Flycutting question

#21

On The Tree

Thread Starter

iTrader: (2)

Join Date: Feb 2004

Location: Pewaukee, WI

Posts: 143

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by Irocss85

damn, too bad I was too busy to get on here lately. but your supposed to cut the back side of the cutter down. just like if you were cutting a valve job. but with a bench grinder.

The exhaust cutter didn't even hit the seats, it bound up on the chamber walls.

I ground the backside down until it sat better in the head...but after claying, it turns out I didn't even need to cut for the exhaust valve clearance anyways.

No worries, it's done and turned out just fine.

#23

TECH Junkie

iTrader: (28)

The LG motorsports tool is an ISKY cutting tool. I rented it also at one point.

Only did the intake side on my car. Not hard to use... just need to take your time and not let debris fly into the engine.

Thimble- depending upon your mileage... you may want to have Harlan Sharp rebuild your stock rockers. Good insurance.

-Mark

Only did the intake side on my car. Not hard to use... just need to take your time and not let debris fly into the engine.

Thimble- depending upon your mileage... you may want to have Harlan Sharp rebuild your stock rockers. Good insurance.

-Mark

#26

10 Second Club

iTrader: (3)

Originally Posted by quick346

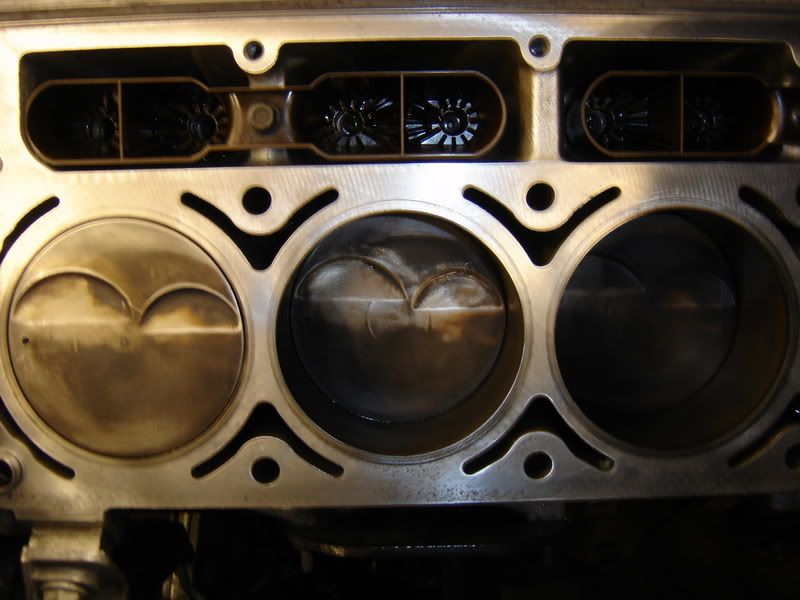

holy rough deck surface batman. Is it just me or is waterbugs surface job a bit extreme? damn I hope that seals.

Scotchbrite here as well, followed with the 3M pad they sale at the auto store.. Its been good to go with no leaking and 100 shot for a year now!

#28

10 Second Club

iTrader: (25)

Join Date: Feb 2004

Location: Canada

Posts: 1,240

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by waterbug1999

It's not as bad as it looks.

Scotchbrite here as well, followed with the 3M pad they sale at the auto store.. Its been good to go with no leaking and 100 shot for a year now!

Scotchbrite here as well, followed with the 3M pad they sale at the auto store.. Its been good to go with no leaking and 100 shot for a year now!

#30

11 Second Club

iTrader: (19)

Join Date: May 2006

Location: Whidbey Island, Wa.

Posts: 965

Likes: 0

Received 0 Likes

on

0 Posts

Hey how hard do you have to push down on your angled cutter to cutt the Eyebrow? Is it pretty slow going? And also, how do you end up getting all of the debris out of the cylinder's?

Lane

Lane

#32

On The Tree

Thread Starter

iTrader: (2)

Join Date: Feb 2004

Location: Pewaukee, WI

Posts: 143

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by crazylane

Hey how hard do you have to push down on your angled cutter to cutt the Eyebrow? Is it pretty slow going? And also, how do you end up getting all of the debris out of the cylinder's?

Lane

Lane

The only notable thing I noticed about cutting...is when you first start the cut, since you're cutting in at an angle, the tool tends to dig in and bind up...hard...to the point you cannot turn it anymore. Although it's probably not best for the life of the tool, I found by starting the initial cut by running the tool backwards (ccw) by hand for the first few turns it helped get by that problem, once the tool was "in" and began cutting a flat surface, it then turned smoothly.

As for chip removal, I used a small shop vac with a tip that tapered down to about a pencil-sized opening. After each cut, I pulled the head off, and vac'd out the chips (which is more like dust), and checked the depth. After doing a couple cyls, you learn to gauge the depth of cut easily just by looking at the width of the eyebrow.

It really is pretty easy. Just take your time on the first cut, get a feel for the tool and the rate of material removal, and although still a little tedious with the on/off action of the head, you'll find it goes pretty quickly.

Just be very meticulous in cleanup and spin the motor over several times, cleaning/wiping out each cyl when the piston is down, and make absolutely sure you got all the chips out.

#34

UNDER PRESSURE MOD

iTrader: (19)

I've got a question. Can you take a junked cylinder head and cut off like two and a half cylinders so it's easier to put on and off? All you really need at one time is the one cylinder bore, so having the other three just makes it more difficult to pull and re-install the head, especially those of us with head studs and f-bodies.

#35

On The Tree

Thread Starter

iTrader: (2)

Join Date: Feb 2004

Location: Pewaukee, WI

Posts: 143

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by The Alchemist

I've got a question. Can you take a junked cylinder head and cut off like two and a half cylinders so it's easier to put on and off? All you really need at one time is the one cylinder bore, so having the other three just makes it more difficult to pull and re-install the head, especially those of us with head studs and f-bodies.

I'm not sure if all the head boltholes in the head are large enough to accommodate these. If they are, then no problem...if not, you'd just have to bore out the other lower bolthole in the "single cyl head" you created until it slid over the roll pin.

#36

TECH Enthusiast

iTrader: (42)

Join Date: Mar 2006

Location: Gettysburg, PA

Posts: 725

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by Thimble

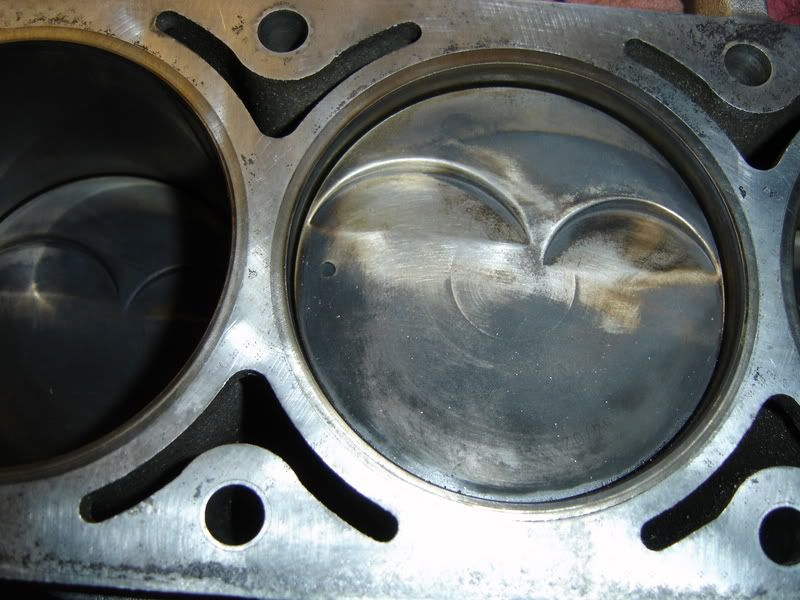

I ended up cutting with the piston about 1/8" down in the bore...since that's about how much the cutter extended out of the head chamber.

I set up the cutter in the head, placed the head on the block, then slowly rotated the engine until the piston just about touched the cutter, then cut. It worked out just fine. When I clayed the heads, the valve dropped slightly below, but still well within in the notch. I cut the notch .100" deep, clayed, and ended up with about .095" valve clearance (clay thickness).

I did not have to notch for the exhaust valve, had a ton of clearance there.

Finished this up Monday morning, car is running extremely well and strong with no issues. The power difference of the heads and added compression is amazing...a nigh and day difference from cam-only.

I set up the cutter in the head, placed the head on the block, then slowly rotated the engine until the piston just about touched the cutter, then cut. It worked out just fine. When I clayed the heads, the valve dropped slightly below, but still well within in the notch. I cut the notch .100" deep, clayed, and ended up with about .095" valve clearance (clay thickness).

I did not have to notch for the exhaust valve, had a ton of clearance there.

Finished this up Monday morning, car is running extremely well and strong with no issues. The power difference of the heads and added compression is amazing...a nigh and day difference from cam-only.

#37

10 Second Club

iTrader: (35)

Join Date: Feb 2005

Location: Indiana boy

Posts: 4,174

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by waterbug1999

The 3M soft bristle round pad you put in a drill. Its made out of some rubberish kind of material.. I dont know the name of it just saw a guy use it before on this site and it works pretty well.

I use them in my body shop all the time.

On a side note, I wet sanded my deck surface on the block with 1000 grit for an ultra fine finish for sealing. And used copper gasket spray on the cometic .040" gaskets.

Also for some of you wondering. I fly cut mine to .145". I know that's a ton. But I've had no problems. And I can fit any cam size I want with a 58cc head and a .040" gasket. Just thought I would throw that out there for you guys.

#38

10 Second Club

iTrader: (3)

Originally Posted by JRracing

It's a 3M rolock scotch disc. They come in all sorts of sizes and color. The color indicates the coarseness of it from fine to course.

I use them in my body shop all the time.

On a side note, I wet sanded my deck surface on the block with 1000 grit for an ultra fine finish for sealing. And used copper gasket spray on the cometic .040" gaskets.

Also for some of you wondering. I fly cut mine to .145". I know that's a ton. But I've had no problems. And I can fit any cam size I want with a 58cc head and a .040" gasket. Just thought I would throw that out there for you guys.

I use them in my body shop all the time.

On a side note, I wet sanded my deck surface on the block with 1000 grit for an ultra fine finish for sealing. And used copper gasket spray on the cometic .040" gaskets.

Also for some of you wondering. I fly cut mine to .145". I know that's a ton. But I've had no problems. And I can fit any cam size I want with a 58cc head and a .040" gasket. Just thought I would throw that out there for you guys.

#39

On The Tree

Thread Starter

iTrader: (2)

Join Date: Feb 2004

Location: Pewaukee, WI

Posts: 143

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by JRracing

Also for some of you wondering. I fly cut mine to .145".

I kept referring to your pics, then looking at my cuts, then measuring, then comparing again, measuring again, and finally thinking...damn, he cut his deep.