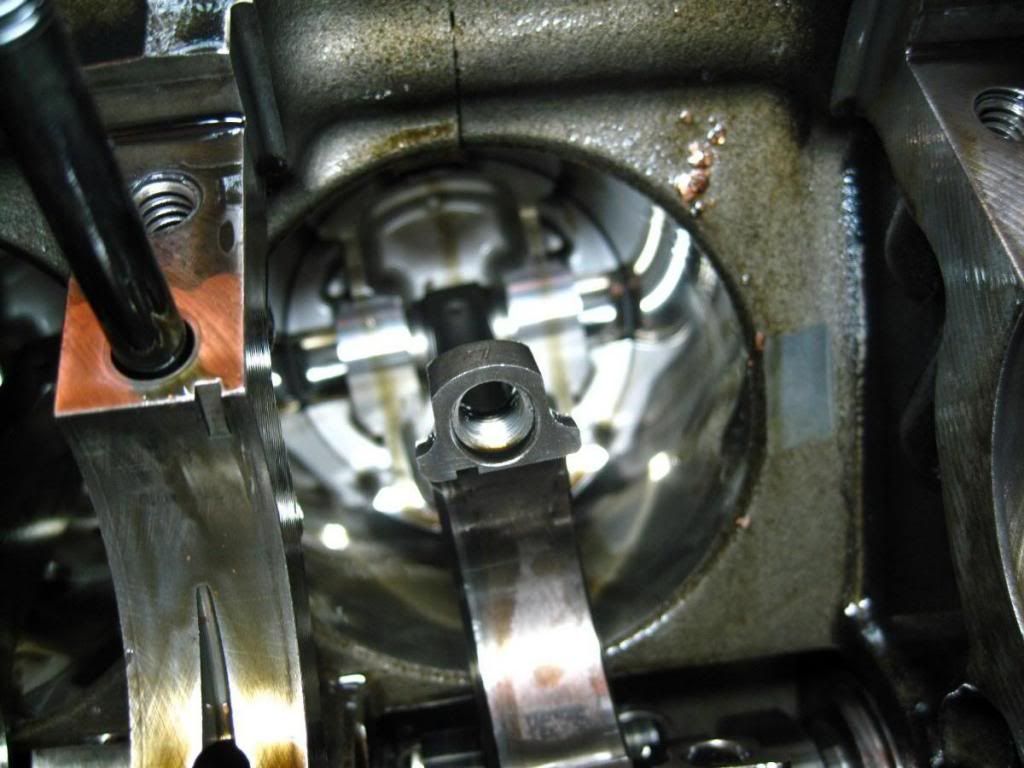

Cylinder walls look good...

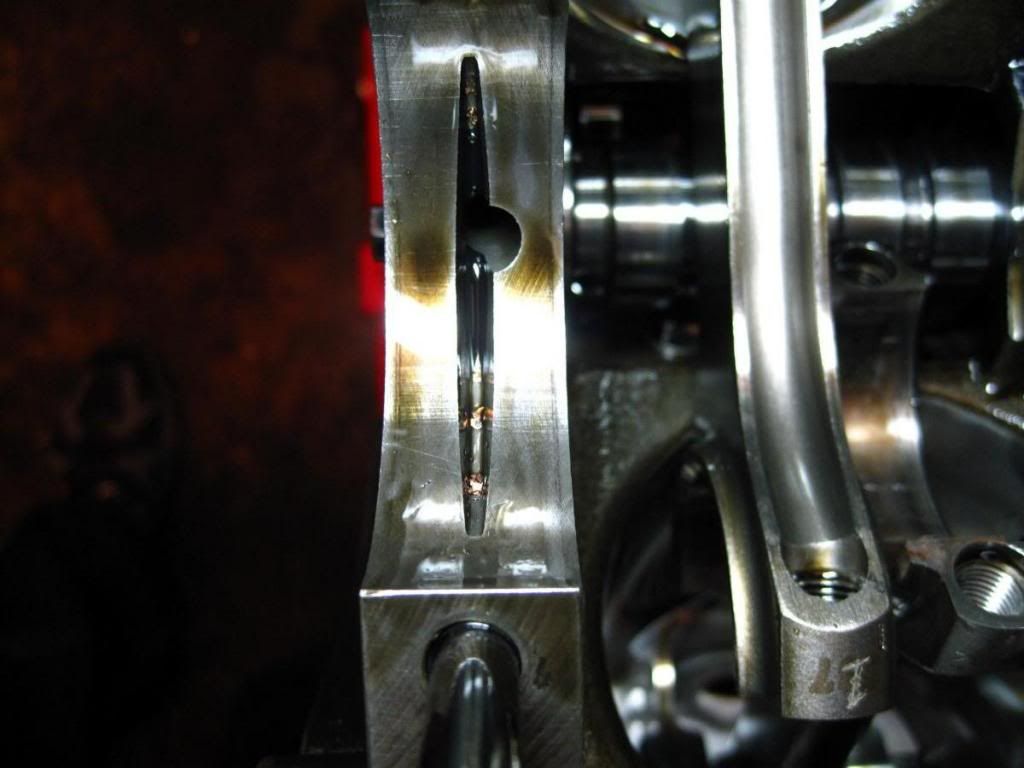

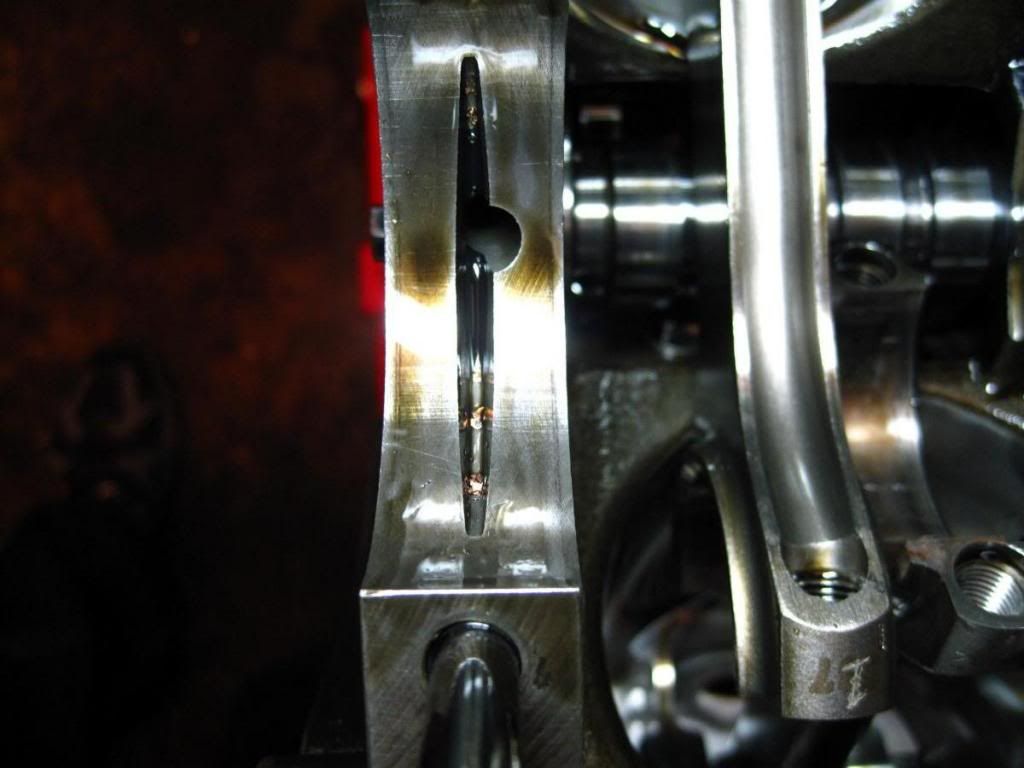

Then the party starts...

Anyway, on to the pics...

Just put in new plugs as well...if you notice 2 timing marks, I pulled 2 degrees out before the last time I ran it. Most timing was around 17 degrees.

Top end looked great to me. Zero evidence of detonation.

Cylinder walls look good...

Then the party starts...

#2

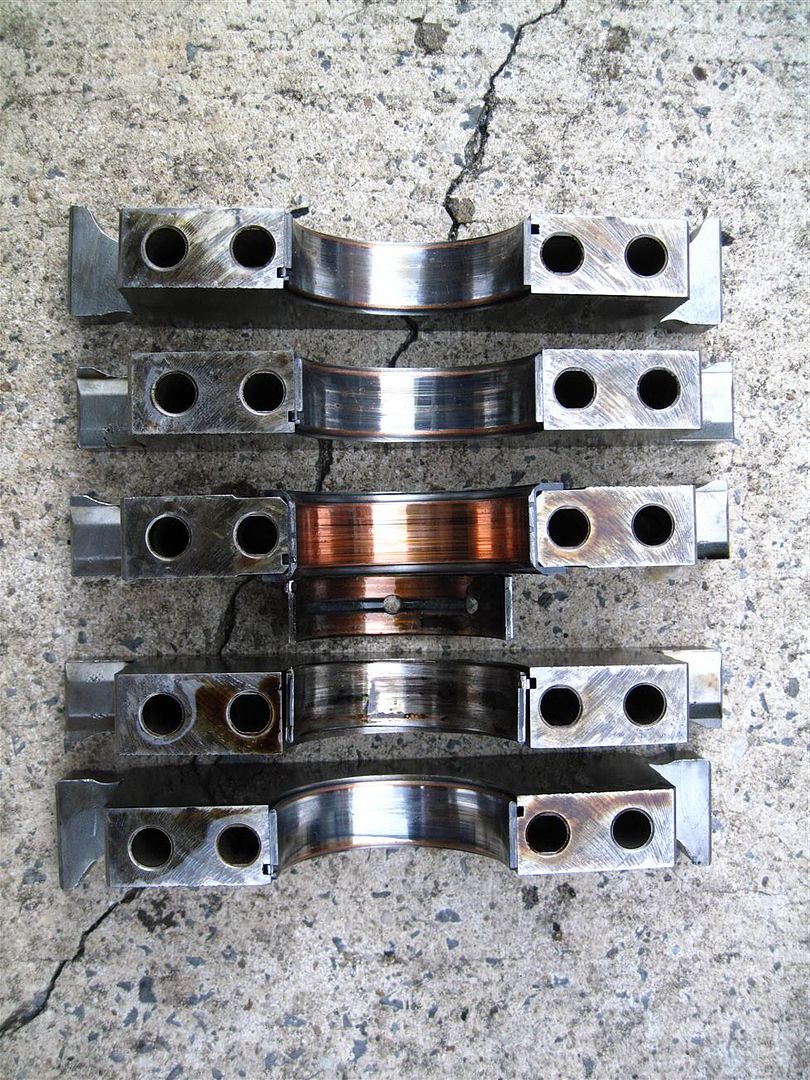

Rod bearings, cyl1 on the left.

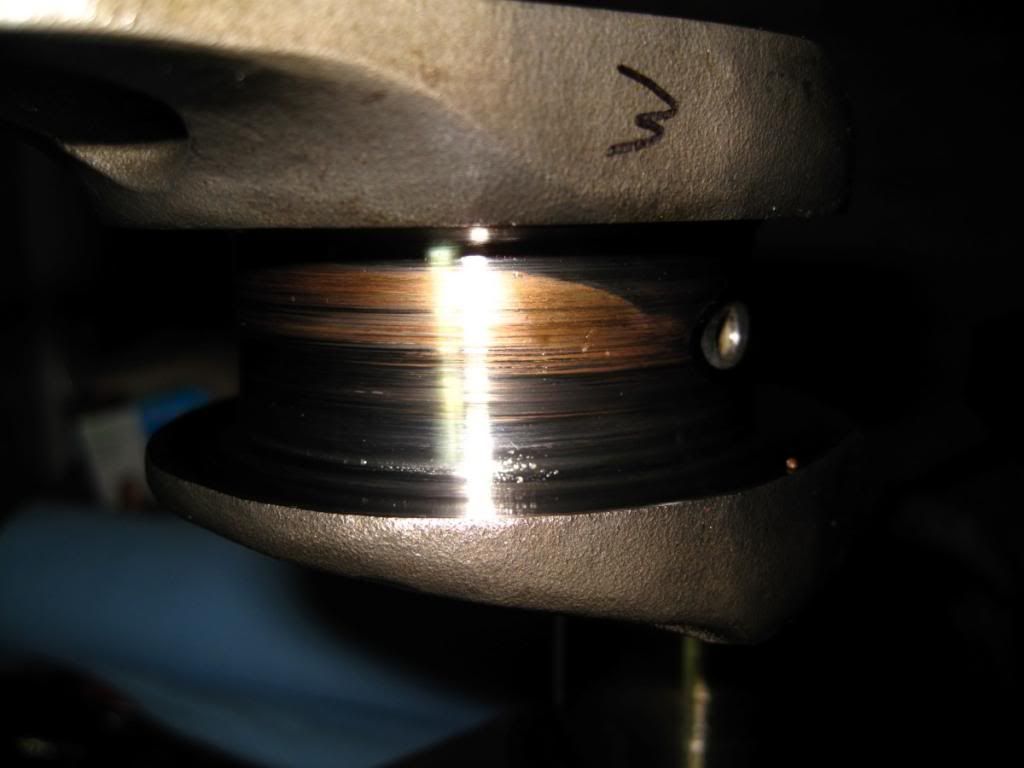

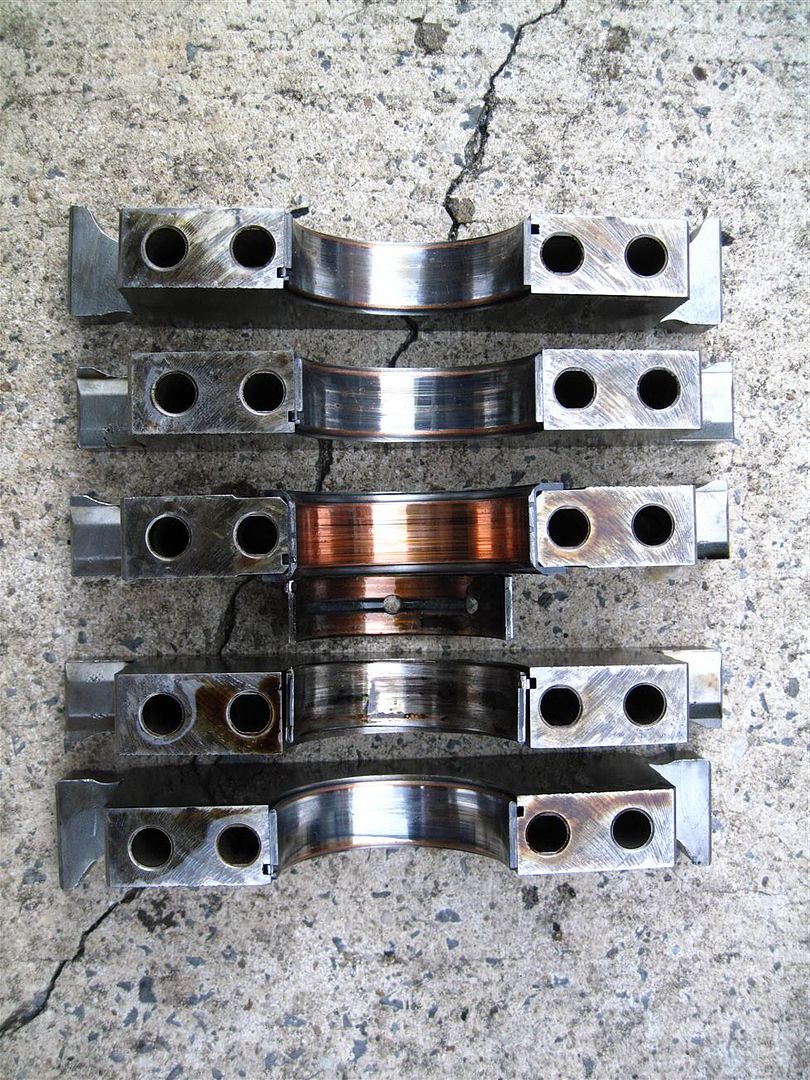

Main bearings, 1 on the left.

I think we found a winner!

Here is number 2....this doesnt quite seem normal...

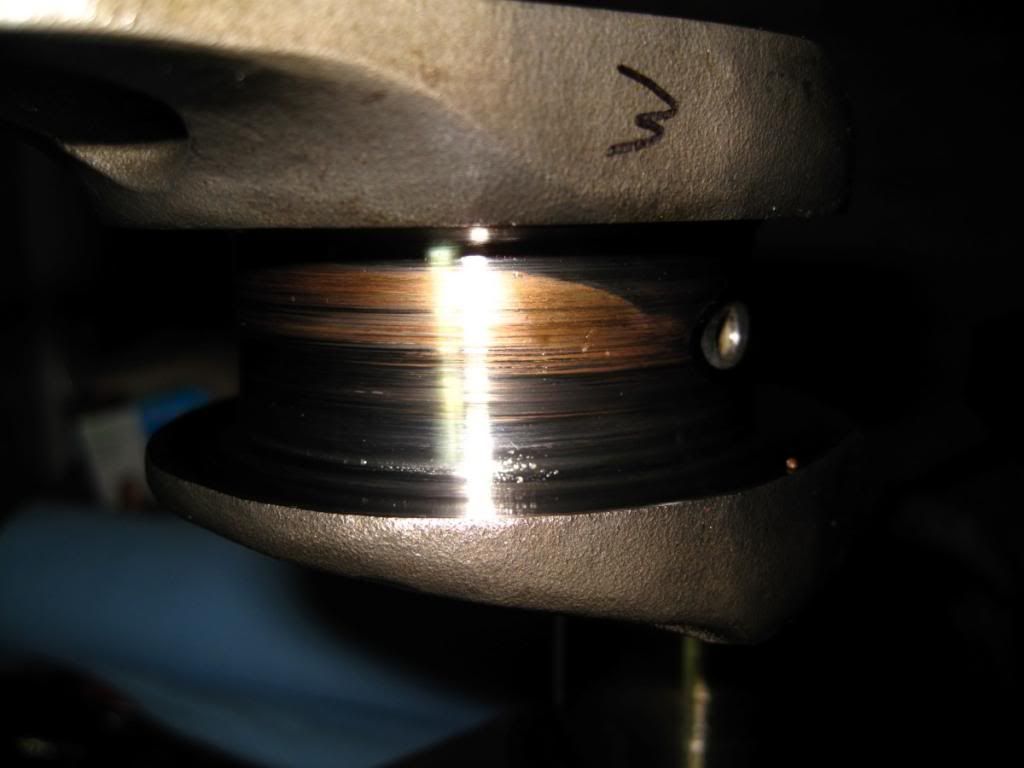

Main journal 1,

Journal 2,

Journal 3,

Journal 4,

Journal 5,

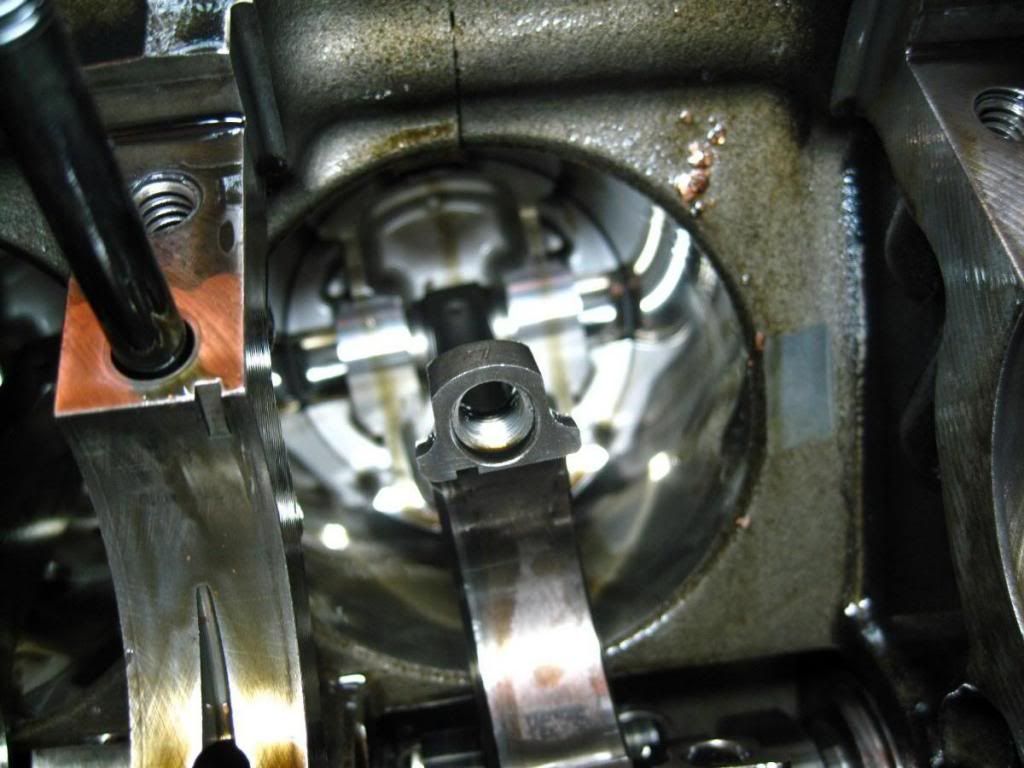

Looking at cylinder 7, notice the bearing material hanging out...

Block journal 1,

I havent pulled the cam yet, because frankly im not sure how to pull out the cam bearings out besides with a screwdriver. The cam lobes look fine though.

Normal oil pressure was around 60ish, with 80+ at WOT....noticed the gauge sitting around 40cold, then dropping to 30 hot with barely any increase with rpm.

this is the second engine this crank has been in that has exhibited the exact same thing. Only things reused were the crank and rods...

Here are the mains from the 408 this crank was in first...

Mains were set to 0.0027, and rods were 0.0025. Used 10w30 and 20w50 brad penn oil.

Checked runout this morning...

Main1: 0.001

Main2: 0.005

Main3: 0.004

Main4: 0.001

Main5: 0.001

I thought the factory spec for runout was in the 0.007 range...

Here is a video of number 3:

Edit: Everything Ive found says max runout for main journal is actually 0.0003"

Main bearings, 1 on the left.

I think we found a winner!

Here is number 2....this doesnt quite seem normal...

Main journal 1,

Journal 2,

Journal 3,

Journal 4,

Journal 5,

Looking at cylinder 7, notice the bearing material hanging out...

Block journal 1,

I havent pulled the cam yet, because frankly im not sure how to pull out the cam bearings out besides with a screwdriver. The cam lobes look fine though.

Normal oil pressure was around 60ish, with 80+ at WOT....noticed the gauge sitting around 40cold, then dropping to 30 hot with barely any increase with rpm.

this is the second engine this crank has been in that has exhibited the exact same thing. Only things reused were the crank and rods...

Here are the mains from the 408 this crank was in first...

Mains were set to 0.0027, and rods were 0.0025. Used 10w30 and 20w50 brad penn oil.

Checked runout this morning...

Main1: 0.001

Main2: 0.005

Main3: 0.004

Main4: 0.001

Main5: 0.001

I thought the factory spec for runout was in the 0.007 range...

Here is a video of number 3:

Edit: Everything Ive found says max runout for main journal is actually 0.0003"

#3

TECH Resident

iTrader: (5)

Wow! I would be pissed. What crank is that? Looks bent to me. I would be calling whoever built it. I plan on checking all my **** when it gets back from the machine shop. Your block may need to be line honed, and that crank? Not real sure. I would think that someone could straighten it out, then have it turned .010.

#4

TECH Veteran

iTrader: (14)

I agree the crank looks like it might be bent. I'd have the motor torn down, block looks like it needs a line honing. As for the crank though idk if I would even want to straighten it, I know its a stroker one and all but I'd feel better with a good used one or new one especially when you have that much tied into the engine.

#5

Crank is a K1 forged 4"

Yea I plan on calling the shop monday. But really, I dont know if this would be a machining issue or just the fact of pushing beyond the limits of the part. I was pushing above 1k hp at the engine im sure. All journals should have been turned/polished which I believe were. Leading theory now is the crank is bent or cracked. Regardless, I am not reusing this crank again.

Yea I plan on calling the shop monday. But really, I dont know if this would be a machining issue or just the fact of pushing beyond the limits of the part. I was pushing above 1k hp at the engine im sure. All journals should have been turned/polished which I believe were. Leading theory now is the crank is bent or cracked. Regardless, I am not reusing this crank again.

#6

TECH Resident

iTrader: (5)

Crank is a K1 forged 4"

Yea I plan on calling the shop monday. But really, I dont know if this would be a machining issue or just the fact of pushing beyond the limits of the part. I was pushing above 1k hp at the engine im sure. All journals should have been turned/polished which I believe were. Leading theory now is the crank is bent or cracked. Regardless, I am not reusing this crank again.

Yea I plan on calling the shop monday. But really, I dont know if this would be a machining issue or just the fact of pushing beyond the limits of the part. I was pushing above 1k hp at the engine im sure. All journals should have been turned/polished which I believe were. Leading theory now is the crank is bent or cracked. Regardless, I am not reusing this crank again.