Oil Priming

#21

On The Tree

Join Date: Jul 2013

Location: Augusta, GA

Posts: 132

Likes: 0

Received 0 Likes

on

0 Posts

Fair enough, but most people really don't want to go chasing parts down to rig something up, and after you spend five to ten grand building an engine, what's another 79 bucks. And hey, you can get it and use it once then throw it on ebay, Ive done that plenty with tools.

#22

That's MISTER MODERATOR

iTrader: (9)

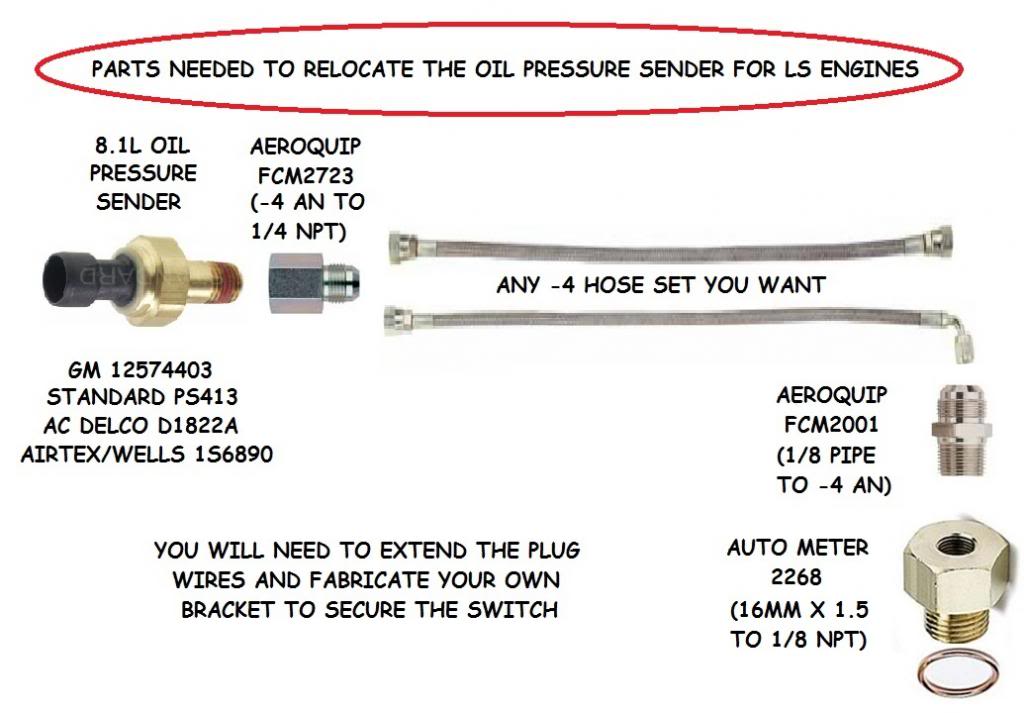

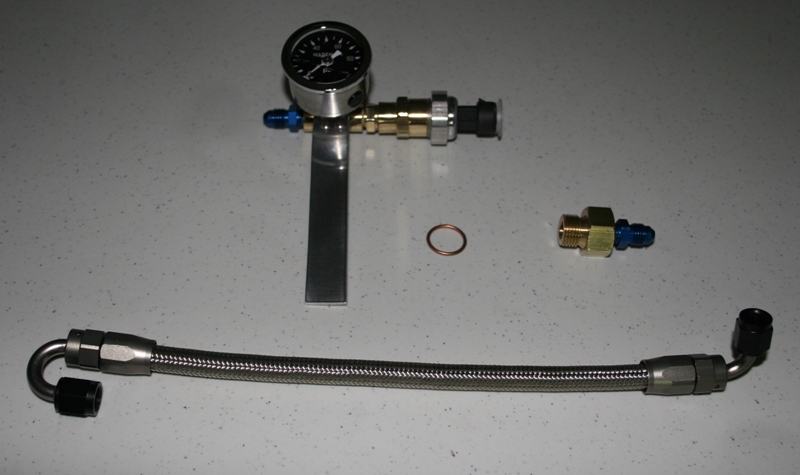

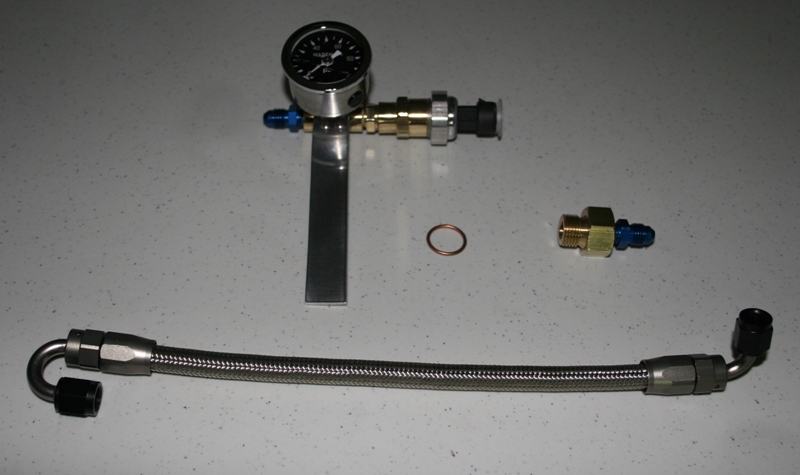

To re-locate your OPSU, you need to setup a kit like this. It's from a non-sponsor so I won't say who. You need an adapter from whatever the thread on the OPSU is to like -4 AN, a length of hose and an adapter back. The gauge shown is optional and not needed-unless you want it.

#31

For anyone that stumbles on this... On my LQ9, the port on the drivers side front of the block is a M16-1.5 thread. Just a FYI... This isn't a "I think mine is..." post, it literally is... I bought the part today and threaded it in by hand fully seated.

Going to pull the valve covers probably this weekend and give this a shot, I've got all the fittings in hand to knock it out...

Going to pull the valve covers probably this weekend and give this a shot, I've got all the fittings in hand to knock it out...

Last edited by sirhk100; 07-30-2014 at 09:41 AM.

#36

TECH Veteran

iTrader: (14)

Join Date: Apr 2005

Location: N. Falmouth MA

Posts: 4,085

Likes: 0

Received 0 Likes

on

0 Posts

you can turn it over with the starter for a few seconds at a time (ignition and fuel system disabled of course) until you get pressure then fire it up. Best is to use a pre lubber though. The one in the picture would work great and I like the inventiveness. I personally use the Kentmoore Pre Lubber (looks a lot like the one a few posts above).

#38

I wnt to add a warning to this thread. If you build this DO NOT USE Teflon thread tape on the fitting. Go buy the liquid thread sealer or use nothing. That thread tape can cause ALOT of problems if even a tiny piece gets into the engine oil system. It is only for water systems.....don't say no one ever 4 warned you.

#39

On The Tree

iTrader: (7)

Old thread but good info here. Do you rotate the crank shaft during the priming process to lub all bearings for rod, crank, and cam? Im also assuming that the lifters will bleed oil onto the cam lobs as well.

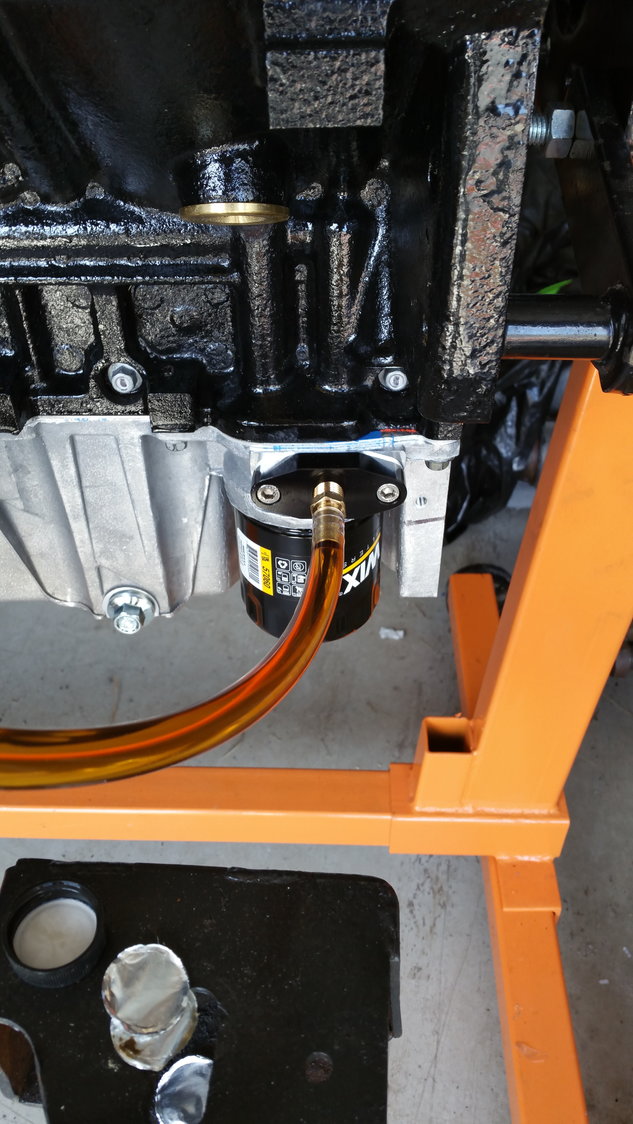

I used the garden sprayer technique. I highly suggest using the port by the timing chain. If you dump oil into the oil pressure port, you are bypassing the filter (bad if there is a contaminate in your oil or pressure device.

The AN fitting and reducers are about $20 from Summit. M10-1.5 and -4 and -6 AN

Attachment 609367

Attachment 609368

The AN fitting and reducers are about $20 from Summit. M10-1.5 and -4 and -6 AN

Attachment 609367

Attachment 609368