Ls2 custom Cam design

#21

Old School Heavy

iTrader: (16)

Thanks for all that info guys....

I want something bigger than the 231/239, so maybe I should just go with the Titan King 236/244 and not mill my heads. I wanted to bump up the compression but not if I'll have ptv issues.

I'm going to talk to my guy and see how much it will cost to flycut the pistons.

Will running the Titan King kill my low end torque?

I want something bigger than the 231/239, so maybe I should just go with the Titan King 236/244 and not mill my heads. I wanted to bump up the compression but not if I'll have ptv issues.

I'm going to talk to my guy and see how much it will cost to flycut the pistons.

Will running the Titan King kill my low end torque?

If you wanted to get max lope and concentrate the power a little lower, you could get a custom cam of 233/241 110.5 +3. Cam Motion makes custom cams at no extra charge. You can order it with this custom grind # XA233/365-XA241/355-10.5+3.

Last edited by speedtigger; 06-07-2016 at 01:05 PM.

#22

TECH Senior Member

iTrader: (27)

Thanks for all that info guys....

I want something bigger than the 231/239, so maybe I should just go with the Titan King 236/244 and not mill my heads. I wanted to bump up the compression but not if I'll have ptv issues.

I'm going to talk to my guy and see how much it will cost to flycut the pistons.

Will running the Titan King kill my low end torque?

I want something bigger than the 231/239, so maybe I should just go with the Titan King 236/244 and not mill my heads. I wanted to bump up the compression but not if I'll have ptv issues.

I'm going to talk to my guy and see how much it will cost to flycut the pistons.

Will running the Titan King kill my low end torque?

#23

Speedtrigger...you mentioned different sized valves also possibly affecting ptv clearance.

I want to upgrade my valves to 2.02 and 1.57. Will that cause any additional ptv issues along with the mill?

Would flycutting solve my problem of wanting a bigger cam along with milled heads and slightly bigger valves?

What if I wanted to go 231/242 110.5 with a 15 degree overlap? Will that work with a mill and bigger valves....or does it need to stay 239 and 112.5 lsa to stay in clearance?

And yes I do.want it to sound nasty....I liked my last cam but every time I drove it I wanted a much heavier chop. I just dont want all the power concentrated over 3000 rpm

I want to upgrade my valves to 2.02 and 1.57. Will that cause any additional ptv issues along with the mill?

Would flycutting solve my problem of wanting a bigger cam along with milled heads and slightly bigger valves?

What if I wanted to go 231/242 110.5 with a 15 degree overlap? Will that work with a mill and bigger valves....or does it need to stay 239 and 112.5 lsa to stay in clearance?

And yes I do.want it to sound nasty....I liked my last cam but every time I drove it I wanted a much heavier chop. I just dont want all the power concentrated over 3000 rpm

Last edited by Fullblast; 06-07-2016 at 09:27 PM.

#26

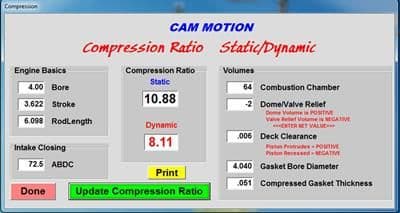

The ls2 compression ratio is 10.9:1 and if i mill the heads to .012 it will bump it to 11.3:1

Milled .015 I'll get 11.4:1

What's the best compression ratio for a street car on 93?

If I get them milled .012 instead of .020, would I be able to fit a 232/242 111 cam with 15 degrees overlap and the 2.02 and 1.57 valves?

Milled .015 I'll get 11.4:1

What's the best compression ratio for a street car on 93?

If I get them milled .012 instead of .020, would I be able to fit a 232/242 111 cam with 15 degrees overlap and the 2.02 and 1.57 valves?

#27

Old School Heavy

iTrader: (16)

The ls2 compression ratio is 10.9:1 and if i mill the heads to .012 it will bump it to 11.3:1

Milled .015 I'll get 11.4:1

What's the best compression ratio for a street car on 93?

If I get them milled .012 instead of .020, would I be able to fit a 232/242 111 cam with 15 degrees overlap and the 2.02 and 1.57 valves?

Milled .015 I'll get 11.4:1

What's the best compression ratio for a street car on 93?

If I get them milled .012 instead of .020, would I be able to fit a 232/242 111 cam with 15 degrees overlap and the 2.02 and 1.57 valves?

With .015" milled off, I get 11.22:1:

As far as valve clearance goes with a modified head, I would want to take a valve drop measurement when you were done. Aftermarket stainless valves will likely have a thicker margin and may have a different installed height when done. With all these variables, I would take a valve drop measurement before ordering your camshaft unless you intend to cut some valve-reliefs in your pistons.

#29

Old School Heavy

iTrader: (16)

Lots of guys have run 11-11.5:1 on 92-94 octane. As for the valves, if I was going to do anything to stock heads short of sending them for a full CNC, I would just have a very good performance machine shop put a nice 5 angle valve job on them and maybe a light bowl blend.

#32

I may just skip upgrading to bigger valves and get a valve job instead.

I'm considering just using a cometic .40 head gasket instead of milling the heads.

How reliable is the cometic .040 gasket compared to the mls .51? I would think the thicker gasket more reliable in the long run. I'm also using Arp head studs.

That should give me around 11.1:1 compression.

Could I use a 230/238 10.5+2 with 13 degree overlap with just the cometic .40?

I want a huge amount of chop while keeping torque and under the curve power.

That cam is similar to the titan 5 which is 232/238 113+4, but should have a better torque curve.

I'm considering just using a cometic .40 head gasket instead of milling the heads.

How reliable is the cometic .040 gasket compared to the mls .51? I would think the thicker gasket more reliable in the long run. I'm also using Arp head studs.

That should give me around 11.1:1 compression.

Could I use a 230/238 10.5+2 with 13 degree overlap with just the cometic .40?

I want a huge amount of chop while keeping torque and under the curve power.

That cam is similar to the titan 5 which is 232/238 113+4, but should have a better torque curve.

#33

Old School Heavy

iTrader: (16)

I may just skip upgrading to bigger valves and get a valve job instead.

I'm considering just using a cometic .40 head gasket instead of milling the heads.

How reliable is the cometic .040 gasket compared to the mls .51? I would think the thicker gasket more reliable in the long run. I'm also using Arp head studs.

That should give me around 11.1:1 compression.

Could I use a 230/238 10.5+2 with 13 degree overlap with just the cometic .40?

I want a huge amount of chop while keeping torque and under the curve power.

That cam is similar to the titan 5 which is 232/238 113+4, but should have a better torque curve.

I'm considering just using a cometic .40 head gasket instead of milling the heads.

How reliable is the cometic .040 gasket compared to the mls .51? I would think the thicker gasket more reliable in the long run. I'm also using Arp head studs.

That should give me around 11.1:1 compression.

Could I use a 230/238 10.5+2 with 13 degree overlap with just the cometic .40?

I want a huge amount of chop while keeping torque and under the curve power.

That cam is similar to the titan 5 which is 232/238 113+4, but should have a better torque curve.

#35

Old School Heavy

iTrader: (16)

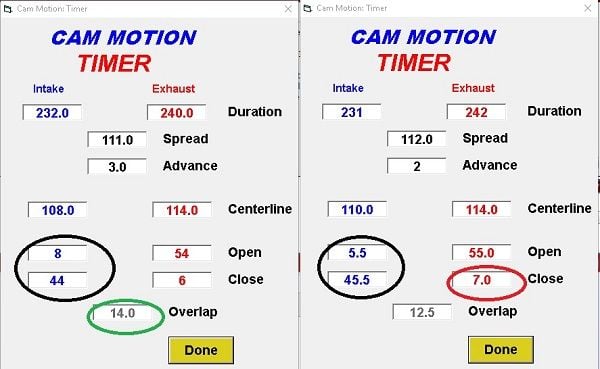

As you can see the 232/240 111+3 camshaft has earlier intake valve events and more overlap than the 231/242 112+2 camshaft. The earlier intake valve open will be more efficient at filling the cylinder and let the 232/240 111+3 camshaft make more power but the earlier intake valve close will bottle up more cylinder pressure through the lower RPM and mid-range for more torque which is what you said you wanted. Also, the additional overlap will give more thump to the idle which is the other characteristic that you specified. Since there is no extra cost to going with a custom camshaft, you might as well get exactly what you want.

#36

Looks good to me. I'm going with a Cam motion 232/240 111+3

How would that cam compare to the 228/232 in regards to driveability and bucking?

The only time it bucked was in parking lots or heavy traffic I could drive down the street in 6th gear no problem most of the time.

I have 3.42s now....would it help out a lot to go with 3.73s.....in regards to driveability and performance?

How would that cam compare to the 228/232 in regards to driveability and bucking?

The only time it bucked was in parking lots or heavy traffic I could drive down the street in 6th gear no problem most of the time.

I have 3.42s now....would it help out a lot to go with 3.73s.....in regards to driveability and performance?

#37

Old School Heavy

iTrader: (16)

It is going to buck and fuss more. That is the price of overlap. It will take more RPM for it to "clean up". I had a cam with 16 degrees of overlap and it would buck a bit as high as 1700 RPM under light loads. Going to a deeper gear does make it easier because it raises the RPM for a given speed.

#38

I'm fine with a bit of fussing....it's not going to be my daily driver again. I want this new motor to last a few years at least.

Since I'm adding the bigger cam, slightly higher compression, and extra torque from the ls2....will my 36# injectors & oem fuel rail hold up to the extra power?

I already have the fast 102 intake and Tb, ported heads and headers, udp...basically all bolt ons.

Will the 36#ers hold up.....or should I use the Gtp 41#ers ?

Since I'm adding the bigger cam, slightly higher compression, and extra torque from the ls2....will my 36# injectors & oem fuel rail hold up to the extra power?

I already have the fast 102 intake and Tb, ported heads and headers, udp...basically all bolt ons.

Will the 36#ers hold up.....or should I use the Gtp 41#ers ?

Last edited by Fullblast; 06-12-2016 at 01:14 AM.

#39

I spoke with Kip today and he said if I were to run a 232/240 111+2, that I should run a stock head gasket and no milling due to ptv clearance....unless I wanted to flycut. I may do a 100-150 shot in the future...whichis why I'd rather not flycut.

He said that big of a cam would buck a lot more and hurt my low end torque and basically was against using a cam this size without increasing compression, because it could actually hurt my performance and not sound as good at idle with the stock compression.

He said my current cam 228/232 112 is a good performer and would be even better milling the heads and raising compression....and that compression does affect the sound and the chop.

Since my engine is apart anyway, I really would like to have more overlap for more chop and also mill the heads .020 - .030 and use an ls9 head gasket.

2 questions. What's the max amount I can mill the heads and run my 228/232?

I'm interested in the Fti Hellraiser grind 229/236 111+2 with 10.5 degrees overlap. How much can I mill the heads with this grind? Thanks

He said that big of a cam would buck a lot more and hurt my low end torque and basically was against using a cam this size without increasing compression, because it could actually hurt my performance and not sound as good at idle with the stock compression.

He said my current cam 228/232 112 is a good performer and would be even better milling the heads and raising compression....and that compression does affect the sound and the chop.

Since my engine is apart anyway, I really would like to have more overlap for more chop and also mill the heads .020 - .030 and use an ls9 head gasket.

2 questions. What's the max amount I can mill the heads and run my 228/232?

I'm interested in the Fti Hellraiser grind 229/236 111+2 with 10.5 degrees overlap. How much can I mill the heads with this grind? Thanks

Last edited by Fullblast; 06-15-2016 at 01:19 AM.

#40

Old School Heavy

iTrader: (16)

Stuff like "drivability" and "low end power" are largely subjective. Just like if you ask one guy "how fast is fast?" or, "what makes a woman beautiful?", you are going to get different answers depending on who you ask.

I am a street/strip guy who's earliest memories were riding around in my dads 61 Corvette NHRA drag car on the street. That car idled at 1200 RPM and would shake the windows everywhere we went. My current toy has 27 degrees of overlap and I think it drives like a kitten. I have other friends that went turbo because they wanted their car to have all the power yet act stock while they drove around. They could not stand the lopey idle and wanted the car to idle smooth.

Kip's advice on compression is a winner. Increasing the compression is going to increase your power everywhere from idle to redline with no adverse effects on drivability. It will even improve your fuel mileage if you can behave enough to notice. I also agree 100% that your existing camshaft is an excellent performance grind and is pretty much perfect for your application. I am sure the last thing that Kip wants is to sell you a camshaft that will make you enjoy driving your car less.

If you want the lopey, wicked idle, you are also going to get the bucking and fussing that goes with it. That is the trade off. In a stick shift car, it is a concern where it might not be in an automatic with a performance high stall speed converter. Putting a 4.10 gear in the back will help at low speeds, but you are still probably going to have to slip the clutch and/or accelerate then coast in traffic and parking lots.

I don't see many cam companies do it these days, but back in the day we would put stick shift camshafts on wider lobe separation angles because we felt they worked better in stickshift cars both for drivability and performance.

In the end you will have to decide if the killer idle sound is worth the trade off in drivability.

If it were mine, and I was going to a big thumping cam with more overlap, I would put a 4.10 gear in it at the same time.

I am a street/strip guy who's earliest memories were riding around in my dads 61 Corvette NHRA drag car on the street. That car idled at 1200 RPM and would shake the windows everywhere we went. My current toy has 27 degrees of overlap and I think it drives like a kitten. I have other friends that went turbo because they wanted their car to have all the power yet act stock while they drove around. They could not stand the lopey idle and wanted the car to idle smooth.

Kip's advice on compression is a winner. Increasing the compression is going to increase your power everywhere from idle to redline with no adverse effects on drivability. It will even improve your fuel mileage if you can behave enough to notice. I also agree 100% that your existing camshaft is an excellent performance grind and is pretty much perfect for your application. I am sure the last thing that Kip wants is to sell you a camshaft that will make you enjoy driving your car less.

If you want the lopey, wicked idle, you are also going to get the bucking and fussing that goes with it. That is the trade off. In a stick shift car, it is a concern where it might not be in an automatic with a performance high stall speed converter. Putting a 4.10 gear in the back will help at low speeds, but you are still probably going to have to slip the clutch and/or accelerate then coast in traffic and parking lots.

I don't see many cam companies do it these days, but back in the day we would put stick shift camshafts on wider lobe separation angles because we felt they worked better in stickshift cars both for drivability and performance.

In the end you will have to decide if the killer idle sound is worth the trade off in drivability.

If it were mine, and I was going to a big thumping cam with more overlap, I would put a 4.10 gear in it at the same time.