Alum ERL 4.125 vs RHS

#21

TECH Enthusiast

iTrader: (4)

The Racing Head Service (RHS) block also has a raised camshaft location and can use roller camshaft bearings. The raised camshaft location will give you shorter pushrods. But, the RHS block requires a different front cover if I'm not mistaken.

The nice thing about the ERL block is that all the normal LS stuff bolts right up. No special covers or holes to be drilled and tapped.

Edit:

One additional feature the RHS block has over using a factory 5.3, 6.0, or 6.2 block is that the bay-to-bay breathing ports are built in. With the factory block you need a 7.0 version to get the enlarged ports. Now, I don't know if this can be machined open, but if it can it helps with applications that have high speed usage. If a vacuum pump can be used to offset this difference is something I would like to know.

The nice thing about the ERL block is that all the normal LS stuff bolts right up. No special covers or holes to be drilled and tapped.

Edit:

One additional feature the RHS block has over using a factory 5.3, 6.0, or 6.2 block is that the bay-to-bay breathing ports are built in. With the factory block you need a 7.0 version to get the enlarged ports. Now, I don't know if this can be machined open, but if it can it helps with applications that have high speed usage. If a vacuum pump can be used to offset this difference is something I would like to know.

Last edited by Gregory; 05-19-2013 at 11:21 PM. Reason: Added breathing port paragraph.

#22

TECH Enthusiast

iTrader: (4)

Last time I checked, about a year ago, you could bores finished at 4.125" or 4.165".

They do, but how "finished" is it is the question. Probably like some aftermarket parts say direct fit", but still need a little tweaking. Besides, RHS say nothing about the block being deck or align honed. I'm personally going with RHS myself, but I expect to have to do some small prepping though.

#23

TECH Fanatic

iTrader: (10)

Join Date: Mar 2011

Location: Miami gardens FL 33055

Posts: 1,023

Likes: 0

Received 0 Likes

on

0 Posts

Hello guys and girls, kindly the last time I checked the LS engine blocks have build in priority mains oiling system which means the crank rods cam and lifters get their oil first in that order, directly off the oil pump then the rockers, and it is an excellent oiling system.

The barbell in the back of the block on the drivers side at the end of the oil distribution channel, is there cause when the channel is drilled across, is done from both ends, and that end needs to be plugged, across the other end is the oil pump feeding the entire engine block with your favorite oil.

Please join me on a voice to let GM know, we are waiting on an aluminum version of the LSX block we can bore out to 4.250 with interchangeable cast iron cylinder sleeves.

That's all the block we need IMO.

Hopefully some one reading with the leverage to make it happen., will pass this on....

The barbell in the back of the block on the drivers side at the end of the oil distribution channel, is there cause when the channel is drilled across, is done from both ends, and that end needs to be plugged, across the other end is the oil pump feeding the entire engine block with your favorite oil.

Please join me on a voice to let GM know, we are waiting on an aluminum version of the LSX block we can bore out to 4.250 with interchangeable cast iron cylinder sleeves.

That's all the block we need IMO.

Hopefully some one reading with the leverage to make it happen., will pass this on....

#24

On The Tree

Join Date: Dec 2004

Location: Northville, Michigan

Posts: 124

Likes: 0

Received 0 Likes

on

0 Posts

Correction:

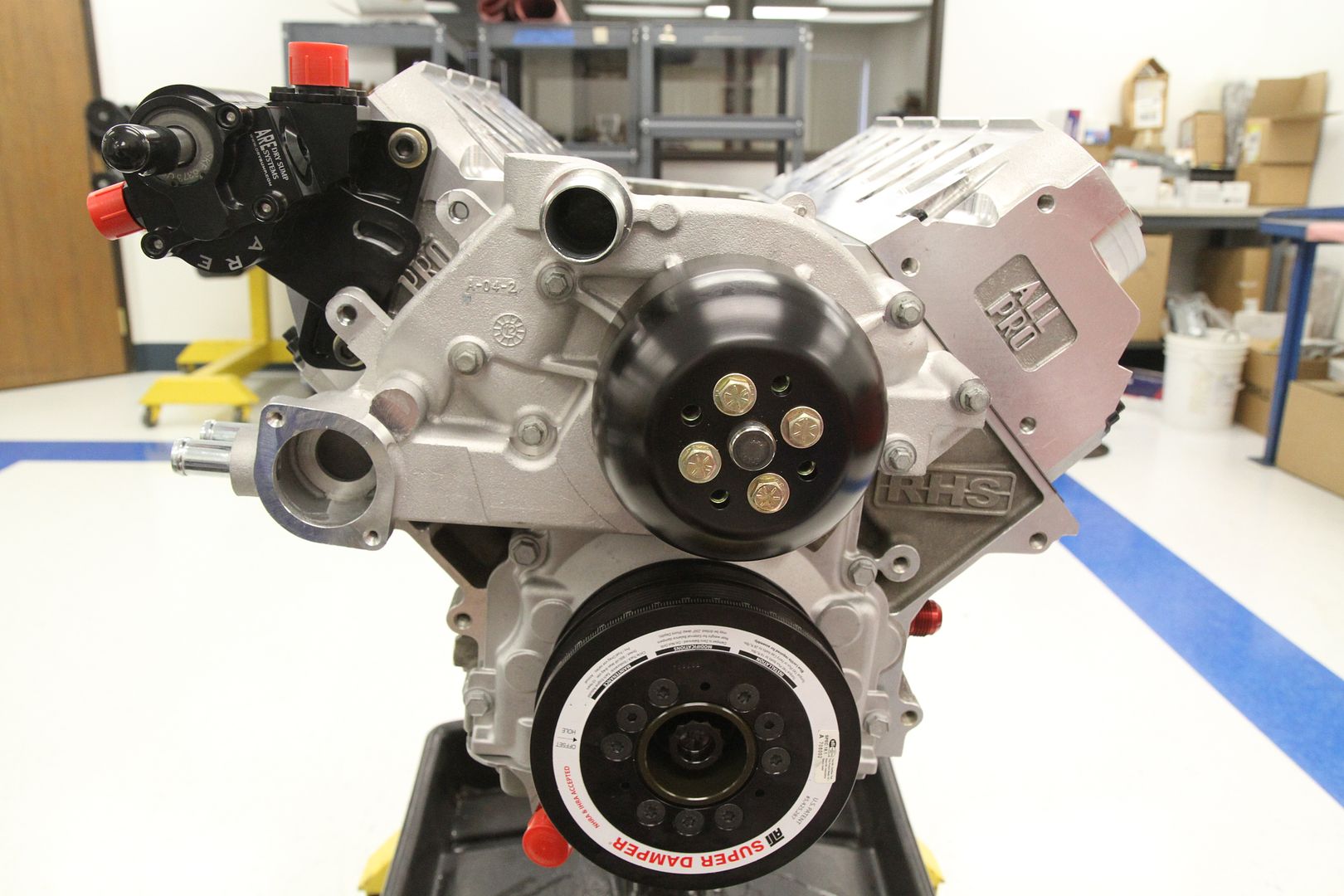

The RHS block uses the standard LS front cover:

#25

On The Tree

Join Date: Dec 2004

Location: Northville, Michigan

Posts: 124

Likes: 0

Received 0 Likes

on

0 Posts

By using the stock block as a base such as the ERL route, you are stuck with the factory oiling system. The RHS block uses a priority main system and removes the stupid barbell at the rear in the process. Better system to feed the critical bottom end in the case of low pressure/loss. I think the RHS block is already setup for dry sump should you choose.

You are correct, the RHS block is set up for a dry-sump system:

The two red AN fittings on the driver's side of my block are for use with a dry-sump system. I am using an A.R.E. system. The front fitting in my case is plumbed to go directly to my oil filters (2) and from there to my oil cooler. The rear fitting is where the oil comes back from the cooler and feeds directly to the mains.

With the RHS block you can use either an aftermarket external pressure pump or you can use the internal location for a Melling oil pump. And as you can read, I am using a Cloyes Hex-A-Just timing chain and gear set. If you look closely you can read where we had to slightly retard the timing set in order to match the cam manufacturer's specs.

#26

Banned

Join Date: Mar 2013

Location: Studewood/Acres-Homes TX.

Posts: 1,137

Likes: 0

Received 2 Likes

on

2 Posts

Camster:you may want to get in contact with Rocko Parker: Head of LSX cylinder head Division about. letting GM know, we are waiting on an aluminum version of the LSX block we can bore out to 4.250 with interchangeable cast iron cylinder sleeves.

#28

Banned

Join Date: Mar 2013

Location: Studewood/Acres-Homes TX.

Posts: 1,137

Likes: 0

Received 2 Likes

on

2 Posts

I'm not picky but RHS has CAST iron liners for 5000 dollars it would be nice to have Ductile Iron Sleeves I called RHS when the block 1st came out and they had no response about using cheaper sleeves....Kerry at Proline said that they should have done this and to resleeve RHS block is more than a ERL block with all the bells and whistles .....more than 3 grand to redo sleeves on the RHS. BORE limit is 4.165 I've seen some mags do more but that is for ratings and not for a street engine Hot Rod RHS tall deck with 4.185 bore is a little concerning for me...RHS has a damn good block just Cheap Sleeves.

#29

Moderator

iTrader: (20)

Hello guys and girls, kindly the last time I checked the LS engine blocks have build in priority mains oiling system which means the crank rods cam and lifters get their oil first in that order, directly off the oil pump then the rockers, and it is an excellent oiling system.

The oiling system on the OEM blocks is far from excellent, but it looks like the aftermarket blocks make it possible to fix it, or at least make it a little better. The new LT1 looks to have done the same as well.

#30

TECH Fanatic

iTrader: (10)

Join Date: Mar 2011

Location: Miami gardens FL 33055

Posts: 1,023

Likes: 0

Received 0 Likes

on

0 Posts

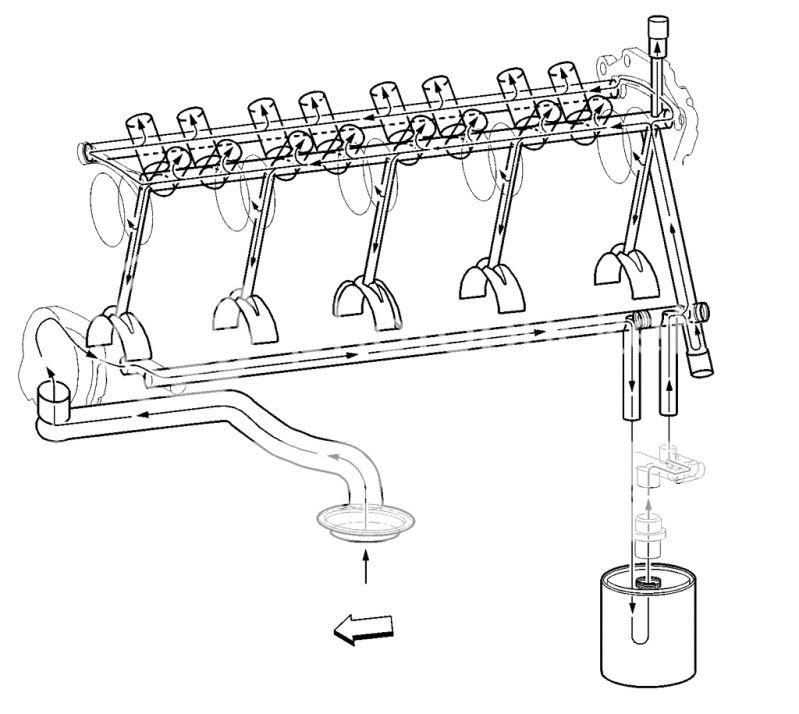

The OEM blocks are not actually priority main oiling. The oil is routed up to the lifters first, then the camshaft, then the crankshaft. The LSX, RHS, etc incorporate a third oil galley above the camshaft tunnel to oil the mains directly.

The oiling system on the OEM blocks is far from excellent, but it looks like the aftermarket blocks make it possible to fix it, or at least make it a little better. The new LT1 looks to have done the same as well.

The oiling system on the OEM blocks is far from excellent, but it looks like the aftermarket blocks make it possible to fix it, or at least make it a little better. The new LT1 looks to have done the same as well.

I stand my ground in the fact that the LSX block is the best available block there is to this day, sure I have to admit is heavy but then it more than lift itself up in the air over anything else out there.

I use it myself and the extra weight in the block can surely be removed from some where else, I call it weight management, is not hard to remove 140 lbs. from the front of a car to have the benefit of a rock solid foundation, not to mention a real LSX block cause nothing else is, so you can arguably have a real LSX engine.

The Earl block with the 6 head bolts obtion configuration forge mains longer sleeves and 4.185 bore IMO is the best practical light weight option.

#31

Moderator

iTrader: (20)

It is not my style or my intentions ever to enter in to conflict with any one over any point of working mechanics, but I also don't gather information from anyone I storied and followed the oiling system internal galleries and you just can't miss the oil taking a straight shot at the main first which is where the rod bearings pick up their oil then simultaneously the camshaft bearings.

The oil is routed from the filter up to the two passages parallel to the cam tunnel. These passages intersect the lifter bores, so they are the first to receive oil. From there, the oil makes its way towards the mains, oiling the camshaft first before it reaches the mains.

Now the aftermarket blocks look like this:

This is a cut away cross section of a Dart block. The LSX, RHS, and Warhawk are all pretty much the same. The two oil passages that run through to all of the lifters are still there, but a third oil passage is incorporated along the cam tunnel which receives oil from the filter, and it oils directly to the mains. This is the difference between the OEM block that are not priority main oiling because the oil feeds the lifters and cam before the mains, and the aftermarket priority main oiling which oils the mains directly.

#32

TECH Fanatic

iTrader: (10)

Join Date: Mar 2011

Location: Miami gardens FL 33055

Posts: 1,023

Likes: 0

Received 0 Likes

on

0 Posts

I won't take any credit from any of the aftermarket blocks though I have not use them because the price tag.

PUMBA:

I know doctile iron is better than cast iron however both are cast iron, and when heat treated can be extremely hard.

KCS;

Now understand why I'm running the LSX block.

Going back to the LS OEM blocks GM calls it priority mains, while the front and much desirable additional oil passage is not there, the tunnel true the center of the block does take the oil a clean straight shot to the mains, this is physically obvious looking in from back of the block, there's no obstruction for the oil to get a straight shot to the mains straight from that channel, the only argument you may have is that; the oil channel itself is closer distance to the camshaft mains that it is to the crankshaft mains, regardless it is still an unrestricted and generous straight channel oiling each main directly, before going anywhere else, and every one LS enthusiast should take comfort in that.

PUMBA:

I know doctile iron is better than cast iron however both are cast iron, and when heat treated can be extremely hard.

KCS;

Now understand why I'm running the LSX block.

Going back to the LS OEM blocks GM calls it priority mains, while the front and much desirable additional oil passage is not there, the tunnel true the center of the block does take the oil a clean straight shot to the mains, this is physically obvious looking in from back of the block, there's no obstruction for the oil to get a straight shot to the mains straight from that channel, the only argument you may have is that; the oil channel itself is closer distance to the camshaft mains that it is to the crankshaft mains, regardless it is still an unrestricted and generous straight channel oiling each main directly, before going anywhere else, and every one LS enthusiast should take comfort in that.

#33

Moderator

iTrader: (20)

KCS;

Now understand why I'm running the LSX block.

Going back to the LS OEM blocks GM calls it priority mains, while the front and much desirable additional oil passage is not there, the tunnel true the center of the block does take the oil a clean straight shot to the mains, this is physically obvious looking in from back of the block, there's no obstruction for the oil to get a straight shot to the mains straight from that channel, the only argument you may have is that; the oil channel itself is closer distance to the camshaft mains that it is to the crankshaft mains, regardless it is still an unrestricted and generous straight channel oiling each main directly, before going anywhere else, and every one LS enthusiast should take comfort in that.

Now understand why I'm running the LSX block.

Going back to the LS OEM blocks GM calls it priority mains, while the front and much desirable additional oil passage is not there, the tunnel true the center of the block does take the oil a clean straight shot to the mains, this is physically obvious looking in from back of the block, there's no obstruction for the oil to get a straight shot to the mains straight from that channel, the only argument you may have is that; the oil channel itself is closer distance to the camshaft mains that it is to the crankshaft mains, regardless it is still an unrestricted and generous straight channel oiling each main directly, before going anywhere else, and every one LS enthusiast should take comfort in that.

#34

[/QUOTE]Now the aftermarket blocks look like this:

This is a cut away cross section of a Dart block. The LSX, RHS, and Warhawk are all pretty much the same. The two oil passages that run through to all of the lifters are still there, but a third oil passage is incorporated along the cam tunnel which receives oil from the filter, and it oils directly to the mains. This is the difference between the OEM block that are not priority main oiling because the oil feeds the lifters and cam before the mains, and the aftermarket priority main oiling which oils the mains directly.[/QUOTE]

Actually feeding oil directly at the bottom of the cam where the oil wedge is needed is a bad location. I don't remember the exact location from tests I've seen, but oil should be fed in at an angle greater than 90*( I believe 120*-130* is best) to where you want the oil wedge and where there is no load to create the best possible oil wedge. Look at where the main bearing feed is.

That type of "priority main" oiling can be done on a stock block when adding lifter bushings to regulate oil flow to the lifters. On dedicated road race or high spring pressure drag applications I recommend bronze lifter bushings for wear and oil control.

Actually with all the high HP drag as well as road race engines I see the stock oil routing hasn't been an issue and I don't believe GM changed the internal oil routing on any of their Lemans, GT, etc. engines. The only bearing I see starving for oil is the thrust due to the load put on the big turbo engines by the trans/convertor when line pressure isn't regulated and priority main doesn't help that.

This is a cut away cross section of a Dart block. The LSX, RHS, and Warhawk are all pretty much the same. The two oil passages that run through to all of the lifters are still there, but a third oil passage is incorporated along the cam tunnel which receives oil from the filter, and it oils directly to the mains. This is the difference between the OEM block that are not priority main oiling because the oil feeds the lifters and cam before the mains, and the aftermarket priority main oiling which oils the mains directly.[/QUOTE]

Actually feeding oil directly at the bottom of the cam where the oil wedge is needed is a bad location. I don't remember the exact location from tests I've seen, but oil should be fed in at an angle greater than 90*( I believe 120*-130* is best) to where you want the oil wedge and where there is no load to create the best possible oil wedge. Look at where the main bearing feed is.

That type of "priority main" oiling can be done on a stock block when adding lifter bushings to regulate oil flow to the lifters. On dedicated road race or high spring pressure drag applications I recommend bronze lifter bushings for wear and oil control.

Actually with all the high HP drag as well as road race engines I see the stock oil routing hasn't been an issue and I don't believe GM changed the internal oil routing on any of their Lemans, GT, etc. engines. The only bearing I see starving for oil is the thrust due to the load put on the big turbo engines by the trans/convertor when line pressure isn't regulated and priority main doesn't help that.

#35

Moderator

iTrader: (20)

Actually feeding oil directly at the bottom of the cam where the oil wedge is needed is a bad location. I don't remember the exact location from tests I've seen, but oil should be fed in at an angle greater than 90*( I believe 120*-130* is best) to where you want the oil wedge and where there is no load to create the best possible oil wedge. Look at where the main bearing feed is.

That type of "priority main" oiling can be done on a stock block when adding lifter bushings to regulate oil flow to the lifters. On dedicated road race or high spring pressure drag applications I recommend bronze lifter bushings for wear and oil control.

That type of "priority main" oiling can be done on a stock block when adding lifter bushings to regulate oil flow to the lifters. On dedicated road race or high spring pressure drag applications I recommend bronze lifter bushings for wear and oil control.

Actually with all the high HP drag as well as road race engines I see the stock oil routing hasn't been an issue and I don't believe GM changed the internal oil routing on any of their Lemans, GT, etc. engines. The only bearing I see starving for oil is the thrust due to the load put on the big turbo engines by the trans/convertor when line pressure isn't regulated and priority main doesn't help that.