12.0:1 ls3

#1

Curious to see some combos with 12.0 range compression. Aiming to go with DSS +6 dome piston, stock rod/crank in a 6.2 block. Final bore is dependent on the engine shop inspecting block next week. Looking at either 4.065 or 4.070.

The remainder of combo will be ls3 style head, milled with a .040-.045 gasket to achieve compression goals (dependent on the how much piston is in/out of hole. Cam is still undecided but this will be in a 96 c1500 single cab truck. 6L80/90 trans and 4000 minimum stall, possibly as high as 4500-4600 from Circle D if the combo needs it. E85 fuel. Gen 4 truck intake.

Truck will be primarily street driven. Maybe a track visit here and there. Looking for a stout truck thatíll be fun to drive on weekends.

While Iím here, I donít really want to send the heads out for CNC work or port work. Iíd like to keep costs down where I can currently and can do so later. But, with compression where I want to be, would I benefit from massaging the bowls, valve job, or anything from hand porting to help keep this combo happy?

The remainder of combo will be ls3 style head, milled with a .040-.045 gasket to achieve compression goals (dependent on the how much piston is in/out of hole. Cam is still undecided but this will be in a 96 c1500 single cab truck. 6L80/90 trans and 4000 minimum stall, possibly as high as 4500-4600 from Circle D if the combo needs it. E85 fuel. Gen 4 truck intake.

Truck will be primarily street driven. Maybe a track visit here and there. Looking for a stout truck thatíll be fun to drive on weekends.

While Iím here, I donít really want to send the heads out for CNC work or port work. Iíd like to keep costs down where I can currently and can do so later. But, with compression where I want to be, would I benefit from massaging the bowls, valve job, or anything from hand porting to help keep this combo happy?

#2

TECH Enthusiast

iTrader: (1)

I think the issue is resale on this you might want to consider. E85 is not everywhere and it has its nuanaces that require changing a few things (like a fuel pump and injectors). The difference in power between 11 to 1 (pump gas) and 12 to 1 is negligible and E85 does not make that much more power in an NA situation like yours. Most people that run E85 are like 13 to 1 and or a blower/turbo kind of guys. You would be better off putting money into a good heads and cam package.

The following 2 users liked this post by Double06:

G Atsma (01-22-2024), KnightmareLS1 (02-02-2024)

#3

TECH Junkie

iTrader: (28)

Every increase in compression is about 3% more power. So 11:1 going to 12:1 making for example 450rwhp would increase it about 14rwhp or so. May not be worth the headache unless you are going for 13.5:1 which e85 will support.

We just put a very baby LG Motorsports executive cam in a new GM crate LS3 (10.7:1 compression) which has basically a stock idle with hint of something bigger and it made 456rwhp/446rwtq with a ported/rod modded LS3 intake, stock DBW TB and Sikky e36 mid length swap headers into a nice dual 2.5" exhaust on 91 octane using LSA/LS9 injectors and T56 Magnum with heavy McLeod steel flywheel/RXT clutch. Dumping in winter blend e85 which got it up to e58 mixture it made 470rwhp/457rwtq. In summer when the e85 content is higher I'm sure more power can be made. It was making over 330rwtq at 1500 basically and peaked at 6000rpm which is exactly what it is described as.

on the flip side I've used this same cam in a fully built 6.2 with MAST LS3 heads, stock LS3 intake/TB, Precision 88mm turbo and made 1060rwhp on 14psi with perfect street manners and a hint of non stock idle. On 22psi the car was a maniac (1450hp rated turbo) and made power well past 7000rpm.

We just put a very baby LG Motorsports executive cam in a new GM crate LS3 (10.7:1 compression) which has basically a stock idle with hint of something bigger and it made 456rwhp/446rwtq with a ported/rod modded LS3 intake, stock DBW TB and Sikky e36 mid length swap headers into a nice dual 2.5" exhaust on 91 octane using LSA/LS9 injectors and T56 Magnum with heavy McLeod steel flywheel/RXT clutch. Dumping in winter blend e85 which got it up to e58 mixture it made 470rwhp/457rwtq. In summer when the e85 content is higher I'm sure more power can be made. It was making over 330rwtq at 1500 basically and peaked at 6000rpm which is exactly what it is described as.

on the flip side I've used this same cam in a fully built 6.2 with MAST LS3 heads, stock LS3 intake/TB, Precision 88mm turbo and made 1060rwhp on 14psi with perfect street manners and a hint of non stock idle. On 22psi the car was a maniac (1450hp rated turbo) and made power well past 7000rpm.

#4

I think the issue is resale on this you might want to consider. E85 is not everywhere and it has its nuanaces that require changing a few things (like a fuel pump and injectors). The difference in power between 11 to 1 (pump gas) and 12 to 1 is negligible and E85 does not make that much more power in an NA situation like yours. Most people that run E85 are like 13 to 1 and or a blower/turbo kind of guys. You would be better off putting money into a good heads and cam package.

#5

Every increase in compression is about 3% more power. So 11:1 going to 12:1 making for example 450rwhp would increase it about 14rwhp or so. May not be worth the headache unless you are going for 13.5:1 which e85 will support.

We just put a very baby LG Motorsports executive cam in a new GM crate LS3 (10.7:1 compression) which has basically a stock idle with hint of something bigger and it made 456rwhp/446rwtq with a ported/rod modded LS3 intake, stock DBW TB and Sikky e36 mid length swap headers into a nice dual 2.5" exhaust on 91 octane using LSA/LS9 injectors and T56 Magnum with heavy McLeod steel flywheel/RXT clutch. Dumping in winter blend e85 which got it up to e58 mixture it made 470rwhp/457rwtq. In summer when the e85 content is higher I'm sure more power can be made. It was making over 330rwtq at 1500 basically and peaked at 6000rpm which is exactly what it is described as.

on the flip side I've used this same cam in a fully built 6.2 with MAST LS3 heads, stock LS3 intake/TB, Precision 88mm turbo and made 1060rwhp on 14psi with perfect street manners and a hint of non stock idle. On 22psi the car was a maniac (1450hp rated turbo) and made power well past 7000rpm.

We just put a very baby LG Motorsports executive cam in a new GM crate LS3 (10.7:1 compression) which has basically a stock idle with hint of something bigger and it made 456rwhp/446rwtq with a ported/rod modded LS3 intake, stock DBW TB and Sikky e36 mid length swap headers into a nice dual 2.5" exhaust on 91 octane using LSA/LS9 injectors and T56 Magnum with heavy McLeod steel flywheel/RXT clutch. Dumping in winter blend e85 which got it up to e58 mixture it made 470rwhp/457rwtq. In summer when the e85 content is higher I'm sure more power can be made. It was making over 330rwtq at 1500 basically and peaked at 6000rpm which is exactly what it is described as.

on the flip side I've used this same cam in a fully built 6.2 with MAST LS3 heads, stock LS3 intake/TB, Precision 88mm turbo and made 1060rwhp on 14psi with perfect street manners and a hint of non stock idle. On 22psi the car was a maniac (1450hp rated turbo) and made power well past 7000rpm.

I want to build something a little more on the aggressive side. I would like to rev to ~7-7200 with a setup like this. Peak torque in mid 4K range. Between a good matched converter, ~4.10-4.30 gear, and 6L trans gearing I believe I can still get by with missing a tad low end of power. Only reason Iím skimping a 416 project is this is a starting from scratch deal and donít want to go that route until Iím bored with the power here.

Side note, it is interesting to still see a good gain on E with that setup given the compression and setup you described. E85 is everywhere for me so itís a no brainer. truthfully, Iím not against running an even higher compression but still undecided. I do want to be minimum 12.0:1 though.

#6

TECH Enthusiast

iTrader: (11)

My 12:1 93 pump gas build lost ~30HP going to 11:1. A lot of focus for the NA build was the cam. If you're staying NA then I'd consider even more compression with E85 and make sure you work with a good cam guy/company. My builder used Straub and the performance speaks for itself.

The following users liked this post:

02EBC5Z06 (01-23-2024)

#7

My 12:1 93 pump gas build lost ~30HP going to 11:1. A lot of focus for the NA build was the cam. If you're staying NA then I'd consider even more compression with E85 and make sure you work with a good cam guy/company. My builder used Straub and the performance speaks for itself.

The following users liked this post:

cdubbzz (01-22-2024)

Trending Topics

#8

ModSquad

iTrader: (6)

The LS chamber designs are very efficient. My 434 in my Chevelle is 12.42:1 and I run 93 pump exclusively. Never tried E85, although I might toy with it some this summer.

Quench is ultra important at 12:1 on pump gas. Get it down to .035, which is safe. I wouldn’t try any less for a street build. Tony Mamo tried .028 and it failed. Production tolerances come into play at that level, meaning if you have one rod out of a set that’s .001 longer, center to center length, for example, then you’ve got problems. Pin heights of pistons, rod journal heights on the cranks stroke not exactly perfect…That’s why I don’t like to go less than .035 quench, but .035 works to achieve what your after and that’s controlling the flame front as much as possible. If you come out at .033, I wouldn’t tear it all back apart to look for a .002 gain…just be aware that it’s ultra-tight while your revving to 7k+…

Tune will need to be great, not just good enough. You’ll want to use 93 pump from newer, clean stations, to avoid old, or even cheaper grades of 93. If you don’t mind the E85 route, then by all means, your super safe.

Don’t adjust your compression with headgaskets. It’s a bad practice. Use the headgasket to adjust quench only, and adjust the static compression with chamber volume and piston dome design. You’ll want valve reliefs that are deep but not crazy deep. It will require you mocking it all up a couple times to get it right and you MUst use the right measuring tools to find your out-of-hole numbers. A deck bridge with dual dial indicators is mandatory to find that number. Rock the piston at true TDC with the two indicators in the correct 12 o’clock-6 oclock position to find that number. You have to do this to all 8 holes to correctly evaluate your deck height and order the correct headgaskets. There is no guessing, based off of another build. Every build is different.

At the end of the day here, your engine doesn’t know or care what the static compression really is. Dynamic compression is what matters and is comprised by the valve events of the camshaft. Dynamic compression is what cylinder pressure is based off of and the static compression is simply a tuning aid at the end of the day. It’s all a fairly involved process that requires you choosing the right piston design, cutting the heads to the correct chamber volume, working with the camshaft company to get the valve events perfect, and setting up quench as tight as possible without letting the piston actually touch the head at high rpm. Then you have to rely on a tuner to get this optimized with fuel VE and not to put toooo much ignition timing in it.

I like to say to guys that are looking for max-effort stuff…”you have to build the engine first before you can actually build the engine at final assembly”.

Quench is ultra important at 12:1 on pump gas. Get it down to .035, which is safe. I wouldn’t try any less for a street build. Tony Mamo tried .028 and it failed. Production tolerances come into play at that level, meaning if you have one rod out of a set that’s .001 longer, center to center length, for example, then you’ve got problems. Pin heights of pistons, rod journal heights on the cranks stroke not exactly perfect…That’s why I don’t like to go less than .035 quench, but .035 works to achieve what your after and that’s controlling the flame front as much as possible. If you come out at .033, I wouldn’t tear it all back apart to look for a .002 gain…just be aware that it’s ultra-tight while your revving to 7k+…

Tune will need to be great, not just good enough. You’ll want to use 93 pump from newer, clean stations, to avoid old, or even cheaper grades of 93. If you don’t mind the E85 route, then by all means, your super safe.

Don’t adjust your compression with headgaskets. It’s a bad practice. Use the headgasket to adjust quench only, and adjust the static compression with chamber volume and piston dome design. You’ll want valve reliefs that are deep but not crazy deep. It will require you mocking it all up a couple times to get it right and you MUst use the right measuring tools to find your out-of-hole numbers. A deck bridge with dual dial indicators is mandatory to find that number. Rock the piston at true TDC with the two indicators in the correct 12 o’clock-6 oclock position to find that number. You have to do this to all 8 holes to correctly evaluate your deck height and order the correct headgaskets. There is no guessing, based off of another build. Every build is different.

At the end of the day here, your engine doesn’t know or care what the static compression really is. Dynamic compression is what matters and is comprised by the valve events of the camshaft. Dynamic compression is what cylinder pressure is based off of and the static compression is simply a tuning aid at the end of the day. It’s all a fairly involved process that requires you choosing the right piston design, cutting the heads to the correct chamber volume, working with the camshaft company to get the valve events perfect, and setting up quench as tight as possible without letting the piston actually touch the head at high rpm. Then you have to rely on a tuner to get this optimized with fuel VE and not to put toooo much ignition timing in it.

I like to say to guys that are looking for max-effort stuff…”you have to build the engine first before you can actually build the engine at final assembly”.

The following 4 users liked this post by Che70velle:

#9

The LS chamber designs are very efficient. My 434 in my Chevelle is 12.42:1 and I run 93 pump exclusively. Never tried E85, although I might toy with it some this summer.

Quench is ultra important at 12:1 on pump gas. Get it down to .035, which is safe. I wouldnít try any less for a street build. Tony Mamo tried .028 and it failed. Production tolerances come into play at that level, meaning if you have one rod out of a set thatís .001 longer, center to center length, for example, then youíve got problems. Pin heights of pistons, rod journal heights on the cranks stroke not exactly perfectÖThatís why I donít like to go less than .035 quench, but .035 works to achieve what your after and thatís controlling the flame front as much as possible. If you come out at .033, I wouldnít tear it all back apart to look for a .002 gainÖjust be aware that itís ultra-tight while your revving to 7k+Ö

Tune will need to be great, not just good enough. Youíll want to use 93 pump from newer, clean stations, to avoid old, or even cheaper grades of 93. If you donít mind the E85 route, then by all means, your super safe.

Donít adjust your compression with headgaskets. Itís a bad practice. Use the headgasket to adjust quench only, and adjust the static compression with chamber volume and piston dome design. Youíll want valve reliefs that are deep but not crazy deep. It will require you mocking it all up a couple times to get it right and you MUst use the right measuring tools to find your out-of-hole numbers. A deck bridge with dual dial indicators is mandatory to find that number. Rock the piston at true TDC with the two indicators in the correct 12 oíclock-6 oclock position to find that number. You have to do this to all 8 holes to correctly evaluate your deck height and order the correct headgaskets. There is no guessing, based off of another build. Every build is different.

At the end of the day here, your engine doesnít know or care what the static compression really is. Dynamic compression is what matters and is comprised by the valve events of the camshaft. Dynamic compression is what cylinder pressure is based off of and the static compression is simply a tuning aid at the end of the day. Itís all a fairly involved process that requires you choosing the right piston design, cutting the heads to the correct chamber volume, working with the camshaft company to get the valve events perfect, and setting up quench as tight as possible without letting the piston actually touch the head at high rpm. Then you have to rely on a tuner to get this optimized with fuel VE and not to put toooo much ignition timing in it.

I like to say to guys that are looking for max-effort stuffÖĒyou have to build the engine first before you can actually build the engine at final assemblyĒ.

Quench is ultra important at 12:1 on pump gas. Get it down to .035, which is safe. I wouldnít try any less for a street build. Tony Mamo tried .028 and it failed. Production tolerances come into play at that level, meaning if you have one rod out of a set thatís .001 longer, center to center length, for example, then youíve got problems. Pin heights of pistons, rod journal heights on the cranks stroke not exactly perfectÖThatís why I donít like to go less than .035 quench, but .035 works to achieve what your after and thatís controlling the flame front as much as possible. If you come out at .033, I wouldnít tear it all back apart to look for a .002 gainÖjust be aware that itís ultra-tight while your revving to 7k+Ö

Tune will need to be great, not just good enough. Youíll want to use 93 pump from newer, clean stations, to avoid old, or even cheaper grades of 93. If you donít mind the E85 route, then by all means, your super safe.

Donít adjust your compression with headgaskets. Itís a bad practice. Use the headgasket to adjust quench only, and adjust the static compression with chamber volume and piston dome design. Youíll want valve reliefs that are deep but not crazy deep. It will require you mocking it all up a couple times to get it right and you MUst use the right measuring tools to find your out-of-hole numbers. A deck bridge with dual dial indicators is mandatory to find that number. Rock the piston at true TDC with the two indicators in the correct 12 oíclock-6 oclock position to find that number. You have to do this to all 8 holes to correctly evaluate your deck height and order the correct headgaskets. There is no guessing, based off of another build. Every build is different.

At the end of the day here, your engine doesnít know or care what the static compression really is. Dynamic compression is what matters and is comprised by the valve events of the camshaft. Dynamic compression is what cylinder pressure is based off of and the static compression is simply a tuning aid at the end of the day. Itís all a fairly involved process that requires you choosing the right piston design, cutting the heads to the correct chamber volume, working with the camshaft company to get the valve events perfect, and setting up quench as tight as possible without letting the piston actually touch the head at high rpm. Then you have to rely on a tuner to get this optimized with fuel VE and not to put toooo much ignition timing in it.

I like to say to guys that are looking for max-effort stuffÖĒyou have to build the engine first before you can actually build the engine at final assemblyĒ.

I will chat it over with machine shop when I drop off the block and see what they suggest on a combo like this.

#10

Dropped off block today for inspection and clean up. In the mean time I filled out Cam Motion cam form and I received back a recommendation of

236/250 Duration @ .050''

111 LSA, 108 ICL (111+3)

.629''/.612'' Lift with 1.7

What do you guys think? Leaning towards a 4l80e possibly. Same stall range around 4500-5000. Definitely seems like a good sized cam with 21į overlap. I like it. Would this cam tap out around 7K or possibly higher?

236/250 Duration @ .050''

111 LSA, 108 ICL (111+3)

.629''/.612'' Lift with 1.7

What do you guys think? Leaning towards a 4l80e possibly. Same stall range around 4500-5000. Definitely seems like a good sized cam with 21į overlap. I like it. Would this cam tap out around 7K or possibly higher?

#11

12 Second Club

I would use the 6L80. It has way better gearing. The lower gears will help get your truck moving off the line. The higher gears are also better for MPGs once you get up to speed and are just cruising down the road.

If Cam-Motion recommended that cam for that rpm range, then I'm sure it will spin 7k or more. Just make sure you get the right springs for that cam and rpm.

If Cam-Motion recommended that cam for that rpm range, then I'm sure it will spin 7k or more. Just make sure you get the right springs for that cam and rpm.

#12

The only reason I consider then 4l80e route is I believe I can adapt my harness in the 96 now for a gen 3 LS setup. But other than the ease of that, I still will probably go 6L trans route.

#14

TECH Resident

iTrader: (3)

Back in 07 I built a 383 ls6 that was 11.8:1, 58cc CNC 243's, 238 242 114+0 (8.4:dcr) cam and with the stock ls6 intake it made 482whp 440wtq in a manual C5. Later I ported a fast 90 which then made 501whp and it would run 91 octane no issues so I think you are where I'd want to be for solid NA power on either pump or e85. Your cam choice will drive higher DCR also it should rip!

#15

Going to stick with the truck style manifold for this one. Hoping to have a little more broad torque curve. Would you say the torque on that one fell off a little early due to the vic intake?

#16

Back in 07 I built a 383 ls6 that was 11.8:1, 58cc CNC 243's, 238 242 114+0 (8.4:dcr) cam and with the stock ls6 intake it made 482whp 440wtq in a manual C5. Later I ported a fast 90 which then made 501whp and it would run 91 octane no issues so I think you are where I'd want to be for solid NA power on either pump or e85. Your cam choice will drive higher DCR also it should rip!

#17

TECH Resident

iTrader: (3)

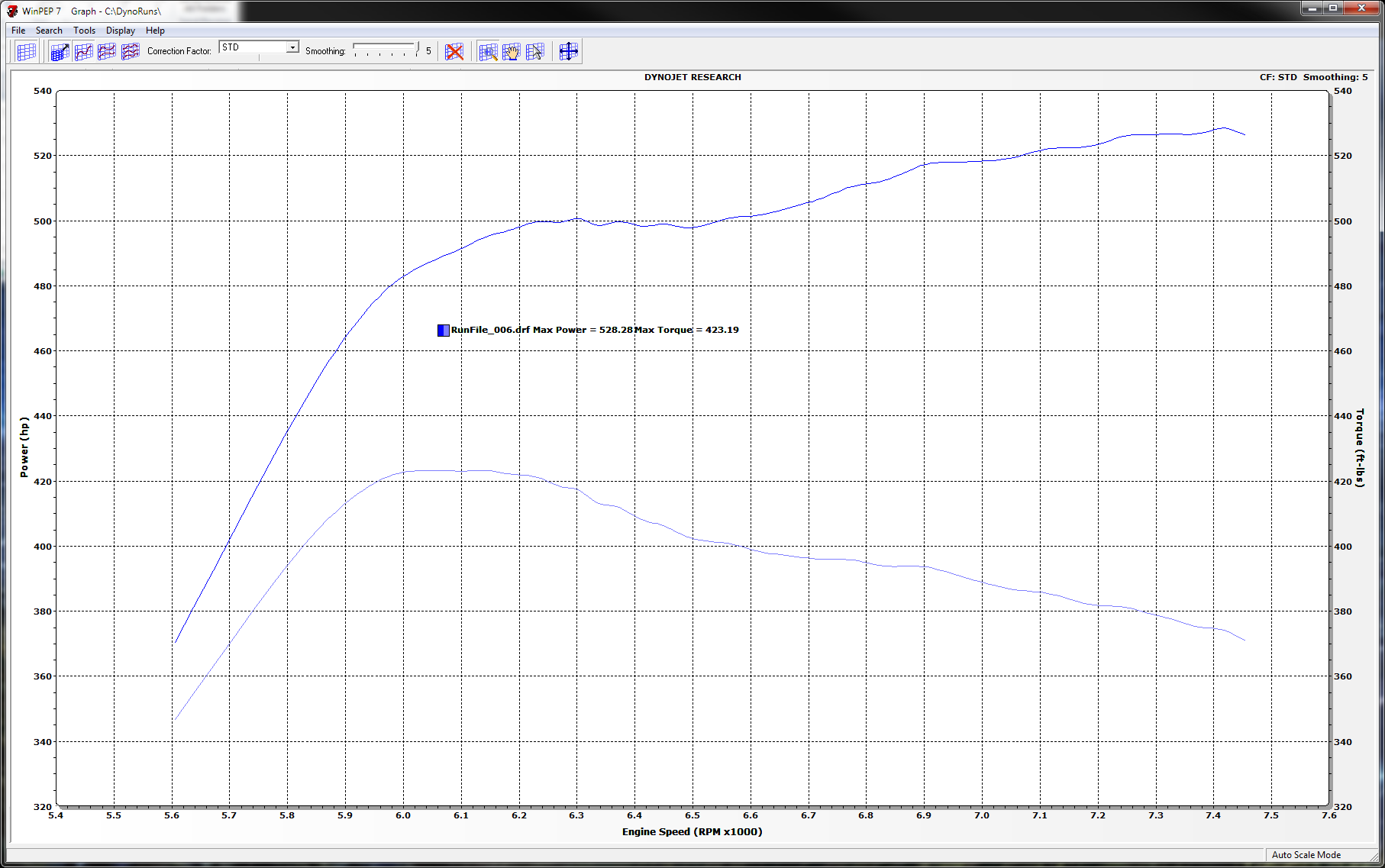

Oh I think you would make some steam for sure. I'd go ahead and clean up any boogers or easy stuff around the valve seats etc just don't nick a seat. Probably some left on the table with the stock valve job. I built a 6.2 truck engine with ls3 pistons, ws6store high lift asa cam and porting on the exhaust side only of the heads with little cleanup on the intake(very little). In a old C10 with a 6l80, unlocked 3200 yank, 373 gears and 20" steel heavy as f wheels in made 435whp in 3rd on the dyno. They didn't want to push driveshaft speed, but had it been in 4th the operator thought it would have been in the 470whp range (I don't know how that all jives as I wasn't there, but it was Carl at twin city in MN).

#19

cammotion and some 4.11ís. Truck manifold to maintain a little more power under curve as Iím fine giving up a little extra RPM/power up top if truck manifold has those type of characteristics over a ls3 mani.