Ls2 408 motor build- compression

#1

Teching In

Thread Starter

iTrader: (2)

Join Date: Sep 2016

Posts: 23

Likes: 0

Received 0 Likes

on

0 Posts

What is the max compression you would run this motor on with 93 pump gas? e85? Would you lessen the quench area to .040?

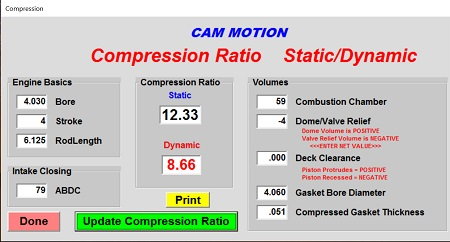

Cylinder Head Volume (cc) 59 Cylinder Head Vol (cubic in.) 3.599

Piston Head Volume (cc) 4 Piston Head Vol (cubic in.) 0.244

Gasket Thickness (in.) .051 Swept Volume (cubic in.) 51.086

Gasket Bore (in.) 4.060 T.D.C. Volume (cubic in.) 4.503

Cylinder Bore Diameter (in.) 4.0325 Gasket Volume (cubic in.) 0.660

Deck Clearance (in.)

Note: Neg. number above deck, Pos. number below deck 0 Deck Volume (cubic in.) 0.000

Stroke (in.) 4 Static Compression Ratio 12.345

OPTIONAL DATA

Rod Length (in.) 6.125 Adjusted Stroke (in.) 3.092

Intake Closing Point (degrees) ABDC @ 0.050 lift plus 15 degrees 66 Dynamic Effective Compression Ratio 9.770

Cylinder Head Volume (cc) 59 Cylinder Head Vol (cubic in.) 3.599

Piston Head Volume (cc) 4 Piston Head Vol (cubic in.) 0.244

Gasket Thickness (in.) .051 Swept Volume (cubic in.) 51.086

Gasket Bore (in.) 4.060 T.D.C. Volume (cubic in.) 4.503

Cylinder Bore Diameter (in.) 4.0325 Gasket Volume (cubic in.) 0.660

Deck Clearance (in.)

Note: Neg. number above deck, Pos. number below deck 0 Deck Volume (cubic in.) 0.000

Stroke (in.) 4 Static Compression Ratio 12.345

OPTIONAL DATA

Rod Length (in.) 6.125 Adjusted Stroke (in.) 3.092

Intake Closing Point (degrees) ABDC @ 0.050 lift plus 15 degrees 66 Dynamic Effective Compression Ratio 9.770

#4

Teching In

Thread Starter

iTrader: (2)

Join Date: Sep 2016

Posts: 23

Likes: 0

Received 0 Likes

on

0 Posts

The problem is that the cam is a fairly large cam. I am worried by running down to .035 quench that I will have ptv problems. I'm running a .625 dual pac spring am the motor won't see past 6800rpm, but still a tad worried.

#5

Teching In

Thread Starter

iTrader: (2)

Join Date: Sep 2016

Posts: 23

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by .boB

That's a lot of compression for pump gas. I think you're asking for trouble there.

Yes, certainly keep the quench as close to 0.040" as possible. Some people here advocate closer to 0.035".

Yes, certainly keep the quench as close to 0.040" as possible. Some people here advocate closer to 0.035".

Trending Topics

#8

Old School Heavy

iTrader: (16)

Dynamic compression is an imperfect predictor. The reason is, that it does not take volumetric efficiency into consideration. So, in the end it is just a mathematical expression of the camshaft's IVC and static compression. With volumetric efficiency not included, it cannot predict cylinder pressures at various RPMs.

With that said, a later IVC will still help.

With that said, a later IVC will still help.

#9

TECH Resident

iTrader: (1)

Still kinda pushing it with pump e-85. The problem is the 15% gasoline. It's the worst and lowest octane fuel available. Kinda the dregs from the bottom of the barrel. It can cause detonation under the ring lands, and your pistons end up looking like this.

You can get away with high static and dynamic compression with E-85; it does have a higher octane and it will certainly run cooler. Just don't go too crazy. And make sure your cooling system is up to the task, too. If it gets too hot - like above 200* or so - it will detonate badly.

You can get racing e-85, with 15% high octane racing fuel. But it's not cheap and it's not easy to come by.

As said above, a later IVC point will lower dynamic compression. But it will increase cylinder pressures at higher rpm's.

You can get away with high static and dynamic compression with E-85; it does have a higher octane and it will certainly run cooler. Just don't go too crazy. And make sure your cooling system is up to the task, too. If it gets too hot - like above 200* or so - it will detonate badly.

You can get racing e-85, with 15% high octane racing fuel. But it's not cheap and it's not easy to come by.

As said above, a later IVC point will lower dynamic compression. But it will increase cylinder pressures at higher rpm's.