Cam lobes new yzooom

#101

TECH Apprentice

Thread Starter

Yes we are working on that now. We are braking it down onto all engine sizes 4.8 to 7.0 from trucks to cars. We will have a few for each engine size. You canít make a cam that is good for a stock 4.8 and it be good for a 7.0. We see this advertised. The cams we will have as shelf cams might look small for some but we feel these will be the best for shelf in cams. Unfortunately most people want a cam that is to big for there combination. Itís better to have one a little small than a little big. Anyone that wants to maximizes cam spec you contact a tech. We will also have spec sheet to fill out we were the first company that I know of to start this process. I canít understand how someone can recommend a cam without knowing some of the engines specs. We will have a complete line of parts to go with a cam change. It all should be up soon. Thanks.

#104

10 Second Club

iTrader: (15)

Join Date: Nov 2001

Location: St. Michael, MN.

Posts: 4,519

Likes: 0

Received 0 Likes

on

0 Posts

All lobes are designed for a loft profile letís say I make a Hyd Roller lobe for your SBC I want 230 @.05 with 350 lobe lift and we are using a .842 lifter with a .750 wheel. In the old days and still now when we made a lobe like this it was made on a mill by hand it was call a model lobe now after making it you have to make a master for the grinding machine and it worked fine for a designed base circle size. This lobe for a SBC would be made on a 1.158 base circle. If we ground the new cam with this base circle it would come out with the correct specs. If we used the same master for a LS1 cam the base circle would be 1.455 now if you measure the dur @.05 with this big base circle it will come out to be about 6 degrees larger 236@.05 because of the geometry. Now all of our lobe are made on the computer and feed into the CNC grinding machine. So this lobe file is just a lift data file before we grind the cam we need to tell the grinding program or machine what we want to end up with. For a lobe to come out what we want like a 230/350 we program 1 Base circle finish size 2 roller wheel diameter and grinding wheel size. If we grind a cam lobe that is 230/350 for a roller lifter with a .700 wheel and you put in lifters with a wheel size of .750 the duration will be a little bigger. Going from .700 to .750 is not much difference but going from .700 to .850 is a fair amount. Now for the week pushrods & spring pressers. No one can made a valve train to stiff the larger the cam core the stiffer the pushrods the most sturdy the rocker stands the lighter the valve retainers the better the system will work and live. On spring presser you only need as much as it takes to not have valve float for your RPM range. Most drag racers over spring because they think more is better. Rockers can fool you. A good expensive set of rockers may work as well as stock or another set that are not expensive. On components like springs and valve spring Frequency can get complicated because a spring can be good for this engine and not for this one so if they work use them if they done try some others there is a lot more to this but I will leave it for now.

That mentality is also common in the LS world as well. Not too many focus on lightening the key parts of the valve train; but rather just put mega dual springs with crazy pressures even on cams with .600 lift or less and call it a day. Heck, I wonder how many actually measure for pushrod length or will degree a new cam?

Speaking of valve train; what are your thoughts on valve springs, ti retainers, etc and the impact they have on engine performance and durability?

#105

TECH Apprentice

Thread Starter

Thanks for the question. We have done testing and make cams for the VVT engines they work fine the only reason I think GM and other cam mfg have gone to VVT and DOD or AFM is to get a better gas mileage so they can clam 25 instead of 22 or whatever they get. You can optimize your mileage with this technology. If I had a car/ truck and was going to put an aftermarket in it I would take off the DOD/AFM to me that looks like a can of worms. I may even take off the VVT depending on what I plan to do. I do not plan on making any cams for the DOD/AFM we will make the VVT I think making a after market performance for the DOD/AFM is asking for trouble. I do think the VVT is here to stay the DOD/AFM I donít know. I know they are having some problems with that system. They are having to change some of the cams in stock cars what happens is the DOD/AFM comes on and the spring that holds the roller wheel on the cam does not do it job the lifter is off the base circle when the lobe comes around the lobe crashes into the lifter itís starts dining up the cam then you have to change cam and DOD/AFM lifters. So I donít know how long that will last but they have been around for awhile.

#106

TECH Apprentice

Thread Starter

OK most of the combination I see on this site and the customers we deal with are just trying to have a nice street car that should not be a problem. Itís easy to out trick your self or over do it. Like I said above the stiffer you make your valve train the better but more is not better when it comes to spring presser. Ti retainers are good do you need them for a street engine probably not. Is a 5/16 .08 wall push rod as good as a 5/16 .120 wall? .08 wall could be just as good as .120 wall on some combination but on another combination with higher lifts and spring presses the .120 is better. Will the 5/16 work yes for some systems. Some of the problem I see is some companyís try to do to much with a given lobe design for a given combination witch will wreck the valve train just to get 2 more HP. Thatís OK if you are DRAG race only but not for a street car. It looks like some are over springing to keep the undesirably lobe profiles in check. You only need as much presser as it takes to control your system more just beats up your system. Do you know how much spring presser a NASCAR engine has on the seat? 120lbs why because thatís all it take to control the system at over 9000 rpms. Does this help?

First, thanks for coming on here and sharing your knowledge and experience. It reminds me of the old days here when the LS1 was still in it's infancy and there was a lot of true tech.

That mentality is also common in the LS world as well. Not too many focus on lightening the key parts of the valve train; but rather just put mega dual springs with crazy pressures even on cams with .600 lift or less and call it a day. Heck, I wonder how many actually measure for pushrod length or will degree a new cam?

Speaking of valve train; what are your thoughts on valve springs, ti retainers, etc and the impact they have on engine performance and durability?

That mentality is also common in the LS world as well. Not too many focus on lightening the key parts of the valve train; but rather just put mega dual springs with crazy pressures even on cams with .600 lift or less and call it a day. Heck, I wonder how many actually measure for pushrod length or will degree a new cam?

Speaking of valve train; what are your thoughts on valve springs, ti retainers, etc and the impact they have on engine performance and durability?

#107

TECH Junkie

iTrader: (1)

Yes we are working on that now. We are braking it down onto all engine sizes 4.8 to 7.0 from trucks to cars. We will have a few for each engine size. You canít make a cam that is good for a stock 4.8 and it be good for a 7.0. We see this advertised. The cams we will have as shelf cams might look small for some but we feel these will be the best for shelf in cams. Unfortunately most people want a cam that is to big for there combination. Itís better to have one a little small than a little big. Anyone that wants to maximizes cam spec you contact a tech. We will also have spec sheet to fill out we were the first company that I know of to start this process. I canít understand how someone can recommend a cam without knowing some of the engines specs. We will have a complete line of parts to go with a cam change. It all should be up soon. Thanks.

#108

Launching!

Thanks for the question. We have done testing and make cams for the VVT engines they work fine the only reason I think GM and other cam mfg have gone to VVT and DOD or AFM is to get a better gas mileage so they can clam 25 instead of 22 or whatever they get. You can optimize your mileage with this technology. If I had a car/ truck and was going to put an aftermarket in it I would take off the DOD/AFM to me that looks like a can of worms. I may even take off the VVT depending on what I plan to do. I do not plan on making any cams for the DOD/AFM we will make the VVT I think making a after market performance for the DOD/AFM is asking for trouble. I do think the VVT is here to stay the DOD/AFM I donít know. I know they are having some problems with that system. They are having to change some of the cams in stock cars what happens is the DOD/AFM comes on and the spring that holds the roller wheel on the cam does not do it job the lifter is off the base circle when the lobe comes around the lobe crashes into the lifter itís starts dining up the cam then you have to change cam and DOD/AFM lifters. So I donít know how long that will last but they have been around for awhile.

#109

TECH Resident

iTrader: (34)

Join Date: Jan 2008

Location: Houston Tx

Posts: 899

Likes: 0

Received 0 Likes

on

0 Posts

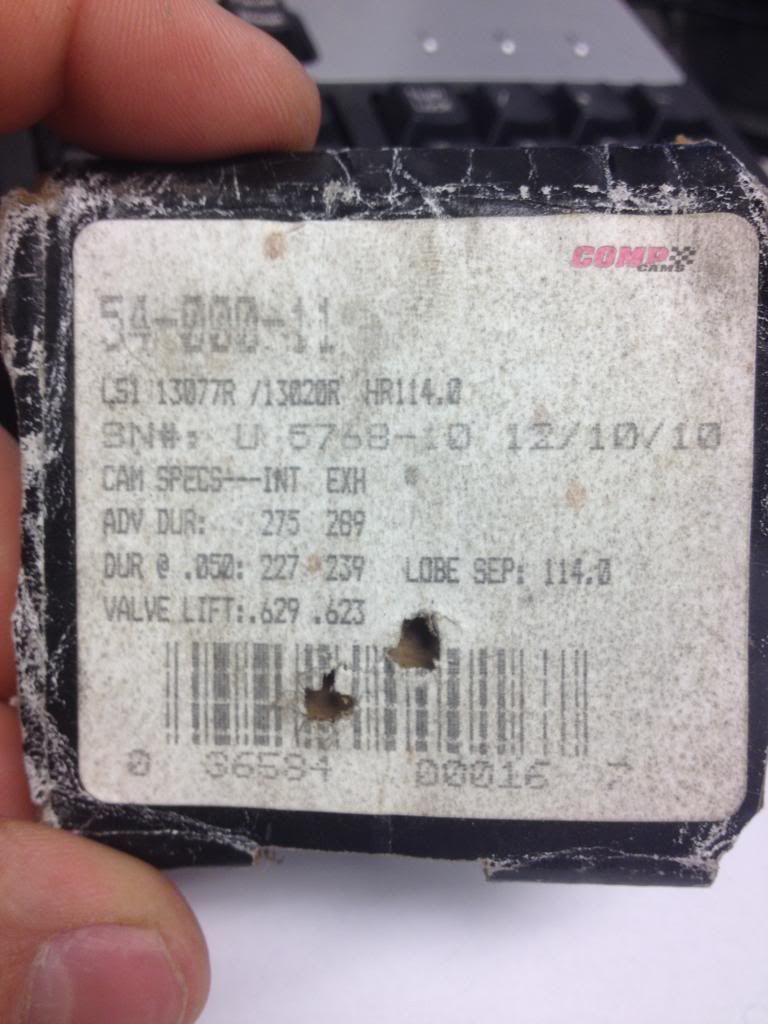

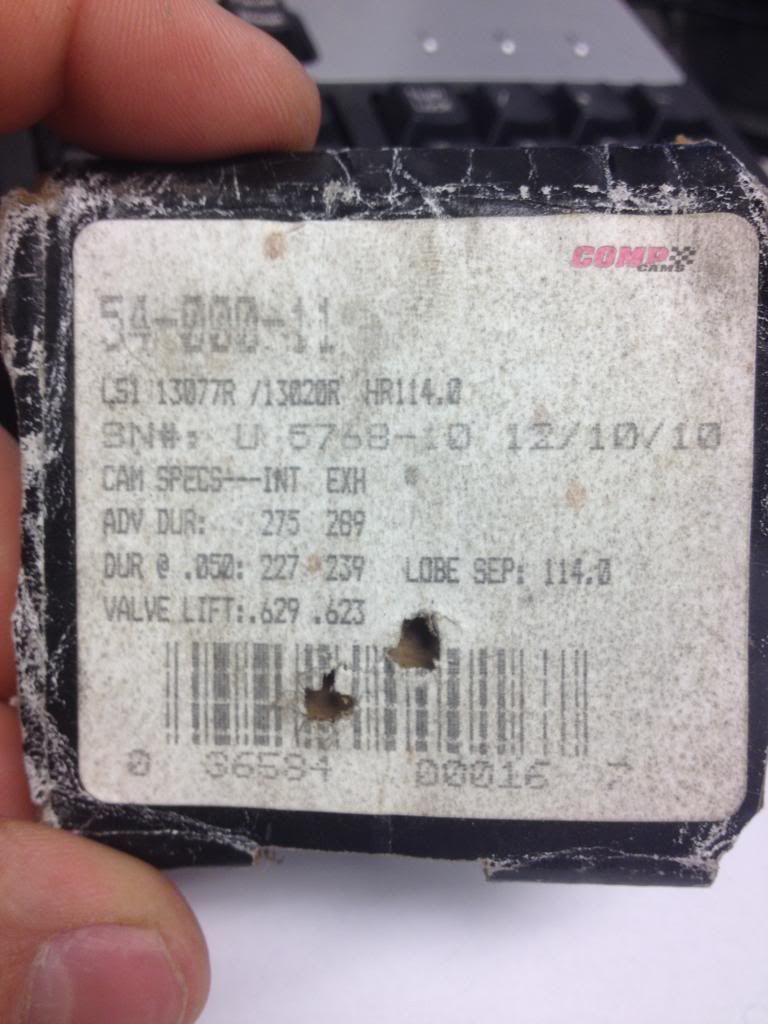

Ill post this in here and maybe I can get a little help. Im planning on running this cam with a set of prc ls3 heads but the heads have the heavier stainless intake valves not the hollow stem. Im afraid the cam will have too aggressive of lobes with the heavier valves but Im not even sure what lobes the cam has. I posted another thread with the cam info from the box but didn't get any info on it. Will this cam have too aggressive of lobes for the heavier stainless intake valves? I will be runniing the larger 3/8s diameter Trend pushrod as well as the BTR dual valve springs.