lq9 build possibilities

#21

Teching In

Thread Starter

AHHH SWEET! but yea i just got out like two weeks ago! so idk if they'll give it to me now aha, but ahhh thank you I'm gonna have to play with that cr calc!

#22

Teching In

Thread Starter

side note, going with a stroker forged bottom end(pistons .030 over, rods and crank) for $1800, using the stock 317 heads with stock springs and rockers and then going with a lunati cam, and possibly the speed master 96mm intake manifold

#24

i dont know how you guys are finding such good deals on 6.0 blocks, the cheapest one ive found in my area is 1500$ for a 180k pullout, just heads and block.

There was another 6.0 for sale but it had some serious rust issues in the bores being stored outside.

There was another 6.0 for sale but it had some serious rust issues in the bores being stored outside.

#25

TECH Enthusiast

You need to shop around... I picked mine up for 900 Canadian lol.

#26

I paid $350 for a pullout with a bottom end knock. So it was really sort of a gamble because it could have been a totally trashed block. It was complete, but looked like it came out of a mudding truck, and then sat in a mud puddle for a month after it was pulled. That kind of motor isn't going to sell for much. Fortunately my shop was able to clean up the main that had spun so I saved money over buying a new short block.

#27

I paid $350 for a pullout with a bottom end knock. So it was really sort of a gamble because it could have been a totally trashed block. It was complete, but looked like it came out of a mudding truck, and then sat in a mud puddle for a month after it was pulled. That kind of motor isn't going to sell for much. Fortunately my shop was able to clean up the main that had spun so I saved money over buying a new short block.

#28

Teching In

Thread Starter

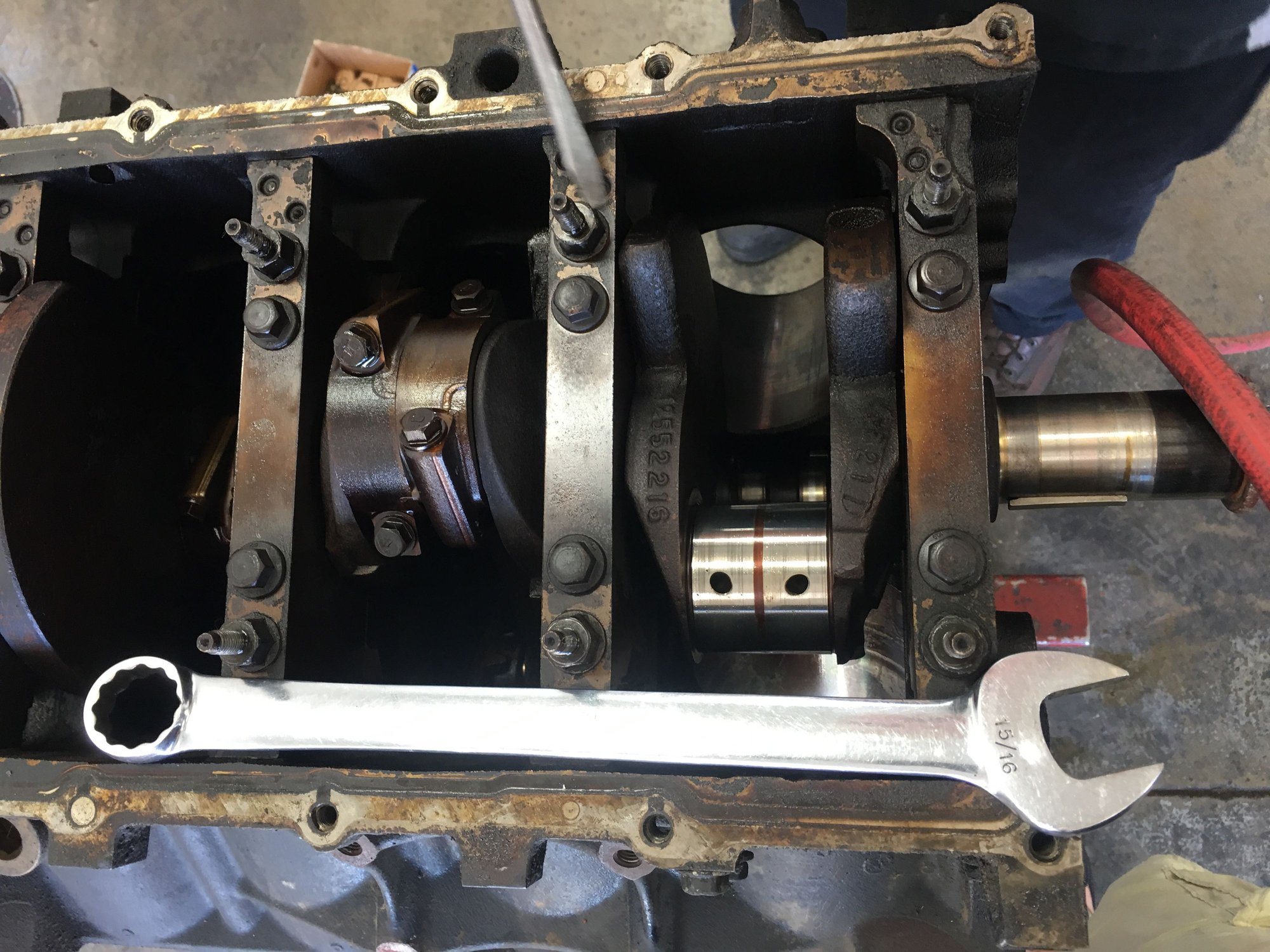

after we picked the block up, pulled off a head cause it wouldn't turn over even with a huge breaker bar

this piston was the issue, it was rusted to the cylinder wall, this is why we went with the bore, took a lot of wd40, and a scribe to pick out the crap, afterwards it turned over no problem.

just showing the difference in the cylinder walls

pulling the pistons out

ready for machine shop, getting .030 bore, to match pistons, and cam bearings

the new pistons, -5cc

assembling the forged rods, and pistons

went with this double, instead of the single, some people say it loses a bit of horsepower, and lots of people say you don't need it, cause a lot of top race cars use a single, but eh I'm sure this will last longer and won't stretch as much as a single over a lifetime

#29

Teching In

Thread Starter

I'm a bit different and went with Option 3 for my LQ4 build, which is currently underway. Went this route because it's easier for me to change out top end parts like H/I later on as budget permits. Block, reciprocating assembly, and heads are at the machine shop waiting their turn. Build as of now:

-complete LQ4 from '07 Silverado Classic ($350)

-Bored .030

-K1 crank (4" stroke)

-K1 rods w/ARP 2000 bolts (6.125")

-Wiseco pistons (K394X3)

-Rotating assembly getting balanced by the engine builder (i got the parts from two different vendors)

-Stock 317 heads getting cleaned up, valve job and decked slightly

-Stock rockers with Straub bushing trunnion upgrade

-New seals, seats, etc

-New dual springs

-Cam Motion custom grind cam

-LS6 intake (truck intake too tall for my swap as well)

I did some sale shopping and got my crank/rods/pistons for around $2000 total. I kept the compression low for ease of pump gas. Should be around 9.4:1 when complete, so I'm not sure what the power output will be, but its a 408 going in a light car so it'll move out nicely.

-complete LQ4 from '07 Silverado Classic ($350)

-Bored .030

-K1 crank (4" stroke)

-K1 rods w/ARP 2000 bolts (6.125")

-Wiseco pistons (K394X3)

-Rotating assembly getting balanced by the engine builder (i got the parts from two different vendors)

-Stock 317 heads getting cleaned up, valve job and decked slightly

-Stock rockers with Straub bushing trunnion upgrade

-New seals, seats, etc

-New dual springs

-Cam Motion custom grind cam

-LS6 intake (truck intake too tall for my swap as well)

I did some sale shopping and got my crank/rods/pistons for around $2000 total. I kept the compression low for ease of pump gas. Should be around 9.4:1 when complete, so I'm not sure what the power output will be, but its a 408 going in a light car so it'll move out nicely.

so going with the same setup basically, except pistons we have seem to be -5cc, although, they look the same as those weisco ones you have, we decided to go with the 317 heads, since the compression is going to be at about 11.1:1, with a 853 head it would be at about 11.5:1 to 11.7:1

what length pushrods are you going to use? i was planning on getting the pushrod length checker,

also how much are you getting your heads milled by?

Last edited by Jon USMC 702; 11-03-2016 at 01:16 PM.

#30

On The Tree

iTrader: (1)

I picked up my LQ9 from a JY here in MN for $1500 ($1K plus $500 core charge) that had been sitting in the yard for 4 years. Mileage is 160k-ish. Still spins though it's rusty as all get-out.

Back to the original thread, this looks like a fun build, one that is very similar to what I had planned. I look forward to seeing what comes of it!

Back to the original thread, this looks like a fun build, one that is very similar to what I had planned. I look forward to seeing what comes of it!

#31

so going with the same setup basically, except pistons we have seem to be -5cc, although, they look the same as those weisco ones you have, we decided to go with the 317 heads, since the compression is going to be at about 11.1:1, with a 853 head it would be at about 11.5:1 to 11.7:1

what length pushrods are you going to use? i was planning on getting the pushrod length checker,

also how much are you getting your heads milled by?

what length pushrods are you going to use? i was planning on getting the pushrod length checker,

also how much are you getting your heads milled by?

#33

Teching In

Thread Starter

too just an update the rings scratched the 2 different cylinder walls, too deep to hone, soo its back to the machine shop, I'm going to have them install the pistons and crank, just so if the rings scratch up the walls theyll fix it, they said because of thanksgiving week being so short it'll take 2-3 weeks =(

#36

Teching In

Thread Starter

ooookkkkk! been a long while since i posted, been distracted, ran into setbacks buttttttt its finally coming to a close! ill be sure to keep posting until the end! unlike some people who start awesome posts but then don't show the end result!

#40

Teching In

Thread Starter

so the machine shop gave us this nic present of a nice ding in the front cam bearings, i took it back to the machine shop and they replaced it, one of the workers there said its cause they hot tanked the block after putting the cam bearing in and the way the block was sitting something holding it in place snagged it

if you zoom in you can see a good looking valve vs a very pitted valve, went with a new set of valves

piston rings on

ugly poopy valve

another ugly poopy valve

some of these valves cleaned up ok, but a couple exhaust valves were just pitted to badly for comfort

machine shop replaced the came bearing