New Melling 10295 and 10psi

#21

TECH Enthusiast

iTrader: (1)

The o-ring itself on the stock and SCC Billet piece are both very snug in the bore, the actual barbell is what I was referring to, it had a lot of play on the end with no o-ring. GM had no way to manufacture the block this way with the direction of the oil passages, so they designed the barbell. If they could of, it would of been a just a part of the block with oil passages.

My opinion is GM did not manufacture these to allow oil by-pass under normal conditions, there is a by-pass located in the oil filter for those reasons. I am pretty sure they manufactured these with loser tolerances to prevent them from getting stuck in the bore and can make them easier to be removed. The SCC has a threaded hole that allows you to use a bolt, can't remember the size, to thread into the barbell to pull it out. If the stock piece was very snug/tight in the bore, it would not be easy to remove and would make it more difficult on GM techs or any tech to service them. There is no actual way to grab them and pull them out, I had to drill a tiny hole in mine and use a hooked pick to pull it out.

My opinion is GM did not manufacture these to allow oil by-pass under normal conditions, there is a by-pass located in the oil filter for those reasons. I am pretty sure they manufactured these with loser tolerances to prevent them from getting stuck in the bore and can make them easier to be removed. The SCC has a threaded hole that allows you to use a bolt, can't remember the size, to thread into the barbell to pull it out. If the stock piece was very snug/tight in the bore, it would not be easy to remove and would make it more difficult on GM techs or any tech to service them. There is no actual way to grab them and pull them out, I had to drill a tiny hole in mine and use a hooked pick to pull it out.

#22

Banned

iTrader: (1)

The o-ring itself on the stock and SCC Billet piece are both very snug in the bore, the actual barbell is what I was referring to, it had a lot of play on the end with no o-ring. GM had no way to manufacture the block this way with the direction of the oil passages, so they designed the barbell. If they could of, it would of been a just a part of the block with oil passages.

My opinion is GM did not manufacture these to allow oil by-pass under normal conditions, there is a by-pass located in the oil filter for those reasons. I am pretty sure they manufactured these with loser tolerances to prevent them from getting stuck in the bore and can make them easier to be removed. The SCC has a threaded hole that allows you to use a bolt, can't remember the size, to thread into the barbell to pull it out. If the stock piece was very snug/tight in the bore, it would not be easy to remove and would make it more difficult on GM techs or any tech to service them. There is no actual way to grab them and pull them out, I had to drill a tiny hole in mine and use a hooked pick to pull it out.

My opinion is GM did not manufacture these to allow oil by-pass under normal conditions, there is a by-pass located in the oil filter for those reasons. I am pretty sure they manufactured these with loser tolerances to prevent them from getting stuck in the bore and can make them easier to be removed. The SCC has a threaded hole that allows you to use a bolt, can't remember the size, to thread into the barbell to pull it out. If the stock piece was very snug/tight in the bore, it would not be easy to remove and would make it more difficult on GM techs or any tech to service them. There is no actual way to grab them and pull them out, I had to drill a tiny hole in mine and use a hooked pick to pull it out.

The oil filter bypass sounds like it only works at high pressure (its got a spring in it, right? I really dont know) so it would not be available to an engine cranking with an empty filter or partially full filter. whereas the barbell can bypass oil any time, under any circumstance, it seems. Also, in applications with long relocation hoses that lead to the oil filter, how does the bypass function for a cold, empty filter engine cranking?

#23

LS1Tech Sponsor

iTrader: (3)

that is exactly what I am saying- GM manufactures what seems like an infinite number of parts, some with tolerances and clearances in the .000X" range. You'd think that if they wanted to make a tight fitting part they would make it tight fitting. The fact that they are ALL loose fitting explicitly implies they wanted it to be that way for some reason- whether just because it was cheaper or the materials needed the space because they were cheap, or because it was intentionally loose to allow oil to bypass under other circumstances, is not clear. I know my engine at one point cranked for over around 30 seconds without oil pressure showing up at the oil filter because of the relocation lines and empty filter. perhaps if I had blocked off the barbell "bypass" point the engine would have been worse off while it was waiting for the filter and lines to fill? Maybe my loose OEM barbell saved my engine by allowing some oil to reach the bearings while it waited on the filter.

I can assure you that the amount of oil that passes by the barbell is not enough flow to have saved your engine while you were cranking it over for 30 sec. What saves any new engine while cranking is assembly lube and priming the engine. The barbell has enough of a gap to let good size particles coming unfiltered straight from the bottom of the oil pan passing by the barbell into your bearings. That being said, those little ruffles on the end of the barbel are there to create turbulence to slow leakage past the BB. Its kind of like an labyrinth seal in some aspect. But it doesn't eliminate oil passing through it. We believe its best that ALL the oil should go through the oil filter. Thats why we also have the Bypass Delete. The bypass check valve is not needed either unless you never change your filter and it plugs up. Even in the event, most oil filters have a built in bypass. The Bypass check valve can crack open with oil differential pressures from revving the engine or what ever you are doing to make the oil pressure quickly change letting more unfiltered oil in to the bearings.

We have these parts in a pumped up Cadi CTS-V with 55k miles DD and does get into a lot of races and just driven hard. We also have them in a C5 Zo6 with a 440ci big cam 26k miles. The CTS-V broke a valve spring at 44K miles and the valve punched a small hole in the piston. We tore it down and the bearings were perfect so we reused them. Zero sign of anything embedded in the bearings. Here is some info on bearings.

Thank you

Christian

This info taken from http://www.agkits.com/bearing-failure-analysis.aspx

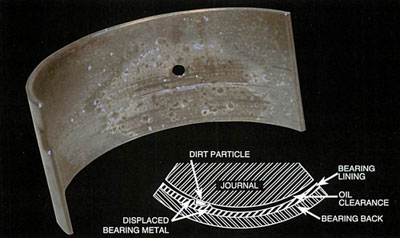

Dirt Embedment

Appearance: Bearing surface speckled, darkened and lightly or heavily scratched.

Causes: Foreign particle contamination. Engine components not thoroughly cleaned prior to assembly. Wear particles from another engine components. Faulty oil filtration. Neglected oil filter replacement. Dirt entering engine during oil addition.

__________________

Don't forget to check out our products at www.saccitycorvette.com

If you like our products, tell others! If not, tell us!

Don't forget to check out our products at www.saccitycorvette.com

If you like our products, tell others! If not, tell us!

#24

TECH Enthusiast

iTrader: (1)

So you are saying the GM Engineers that designed the oiling system were not smart enough to realize they could also put a threaded hole on the end of the stock barbel? Not sure I buy that, there might be a reason besides "it would be too tight" that they allow it so loose of a fit, maybe. The same question is raised- what about contaminants that pass the barbell? The engineers must have weighed the pros and cons of the tiny bypass and decided it was better for the engine to allow contamination through for some reason.

The oil filter bypass sounds like it only works at high pressure (its got a spring in it, right? I really dont know) so it would not be available to an engine cranking with an empty filter or partially full filter. whereas the barbell can bypass oil any time, under any circumstance, it seems. Also, in applications with long relocation hoses that lead to the oil filter, how does the bypass function for a cold, empty filter engine cranking?

The oil filter bypass sounds like it only works at high pressure (its got a spring in it, right? I really dont know) so it would not be available to an engine cranking with an empty filter or partially full filter. whereas the barbell can bypass oil any time, under any circumstance, it seems. Also, in applications with long relocation hoses that lead to the oil filter, how does the bypass function for a cold, empty filter engine cranking?

#25

LS1Tech Sponsor

iTrader: (3)

kingtal0n,

Our 440ci Zo6 has AN-12 hoses (most run AN-10) running all the way up under front bumper into a dual oil filters, oil thermostat, into a big oil cooler and back to to engine. The hoses do not empty out, neither does the cooler or the filters and they lay horizontal. Oil filters come with a oneway check valve so they wont drain.

The Z is usually only driven on weekends and when it starts after sitting a week it has perfect oil pressure in about 2-3 seconds.

So if you are having empty filters and relocation hoses etc. you should rethink how your system is set up.

Your system should not need a leaky barbell and bypass valve to survive

start ups.

Thank you

Christian

This under the front of our Zo6.

Our 440ci Zo6 has AN-12 hoses (most run AN-10) running all the way up under front bumper into a dual oil filters, oil thermostat, into a big oil cooler and back to to engine. The hoses do not empty out, neither does the cooler or the filters and they lay horizontal. Oil filters come with a oneway check valve so they wont drain.

The Z is usually only driven on weekends and when it starts after sitting a week it has perfect oil pressure in about 2-3 seconds.

So if you are having empty filters and relocation hoses etc. you should rethink how your system is set up.

Your system should not need a leaky barbell and bypass valve to survive

start ups.

Thank you

Christian

This under the front of our Zo6.

__________________

Don't forget to check out our products at www.saccitycorvette.com

If you like our products, tell others! If not, tell us!

Don't forget to check out our products at www.saccitycorvette.com

If you like our products, tell others! If not, tell us!

#26

Banned

iTrader: (1)

Thanks for the replys, I was mainly curious if you have any 150k mile engines using the barbell. 50k is not bad, I hope you take a look again at 100 and 150k. Several 150k mile OEM engines come apart looking pretty good, even with the crappy OEM barbell. Oil is what might carry the contaminants around, they don't "roll" by themselves.

I took a stock engine from a junkyard and changed the oil pan, added relocation lines, and changed the oil pump. thus, there was no assembly lube, and no oil in any of the parts the first time I primed the oil system by cranking the engine. It worried me, and yet the motor appears to fine, so I always wondered if some oil made it to the top of the engine somehow. apparently not, and it was just residual oi left behind from the previous years? I am also curious if you've ever tried cranking the engine without an oil filter, allowing 0psi of pressure at the filter and checking to see what comes out the "oil pressure sensor" hole at the top of the engine. Kind of a cave-man (non scientific) means of determining whether or not oil is bypassing anything to get there.

I took a stock engine from a junkyard and changed the oil pan, added relocation lines, and changed the oil pump. thus, there was no assembly lube, and no oil in any of the parts the first time I primed the oil system by cranking the engine. It worried me, and yet the motor appears to fine, so I always wondered if some oil made it to the top of the engine somehow. apparently not, and it was just residual oi left behind from the previous years? I am also curious if you've ever tried cranking the engine without an oil filter, allowing 0psi of pressure at the filter and checking to see what comes out the "oil pressure sensor" hole at the top of the engine. Kind of a cave-man (non scientific) means of determining whether or not oil is bypassing anything to get there.

#27

TECH Senior Member

Since you did not fully disassemble JY motor, there was likely residual oil in the system, as you said, and that is why you had no problem. A newly-assembled engine has NO oil in it except what it is assembled with (hopefully assembly lube...}

#28

Banned

iTrader: (1)

I have zero knowledge of the LS-oil system. I think that is partially why I am so skeptical of everything inside it (not knowing how it works is scary to me). I think this skepticism is transferring over to all oil-related parts, both OEM and non. I keep waking up each day expecting the engine to suddenly have a rod knock because I cannot visualize oil getting to the bearings. I read somewhere that oil has to pass the filter area first before it will push to the top of the engine and forward to the bearings- I still have a really hard time believing they would design it like that, having oil traverse the entire length of the engine to the back of the engine (passing all the parts that need oil) to go through the filter back there FIRST, and THEN going up and over to those parts. Its almost like something is missing? I have a spare engine to play with and I am considering sacrificing it to examine more thoroughly the oil system.

#29

12 Second Club

iTrader: (3)

I am also curious if you've ever tried cranking the engine without an oil filter, allowing 0psi of pressure at the filter and checking to see what comes out the "oil pressure sensor" hole at the top of the engine. Kind of a cave-man (non scientific) means of determining whether or not oil is bypassing anything to get there.

#30

Banned

iTrader: (1)

I imagine you'd get zero oil pressure there too. The oil pretty much makes a 90 degree turn at the barbell, down into the oil filter, then back up. Without a filter, oil is going to hit the barbell, turn 90* down and spray all over the floor. Even it if it were to make it past the barbell, the passage it would take would be open at the bottom (without an oil filter) and thus no flow upward. It would also end up just hitting the floor.

Thanks for the info, I will have to think about that for a while. The pump seems painfully far from the relocated filter in my application, and I was considering swapping to a GTO oil pan to get rid of the lines. On the other hand, I might just go to an higher volume pump. But that comes with its own list of uncertainties. I may also try an accumulator. trying to decide which one is the least amount of work with the biggest benefit I guess. Just trying to make my first LS engine last, I dont want to make any novice mistakes with something as important as the oil system.

#31

LS1Tech Sponsor

iTrader: (3)

Hi,

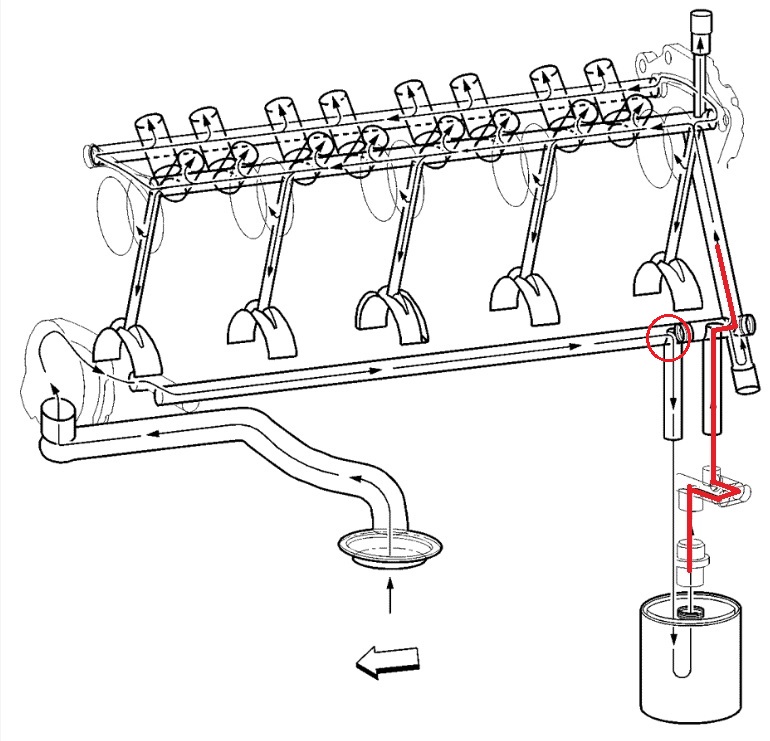

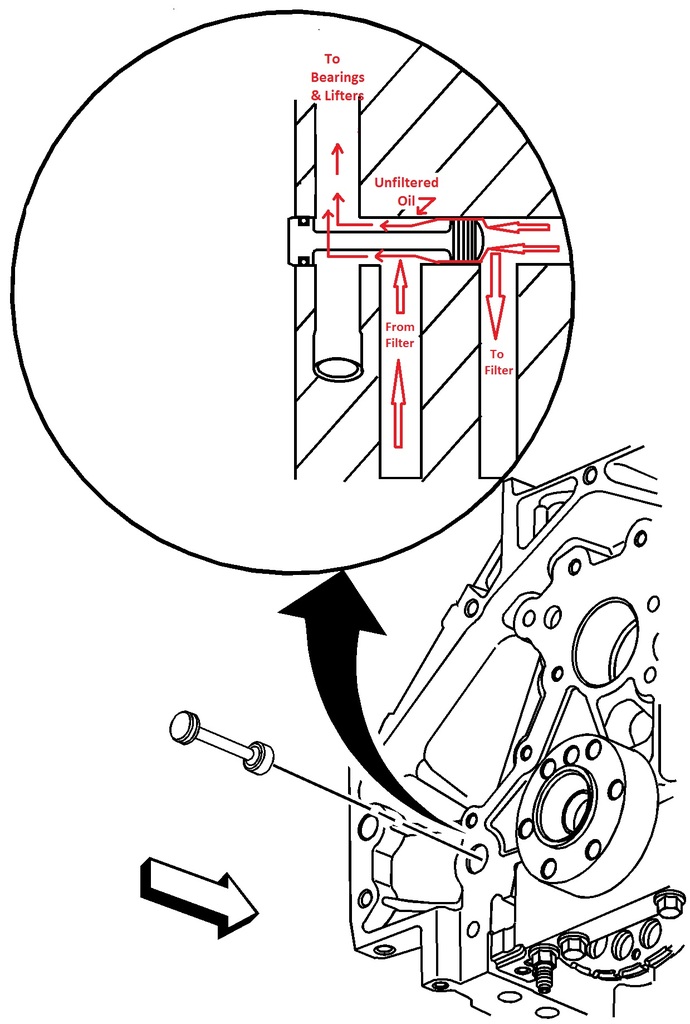

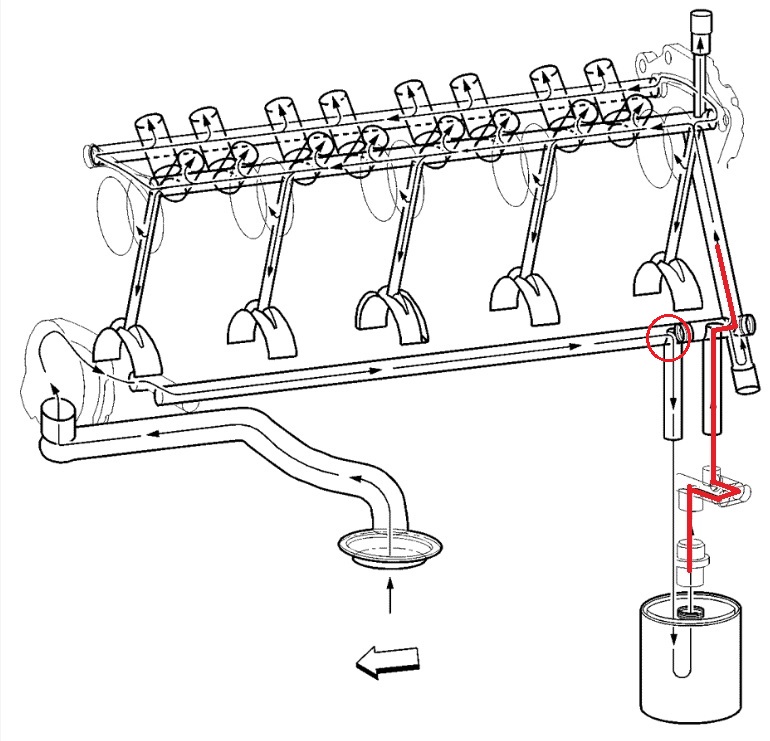

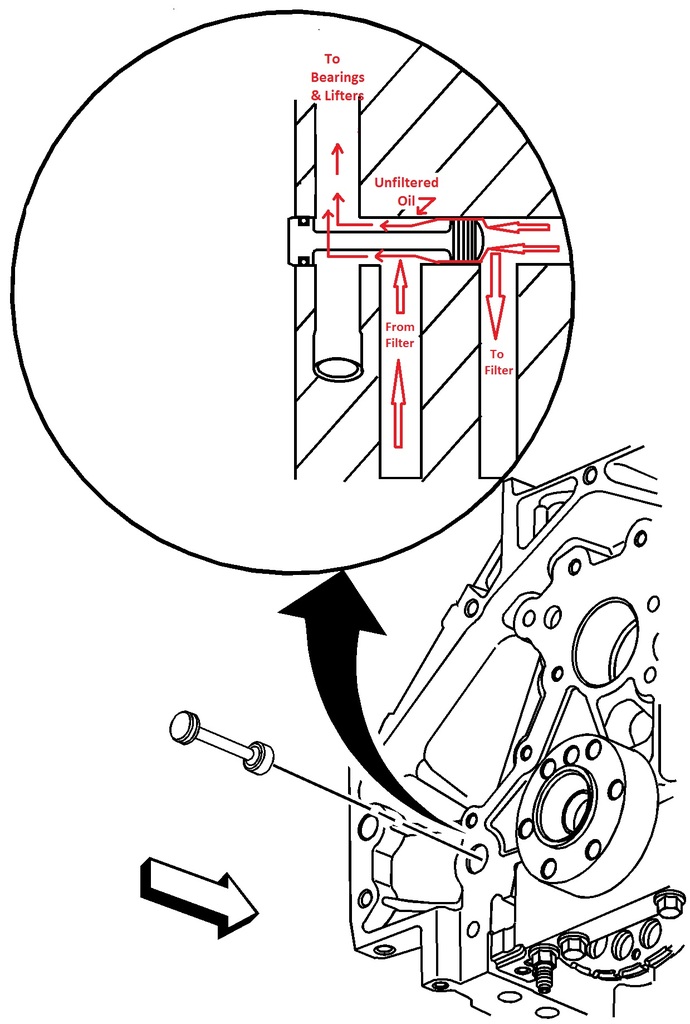

Here are a couple diagrams that will help you see how the oil flows in the LS.

You can see how the oil has to flow around the shaft on the barbell, one other advantage with our barbell besides stopping the unfiltered oil, it also has a 30% smaller shaft making it less restrictive by allowing the oil to flow past easier.

Thanks

Christian

Here are a couple diagrams that will help you see how the oil flows in the LS.

You can see how the oil has to flow around the shaft on the barbell, one other advantage with our barbell besides stopping the unfiltered oil, it also has a 30% smaller shaft making it less restrictive by allowing the oil to flow past easier.

Thanks

Christian

__________________

Don't forget to check out our products at www.saccitycorvette.com

If you like our products, tell others! If not, tell us!

Don't forget to check out our products at www.saccitycorvette.com

If you like our products, tell others! If not, tell us!

#32

TECH Senior Member

Kingtalon- The LS oil system is very well designed, leaky barbell notwithstanding. Far better than the old Gen I small block system. Taking the oil the length of the block is not a big deal.

What is funny is, on the one hand you say you know nothing of the LS oil system, but once you find a few facts about it you criticize it? Read a few more books on the LS engine and educate yourself further.

What is funny is, on the one hand you say you know nothing of the LS oil system, but once you find a few facts about it you criticize it? Read a few more books on the LS engine and educate yourself further.

#33

Banned

iTrader: (1)

Kingtalon- The LS oil system is very well designed, leaky barbell notwithstanding. Far better than the old Gen I small block system. Taking the oil the length of the block is not a big deal.

What is funny is, on the one hand you say you know nothing of the LS oil system, but once you find a few facts about it you criticize it? Read a few more books on the LS engine and educate yourself further.

What is funny is, on the one hand you say you know nothing of the LS oil system, but once you find a few facts about it you criticize it? Read a few more books on the LS engine and educate yourself further.

#34

TECH Senior Member

What you have to go by is how many of these engines COMMONLY surpass 200K miles with little to no mechanical repair of any kind. This speaks to the general durability in general and the oiling system in particular. Detailed evidence is only needed when the overall picture has flaws in it. Here, the general durability and performance picture is excellent compared to most or even all other American V8 engines. These engines flat WORK, and work well.

The parts that Saccity Corvette puts out, namely the billet barbell and the bypass plug, only improve on an excellent present system

The parts that Saccity Corvette puts out, namely the billet barbell and the bypass plug, only improve on an excellent present system

#35

OP: +1 for WS6 store. Their customer service is second to none. Ive been building a swap, and they have sourced parts for my custom application numerous times, and spent a lot of time with me over the last year (without any complaint or hesitation). Really good vendor to work with.

#36

Banned

iTrader: (1)

IF I had the OEM oiling system intact I would not even have mentioned it, "carry on" as you say. However, I do not still have the OEM pan, nor do I have the OEM oiling configuration for the filter. I now have an aftermarket pan, with 8 feet of relocation line, and it uses the OEM Nissan Oil filter of all things. So this sets a new bar for oil system performance; I am monitoring it carefully and trying to decide (purely anecdotal) if I like what I see, or not, and if not, how to improve upon those aspects. Therefore, "looking at the statistics for previous engine track records of oil performance", is only partially useful, in my case, and does not tell the whole story.

#37

LS1Tech Sponsor

iTrader: (3)

Kingtal0n,

You keep mentioning getting 200k miles out of you LS engine. It all depends on how that engine is going to be used and the type of maintenance it will receive. If it gets regular oil changes etc. and it is driven like a normal everyday driver sure it might get 200k miles. There other thing that go bad besides bearings, like rocker needle bearings. If your planning on driving it hard or racing good luck getting 200k miles.

Also, I want to say that I'm not trying to sell you a barbell, we don't expect everyone to want one. I just want to stand behind our product and show that it is beneficial. Our barbell doesn't really need all the testing you talk about. This is not really rocket science. The barbell is just a part that if you mic everything out and understand the LS oil system works you might think different. We have spent a lot time with the LS oil system. In our test LS test engine (LS2 440ci 700hp) we have eliminated 7 internal 90 degree turns in the oiling system. Compared to the readings before the modifications the new system works awesome compared to the stock system. Idles hot at 28 psi and 90psi at 7000 rpm with 10w30 oil and holds strong without fluctuating or dropping off like a lot of LS engines do. Our barbell was just one part of making the system better. Maybe GM made their Barbell loose because the are mass produced and the plastic that is not even exactly round so having them loose there wont be fitment issues. Only they know. Obviously they felt a little unfiltered oil is OK. It just wasn't with us. For us, when you put thousands and thousands of dollars in your engine we want all the oil filtered. On our website (http://www.saccitycorvette.com/Billet-BarBell.html) we describe our findings and show how loose it is and how it works, even with videos. If someone checks it out and thinks there is a reason to let oil unfiltered oil into the engine that's fine and our product is not for them.

Thank you

Christian

You keep mentioning getting 200k miles out of you LS engine. It all depends on how that engine is going to be used and the type of maintenance it will receive. If it gets regular oil changes etc. and it is driven like a normal everyday driver sure it might get 200k miles. There other thing that go bad besides bearings, like rocker needle bearings. If your planning on driving it hard or racing good luck getting 200k miles.

Also, I want to say that I'm not trying to sell you a barbell, we don't expect everyone to want one. I just want to stand behind our product and show that it is beneficial. Our barbell doesn't really need all the testing you talk about. This is not really rocket science. The barbell is just a part that if you mic everything out and understand the LS oil system works you might think different. We have spent a lot time with the LS oil system. In our test LS test engine (LS2 440ci 700hp) we have eliminated 7 internal 90 degree turns in the oiling system. Compared to the readings before the modifications the new system works awesome compared to the stock system. Idles hot at 28 psi and 90psi at 7000 rpm with 10w30 oil and holds strong without fluctuating or dropping off like a lot of LS engines do. Our barbell was just one part of making the system better. Maybe GM made their Barbell loose because the are mass produced and the plastic that is not even exactly round so having them loose there wont be fitment issues. Only they know. Obviously they felt a little unfiltered oil is OK. It just wasn't with us. For us, when you put thousands and thousands of dollars in your engine we want all the oil filtered. On our website (http://www.saccitycorvette.com/Billet-BarBell.html) we describe our findings and show how loose it is and how it works, even with videos. If someone checks it out and thinks there is a reason to let oil unfiltered oil into the engine that's fine and our product is not for them.

Thank you

Christian

__________________

Don't forget to check out our products at www.saccitycorvette.com

If you like our products, tell others! If not, tell us!

Don't forget to check out our products at www.saccitycorvette.com

If you like our products, tell others! If not, tell us!

#38

Banned

iTrader: (1)

Kingtal0n,

You keep mentioning getting 200k miles out of you LS engine. It all depends on how that engine is going to be used and the type of maintenance it will receive. If it gets regular oil changes etc. and it is driven like a normal everyday driver sure it might get 200k miles. There other thing that go bad besides bearings, like rocker needle bearings. If your planning on driving it hard or racing good luck getting 200k miles.

You keep mentioning getting 200k miles out of you LS engine. It all depends on how that engine is going to be used and the type of maintenance it will receive. If it gets regular oil changes etc. and it is driven like a normal everyday driver sure it might get 200k miles. There other thing that go bad besides bearings, like rocker needle bearings. If your planning on driving it hard or racing good luck getting 200k miles.

When I use '200k miles' it is a statistical inference. It doesn't actually mean I am trying to get 200k out of an engine. What it means is that we are 'attempting' or 'propagating a situation' which should cause an engine to last 'some number of miles total', in this case I chose 200k as a rounded off figure for approx 20 years of service total, and plotting that as a probability which depends on application.

Many budget LS projects use engines which already have 120k or 150k miles, the 200k mark is only about 3 to 4 years of attempted daily driving for those swaps, and the previous methods of maintenance using OEM parts have taken their toll. I am only interested in daily drivers with high economy. A worn engine with 150k has a couple advantages over a freshly built engine; for example, it is probably looser than it started out in some respects, and has a track record of reliability for over 10 years and 150k already. If we take care of it from this point, there is a high probability it will last. Often the question is "how much power/abuse" and while this is a critical aspect of use, often we overlook other very important aspects such as "how it is maintained differently with this new level of abuse" and "how the oil system is altered because of unique swaps/components" which may play a role in the engine's demise (the stock engine might tolerate the new level of abuse, but not the oil starvation caused by the conditions brought on by the power increase for example).

The possibility or probability of ruining a good engine by accident of the end user (consumer of power) will play a (minor) role in the X (any number) mile statistic of survival, since accidents can be random (even if they are common accidents). In other words, the probability of making it from 150k to 200k might be reduced by the chance that a 'modification' we do to the engine reduces it's chance of survival, for example if i take off the oil pan and disturb the pickup O-ring and cause oil starvation. So the act of going into an engine to "freshen it up" can lead to catastrophic failure in some cases. Anytime we make a modification, even one which is supposed to improve the longevity of the engine, initially it counts against the reliability of that engine until a certain amount of track record has been established. That is why 100k/150k/200k mile statistics are so powerful, the less done to the engine at that exact point we take it for our own personal abuse setting, the more confidence we have in it's operation, provided we do not exceed a materials/systems limitation.

#40

TECH Senior Member

^^^^ huh? ^^^^^^