Strange oiling issue resulting in destroyed bearings

#21

TECH Apprentice

iTrader: (18)

Yes, lifters were quiet and all seemed well. The easiest indicator was a lack of oil to the top end. As oil comes out of the upper galley, it is fed up the pushrods, and down to the rods. Oil at the topend=oil at the bearings. I didnt catch this in time and spun a rod bearing. On a new engine it started doing it AGAIN which prompted me to dig deeper. I found the pickup was on the pan floor. Raised it 1/2", and now the pushrods/rockers have oil slinging out of them.

0. It was against the pan floor.

0. It was against the pan floor.

#22

Many variables here. Donít know the clearances and could they have been even larger the second time around even though the block was new since crank had an additional polishing procedure ??

Iím of the belief that you simply canít pump more oil unless you have more oil

Pan designed for stock volume pump should not be used with a high volume pump. Most builds are just fine with a ported and shimmed factory pump.

Every single street engine Iíve ever seen where a high volume pump was put into a stock capacity oil pan ended with bearings that looked like yours. Within a few thousand miles

Iím of the belief that you simply canít pump more oil unless you have more oil

Pan designed for stock volume pump should not be used with a high volume pump. Most builds are just fine with a ported and shimmed factory pump.

Every single street engine Iíve ever seen where a high volume pump was put into a stock capacity oil pan ended with bearings that looked like yours. Within a few thousand miles

#23

Yes, lifters were quiet and all seemed well. The easiest indicator was a lack of oil to the top end. As oil comes out of the upper galley, it is fed up the pushrods, and down to the rods. Oil at the topend=oil at the bearings. I didnt catch this in time and spun a rod bearing. On a new engine it started doing it AGAIN which prompted me to dig deeper. I found the pickup was on the pan floor. Raised it 1/2", and now the pushrods/rockers have oil slinging out of them.

0. It was against the pan floor.

0. It was against the pan floor.

#25

TECH Senior Member

#26

TECH Senior Member

iTrader: (96)

Join Date: Aug 2007

Location: Turnin' Wrenches Infractions: 005

Posts: 24,241

Likes: 0

Received 81 Likes

on

72 Posts

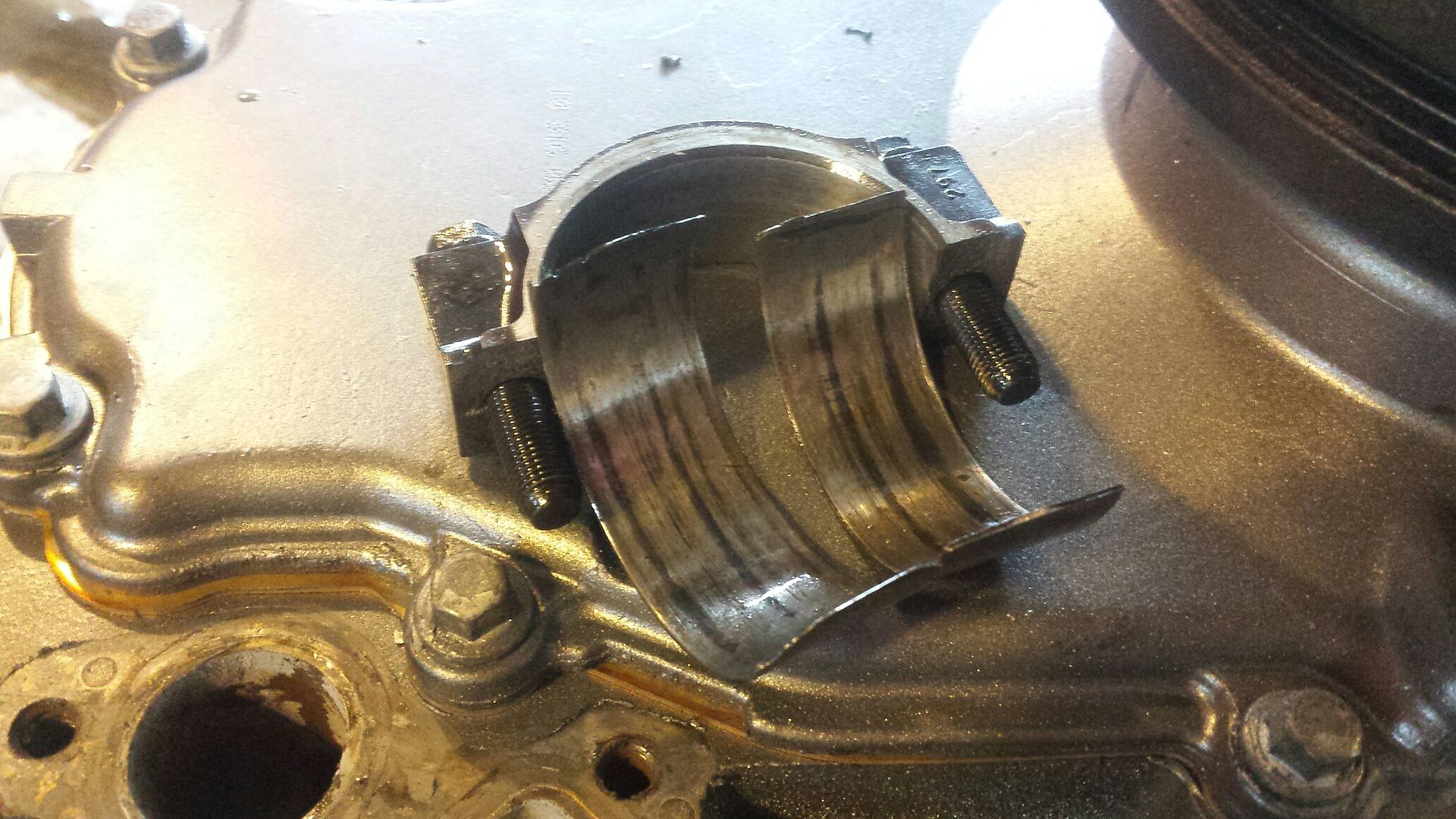

Here's the damage it caused: All other rod bearings showed signs of oil starvation also.

None may have been the wrong word. Very little may have been more accurate.

#27

Staging Lane

Not knocking the OP in anyway but are you sure the weld job on the oil pick up tube is not sucking in air?

What viscosity oil did you use and did you use break in oil at all?

Tim

What viscosity oil did you use and did you use break in oil at all?

Tim

#29

TECH Senior Member

iTrader: (96)

Join Date: Aug 2007

Location: Turnin' Wrenches Infractions: 005

Posts: 24,241

Likes: 0

Received 81 Likes

on

72 Posts

Considering i made my living as a certified welder for years Im confident it did not leak. Not tooting my own horn, it just isnt difficult for a competent welder to seal two pipes of the same size/material with a decent fitting joint.

#30

Staging Lane

Tim

Last edited by timharber; 01-15-2018 at 09:01 AM. Reason: Added comments

#31

I dropped the assembled engine at the machine shop and haven't picked it up yet. They couldn't find anything that they thought would allow air in. I ordered a new pickup and bought a ported LS6 pump as insurance. I hope to find the problem once I pickup my short block and all my old parts.

Outside of a cracked pickup, my working theories are I distorted the oil pickup tube end either out of round or used an o-ring that was too big. Maybe when I went back to the factory o-ring, it couldn't make an air tight seal.

This has happened twice though, same symptoms, ticking oil pressure gauge, top end noise, and absolutely wrecked bearing. I blamed the machine shop the first time thinking they didn't clean up after machining, since the all the plugs were still in. I used a different machine shop the second time, with all CNC machines, very reputable etc. Same result.

Oil was 10w-30 Driven Racing oil, the Joe Gibbs racing stuff.

Outside of a cracked pickup, my working theories are I distorted the oil pickup tube end either out of round or used an o-ring that was too big. Maybe when I went back to the factory o-ring, it couldn't make an air tight seal.

This has happened twice though, same symptoms, ticking oil pressure gauge, top end noise, and absolutely wrecked bearing. I blamed the machine shop the first time thinking they didn't clean up after machining, since the all the plugs were still in. I used a different machine shop the second time, with all CNC machines, very reputable etc. Same result.

Oil was 10w-30 Driven Racing oil, the Joe Gibbs racing stuff.

#32

Please sanity check me on this, the air HAS to be getting in downstream of the pump right?

My oil cooler lines were leaking, but if the lines have 40+ PSI on them I can't see the oil flowing fast enough to create a venturi effect and suck air in.

My oil cooler lines were leaking, but if the lines have 40+ PSI on them I can't see the oil flowing fast enough to create a venturi effect and suck air in.

#34

TECH Senior Member

iTrader: (96)

Join Date: Aug 2007

Location: Turnin' Wrenches Infractions: 005

Posts: 24,241

Likes: 0

Received 81 Likes

on

72 Posts

Sorry i din't realize it wasn't the OP pick up tube. It was just a suggestion, not a knock. Sometimes the most obvious things escape us when we beat our heads into a block wall over and over again. If there is the slightest little air hole in the welds or the tube is bowed, it could cause issues. Sorry if I offended you, it was not my intent at all.

Tim

Tim

Last edited by 01ssreda4; 01-16-2018 at 01:29 PM.

#36

The real problem is the pressure sensor doesn't know if it is reading oil pressure or air pressure. So 70 psi reading on the gauge could mean anything from all oil or half air. I'll tell you what you could try is pull the spark plugs crank the engine until you have pressure on the gauge so you know the bearings have oil. The pull the oil filter off then use a clear container to collect oil from the oil filter inlet. Crank the engine and see if it pumps out clear into the container, It should. I would do all this before installing the engine, you need to find your gremlin before it costs you anything more.

You could do this with the heads off, good way to play with it without running the engine. Thing is some air in the oil won't hurt anything as long as the engine is run low rpm no load. But putting any load on the engine with air bubbles in the oil will cause wear. The only place air can enter is on the suction side of the pump, once the oil is under pressure it is above atmosphere and air can not enter because it is lower pressure than the oil.

You could do this with the heads off, good way to play with it without running the engine. Thing is some air in the oil won't hurt anything as long as the engine is run low rpm no load. But putting any load on the engine with air bubbles in the oil will cause wear. The only place air can enter is on the suction side of the pump, once the oil is under pressure it is above atmosphere and air can not enter because it is lower pressure than the oil.

#37

The real problem is the pressure sensor doesn't know if it is reading oil pressure or air pressure. So 70 psi reading on the gauge could mean anything from all oil or half air. I'll tell you what you could try is pull the spark plugs crank the engine until you have pressure on the gauge so you know the bearings have oil. The pull the oil filter off then use a clear container to collect oil from the oil filter inlet. Crank the engine and see if it pumps out clear into the container, It should. I would do all this before installing the engine, you need to find your gremlin before it costs you anything more.

You could do this with the heads off, good way to play with it without running the engine. Thing is some air in the oil won't hurt anything as long as the engine is run low rpm no load. But putting any load on the engine with air bubbles in the oil will cause wear. The only place air can enter is on the suction side of the pump, once the oil is under pressure it is above atmosphere and air can not enter because it is lower pressure than the oil.

You could do this with the heads off, good way to play with it without running the engine. Thing is some air in the oil won't hurt anything as long as the engine is run low rpm no load. But putting any load on the engine with air bubbles in the oil will cause wear. The only place air can enter is on the suction side of the pump, once the oil is under pressure it is above atmosphere and air can not enter because it is lower pressure than the oil.

Excellent idea, thank you! I built a setup to run a mechanic oil pressure gauge on the motor and my sending unit simultaneously. I'm gonna pull my starter off put it on the block once I'm all assembled and prime, then run the starter to get oil pressure all while on the engine stand. The clear jar at the oil filter neck is awesome, should be able to crank this engine with confidence now. The only variable I can't include is the oil cooler, but being it's downstream of the pump, I can't see it being the issue.

#38

+1 vote for high volume pump sucking all of the oil out of the pan. Check out the picture of bearings here (not mine):

https://ls1tech.com/forums/forced-in...l#post19594989

https://ls1tech.com/forums/forced-in...l#post19594989

#39

I agree, this time he has to cover all bases or pay the consequences. Sometimes its not so easy to solve a simple problem like this because you can't find anything obviously wrong BUT the gauge ticking 5psi all the time is a dead giveaway something is way wrong.

#40

yeah, i wonder if the pump sucks all the oil until it's just air (gauge drops), enough oil returns to the pan so it gets oil again (gauge increases)... repeat...

agreed, it could be different reasons. OP mentioned a HV oil pump, so that's a possibility given others experiences with them.

agreed, it could be different reasons. OP mentioned a HV oil pump, so that's a possibility given others experiences with them.