Question on lifter preload and lifter plunger.

#61

Guys, Poltergeists theory is correct. Rocker ratio is factored into preload. Try this little test if you're sitting at a computer desk like I am. Space 3 ink pens out vertically in front of you. Think of the left most pen as your pushrod. the middle as your bolt, and the right as your valve. We know the valve doesn't move in preload adjustment. Lay a 4th pen horizontally across the top of all 3 pens to simulate the rocker. Now, slide the center pen down as if you were tightening the bolt. You'll see that it pushes the pen on the left (pushrod) down further. With that being said, the info I posted states that 1 turn equals .047" at the pushrod/rocker interface, not at the bolt itself?????

Last edited by showvette; 09-24-2013 at 11:35 PM.

#63

You said your piece, now move along. That's why I hate people like you who try to cram your opinion down people's throat. If you were right I STILL wouldn't listen because you are annoying and that makes people not like you. I said what I had to say, OP can do what he likes. That's what I meant from I could care less. Jeez its like talking to a woman.

#64

I don't need to prove anything. I'm just trying to help this guy out. Also I am not discrediting Shanes method, as that method will work for stock lifters that need around .100" preload.

#65

TECH Senior Member

iTrader: (96)

Join Date: Aug 2007

Location: Turnin' Wrenches Infractions: 005

Posts: 24,241

Likes: 0

Received 81 Likes

on

72 Posts

You're discrediting his math genius. Don't try to crawfish now. Either he's right or you're right, but not both. Prove it is all I said fella or stop arguing.

#67

Oh, and for 01ssreda4

Instead of trying to insult me with name calling and saying my method is BS, why not prove me wrong? You sound like you see a flaw in the method I use. If you have please explain with big boy answers.

#68

8 Second Club

iTrader: (16)

I'm gonna say it once again just like I did ealier...but I'm gonna say it with more math so that the knuckle heads who think its .049 can see that they are wrong...

You'll need to know the thread pitch first and then the preload per turn can be calculated. The common metric thread pitches of our LSx Rockers are 1.25mm.

That means every turn of the bolt results in 1.25mm travel of the bolt or 1.25/25.4=.0492". (BOLT TRAVEL ONLY....NOT ROCKER TRAVEL)

Since the valve end of the rocker arm is essentially constrained from moving while turning the rocker arm bolt down from zero lash, it becomes the pivot point of the rocker and the movement at the pushrod end of the rocker arm gets multiplied by the ratio of the distance from the valve to the pushrod divided by the distance from the valve to the rocker arm bolt. Since it's just a ratio, the units and actual dimensions aren't really needed since we already know the ratio with the rocker arm bolt as the pivot point. We know the rocker arm ratio is 1.7:1 which means the distance from the pushrod to the rocker arm bolt is "1x" and the distance from the rocker arm bolt to the valve is "1.7x"...again, the units and actual dimensions aren't needed...its still Just a 1.7:1 ratio from one side to the other. That means the total rocker arm length from the valve to the pushrod is "2.7x" so we have all the numbers we need...2.7/1.7=1.588. With a 1.25mm pitch, the lifter preload for each turn of the bolt will be .0492*1.588=.078" and each 1/4 turn will be .0195" or ~.020". For a 1mm pitch, one turn will be .0625" and 1/4 turn will be .0156".

I have measured with a dial indicator on every LS Car I have ever worked on to make sure I have the right pushrod length and right lifter preload.....it is indeed 0.78 per one full turn of the rocker bolt

If you're not getting enough lifter preload, you'll need a longer pushrod.

if you are getting too much preload, you need a shorter pushrod

I use adjustable rockers in my engine...and I use my dial indicator to get .025 preload on all my lifters....my current rocker adjust differently than stock LS rockers...but I will try to see if I have any laying around that I can throw in to measure for show and tell...no guarantees I can find any of them...I havent used stock rockers in a long long time

You'll need to know the thread pitch first and then the preload per turn can be calculated. The common metric thread pitches of our LSx Rockers are 1.25mm.

That means every turn of the bolt results in 1.25mm travel of the bolt or 1.25/25.4=.0492". (BOLT TRAVEL ONLY....NOT ROCKER TRAVEL)

Since the valve end of the rocker arm is essentially constrained from moving while turning the rocker arm bolt down from zero lash, it becomes the pivot point of the rocker and the movement at the pushrod end of the rocker arm gets multiplied by the ratio of the distance from the valve to the pushrod divided by the distance from the valve to the rocker arm bolt. Since it's just a ratio, the units and actual dimensions aren't really needed since we already know the ratio with the rocker arm bolt as the pivot point. We know the rocker arm ratio is 1.7:1 which means the distance from the pushrod to the rocker arm bolt is "1x" and the distance from the rocker arm bolt to the valve is "1.7x"...again, the units and actual dimensions aren't needed...its still Just a 1.7:1 ratio from one side to the other. That means the total rocker arm length from the valve to the pushrod is "2.7x" so we have all the numbers we need...2.7/1.7=1.588. With a 1.25mm pitch, the lifter preload for each turn of the bolt will be .0492*1.588=.078" and each 1/4 turn will be .0195" or ~.020". For a 1mm pitch, one turn will be .0625" and 1/4 turn will be .0156".

I have measured with a dial indicator on every LS Car I have ever worked on to make sure I have the right pushrod length and right lifter preload.....it is indeed 0.78 per one full turn of the rocker bolt

If you're not getting enough lifter preload, you'll need a longer pushrod.

if you are getting too much preload, you need a shorter pushrod

I use adjustable rockers in my engine...and I use my dial indicator to get .025 preload on all my lifters....my current rocker adjust differently than stock LS rockers...but I will try to see if I have any laying around that I can throw in to measure for show and tell...no guarantees I can find any of them...I havent used stock rockers in a long long time

#69

The Scammer Hammer

iTrader: (49)

I'm torn here. Shane's built a LOT of **** while he worked at Thunder. We even spoke on the phone doing his method, which HE says HE's backed up with a dial indicator before as well.

I did one full turn from zero lash and have always assumed I had .047 preload.

Worthless post really, but just sharing my personal experience.

I did one full turn from zero lash and have always assumed I had .047 preload.

Worthless post really, but just sharing my personal experience.

#72

TECH Regular

iTrader: (34)

Join Date: Mar 2004

Location: Corpus Christi, TX

Posts: 423

Likes: 0

Received 0 Likes

on

0 Posts

It's funny how so many people believe in something without ever doing the actual leg work. Those old instructions that have been floating around for years have helped many people, and because stock type lifters have a bigger range of preload most of the times you can get away with having more preload than you thought and never even knowing it.

I have done many cam swaps and measure all the time. If you go by measuring pushrod length at zero lash with a pushrod checker, say it's 7.35. Then choose to have .075 preload so that you can order 7.425 pushrods. I keep different lengths on the shelf so it's easy for me to go grab the pushrods I need and put them in there. So I already know my preload, but I'll still count the turns as a way of checking my work. When it's .075 preload I always end up with just under 1 full turn, which supports Sound Engineers math. Give it a try and put your mind at ease, but if you're going to "only" count turns then I would shoot for 3/4 to 1 1/4 turn.

I have done many cam swaps and measure all the time. If you go by measuring pushrod length at zero lash with a pushrod checker, say it's 7.35. Then choose to have .075 preload so that you can order 7.425 pushrods. I keep different lengths on the shelf so it's easy for me to go grab the pushrods I need and put them in there. So I already know my preload, but I'll still count the turns as a way of checking my work. When it's .075 preload I always end up with just under 1 full turn, which supports Sound Engineers math. Give it a try and put your mind at ease, but if you're going to "only" count turns then I would shoot for 3/4 to 1 1/4 turn.

#73

With that said, you're right in most cases of people posting here for pushrod length help. Don't want to drop $20 for the pushrod tool or read up on how to use it correctly.

#74

I got news for all of you. ANY preload, as long as its not too much that it holds the valve open is enough. Your engine is constantly moving around expanding and contracting CONSTANTLY, the hydraulic lifters are the to compensate for this.

Now everything changes if someone changes the design and the engineer finds he needs .100 preload cold for example to work properly.

Hydraulic lifters have been around a very long time, don't overthink them. Anything from 1/8th to 2 turns is fine as long as the valve closes completely.

Now everything changes if someone changes the design and the engineer finds he needs .100 preload cold for example to work properly.

Hydraulic lifters have been around a very long time, don't overthink them. Anything from 1/8th to 2 turns is fine as long as the valve closes completely.

#75

8 Second Club

iTrader: (16)

I got news for all of you. ANY preload, as long as its not too much that it holds the valve open is enough. Your engine is constantly moving around expanding and contracting CONSTANTLY, the hydraulic lifters are the to compensate for this.

Now everything changes if someone changes the design and the engineer finds he needs .100 preload cold for example to work properly.

Hydraulic lifters have been around a very long time, don't overthink them. Anything from 1/8th to 2 turns is fine as long as the valve closes.

Now everything changes if someone changes the design and the engineer finds he needs .100 preload cold for example to work properly.

Hydraulic lifters have been around a very long time, don't overthink them. Anything from 1/8th to 2 turns is fine as long as the valve closes.

this is a partially wrong statement...

yes, as long as there is preload the valve will close and open...however...it may not be ideal,and will shorten your valve-train/cam life if it is too much or too little

there is a reason why aftermarket cam manufacturers recommend less preload than stock... the blank they use is a softer material than stock and can be damaged by too much preload....especially with more aggressive ramp rates that will "toss" the lifters off the lobes...too much preload means more pressure on the spring inside the lifter, which means its going to be slammed down harder..

also, 1/8 to 2 turns is not necessarily correct either..some styles of lifters have a shorter travel....

and 2 turns is close to .160 preload..which is the max of any version of LS lifter.

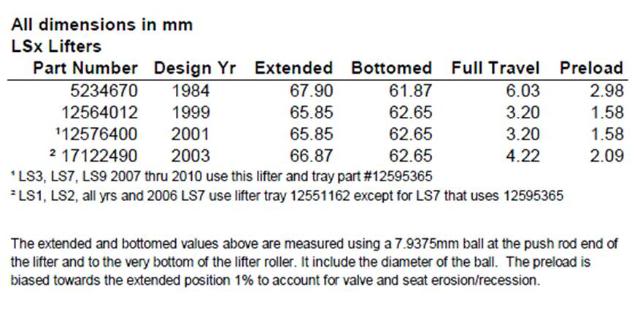

you can see in the picture below.. the largest range of lifter movement is .153

and the 2003 LS1 lifter is a .107 MAX Travel (1.37 turns)

and the smallest movement is only 1 Full turn MAX TRAVEL

also, aftermarket lifters can have a differnt amount of Max travel and also can have a different internal spring to make them more durable....

Lots of Variables, which is why you have to measure...and as you see..error on the low side is smarter than error on the high side...much smarter to be less preload

also, less preload gives your lifter more room to absorb the valvetrain.

#76

I should have been more specific that the info I stated is for stock only.

I did add however aftermarket engineers state what they want in their setup info.

I'M NOT experienced in the aftermarket EXCEPT my limited experience with comp cams. I followed their setup instructions and honestly it didn't sound or run any different than using the stock instructions.

I personally like to run 1/8th to 1/4 turn preload, engine runs a little smoother and better imo.

I did add however aftermarket engineers state what they want in their setup info.

I'M NOT experienced in the aftermarket EXCEPT my limited experience with comp cams. I followed their setup instructions and honestly it didn't sound or run any different than using the stock instructions.

I personally like to run 1/8th to 1/4 turn preload, engine runs a little smoother and better imo.

#77

8 Second Club

iTrader: (16)

I should have been more specific that the info I stated is for stock only.

I did add however aftermarket engineers state what they want in their setup info.

I'M NOT experienced in the aftermarket EXCEPT my limited experience with comp cams. I followed their setup instructions and honestly it didn't sound or run any different than using the stock instructions.

I did add however aftermarket engineers state what they want in their setup info.

I'M NOT experienced in the aftermarket EXCEPT my limited experience with comp cams. I followed their setup instructions and honestly it didn't sound or run any different than using the stock instructions.

I guess you didnt comprehend that part where I talked about wear and tear....

they use a softer than stock material for the blanks for aftermarket cams.....which means you need less preload or you get premature wear and tear on the cam lobes...

there is a small spring inside of the lifter...all springs increase pressure as they are compressed... more preload means more pressure..more pressure means more wear and tear on an aftermarket cam...

it is recommended .020~.060 preload from most cam grinders.

#80

I got news for anybody who read your advice above...there is such a thing as not enough preload. Especially on an aluminum block with aluminum heads.

Originally Posted by RockinWs6

...cam on base tighten rocker nut until THERE IS NO PLAY IN THE PR

Once you hit 0 lash COUNT the amount of turns it takes to tighten the nut.

Once you hit 0 lash COUNT the amount of turns it takes to tighten the nut.