Hand porting heads

#22

TECH Junkie

iTrader: (1)

Here is the link to the YT porting. Pt#1.

Shortly, I will be doing the same.

I had previously completed the bowls & chambers, in addition to smoothing the runners.

Even a mild port behind the valves will be effective.

If you smooth the combustion chambers, compression will be reduced, slightly.

Shortly, I will be doing the same.

I had previously completed the bowls & chambers, in addition to smoothing the runners.

Even a mild port behind the valves will be effective.

If you smooth the combustion chambers, compression will be reduced, slightly.

#25

13 Second Truck Club

iTrader: (17)

Join Date: Aug 2008

Location: baton rouge

Posts: 637

Likes: 0

Received 0 Likes

on

0 Posts

I lightly hand ported a set of 799s last month. Mostly worked on the bowls seat area rocker hump and valve guide areas. It was my first time porting and even with a stock vj the heads picked up 10 to 12 cfm on the intake and exhaust side.

#26

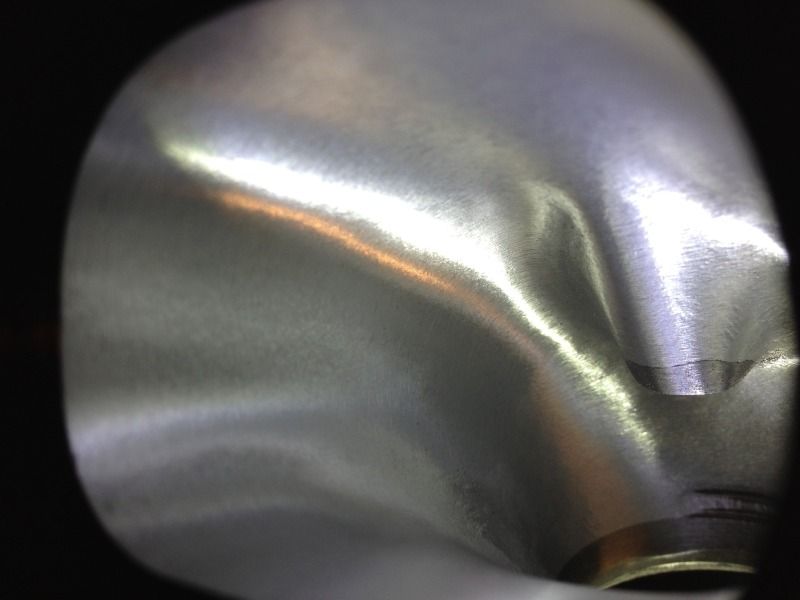

Damn dude! I can only hope to get mine looking half that good. lol It is actually going alright. I have them roughed out, just waiting on some finishing material for the exhaust side. Still roughing out the intakes with my carbide burrs before finishing it off with 80 grit.

#28

Well I had my heads flow tested. It went really well, surprisingly! I kept it safe and didn't get super aggressive with them. Turns out they are flowing:

.500 Intake 287cfm, exhaust 201cfm

.600 Intake 298cfm, exhaust 210cfm

I forgot to take the damn sheet home with me, so I don't have the exact numbers down to the decimal.

One thing the machinist suggested, was taking more out of the bottom of the intake floor. When I did this the numbers went way up above .500 lift. before that they were nose diving a lot when approaching .600. Hopefully I'll see some good rwhp numbers as a result. Thanks to all who helped!

.500 Intake 287cfm, exhaust 201cfm

.600 Intake 298cfm, exhaust 210cfm

I forgot to take the damn sheet home with me, so I don't have the exact numbers down to the decimal.

One thing the machinist suggested, was taking more out of the bottom of the intake floor. When I did this the numbers went way up above .500 lift. before that they were nose diving a lot when approaching .600. Hopefully I'll see some good rwhp numbers as a result. Thanks to all who helped!