LXL lobe valve spring reccomendations for endurance.

#21

Hi folks I need help choosing valve springs. The cam will be a Comp LXL lobed unit going into a stock 2002 LS1 shortblock. I will be using new LS7 lifters, LS2 trays, Trend 3/8" pushrods, Comp trunions, and stock 2.00" 1.55" valves in professionally ported 241 heads. The engine will at times be subjected to 6000+rpm for extended periods.

I would prefer to use .625" max lift beehive springs such as PSI 1511ML (130lbs@1.800") or PAC 1219X (145lbs@1.800") but I'm wondering if either will be enough.

I know many people recommend the Brian Tooley .660" Platinum double spring kit (155lbs@1.78") but I feel it may be a bit overkill for me.

The LXL lobed cam I have chosen has a relatively gentle ramp rate of 52 and should make all of its power below 6700rpm. With 7000 being the most the engine will ever see.

LXL Intake lobe #13159.. 230@.05" .609" with 1.7

LXL Exhaust lobe # 13175.. 236@.05" .614 with 1.7

112 lsa with 108 icl.

Thanks in advance.

I would prefer to use .625" max lift beehive springs such as PSI 1511ML (130lbs@1.800") or PAC 1219X (145lbs@1.800") but I'm wondering if either will be enough.

I know many people recommend the Brian Tooley .660" Platinum double spring kit (155lbs@1.78") but I feel it may be a bit overkill for me.

The LXL lobed cam I have chosen has a relatively gentle ramp rate of 52 and should make all of its power below 6700rpm. With 7000 being the most the engine will ever see.

LXL Intake lobe #13159.. 230@.05" .609" with 1.7

LXL Exhaust lobe # 13175.. 236@.05" .614 with 1.7

112 lsa with 108 icl.

Thanks in advance.

Being a solid or a low lash solid does not dictate seat timing. A hydrualic roller, low lash solid or a standard lash solid roller can all be made with the exact same seat timing vs .085" valve timing. The seat timing is simply dictated by the lobe designers preference. Cam motion uses slightly longer seat timing on both their hydraulic and low lash solid roller lobes because it makes for quiet valve train. It is not much more seat timing, just a couple degrees, but those few degrees combined with smooth acceleration rates have a nice positive effect of quiet valve train.

#22

What's the hot lash on a LLSR? What does the lash become when a aluminum block is cold? What does this do to seat timing?

#23

LLSR camshafts are designed mainly with .008-.010" hot lash, so if any duration was added from .000-.006" lobe lift(commonly referred to as seat to seat duration), that duration would never be seen at the valve and thus not seen by the engine.

When the engine is cold and there is .000-.002 lash at the valve I possibly could see the idle quality deteriorating, but that is going to be brief due to the clearance at the valve growing as the engine warms up.

A lot of my LLSR customers report great driving manners and very quiet valve trains.

When the engine is cold and there is .000-.002 lash at the valve I possibly could see the idle quality deteriorating, but that is going to be brief due to the clearance at the valve growing as the engine warms up.

A lot of my LLSR customers report great driving manners and very quiet valve trains.

#24

I will be doing a very detailed write up in the near future. I am in process of switching a hydraulic 230/238 113+3 cam for a LLSR 239/247 113+3 (equates to 234/242 hydraulic).

The kicker is I'm doing it on stock rocker arms by a combination of precision ground valve stem height, pushrod length, and rocker pedestal shims. Shooting for .010" hot lash and .000" cold (possibly even a thousandth or 2 preload due to aluminum block shrink/expansion). I just had my BTR springs tested and they are all still perfect so they will be used on this setup.

This means there will be no changes to the engine or the car other than: cam, pushrods, BTR rocker trunions, and solid lifters. I didn't even run another mill pass on the heads.

I am not a professional tuner but I tuned the previous setup and will be tuning the new one. So I can easily comment on tuning difficulties. Going from 8* overlap to 12* I expect a little right off the bat. Idle tuning is definitely difficult for me so we will see. As far as WOT tuning I always tune the same way: 27.5* and dial in 12.8afr with a rich dip around peak torque.

The car is not my daily driver, but easily could be. I just drove it from Fayetteville, AR to Biloxi, MS and back for Cruisin' the Coast without a hitch. Once it's driving I will be putting a lot of miles on it to gather impressions, fuel mileage, etc.

Speedtigger had excellent results from his setup, but being carbed and using a single plane it's a bit different ballgame. I'm hoping to better demonstrate pros/cons with EFI and long runner composite style intake.

The kicker is I'm doing it on stock rocker arms by a combination of precision ground valve stem height, pushrod length, and rocker pedestal shims. Shooting for .010" hot lash and .000" cold (possibly even a thousandth or 2 preload due to aluminum block shrink/expansion). I just had my BTR springs tested and they are all still perfect so they will be used on this setup.

This means there will be no changes to the engine or the car other than: cam, pushrods, BTR rocker trunions, and solid lifters. I didn't even run another mill pass on the heads.

I am not a professional tuner but I tuned the previous setup and will be tuning the new one. So I can easily comment on tuning difficulties. Going from 8* overlap to 12* I expect a little right off the bat. Idle tuning is definitely difficult for me so we will see. As far as WOT tuning I always tune the same way: 27.5* and dial in 12.8afr with a rich dip around peak torque.

The car is not my daily driver, but easily could be. I just drove it from Fayetteville, AR to Biloxi, MS and back for Cruisin' the Coast without a hitch. Once it's driving I will be putting a lot of miles on it to gather impressions, fuel mileage, etc.

Speedtigger had excellent results from his setup, but being carbed and using a single plane it's a bit different ballgame. I'm hoping to better demonstrate pros/cons with EFI and long runner composite style intake.

Last edited by thunderstruck507; 11-20-2015 at 09:05 AM.

#25

That will be a fun project. I hope you can pull it off. There has been a few members who have done the LLR with EFI with great results:

1sick_eg, 1989GTA and high impact are 3 that come to mind. There are more, but those are the ones I can name.

1sick_eg, 1989GTA and high impact are 3 that come to mind. There are more, but those are the ones I can name.

#26

Thanks for the replies everyone. I was unaware of lofting the valves. Due to seeing several people on here use big xer/lsl lobes with beehives I assumed it was a non issue. I will be using a dual spring setup like BTR.

#28

I will be doing a very detailed write up in the near future. I am in process of switching a hydraulic 230/238 113+3 cam for a LLSR 239/247 113+3 (equates to 234/242 hydraulic).

The kicker is I'm doing it on stock rocker arms by a combination of precision ground valve stem height, pushrod length, and rocker pedestal shims. Shooting for .010" hot lash and .000" cold (possibly even a thousandth or 2 preload due to aluminum block shrink/expansion)

The kicker is I'm doing it on stock rocker arms by a combination of precision ground valve stem height, pushrod length, and rocker pedestal shims. Shooting for .010" hot lash and .000" cold (possibly even a thousandth or 2 preload due to aluminum block shrink/expansion)

#29

#30

Figure in the labor of machining/surface grinding time, and it should exceed the cost of a proven shaft mount.

#31

The project idea was proposed to me by Kip.

I have a friend who has a small machine shop including a valve grinder so cost is minimal to me. Being the race tracks are closed I have plenty of free time in the evenings and on weekends and it's something to occupy me.

Plus I just like experimentation. Who knows it could turn out to be straightforward enough for others to duplicate.

The good rockers are around $1100 plus you then need valve covers or spacers for another $150-300. I can't see any machine shop wanting more than $200-300 to get the valves the same height down to .002" or so, it wasn't that difficult.

Just exploring options off the beaten path...if it doesn't work the way we want it to I can always pick up the rockers and be done. Definitely didn't hurt anything by setting the valves to a closer tolerance.

I'll be starting my thread probably Monday so look for it in this section then for further in depth discussion.

I have a friend who has a small machine shop including a valve grinder so cost is minimal to me. Being the race tracks are closed I have plenty of free time in the evenings and on weekends and it's something to occupy me.

Plus I just like experimentation. Who knows it could turn out to be straightforward enough for others to duplicate.

The good rockers are around $1100 plus you then need valve covers or spacers for another $150-300. I can't see any machine shop wanting more than $200-300 to get the valves the same height down to .002" or so, it wasn't that difficult.

Just exploring options off the beaten path...if it doesn't work the way we want it to I can always pick up the rockers and be done. Definitely didn't hurt anything by setting the valves to a closer tolerance.

I'll be starting my thread probably Monday so look for it in this section then for further in depth discussion.

#33

I found a thread on YellowBullet where a guy was using a LLSR in a LS7 with stock rockers and said he did so by grinding the pushrods to set lash with a "white scotchbrite wheel". He claimed on his setup it was worth as much as 70hp under the curve and 20-25hp up top but was not descriptive of what that setup involved and what changes he made during the cam swap.

#34

Example: I had about 8 that ranged from 7.705-7.718, so I ordered 8 at 7.711, using the natural variability of the rods to match up with the valves. I don't have the exact numbers in front of me, but that is the gist of it

Fine for short travel lifters, but I don't think I would set solid roller lash that way.

#35

Grinding spiral bevels is a simply amazing process that is very difficult to wrap your mind around. All the while maintaining tolerances of .0001" - .0004".

#37

Many of my builds feature short travel hydraulic lifters so its a necessity to do so.

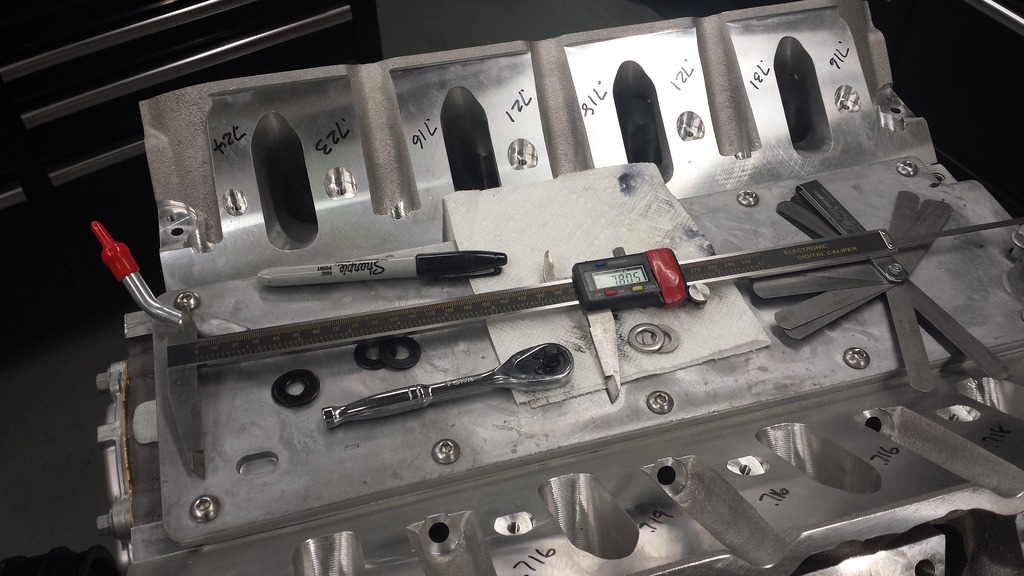

If you have the correct threaded checking rods and use a dial caliper to measure what you need with the adjustable pushrod set to the correct length (see pic below), I normally see the custom length Mantons come in plus or minus .003 from what I order. BTW add a "7" to the three digits you see on the head and that would be the length pushrod I need to get zero lash....I then add in the preload I'm shooting for when I order the actual pushrods).

With a short travel HR lifter, that's well within the window if your setting the pre-load in the middle of the lifters travel.

Even with the solid roller project Thunderstruck is embarking on, its workable but will likely require ordering more pushrods when some don't come in close enough....also it will require really accurate measuring double and triple checking his work if there are hopes of pulling it off without ordering a painful amount of addition pushrods. Its a PITA no doubt but having set many of these short travels exactly where I want them (within a few thou typically) I know I could pull it off but it would be more time consuming than a short travel HR set-up no doubt.

FWIW, I have an LXL custom cam I designed in my CTSV project and have 15000 trouble free miles so far with perfect valve control and a quiet valvetrain even with headers (I did wrap them with high temp DEI exhaust wrap to reduce under hood temps and reduce the ringing/bell effect of the primary tubes and quiet things a little further). Im running PAC 1204 springs set up a little tighter than stock spec for a tad more seat pressure to help things under boost (the boost pressure trying to blow the intake valve open reducing seat load).

For my clients/customers wanting a quieter valvetrain and more longevity I usually run the LXL lobes....I really like them for those types of applications. Typically I run the LSL lobes however as they are smoother than XER's which everyone ran for years (waaay smoother than LSK lobes) and they make more power than the XER lobes. Its pretty much my go to lobe for most of my HR stuff but some cams I will mix and go LSL on the intake and the softer LXL on the exhaust.

OP....consider running the PAC 1204's or 1205 springs.....you would be hard pressed to find a better quality spring IMO, and the PAC stuff is all made at the US plant in Michigan (if you care about that kind of thing). I'm friendly with most of the guys there and they are all gear heads that take pride in what they are manufacturing.

Lots of good stuff in this thread....I had composed a response days ago and never sent it due to my laptop dying....saw it still going on and thought I would chime in quickly

Cheers,

Tony

OP.....I stock alot of PAC springs/hardware....let me know if I can help

__________________

www.mamomotorsports.com

Tony@MamoMotorsports.com

Anything worth doing is worth doing well. Build it right the first time....its alot cheaper than building it twice!!

www.mamomotorsports.com

Tony@MamoMotorsports.com

Anything worth doing is worth doing well. Build it right the first time....its alot cheaper than building it twice!!

#38

So if LXL lobes is gentle on parts and and make great power.... what the difference between a HUC lobe camshaft? I know I've read that HUC lobes are easy on the valve train and last awhile and now you guys saying the same thing about the LXL lobes.

#39

What has good stability in a stock LS valve train will likely be too aggressive in a big block chevy where the valve train is heavier. This is also true in the LS world. What is stable in an LS6 with hollow stem valves may not be stable in an L92 with larger heavier intake valves.

Usage is also a primary consideration in determining what will be "stable" or "easy on valvetrain". RPM and usage is key. You will make a different lobe choice for road racing or a marine application that spends longer periods of time as sustained high RPM than you would for a drag car where higher RPM are only held for a brief time. You might be able to take one punch from Mike Tyson, but you don't want to go 3 rounds in the ring with him. Same thing with your valve train.

The alphabet soup of Comp lobes has been discussed to great length on this site. There are nearly a decades worth of threads talking about each new lobe and how it is the next great thing. I will save you a bunch of time and reading. Here is the readers digest version:

1.)Cams came out for the new LS engine using lobes that were designed for the older smaller diameter cam cores with smaller cam journals and smaller base circles. They were better than stock and LS engines went faster.

2.) Cam grinders made new lobes to take advantage of the larger journal cam cores and the LS engines went faster.

3.) People noticed that new lobes made the LS1 faster and and they developed an appetite for the latest lobe. So, the cam industry responded by making even more aggressive lobes and the marketing departments capitalized on this momentum. Customers started complaining about valve train noise while cam makers sold more LS cams.

4.) Cam makers made even more aggressive lobes and performance shops lined up to have their cams made out off the new next big thing. Valve train noise complaints increase while LS engines started breaking valve springs and having problems.

5.) Smart racers started truly assessing performance and found many advantages to using smoother lobes including better valve train stability, quieter valve train and more high RPM power.

6.) Some performance shops start going back to smoother lobes and quietly phasing out their old radical lobes.

Now people are putting the radical lobe craze behind them. They look back at that phase and say: :"what the hell was I thinking" just like they did with the the mullet hair cut they wore in high school.

#40

I think the gist of it was that the LSL/LXL lobes still have more quickness over the nose than the HUC/Xtreme Marine lobes. They're just designed to be soft at the opening and closing ramps.