Lifter preload delema

#62

Boy, is it hard to separate the wheat from the chaff on here. I have already had lengthy discussions on how to do this, so i do it, and now all of a sudden thats not the way to do it. Please scroll up to see all the previous discussions. I will do it one more time, real quick....9 1/8 turns on the comp checker tool for zero lash. @ .050 per turn that equals .45625. + 6.8" base length=7.25625. + desired preload, .080=7.33625. I had 7.325 which should have had me around .069. But when i double checked the way EVERYBODY SAID TO, by counting the turns from zero lash to the torque wrench clicking on the rocker bolt, it came up short, barely a full turn. So i swapped them for 7.350 which should get me .094. It wound up being a little under 1 3/4 turns.

#63

TECH Junkie

iTrader: (11)

Boy, is it hard to separate the wheat from the chaff on here. I have already had lengthy discussions on how to do this, so i do it, and now all of a sudden thats not the way to do it. Please scroll up to see all the previous discussions. I will do it one more time, real quick....9 1/8 turns on the comp checker tool for zero lash. @ .050 per turn that equals .45625. + 6.8" base length=7.25625. + desired preload, .080=7.33625. I had 7.325 which should have had me around .069. But when i double checked the way EVERYBODY SAID TO, by counting the turns from zero lash to the torque wrench clicking on the rocker bolt, it came up short, barely a full turn. So i swapped them for 7.350 which should get me .094. It wound up being a little under 1 3/4 turns.

1)the biggest issue is the rocker bolt turns. 1 rocker bolt turn is about .076, because the rocker acts as a fulcrum as it lowers........multiple threads here explaining this......you have to multiply the threads by 1.7 because thats the rocker arm ratio. so your .044 movement on 1 rocker bolt turn is false.....

2)nowhere have i ever seen anyone "RECOMMEND" counting turns on a checker, as vettenuts stated earlier, its too easy to be a little off. most recommend using a length checker, then verifying the length of the checker using a caliper to measure end to end. then call your pushrod people up and tell them "END TO END, MY ROD NEEDS TO BE THIS LONG"

#65

But 1.7 is the ratio between valve lift and pushrod travel. The bolt is the fulcrum, which is hlaf way between that. I think you are over thinking things. I just googled it and everyone says about .050 per bolt turn (including an article by LSX Magazine). Gm says its actually .048.

#66

1 rocker bolt turn is roughly .076

Thread pitch is 1.25mm. 1" = 25.4mm.

1.25mm ÷ 25.4 = .0492"

(1.25mm ÷ 25.4) × (2.7 ÷ 1.7) = .0782"

Remember, the bolt is in the center of the rocker, aka the fulcrum. The rocker ratio is 1.7, meaning that the distance from the fulcrum to the push rod is 1 arbitrary unit, and the distance from the fulcrum to the valve is 1.7 of the same units, meaning that the overall rocker is 2.7 units long from valve to push rod. The push rod end of the rocker therefore moves 2.7 ÷ 1.7 times as far as the bolt head, as you tighten it down. (assuming that the ratio is EXACTLY the "nominal" value, which is ... questionable at best, but it's all we've got to go on)

1 turn of the bolt after reaching zero lash (taking up all the play in the push rod, then one full turn to the bolt starting to tighten) is therefore .078" at the push rod end, which about perfect preload on stock lifters, which want around .075". Really, anything from .060" to .090" will probably all work about the same, though. Getting all 16 the same is probably more important in the long run than the absolute value anyway.

I don't like to do it that way though. I prefer the adjustable push rod method. I have the Comp one. Adjust to the length that takes up all the play, add .075 - .080", buy, done. Too eeeeeeezy.

Last edited by RB04Av; 08-12-2018 at 12:03 PM.

#67

So then that would make my preload at 1.5 turns roughly .117? Thats way too high. According to the pushrod tool, with these rods, I should have .094. Why, in all my research and chatting on forums, including this very thread, is this the first im hearing about this? Im not saying you are wrong or right, but i am standing here looking at it ready to put it back in the car! I need to figure this out now, while i still have the other pushrods!

#68

I guess when i think about it, it went a little over 1.5 turns, but that was to torque. So movement probably stopped shortly after 1 or 1 1/4 turns. I will pull the valve cover real quick and do it again. As far as having all of them the same, how would they be any different, and what would you do about it if they were? I checked intake and exhaust on number 1 and 2 cylinders.

#69

Why, in all my research and chatting on forums, including this very thread, is this the first im hearing about this?

how would they be any different

what would you do about it if they were?

I'd check int & exh on at least 1, 2, 7, & 8.

Last edited by RB04Av; 08-12-2018 at 01:03 PM.

#70

TECH Junkie

iTrader: (11)

No idea. But whyever, now you have the facts and the numbers and the physical reality clearly in front of you, to iluminate what to do.

Different wear on moving parts, casting variation, different distance that valves are sunk into seats from wear or machining, ...

Buy different length push rods, according to need. Check Texas Speed house brand.

I'd check int & exh on at least 1, 2, 7, & 8.

Different wear on moving parts, casting variation, different distance that valves are sunk into seats from wear or machining, ...

Buy different length push rods, according to need. Check Texas Speed house brand.

I'd check int & exh on at least 1, 2, 7, & 8.

#71

TECH Junkie

iTrader: (11)

https://ls1tech.com/forums/generatio...ll-advice.html

many people say this is not necessary, but one of the reasons i try to do what i can by myself is to be sure it gets done correctly.....so i did it this way.....i also torqued my rockers to 25 instead of 22......up to you what u do.....i accidentally didn't have the wench set on one and id estimate i got all the way up to about 40 pounds before i noticed and i didn't strip the threads so an extra few pounds should be fine

many people say this is not necessary, but one of the reasons i try to do what i can by myself is to be sure it gets done correctly.....so i did it this way.....i also torqued my rockers to 25 instead of 22......up to you what u do.....i accidentally didn't have the wench set on one and id estimate i got all the way up to about 40 pounds before i noticed and i didn't strip the threads so an extra few pounds should be fine

#72

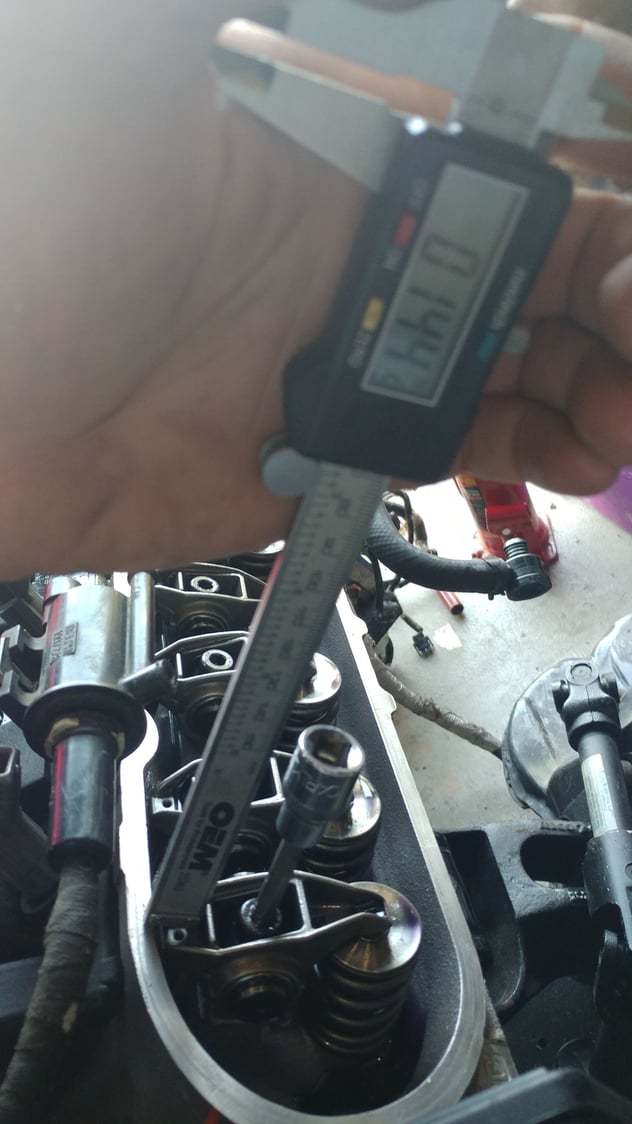

So, here is what i did. See pics. I used a digital caliper to crudely measure actual lifter preload. I tried to steady it as best i could by hand. Im pretty confident it was as accurate as it could be. I did it 4 times, and the numbers wire slightly different, but the measurements were pretty much dead on. I started at zero lash. Measured the distance from the top of the rocker to the top edge of the head. Then tightened the bolt until it seated tightly. Then measured again after torquing it. I got .112 almost every time. Then after cranking the bolt down it went another .010. Total lifter preload was actually .122. WAY too high! How the hell is it so much different than what i measured with the checker tool?

#75

Also, i checked it with comps checker tool again and got 8 3/4 turns. It wasnt fully torqued last time I measured. So 8.75x.050= .4375 + 6.8 = 7.2375. With my 7.350 rods I should have .1125. Dead nuts. So you were absolutely right about the bolt turn issue. Except, it does actually still continue to add preload all the way until it is torqued. Which is the only difference in my numbers from the checker tool. I am glad I checked in here before I put it together! I am goimg to put the 7.325 back in, and should be down to .0875. Good thing i haven't sent them back to summit yet!

#76

it does actually still continue to add preload all the way until it is torqued

But yeah, you have too long push rods; prolly would still work OK, but it would be better to get down into the correct range if you can.

#77

No, it really doesn't... not much anyway... as soon as the trunnion is seated on the guide thing and everything is snugged up and all the metal is metal on metal, further torque on the bolt is just ... further torque on the bolt. Nothing actually moves anymore. Only way anything moves is, if the trunnion isn't absolutely straight, and the extra clamping from the bolt, seats it down into the guide a bit more.

But yeah, you have too long push rods; prolly would still work OK, but it would be better to get down into the correct range if you can.

But yeah, you have too long push rods; prolly would still work OK, but it would be better to get down into the correct range if you can.

#80

Dont know but im sitting pretty right now with a measured .080- .082 preload torqued, so im bolting the valve covers on and walking away! Next time i am investing in a dial gauge.