Rod bolt install write-up

#61

TECH Addict

iTrader: (1)

I bought a hydraulic motorcycle jack to raise and lower transmissions, but it would work well to support the trans while the K member is removed so you can get the pan out. It has two horizontal legs that straddle the trans. I got it on sale from Sears(Craftsman brand) for around $100. It's probably not a good idea to let the engine/trans go unsupported. If you don't have a jack of some sort use a jack stand or come up with something to relieve the load. I'd be concerned about the transmission input shaft.

#62

TECH Addict

Thread Starter

iTrader: (28)

Join Date: Sep 2002

Location: Central Texas

Posts: 2,170

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by calongo_SS

Any problem holding the engine up under the bellhousing? I'm gonna be doing a k-member swap and dropping the oil pan. I'm kind of worried about holding the engine up from there. It doesn't seem like it would be too stable. Did the engine/trans ever feel unstable?

. In all three installs, I jacked the tranny/engine upto where it would rest against the floorboard (notice I said rest, not pushed up against it), so it is sandwiched between the floorboard and the jack.

. In all three installs, I jacked the tranny/engine upto where it would rest against the floorboard (notice I said rest, not pushed up against it), so it is sandwiched between the floorboard and the jack.eallanboggs: I've never pulled the entire engine from my car, but you'd still have to unbolt the motor mounts from the engine in order to be able to pull it out. This would mean you would still have to drop the starter, compressor and alternator. Not to mention you have to unbolt the engine from the transmission. The only real steps you would be skipping is unbolting the shocks, swaybars, and spindles. It would definetely be easier to actually install the rod bolts with the engine pulled, but it does take nearly the same amount of work (if not more) to pull the engine. I guess it just comes down to what you're more comfortable with.

#63

On The Tree

iTrader: (9)

Join Date: May 2006

Location: Colorado

Posts: 126

Likes: 0

Received 0 Likes

on

0 Posts

would it help if you have a strut tower bar brace to help the 2x4 hold the engine and tranny up? Like strapping the headers to it for a little support. I'm about to do it thats why I am thinking of that. What do you guys think?

-Ivan

-Ivan

#64

TECH Enthusiast

iTrader: (4)

Join Date: Aug 2003

Location: Phoenix AZ

Posts: 633

Likes: 0

Received 0 Likes

on

0 Posts

'98-'99....no ferrules

'00....some with ferrules

'01-'02....all have ferrules

found this in a different thread, nice to have all the info in one place.

Do arp bolts really cause the rod end to resize unlike the katechs or is this BS?

not that I don't want to buy katech's, I just happen to have a set of arp's

'00....some with ferrules

'01-'02....all have ferrules

found this in a different thread, nice to have all the info in one place.

Do arp bolts really cause the rod end to resize unlike the katechs or is this BS?

not that I don't want to buy katech's, I just happen to have a set of arp's

Last edited by Gen3Benz; 07-01-2007 at 01:19 PM.

#65

TECH Fanatic

iTrader: (17)

Join Date: Sep 2006

Location: dayton ohio

Posts: 1,638

Likes: 0

Received 0 Likes

on

0 Posts

what bearings to install if you want to swap, clevite?

Is it okay to swap rod bearings while doing this or just leave them alone

thanks

john

Is it okay to swap rod bearings while doing this or just leave them alone

thanks

john

Last edited by john563; 07-04-2007 at 07:57 AM.

#66

TECH Enthusiast

iTrader: (4)

Join Date: Aug 2003

Location: Phoenix AZ

Posts: 633

Likes: 0

Received 0 Likes

on

0 Posts

Just read bulletin 99-06-01-011

It says the bolts without ferrules (gm calls them "retaining sleeves") have one dimple on the bolt head.

Bolts with ferrules have 2 dimples.....

It says the bolts without ferrules (gm calls them "retaining sleeves") have one dimple on the bolt head.

Bolts with ferrules have 2 dimples.....

Last edited by Gen3Benz; 07-24-2007 at 08:32 PM.

#67

TECH Addict

Thread Starter

iTrader: (28)

Join Date: Sep 2002

Location: Central Texas

Posts: 2,170

Likes: 0

Received 0 Likes

on

0 Posts

Gen3Benz, thank you very much for that info and illustration.  It really helps having a visual to know what to look for. I just checked my stock bolts and sure enough, they all only have one dimple on the bolt head and have the "cracked" bolts (or whatever that thread-like part on the shaft is called).

It really helps having a visual to know what to look for. I just checked my stock bolts and sure enough, they all only have one dimple on the bolt head and have the "cracked" bolts (or whatever that thread-like part on the shaft is called).

I don't have any data to say either way about the ARP bolts, but I have installed a set on a friends car and it's doing well.

It really helps having a visual to know what to look for. I just checked my stock bolts and sure enough, they all only have one dimple on the bolt head and have the "cracked" bolts (or whatever that thread-like part on the shaft is called).

It really helps having a visual to know what to look for. I just checked my stock bolts and sure enough, they all only have one dimple on the bolt head and have the "cracked" bolts (or whatever that thread-like part on the shaft is called).I don't have any data to say either way about the ARP bolts, but I have installed a set on a friends car and it's doing well.

#68

TECH Enthusiast

iTrader: (4)

Join Date: Aug 2003

Location: Phoenix AZ

Posts: 633

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by Krab

Gen3Benz, thank you very much for that info and illustration.

I don't have any data to say either way about the ARP bolts, but I have installed a set on a friends car and it's doing well.

I don't have any data to say either way about the ARP bolts, but I have installed a set on a friends car and it's doing well.

I installed my ARP's on monday, 30 loosen, 30 loosen, 40...one bolt at a time.

We'll see what happens.

#72

TECH Fanatic

iTrader: (35)

Join Date: Sep 2004

Location: Maryland/Illinois

Posts: 1,660

Likes: 0

Received 0 Likes

on

0 Posts

I just got done putting a set of katech rold bolts in my engine. Before doing that I did some searching and found some good info, but not quite everything I wanted. This thread has good info on how to install the bolts with the engine in the car, but it seems there is still confusion over the ferrule issue (I was still wondering just what these ferrules looked like). And I did not find any real good photos. So, I am posting up my guide. Now my engine was out and on a stand, but the procedures are the same for in the car.

Some people still wonder if you need to take the ferrules out with Katech bolts. The answer is YES. You take them out and leave them out. I don't know for sure about ARP bolts, so I won't speak about them. If in doubt I would call ARP directly and ask.

Starting product, my 2000 LS1 engine. My car was a late 2000 year build (it had 241 casting heads).

Here is the part of the GM service manual that discusses the ferrules (as said above GM calls them retaining sleeves). Looking at my bolt heads it appeared all of mine had these retaining sleeves. An interesting note from anoter part of the GM service manual was that you cannot have 1 sleeved bolt and 1 non-sleeved bolt on the same connecting rod, but that you could have rods with and without sleeves in the same engine.

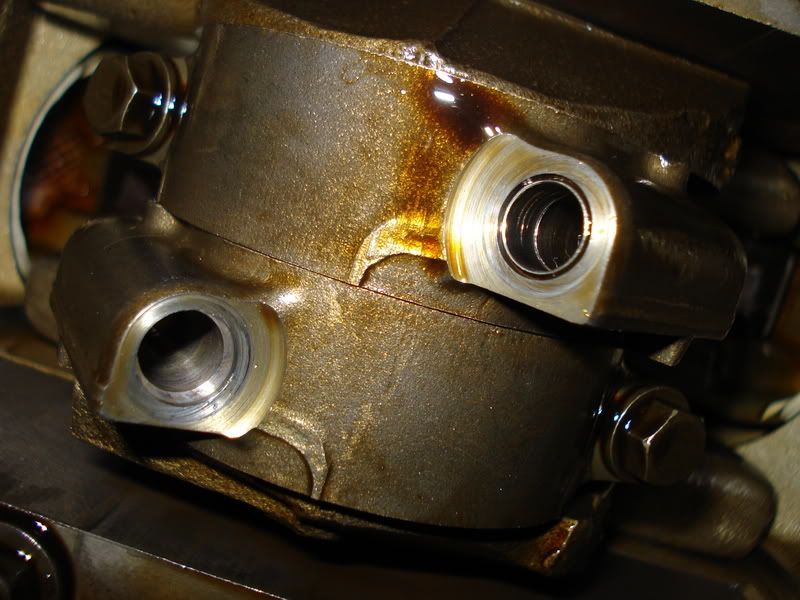

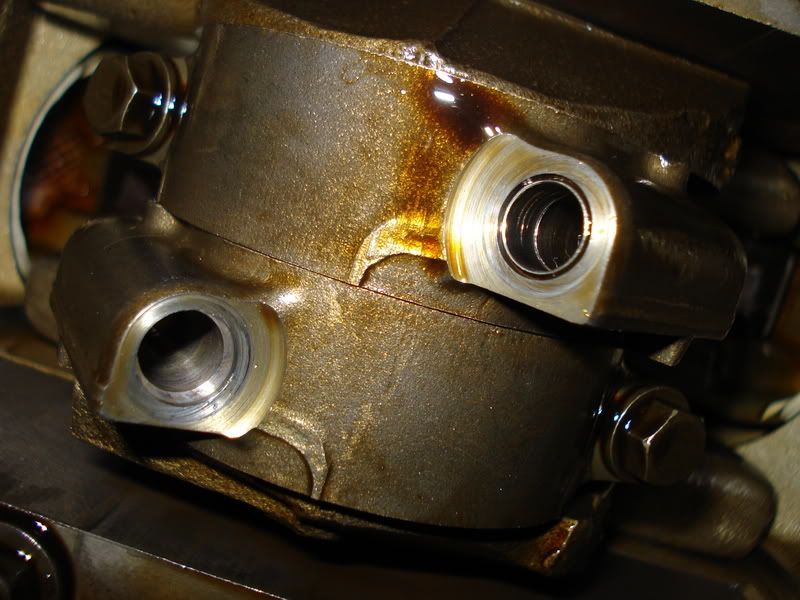

I turned the engine over so 1 pair of rods was near BDC, then proceeded to take 1 bolt out of each rod cap. Now, my retaining sleeves were quite stubborn; they did not just slide out easy with the bolts. My technique was to unscrew the rod bolts until I could just see some thread, then grab the bolt with a pliers and give it a good pull. This worked to get all the sleeves out. Here is the rod cap with a sleeve still in it:

And here is the rod cap with the sleeve out:

Here is a rod bolt with the sleeve on it:

And a pic of the bolt head showing the 2 dimples (sorry for the blurriness):

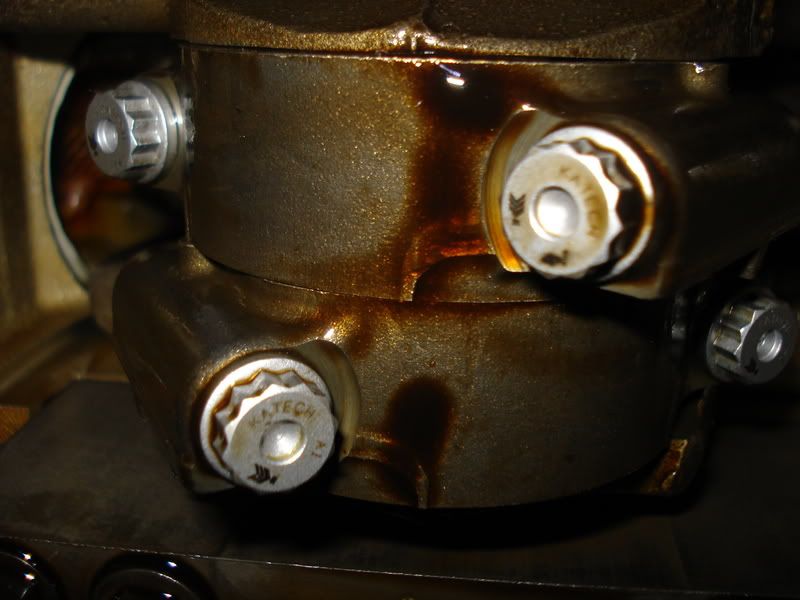

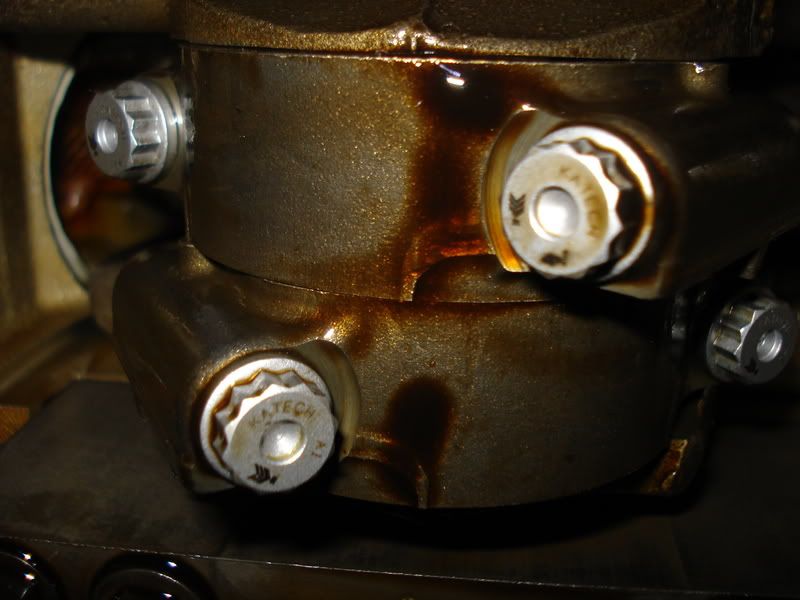

So, doing 1 rod cap bolt at a time I removed the stock bolts and sleeves and installed the katech bolts. Katech supplies a tube of grease to lube the bolts. Here is a properly greased bolt ready for install:

The instructions say to torque them to 30 lb-ft, then loosen. Repeat this procedure at least once more. I did the torque/loosen step 3 times total, then torqued them to the final 50 ft-lb. Once I got all the bolts in I went back and checked them all at 50 ft-lb just to make sure all was good.

The finished product:

Some people still wonder if you need to take the ferrules out with Katech bolts. The answer is YES. You take them out and leave them out. I don't know for sure about ARP bolts, so I won't speak about them. If in doubt I would call ARP directly and ask.

Starting product, my 2000 LS1 engine. My car was a late 2000 year build (it had 241 casting heads).

Here is the part of the GM service manual that discusses the ferrules (as said above GM calls them retaining sleeves). Looking at my bolt heads it appeared all of mine had these retaining sleeves. An interesting note from anoter part of the GM service manual was that you cannot have 1 sleeved bolt and 1 non-sleeved bolt on the same connecting rod, but that you could have rods with and without sleeves in the same engine.

I turned the engine over so 1 pair of rods was near BDC, then proceeded to take 1 bolt out of each rod cap. Now, my retaining sleeves were quite stubborn; they did not just slide out easy with the bolts. My technique was to unscrew the rod bolts until I could just see some thread, then grab the bolt with a pliers and give it a good pull. This worked to get all the sleeves out. Here is the rod cap with a sleeve still in it:

And here is the rod cap with the sleeve out:

Here is a rod bolt with the sleeve on it:

And a pic of the bolt head showing the 2 dimples (sorry for the blurriness):

So, doing 1 rod cap bolt at a time I removed the stock bolts and sleeves and installed the katech bolts. Katech supplies a tube of grease to lube the bolts. Here is a properly greased bolt ready for install:

The instructions say to torque them to 30 lb-ft, then loosen. Repeat this procedure at least once more. I did the torque/loosen step 3 times total, then torqued them to the final 50 ft-lb. Once I got all the bolts in I went back and checked them all at 50 ft-lb just to make sure all was good.

The finished product:

Last edited by bowtieman81; 09-05-2007 at 08:00 AM.

#76

TECH Apprentice

iTrader: (16)

Join Date: Jun 2004

Location: So Cal

Posts: 305

Likes: 0

Received 0 Likes

on

0 Posts

digging this up from the dead but wanted to post my pics of a ferrule since i could only find the above post with pics of it...

bottom rod has it removed and the top one has the ferrule in. when working on getting them out I couldnt budge them by just threading the stock bolts into them and pulling / wiggling like some have suggested but had success by threading a little larger bolt into them and pulling them out.

katechs installed....

bottom rod has it removed and the top one has the ferrule in. when working on getting them out I couldnt budge them by just threading the stock bolts into them and pulling / wiggling like some have suggested but had success by threading a little larger bolt into them and pulling them out.

katechs installed....

#79

Restricted User

iTrader: (18)

Join Date: Apr 2007

Location: Fayetteville, NC

Posts: 1,515

Likes: 0

Received 0 Likes

on

0 Posts

Here's another Rod bolt thread I made. Actually followed this one for my install. Very well done!

Thanks Krab!!!

https://ls1tech.com/forums/showthrea...otor+rod+bolts

Thanks Krab!!!

https://ls1tech.com/forums/showthrea...otor+rod+bolts

#80

I have a question that I didn't see answered anywhere, is there any need to use a rod bolt stretch gauge? I've heard they're very important to use but I didn't see any mention of anyone using one in this thread, so I'm guessing it's not as important as I've read?