What is this inside my oil pan?

#22

TECH Junkie

iTrader: (9)

Hmmm I've been hearing about this excessive oil consumption issue from a few truck owners now. They had no idea what it was but now Im thinking it might be best to just leave the valve off the build im doing instead. It sure would suck *** though if I pushed too much oil pressure. I have to remove the engine to get the pan off ( swap car ) so it would be MUCH easier to do this now.

Thoughts? Is the deflector available yet?

Actually maybe I should just make my own deflector and then run the bypass.

What to do?

Thoughts? Is the deflector available yet?

Actually maybe I should just make my own deflector and then run the bypass.

What to do?

#23

It appears the thread size is 14x1.5mm I am unsure the type of tap to use though. (tapper/bottom/plug) prices on mcmaster-car start at $26.00 I wish someone with solid experience would chime in ( I get the "run-a-round" both times when I called MAST Motorsports. )

)

not the way to be when they want people to purchase their products. Just my .02

)

)not the way to be when they want people to purchase their products. Just my .02

#24

TECH Junkie

iTrader: (9)

It appears the thread size is 14x1.5mm I am unsure the type of tap to use though. (tapper/bottom/plug) prices on mcmaster-car start at $26.00 I wish someone with solid experience would chime in ( I get the "run-a-round" both times when I called MAST Motorsports. )

)

not the way to be when they want people to purchase their products. Just my .02

)

)not the way to be when they want people to purchase their products. Just my .02

As for someone from GM chiming in? Dont hold your breath because that would be so damn impacting in all the right ways it would actually boost their appeal and image on a global standard but hey why would they want to do that? They've always got the Gov't to bail them out when they screw everything up again and guys like us posting on these boards figuring out problems for them too LOL

#25

10 Second Club

iTrader: (4)

Join Date: Oct 2006

Location: wisconsin

Posts: 855

Likes: 0

Received 0 Likes

on

0 Posts

a 1/4" pipe plug threads in just fine, when i built my engine i thought about plugging it and changed my mind at the last minute because i didnt fully know its purpose at the time, if i even have my pan off for anything i will be taking the valve out and pipe plug back in.

#26

TECH Junkie

iTrader: (9)

a 1/4" pipe plug threads in just fine, when i built my engine i thought about plugging it and changed my mind at the last minute because i didnt fully know its purpose at the time, if i even have my pan off for anything i will be taking the valve out and pipe plug back in.

I was thinking of welding a simple hat type deflector on it first though

#30

FormerVendor

Join Date: Mar 2007

Location: Nacogdoches, TX

Posts: 182

Likes: 0

Received 0 Likes

on

0 Posts

It appears the thread size is 14x1.5mm I am unsure the type of tap to use though. (tapper/bottom/plug) prices on mcmaster-car start at $26.00 I wish someone with solid experience would chime in ( I get the "run-a-round" both times when I called MAST Motorsports. )

)

not the way to be when they want people to purchase their products. Just my .02

)

)not the way to be when they want people to purchase their products. Just my .02

This is an Oil Pressure relief valve and is not a necessary part to run with your engine. You will be fine without it as stated before. If you have any further questions please let me know! If I don't know what the answer is I will find out!

Thank You,

#31

My oil pressure relief valve IS 14x1.5mm and a 1/4 plug WILL NOT WORK. Just for the record. LOL

#33

Agree on the tap size. I drilled and tapped the hole in my GM "muscle car" pan based on the 1/4-inch NPT info and the valve won't thread into the hole - not even close.

INTERESTINGLY, I can thread both the 1/4 NPT tap and a 1/4 NPT to AN adapter almost all the way down the hole in the original oil pan. The metric dimensions are very close in size to 1/4 NPT, but the metric is a little bit bigger.

Sounds like I can plug the hole I just spent 2 days and $20 in drill bits and taps trying to drill

INTERESTINGLY, I can thread both the 1/4 NPT tap and a 1/4 NPT to AN adapter almost all the way down the hole in the original oil pan. The metric dimensions are very close in size to 1/4 NPT, but the metric is a little bit bigger.

Sounds like I can plug the hole I just spent 2 days and $20 in drill bits and taps trying to drill

Last edited by gheatly69; 09-28-2010 at 09:25 PM.

#34

ok yes I am a gm tech this is what I know

ok I hope the up load worked. the first pic. is of a gen iv dod block pan. the valve sticking up relives oil pressure at about 55psi aprox (gm gives no spec on this that I can find). I have seen lots stick open and cause no oil pressure. the second is of a gen iii block oil pan no relief pan.

gen iii 2004 5.3 1500 truck oil pressure specs.

6 psig at 1,000 engine RPM

18 psig at 2,000 engine RPM

24 psig at 4,000 engine RPM all specs at the pressure gauge on the top of the valley cover.

gen iv 2009 Yukon 5.3l dod block oil pressure specs.

22 psig at 1,000 engine RPM

30 psig at 2,000 engine RPM

33 psig at 3,000 engine RPM all specs at the pressure gauge on the top of the valley cover.

oil pressure from the pump on a dod block is rated at

55–75 psig Maximum measured at the filler before the bleed valve.

so the dod oil pump puts out much more pressure that is way they have the relief valve. also there is a little cover the when the valve is flowing oil will direct the oil to the pan it is $15. that will solve the oil consumption concern. gm has a bulletin out if the pan is off we are to install this cover. never put a pan on with out the cover.

Question is will the extra oil pressure from a dod pump hurt my gen iv engine if I am running a gen iii pan cause it will not relive the extra pressure. or should I put a gen iii pump on my engine. I have taken out the dod cause they suck believe me I have fixed way to many of those lifters.

has any one run a gen iv block on the higher pressure pump with no relief valve without problems. ?

yes my specs are right out of gm si.

#36

On The Tree

iTrader: (1)

Join Date: May 2007

Location: Fort Lauderdale/Miami

Posts: 110

Likes: 0

Received 0 Likes

on

0 Posts

ok so i am also a GM tech- what Craiger stated above is 100% correct, and no those are most likely actual oil pressures he posted. every GM tech knows the oil press gauge on the cluster is what we call a 'dummy gauge'. when they read accurately, say 8 psi hot idle at 800 rpm everyone was loosing their ****. next thing i know, trucks (mainly) start coming out showing like 40 psi at idle  when the scan tool reads much much lower. which one is right? use a mechanical gauge if you dont believe me. however, those of you who think you need 20-30 psi at 800-1000 rpm are highly mistaken.

when the scan tool reads much much lower. which one is right? use a mechanical gauge if you dont believe me. however, those of you who think you need 20-30 psi at 800-1000 rpm are highly mistaken.

also i want to make a note- ALL GenIV trucks / cars do NOT have the same oil pump, as it seems to have been stated in here (or not stated but assumed). only the DOD vehicles have a much higher VOLUME and pressure pump. so much so, that Melling makes replacements and i found a flow chart recently, volume and psi. Melling even states on two pumps they make- do not use on non-DOD vehicles. As a tech who also does performance work, we only install those huge volume Melling pumps on piston sprayer LS's (not just LSA, we add that to other gen IV blocks too) with external oil coolers, BUT leave the valve in question in place, but with the above stated TSB shield. this way, during events where the oil squirters and cooler would overwhelm a stock gen 3 pump, they do not and get plenty of volume- but at events where the engine is overwhelmed and power would be lost from big pumping losses, the valve kicks in. if you take care of the engine, no sludge etc, the valve 99% wont stick as he stated- ive seen that but only on trucks that really werent cared for with lots of miles.

SO what pump should I use...? You can do the following:

Gen 3 or 4 without DOD- performance option is Melling 10296. You need no valve for this, it can be plugged in gen 4. it also produces like 15% more volume and 10% more pressure (comes with a stock psi spring as well).

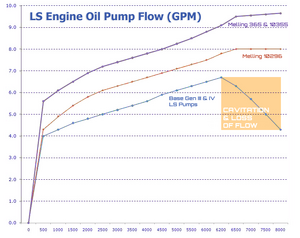

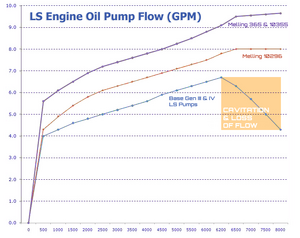

see this shows you just how much more flow and pressure the genIV on DOD uses. Melling 365 is a direct replacement DOD pump- so its numbers on this chart represent how much work GM put into the DOD pumps- it crushes the LS gen3 ported, worked over Melling 10296. But, you do not need that kind of flow unless you have things like i mentioned above. LPE's pump is a modded/ported Melling 365, so again DO NOT pull the valve if running one of those pumps. Just go get the shield and clean out the valve. Me personally, im building an L99 motor right now. I have ripped out VVT (going into a gen3 truck) and DOD obviously. I am going to use the L99 pan, with the valve removed/plugged with a Melling 10296. Hopefully everyone can understand me, i tend to rant on sometimes lol. hope this helps!

John

when the scan tool reads much much lower. which one is right? use a mechanical gauge if you dont believe me. however, those of you who think you need 20-30 psi at 800-1000 rpm are highly mistaken.

when the scan tool reads much much lower. which one is right? use a mechanical gauge if you dont believe me. however, those of you who think you need 20-30 psi at 800-1000 rpm are highly mistaken. also i want to make a note- ALL GenIV trucks / cars do NOT have the same oil pump, as it seems to have been stated in here (or not stated but assumed). only the DOD vehicles have a much higher VOLUME and pressure pump. so much so, that Melling makes replacements and i found a flow chart recently, volume and psi. Melling even states on two pumps they make- do not use on non-DOD vehicles. As a tech who also does performance work, we only install those huge volume Melling pumps on piston sprayer LS's (not just LSA, we add that to other gen IV blocks too) with external oil coolers, BUT leave the valve in question in place, but with the above stated TSB shield. this way, during events where the oil squirters and cooler would overwhelm a stock gen 3 pump, they do not and get plenty of volume- but at events where the engine is overwhelmed and power would be lost from big pumping losses, the valve kicks in. if you take care of the engine, no sludge etc, the valve 99% wont stick as he stated- ive seen that but only on trucks that really werent cared for with lots of miles.

SO what pump should I use...? You can do the following:

Gen 3 or 4 without DOD- performance option is Melling 10296. You need no valve for this, it can be plugged in gen 4. it also produces like 15% more volume and 10% more pressure (comes with a stock psi spring as well).

see this shows you just how much more flow and pressure the genIV on DOD uses. Melling 365 is a direct replacement DOD pump- so its numbers on this chart represent how much work GM put into the DOD pumps- it crushes the LS gen3 ported, worked over Melling 10296. But, you do not need that kind of flow unless you have things like i mentioned above. LPE's pump is a modded/ported Melling 365, so again DO NOT pull the valve if running one of those pumps. Just go get the shield and clean out the valve. Me personally, im building an L99 motor right now. I have ripped out VVT (going into a gen3 truck) and DOD obviously. I am going to use the L99 pan, with the valve removed/plugged with a Melling 10296. Hopefully everyone can understand me, i tend to rant on sometimes lol. hope this helps!

John

#38

ok so i am also a GM tech- what Craiger stated above is 100% correct, and no those are most likely actual oil pressures he posted. every GM tech knows the oil press gauge on the cluster is what we call a 'dummy gauge'. when they read accurately, say 8 psi hot idle at 800 rpm everyone was loosing their ****. next thing i know, trucks (mainly) start coming out showing like 40 psi at idle  when the scan tool reads much much lower. which one is right? use a mechanical gauge if you dont believe me. however, those of you who think you need 20-30 psi at 800-1000 rpm are highly mistaken.

when the scan tool reads much much lower. which one is right? use a mechanical gauge if you dont believe me. however, those of you who think you need 20-30 psi at 800-1000 rpm are highly mistaken.

also i want to make a note- ALL GenIV trucks / cars do NOT have the same oil pump, as it seems to have been stated in here (or not stated but assumed). only the DOD vehicles have a much higher VOLUME and pressure pump. so much so, that Melling makes replacements and i found a flow chart recently, volume and psi. Melling even states on two pumps they make- do not use on non-DOD vehicles. As a tech who also does performance work, we only install those huge volume Melling pumps on piston sprayer LS's (not just LSA, we add that to other gen IV blocks too) with external oil coolers, BUT leave the valve in question in place, but with the above stated TSB shield. this way, during events where the oil squirters and cooler would overwhelm a stock gen 3 pump, they do not and get plenty of volume- but at events where the engine is overwhelmed and power would be lost from big pumping losses, the valve kicks in. if you take care of the engine, no sludge etc, the valve 99% wont stick as he stated- ive seen that but only on trucks that really werent cared for with lots of miles.

SO what pump should I use...? You can do the following:

Gen 3 or 4 without DOD- performance option is Melling 10296. You need no valve for this, it can be plugged in gen 4. it also produces like 15% more volume and 10% more pressure (comes with a stock psi spring as well).

see this shows you just how much more flow and pressure the genIV on DOD uses. Melling 365 is a direct replacement DOD pump- so its numbers on this chart represent how much work GM put into the DOD pumps- it crushes the LS gen3 ported, worked over Melling 10296. But, you do not need that kind of flow unless you have things like i mentioned above. LPE's pump is a modded/ported Melling 365, so again DO NOT pull the valve if running one of those pumps. Just go get the shield and clean out the valve. Me personally, im building an L99 motor right now. I have ripped out VVT (going into a gen3 truck) and DOD obviously. I am going to use the L99 pan, with the valve removed/plugged with a Melling 10296. Hopefully everyone can understand me, i tend to rant on sometimes lol. hope this helps!

John

when the scan tool reads much much lower. which one is right? use a mechanical gauge if you dont believe me. however, those of you who think you need 20-30 psi at 800-1000 rpm are highly mistaken.

when the scan tool reads much much lower. which one is right? use a mechanical gauge if you dont believe me. however, those of you who think you need 20-30 psi at 800-1000 rpm are highly mistaken.also i want to make a note- ALL GenIV trucks / cars do NOT have the same oil pump, as it seems to have been stated in here (or not stated but assumed). only the DOD vehicles have a much higher VOLUME and pressure pump. so much so, that Melling makes replacements and i found a flow chart recently, volume and psi. Melling even states on two pumps they make- do not use on non-DOD vehicles. As a tech who also does performance work, we only install those huge volume Melling pumps on piston sprayer LS's (not just LSA, we add that to other gen IV blocks too) with external oil coolers, BUT leave the valve in question in place, but with the above stated TSB shield. this way, during events where the oil squirters and cooler would overwhelm a stock gen 3 pump, they do not and get plenty of volume- but at events where the engine is overwhelmed and power would be lost from big pumping losses, the valve kicks in. if you take care of the engine, no sludge etc, the valve 99% wont stick as he stated- ive seen that but only on trucks that really werent cared for with lots of miles.

SO what pump should I use...? You can do the following:

Gen 3 or 4 without DOD- performance option is Melling 10296. You need no valve for this, it can be plugged in gen 4. it also produces like 15% more volume and 10% more pressure (comes with a stock psi spring as well).

see this shows you just how much more flow and pressure the genIV on DOD uses. Melling 365 is a direct replacement DOD pump- so its numbers on this chart represent how much work GM put into the DOD pumps- it crushes the LS gen3 ported, worked over Melling 10296. But, you do not need that kind of flow unless you have things like i mentioned above. LPE's pump is a modded/ported Melling 365, so again DO NOT pull the valve if running one of those pumps. Just go get the shield and clean out the valve. Me personally, im building an L99 motor right now. I have ripped out VVT (going into a gen3 truck) and DOD obviously. I am going to use the L99 pan, with the valve removed/plugged with a Melling 10296. Hopefully everyone can understand me, i tend to rant on sometimes lol. hope this helps!

John