Performance Designs XS intake

#21

Edit:

-----

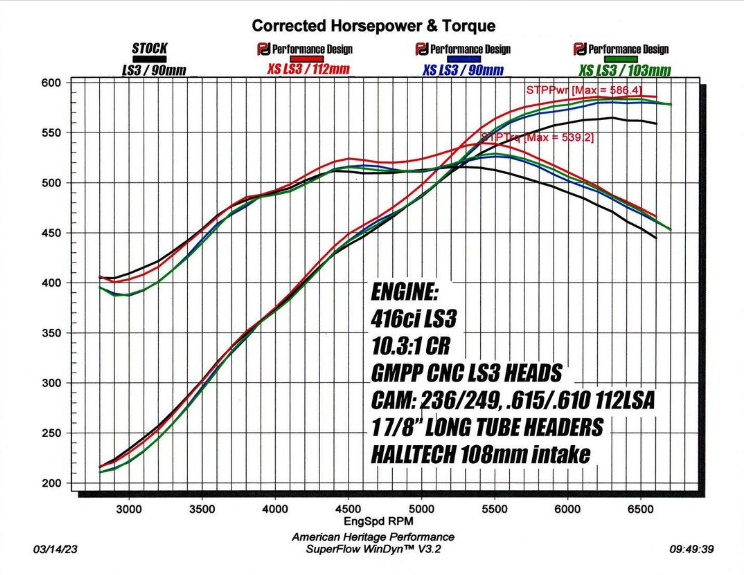

We posted the AHP test which compared it to the stock intake. We haven’t posted anything with a competitor’s intake yet.

-----

Please see the attached photo. This was also posted on our Instagram and Facebook.

-----

Last edited by JimMueller; 04-17-2023 at 11:12 AM.

The following users liked this post:

Double06 (04-23-2023)

#23

I want to see a dyno test on an SBE LS3, because the gains might not be as significant. Plus, the biggest gain was had with a 112MM TB, which would add to the cost of the swap. Without it, I don't know if I'd want to deal with the loss of torque under 4000 RPM. That's where I spend a lot of my time, given my car is 99% street. Someone definitely needs to test this against a ported rod mod.

#24

I want to see a dyno test on an SBE LS3, because the gains might not be as significant. Plus, the biggest gain was had with a 112MM TB, which would add to the cost of the swap. Without it, I don't know if I'd want to deal with the loss of torque under 4000 RPM. That's where I spend a lot of my time, given my car is 99% street. Someone definitely needs to test this against a ported rod mod.

#25

Inside of that intake looks like a huge restriction in flow compared to stock LS3 intake. Looks like its all pancaked in there too tight.

After 15 years of development you think they would have finally made an LS style intake that has the runners facing forward getting fed direct ram air from the TB......the way it should be to actually make the engine breath easier instead of relying 100% on the cylinders doing all the work pulling air into the runners.

After 15 years of development you think they would have finally made an LS style intake that has the runners facing forward getting fed direct ram air from the TB......the way it should be to actually make the engine breath easier instead of relying 100% on the cylinders doing all the work pulling air into the runners.

#27

I'm curious to, maybe someone who designs intakes will figure it out one day. Until then we have a bunch of cheesy intakes to choose from. Thats why sheet metal intakes work so well, they aren't all jammed up inside like pancakes.

#28

I don't recall seeing any long runner metal intakes with common plenum except for the CrossRam or ITBs, whose runners still cross banks. Sheet metal generally has short runners, which sacrifices area under the curve under 6000rpm. If someone wants that design in nylon, then they should just get the LSXT with red runners. And if I'm dreaming, may as well add auto adjustable runner lengths.

The following users liked this post:

G Atsma (04-25-2023)

#29

I don't think they're cheesy, they just want to have a larger market. A larger market makes the RoI easier. Most people don't want to chop their cowl or hood, lower their engine block, or significantly change the induction system in front of the throttle body. All those changes raise the owner's investment and potentially add complexity to future maintenance, and that gets weighed against the subjective value of those gains to the long term costs.

I don't recall seeing any long runner metal intakes with common plenum except for the CrossRam or ITBs, whose runners still cross banks. Sheet metal generally has short runners, which sacrifices area under the curve under 6000rpm. If someone wants that design in nylon, then they should just get the LSXT with red runners. And if I'm dreaming, may as well add auto adjustable runner lengths.

I don't recall seeing any long runner metal intakes with common plenum except for the CrossRam or ITBs, whose runners still cross banks. Sheet metal generally has short runners, which sacrifices area under the curve under 6000rpm. If someone wants that design in nylon, then they should just get the LSXT with red runners. And if I'm dreaming, may as well add auto adjustable runner lengths.

Boosted, we know there's no difference either.

So we are all still waiting for that intake company to design an UN-cheesy, crappy flowing intake. Or, sheet metal intake prices come down and everyone will just buy those.

#30

Well, that LS7 will make torque on accident. Customers bitch about adding a $900 TB, a $2500 ITB setup, etc. They'll all jump on a $4500 sheet metal intake  Maybe call Wilson and give them your ideas on the design and marketing strategy.

Maybe call Wilson and give them your ideas on the design and marketing strategy.

Maybe call Wilson and give them your ideas on the design and marketing strategy.

Maybe call Wilson and give them your ideas on the design and marketing strategy.

#32

I think they're extremely cheesy. Again, what proves they are extremely cheesy is how sheet metal intakes crush them in power production. Why, they have proper and common sense flow into the intake and then into the runners. And all the talk about how using a sheet metal intake is a dog or bad on power down low and mid range compared to the OEM style......take a ride in a 650 RWHP N/A 427ci LS Fbody with a Wilson sheet metal intake on it, I have.....tell me you feel it has low power down low and mid range.....its ridiculous and we keep hearing this same statement since 1998. The only place these lower low-mid range numbers show up is on a computer generated dyno graph. A sheet metal car will smoke the tires through the 1/8th mile with drag radials on the street, there is no noticable difference in power in any street car going from a plastic OEM style intake to a sheet metal intake as long as it's not a factory stock engine. If its a medium to heavy modded N/A engine there's no difference to feel.

Boosted, we know there's no difference either.

So we are all still waiting for that intake company to design an UN-cheesy, crappy flowing intake. Or, sheet metal intake prices come down and everyone will just buy those.

Boosted, we know there's no difference either.

So we are all still waiting for that intake company to design an UN-cheesy, crappy flowing intake. Or, sheet metal intake prices come down and everyone will just buy those.

#33

I think they're extremely cheesy. Again, what proves they are extremely cheesy is how sheet metal intakes crush them in power production. Why, they have proper and common sense flow into the intake and then into the runners. And all the talk about how using a sheet metal intake is a dog or bad on power down low and mid range compared to the OEM style......take a ride in a 650 RWHP N/A 427ci LS Fbody with a Wilson sheet metal intake on it, I have.....tell me you feel it has low power down low and mid range.....its ridiculous and we keep hearing this same statement since 1998. The only place these lower low-mid range numbers show up is on a computer generated dyno graph. A sheet metal car will smoke the tires through the 1/8th mile with drag radials on the street, there is no noticable difference in power in any street car going from a plastic OEM style intake to a sheet metal intake as long as it's not a factory stock engine. If its a medium to heavy modded N/A engine there's no difference to feel.

Boosted, we know there's no difference either.

So we are all still waiting for that intake company to design an UN-cheesy, crappy flowing intake. Or, sheet metal intake prices come down and everyone will just buy those.

Boosted, we know there's no difference either.

So we are all still waiting for that intake company to design an UN-cheesy, crappy flowing intake. Or, sheet metal intake prices come down and everyone will just buy those.

The following 2 users liked this post by Che70velle:

G Atsma (04-26-2023), JimMueller (04-25-2023)

#34

The factor not taken i to account in regards to sheet metal is heatsoak... if a true street car on a warm to hot day a plastic intake will be up a lot of hp on a sheet metal.

I could tell the difference when i tried a different air intake tube which heat soaked big time

I could tell the difference when i tried a different air intake tube which heat soaked big time

#35

The factor not taken i to account in regards to sheet metal is heatsoak... if a true street car on a warm to hot day a plastic intake will be up a lot of hp on a sheet metal.

I could tell the difference when i tried a different air intake tube which heat soaked big time

I could tell the difference when i tried a different air intake tube which heat soaked big time

#36

#37

All it takes is a compression mold and pour in some Nylon 66 plastic pellets, let it melt, form and cool. Put it together and see what you get. If itís the identical specs of a known sheet metal intake thatís low-profile and fits under factory Camaro/Firebird Fbody hoods, then it will perform the same, or better without all the heat soak. Iím not interested in trying that investment because itís not my field of expertise and Iím going the booster route so it means nothing to me.

Im just shocked an intake company like Wilson hasnít done it. They would make 10 times the money selling an affordable plastic intake to the masses compared to a few high priced sheet metal intakes.

The following users liked this post:

G Atsma (04-26-2023)

#39

I also remember many idiots back in 1999-2000 saying thereís no need for TBís larger than 90mm. SOÖÖ

All it takes is a compression mold and pour in some Nylon 66 plastic pellets, let it melt, form and cool. Put it together and see what you get. If itís the identical specs of a known sheet metal intake thatís low-profile and fits under factory Camaro/Firebird Fbody hoods, then it will perform the same, or better without all the heat soak. Iím not interested in trying that investment because itís not my field of expertise and Iím going the booster route so it means nothing to me.

Im just shocked an intake company like Wilson hasnít done it. They would make 10 times the money selling an affordable plastic intake to the masses compared to a few high priced sheet metal intakes.

All it takes is a compression mold and pour in some Nylon 66 plastic pellets, let it melt, form and cool. Put it together and see what you get. If itís the identical specs of a known sheet metal intake thatís low-profile and fits under factory Camaro/Firebird Fbody hoods, then it will perform the same, or better without all the heat soak. Iím not interested in trying that investment because itís not my field of expertise and Iím going the booster route so it means nothing to me.

Im just shocked an intake company like Wilson hasnít done it. They would make 10 times the money selling an affordable plastic intake to the masses compared to a few high priced sheet metal intakes.

The following users liked this post:

Double06 (05-20-2023)

#40

As I'm needing to install an aftermarket FPR, it definitely looks to be a challenge to connect such an FPR directly to the rail (most commonly suggested location) with this manifold. If I were to ever purchase this manifold, I wouldn't want to re-engineer the FPR location.